Professional Documents

Culture Documents

Thw500 Tds (TT - 0416) English

Uploaded by

Masood KhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thw500 Tds (TT - 0416) English

Uploaded by

Masood KhanCopyright:

Available Formats

Thermo-Wrap™500 is a factory-saturated, custom engineered composite repair system com-

patible with temperatures reaching 500°F (260°C). NRI’s patented factory-saturation process

ensures the right fiber-to-resin content ratios are achieved. By eliminating the need for field-

saturation, this product can be applied faster and more efficiently on pipes with elevated oper-

ating and design temperatures. Thermo-Wrap 500 has been tested in accordance with ASME

PCC-2 Article 4.1.

Repairs at extreme temperatures

Flare lines, blow down lines, steam piping, chemical processing lines

Girth welds, elbows, tees

Qualified at extreme temperatures

Factory-saturated, no mixing required

Design conforms to ASME PCC-2, ASME B31, ISO TS24817, DOT, API, and CSA Z662

standards for nonmetallic reinforcing and repair

Sold based on square foot of coverage required

As determined by NRI engineering calculations

N/A

Unlimited at ambient conditions. 2 hours @ 446˚F (230˚C)

Product will not cure at ambient temperatures. Temperature shall be a minimum of 400˚F

(205˚C) and a recommended maximum of 500˚F (260˚C) in order for curing to occur.

The following products are system components of the Thermo-Wrap 500 system:

Filler: Thermo-Wrap™500 Filler

Primer: Thermo-Wrap™500 Primer

High-temperature compression film

UV Protection, if necessary: Syntho-Coat™

THW500 TDS 0416

Page 1 of 2

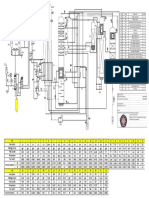

Property Circumferential Direction Axial Direction

Tensile Modulus 4.60 Msi (31.7 GPa) 2.80 Msi (19.3 GPa)

Thermal Expansion Coefficient 5.04 ppm/˚F (9.07 ppm/˚C) 6.17 ppm/˚F (11.1 ppm/˚C)

Property Typical Test Value

Laminate Thickness 0.027 ” (0.69mm)

Poisson Ratio 0.107

Glass Transition Temperature 554˚F (290˚C)

Shear Modulus of Polymer 189 ksi (1.3 GPa)

Shore D Hardness 92

Energy Release Rate @ 500°F 0.52 in.lb/in2 (91 J/m2)

The Thermo-Wrap 500 composite repair system was designed to conform to ASME PCC-2,

ASME B31, ISO TS24817, DOT, API, and CSA Z662 standards for nonmetallic reinforcing

solutions. Consult NRI Engineering for specified use.

Surface preparation and profiling shall promote continuous intimate contact between the FRP

system and pipe by providing a clean, smooth, and circumferential surface. Surface prepara-

tion shall be in accordance with SSPC-SP1 “Solvent Cleaning” and SSPC-SP11 “Power Tool

Cleaning” with a 1-3 mil surface roughness (25-76 microns) minimum. NRI’s composite repair

systems are bond-critical and require a strong adhesive bond between the clean pipe and the

composite system for maximum effectiveness.

Installation of the Thermo-Wrap 500 composite repair system shall be performed by NRI

qualified applicators only. Surface preparation, mixing of epoxy, material saturation, and in-

stallation of the system shall be in accordance with NRI’s product specific installation guides,

latest revision. Quality control inspection during and after installation of the system shall be

performed per NRI’s Installation Validation Procedure: Quality Control Records, latest revi-

sion.

The following cure schedule must be met in order for the product to achieve its full properties.

Initial Cure Post Cure

1 hour @ 356°F (180°C) 4 hours @ 500°F (260°C)

Measure Shore D hardness to confirm full set has been achieved before returning line to service.

For proper information regarding the safe handling, storage, and disposal of chemical prod-

ucts, users shall refer to the most recent SDS, latest revision, containing physical, ecologi-

cal, toxicological, and other safety-related data.

12 months

Store at temperatures below 77˚F (25˚C) away from moisture or any contaminants, in original

packaging

Thermo-Wrap 500 is available in sizes ranging from 2” to 12” (5 to 30cm) in width and 15’ to

60’ (4.6 to 18.3m) in length.

Typically ships in 17” x 15” x 14” boxes (43cm x 38cm x 36cm)

Refer to individual data sheets for system component’s product packaging.

©Neptune Research Inc. (NRI) NRI® is a registered trademark, while Thermo-Wrap™500, Thermo-Fill™500, Thermo-Poxy™500 and

Syntho-Coat™ are trademarks of NRI. NRI utilizes a process of continuous product improvement for all of our products. While we do

strictly adhere to our products’ specifications, we routinely implement product improvements. Therefore, please contact your local NRI

distributor or office for the most current product specifications. NRI warrants the quality of this product when used according to direc-

tions. Apply protective coatings per company standards. User shall determine suitability of product for use and assumes all risk. The

seller will not accept liability for more than product replacement.

THW500 TDS 0416

Page 2 of 2

You might also like

- TDS R4d-IcDocument3 pagesTDS R4d-IcRavie OuditNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- API 650 Storage Tank Load Computations With Ring Wall Foundation Design (8.7-m Diameter X 9.0-m Height)Document25 pagesAPI 650 Storage Tank Load Computations With Ring Wall Foundation Design (8.7-m Diameter X 9.0-m Height)AVBP100% (3)

- Thwi Tds (JK r2 0315) EnglishDocument2 pagesThwi Tds (JK r2 0315) EnglishMasood KhanNo ratings yet

- Titan 218Document2 pagesTitan 218Masood KhanNo ratings yet

- PDS SikaPower-492 EnglishDocument2 pagesPDS SikaPower-492 EnglishpetkoNo ratings yet

- MX 4926N M.CDocument4 pagesMX 4926N M.Csubham chakrabortyNo ratings yet

- Duraplate Uhs EnglishDocument4 pagesDuraplate Uhs EnglishLuis JaraNo ratings yet

- DuraplateDocument4 pagesDuraplatelovaldes62No ratings yet

- Enhanced P L A P: Olyimide Aminate ND RepregDocument4 pagesEnhanced P L A P: Olyimide Aminate ND Repregoutra_pessoaNo ratings yet

- Electrical Resin 260: ScotchcastDocument2 pagesElectrical Resin 260: Scotchcastreddy venkata krishnaNo ratings yet

- Web ProductSheet DiamondWrap 2018 PDFDocument2 pagesWeb ProductSheet DiamondWrap 2018 PDFRiankwnNo ratings yet

- Clock Spring Diamond Wrap BrochureDocument2 pagesClock Spring Diamond Wrap BrochuremuhammadxpNo ratings yet

- Soft Natural Rubber Lining: Technical Data SheetDocument2 pagesSoft Natural Rubber Lining: Technical Data SheetSantosh JayasavalNo ratings yet

- Tds r4d EcthtDocument2 pagesTds r4d EcthtRavie OuditNo ratings yet

- Air/Ship Microwave Material With High Performance: Excellent Dimensional Stability & Phase StabilityDocument4 pagesAir/Ship Microwave Material With High Performance: Excellent Dimensional Stability & Phase StabilityDale XiaoNo ratings yet

- TB Coroflake 23 PDFDocument2 pagesTB Coroflake 23 PDFHatem JafouraNo ratings yet

- 2017 Kynar Wire and Cable SolutionsDocument8 pages2017 Kynar Wire and Cable SolutionsKaarthicNatarajanNo ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- Cycom PR520 RTM 031912Document6 pagesCycom PR520 RTM 031912Angel LagrañaNo ratings yet

- Product Data Sheet SP-8888Document7 pagesProduct Data Sheet SP-8888pablo gonzalezNo ratings yet

- ChemflakeDocument5 pagesChemflakeManohar SeetharamNo ratings yet

- PPG PDS Amercoat 450HDocument6 pagesPPG PDS Amercoat 450HsanguripNo ratings yet

- 370HR Laminate and Prepreg Data Sheet IsolaDocument2 pages370HR Laminate and Prepreg Data Sheet Isolasathi420No ratings yet

- Chersterton Arc 982 PDFDocument2 pagesChersterton Arc 982 PDFMohamed NouzerNo ratings yet

- Me6052 PDS Reg - World en V4 PDS World 4158 10058878Document3 pagesMe6052 PDS Reg - World en V4 PDS World 4158 10058878TANMAY NAYAKNo ratings yet

- TDS LSZH 4001Document2 pagesTDS LSZH 4001Rasel AhmedNo ratings yet

- Scotch-Weld: Structural AdhesiveDocument4 pagesScotch-Weld: Structural AdhesiveAfzal ImamNo ratings yet

- 500ºf Electrically Resistant EpoxyDocument1 page500ºf Electrically Resistant Epoxy李聪No ratings yet

- Technical Data Sheet Sapfoam 323D-M: Polyurethane Spray SystemDocument3 pagesTechnical Data Sheet Sapfoam 323D-M: Polyurethane Spray SystemAbidNo ratings yet

- Epofine 184-Finehard 907 - Acc 062Document4 pagesEpofine 184-Finehard 907 - Acc 062Karishma PrabhuNo ratings yet

- TDS LF-361Document2 pagesTDS LF-361ofershochetNo ratings yet

- Xlpe - Ls243Nta: - 1 Technical Data Sheet Crosslinkable Polyethylene CompoundDocument3 pagesXlpe - Ls243Nta: - 1 Technical Data Sheet Crosslinkable Polyethylene CompoundLe MinhNo ratings yet

- Hyspin ZZ Range: DescriptionDocument2 pagesHyspin ZZ Range: DescriptionDaniel VuletaNo ratings yet

- Le0563 PDS Re - America en V2 PDS Am - 2 4481 10031804Document3 pagesLe0563 PDS Re - America en V2 PDS Am - 2 4481 10031804Aleksa SaricNo ratings yet

- DyneonDocument2 pagesDyneonseeralan_1986No ratings yet

- Guida Coprax Eng 2015 LightDocument82 pagesGuida Coprax Eng 2015 Lightairsys7projec100% (1)

- SP-Q-1002.NGR-XXXX-006 - Pipe Coating Repair SystemDocument9 pagesSP-Q-1002.NGR-XXXX-006 - Pipe Coating Repair SystemSaravoot MetahNo ratings yet

- F F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Document4 pagesF F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Karishma Prabhu100% (1)

- Armorite Soft Natural Rubber: Technical Data SheetDocument2 pagesArmorite Soft Natural Rubber: Technical Data SheetSantosh JayasavalNo ratings yet

- TDS LF-371 - Dec22Document2 pagesTDS LF-371 - Dec22ofershochetNo ratings yet

- Convenience Cpds 660 TechdataDocument2 pagesConvenience Cpds 660 TechdataAlsayed DiabNo ratings yet

- Natural Rubber Lining: Technical Data SheetDocument2 pagesNatural Rubber Lining: Technical Data SheetJaveed KhanNo ratings yet

- Electrically Dissipating Mortar for Tiling and Brick LiningsDocument2 pagesElectrically Dissipating Mortar for Tiling and Brick Liningsshankarkl100% (1)

- Belzona 1111ps EnglDocument2 pagesBelzona 1111ps EnglNikolay GuerreroNo ratings yet

- Datasheet TC5YCA-743Document2 pagesDatasheet TC5YCA-743AdrenalNo ratings yet

- Fuel Resistant Coatings: EC-776 EC-776SRDocument6 pagesFuel Resistant Coatings: EC-776 EC-776SRpokleNo ratings yet

- CR C14 LD2420KDocument3 pagesCR C14 LD2420KJaime222No ratings yet

- Kaolite Insulating CastablesDocument2 pagesKaolite Insulating CastablesChan Keng ChunNo ratings yet

- Dirax PDFDocument2 pagesDirax PDFTom Henry Bernabe Castro100% (1)

- HFX 500P Rev 6 - 2018 PDFDocument2 pagesHFX 500P Rev 6 - 2018 PDFMuhammad Shabbir AwanNo ratings yet

- Epofine 556 - Finehard 22962Document5 pagesEpofine 556 - Finehard 22962Karishma PrabhuNo ratings yet

- tds-500-seriesDocument3 pagestds-500-seriesmmrNo ratings yet

- Kodak Industrex Aa400 Film: Technical Data / Non-Destructive TestingDocument4 pagesKodak Industrex Aa400 Film: Technical Data / Non-Destructive TestingmozymezoNo ratings yet

- Tds Tasnee 100 Black Revised in 2022Document2 pagesTds Tasnee 100 Black Revised in 2022Amir NawazNo ratings yet

- Product Datasheet BiohesiveDocument3 pagesProduct Datasheet Biohesivebolang cepuNo ratings yet

- N4000-6 FC N4000-6 FC LD: Fast-Cure, High-Tg Multifunctional EpoxyDocument2 pagesN4000-6 FC N4000-6 FC LD: Fast-Cure, High-Tg Multifunctional EpoxyRafael CastroNo ratings yet

- Ultradur® B 6550 LN en SI - Product DatasheetDocument2 pagesUltradur® B 6550 LN en SI - Product Datasheetnoto.sugiartoNo ratings yet

- KilnGard - 600SCWDocument2 pagesKilnGard - 600SCWarafatNo ratings yet

- OGDCL - Board of DirectorDocument3 pagesOGDCL - Board of DirectorMasood KhanNo ratings yet

- UP KitDocument1 pageUP KitShawn AngNo ratings yet

- list of Paki companiesDocument27 pageslist of Paki companiesMasood KhanNo ratings yet

- Vs Datasheet - Released 0410Document2 pagesVs Datasheet - Released 0410Masood KhanNo ratings yet

- Trans-Wrap Datasheet (CB 10.19.11)Document1 pageTrans-Wrap Datasheet (CB 10.19.11)Masood KhanNo ratings yet

- Trident WrapTDSDocument1 pageTrident WrapTDSMasood KhanNo ratings yet

- Thermo-Wrap 24 Sealing & Water Proofing System Datasheet (TT R2 0214) EnglishDocument1 pageThermo-Wrap 24 Sealing & Water Proofing System Datasheet (TT R2 0214) EnglishMasood KhanNo ratings yet

- Thermo PoxyDocument2 pagesThermo PoxyMasood KhanNo ratings yet

- Thermo-Wrap 24 HDD System Datasheet (MG R3 - 09.16.13)Document1 pageThermo-Wrap 24 HDD System Datasheet (MG R3 - 09.16.13)Masood KhanNo ratings yet

- TF High Temp Epoxy Putty Datasheet (JRS Rev 1 - 03Document1 pageTF High Temp Epoxy Putty Datasheet (JRS Rev 1 - 03Masood KhanNo ratings yet

- Thermo-Wrap 24 HDD System Datasheet (JRS R1 - 07.24.13) English - WebDocument1 pageThermo-Wrap 24 HDD System Datasheet (JRS R1 - 07.24.13) English - WebMasood KhanNo ratings yet

- Thermo-Wrap Inspectable Datasheet (TT 0214) EnglishDocument1 pageThermo-Wrap Inspectable Datasheet (TT 0214) EnglishMasood KhanNo ratings yet

- Syntho-Poxy SS Datasheet (TT R2 0214) EnglishDocument1 pageSyntho-Poxy SS Datasheet (TT R2 0214) EnglishMasood KhanNo ratings yet

- Thermo-Wrap 24 HDD System Datasheet (TT R4 0615) English - WebDocument1 pageThermo-Wrap 24 HDD System Datasheet (TT R4 0615) English - WebMasood KhanNo ratings yet

- SynthoSleeve Datasheet 2.10.10Document2 pagesSynthoSleeve Datasheet 2.10.10Masood KhanNo ratings yet

- Syntho-Poxy OL Datasheet (TT R2 0214) EnglishDocument1 pageSyntho-Poxy OL Datasheet (TT R2 0214) EnglishMasood KhanNo ratings yet

- Syntho-Glass FX Datasheet (Rev 1. - 12.31.09)Document2 pagesSyntho-Glass FX Datasheet (Rev 1. - 12.31.09)Masood KhanNo ratings yet

- Syntho-Steel Datasheet (KR - 09.29.10)Document1 pageSyntho-Steel Datasheet (KR - 09.29.10)Masood KhanNo ratings yet

- Syntho-Glass24 DatasheetDocument1 pageSyntho-Glass24 DatasheetMasood KhanNo ratings yet

- Syntho-Glass XT TDS (JK R15 0315) EnglishDocument2 pagesSyntho-Glass XT TDS (JK R15 0315) EnglishMasood KhanNo ratings yet

- Syntho-Glass UP TDSDocument2 pagesSyntho-Glass UP TDSMasood KhanNo ratings yet

- Steel-Wrap MCU Subsea Detailed Install Guide R1, 05.10.16Document23 pagesSteel-Wrap MCU Subsea Detailed Install Guide R1, 05.10.16Masood KhanNo ratings yet

- Solar-Wrap Datasheet (TT R4 - 07.13) EnglishDocument1 pageSolar-Wrap Datasheet (TT R4 - 07.13) EnglishMasood KhanNo ratings yet

- SGXT Datasheet (Rev 2. - 2.22.10)Document2 pagesSGXT Datasheet (Rev 2. - 2.22.10)Masood KhanNo ratings yet

- Syntho-Glass XT TDSDocument2 pagesSyntho-Glass XT TDSMasood KhanNo ratings yet

- SubSeaLV Datasheet - Released 0410Document1 pageSubSeaLV Datasheet - Released 0410Masood KhanNo ratings yet

- SGXT Civil Datasheet (CB - 09.01.10)Document2 pagesSGXT Civil Datasheet (CB - 09.01.10)Masood KhanNo ratings yet

- Grounded Medium Frequency Monopole by Valentino Trainotti, Walter G. Fano, and Lazaro Jastreblansky (University of Buenos Aires, Argentina), 2005.Document29 pagesGrounded Medium Frequency Monopole by Valentino Trainotti, Walter G. Fano, and Lazaro Jastreblansky (University of Buenos Aires, Argentina), 2005.Bob Laughlin, KWØRLNo ratings yet

- Cont. Eva.Document2 pagesCont. Eva.Rainwin TamayoNo ratings yet

- Manual Service LN40C550J1RDocument86 pagesManual Service LN40C550J1RAngel Luciano Ramon GomezNo ratings yet

- IrregularitiesDocument7 pagesIrregularitiesGovinda GhimireNo ratings yet

- Errors Gyro CompassDocument13 pagesErrors Gyro CompassReetam BoseNo ratings yet

- Standard TriacDocument4 pagesStandard TriacHector Alberto SanchezNo ratings yet

- Manage industrial equipment inventoryDocument1 pageManage industrial equipment inventorySeyzhea Nimas HapsariNo ratings yet

- Potable Water Expansion Tank Sizing ProgramDocument2 pagesPotable Water Expansion Tank Sizing ProgramChaosNo ratings yet

- Design For Concrete-Filled CHSDocument3 pagesDesign For Concrete-Filled CHSYanfei JinNo ratings yet

- Mkaj 1093 - Unsaturated Soil Mechanics Project SEMESTER II, SESSION 2020/2021Document3 pagesMkaj 1093 - Unsaturated Soil Mechanics Project SEMESTER II, SESSION 2020/2021Lingeswarran Numbikannu0% (1)

- Unit - II Helical and Bevel GearsDocument6 pagesUnit - II Helical and Bevel GearsAnikesh ManeNo ratings yet

- Devicenet: Leoni Special Cables GMBHDocument2 pagesDevicenet: Leoni Special Cables GMBHLeodoletaNo ratings yet

- IEEE Transactions on Automatic Control Filtering Nonstabilizable SystemsDocument9 pagesIEEE Transactions on Automatic Control Filtering Nonstabilizable SystemssumathyNo ratings yet

- Tds Az 1500 SeriesDocument7 pagesTds Az 1500 SeriesIgor_uhuNo ratings yet

- Exhaust Base Vam Tonnage CalculationDocument9 pagesExhaust Base Vam Tonnage CalculationMagical RiyaNo ratings yet

- Struc 2Document14 pagesStruc 2keeno manzanoNo ratings yet

- Inverse Trigonometric FunctionsDocument13 pagesInverse Trigonometric FunctionsCrookedly CrookedNo ratings yet

- Peak Force QNM - Adv Apps Training 2014Document60 pagesPeak Force QNM - Adv Apps Training 2014linhaowen13579No ratings yet

- EXPERIMENT 2 Probe TestDocument8 pagesEXPERIMENT 2 Probe TestNur BazilahNo ratings yet

- Theory of Solutions DPP-2 (Questions) PDFDocument4 pagesTheory of Solutions DPP-2 (Questions) PDFHarshjeetNo ratings yet

- Fin Fin Fin Ut2 Issue 1 2024 1Document26 pagesFin Fin Fin Ut2 Issue 1 2024 1an02023801No ratings yet

- Physics Oscillator ReportDocument14 pagesPhysics Oscillator ReportarushiNo ratings yet

- ME Sci 7 Q3 0902 SGDocument20 pagesME Sci 7 Q3 0902 SGSophia TorresNo ratings yet

- 2021 - JEE Advanced Booster Test - 2 - PaperDocument20 pages2021 - JEE Advanced Booster Test - 2 - PapervikasNo ratings yet

- Mechanical Vibrations Chapter ExercisesDocument15 pagesMechanical Vibrations Chapter ExercisesMohammed Al HelaylNo ratings yet

- Mathematics Second Quarter Review Material: TI NO CODocument10 pagesMathematics Second Quarter Review Material: TI NO COLeanne Dela CruzNo ratings yet

- Goodrive100 PV en V1.1Document85 pagesGoodrive100 PV en V1.1Chico Hermanu BrillianNo ratings yet

- The Principles of Air Flow, Air Pressure, and Air FiltrationDocument12 pagesThe Principles of Air Flow, Air Pressure, and Air FiltrationONAFUWA AyodeleNo ratings yet

- 7 Unit5Document22 pages7 Unit5samsonNo ratings yet