Professional Documents

Culture Documents

EXPERIMENT 2 Probe Test

Uploaded by

Nur BazilahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EXPERIMENT 2 Probe Test

Uploaded by

Nur BazilahCopyright:

Available Formats

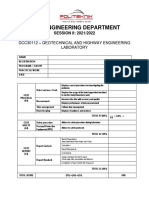

CIVIL ENGINEERING DEPARTMENT

SESSION II: 2021/2022

DCC30112 – GEOTECHNICAL AND HIGHWAY ENGINEERING

LABORATORY

NAME

REGISTRATION

PROGRAM / GROUP

PRACTICAL WORK

DATE

Displays correct procedures for investigating the

problems

Select and uses Tools

Displays the usage of the tools/ apparatus/ machine/

CLO1 to run the study/ laboratory work

PRACTICAL Measures the data with accuracy and quality

(P3) Measurement

Displays performance of data measurement

Time management Follows time management

Housekeeping Displays cleanliness and neatness

𝟎

TOTAL P3 (60%) × 𝟔𝟎% =

𝟑𝟎

CLO2 Safety procedure Adhere to safety procedure during laboratory

SAFETY Personal Protective

(A4) Adhere to safety protocols

Equipment (PPE)

TOTAL A4 (10%)

Result Presentation

(Raw Data/Value/ Plan/ Graph, etc) *if any

Report Analysis Calculation

CLO3 Result Discussions

REPORT

Conclusions

(C4)

Apply a standard format of report

Report Standard (Cover page, title, presentation and tidiness)

Completion of report within the time given

TOTAL C4 (30%)

TOTAL SCORE (P3) + (A4) + (C4) /100

EXPERIMENT 2 : MACINTOSH PROBE TEST

1.0 OBJECTIVE

a. To determine the value of bearing capacity.

b. To determine sub-surface straits graphed and identity materials present.

c. To identify the using of Mackintosh Probe test result.

2.0 LEARNING OUTCOMES

At the end of the course, students should be able to apply the knowledge and skills they have

learned to:

a. Understand the procedure of Mackintosh Probe.

b. Understand how to determine the shear plane of shallow depth.

3.0 THEORY

Dynamic probing is a continuous soil investigation technique, which is one of the simplest soil

penetration tests. It basically consists of repeatedly driving a metal tipped probe into the ground

using a drop weight of fixed mass and travel. Testing is carried out continuously from ground

level to the final penetration depth. The continuous sounding profiles enable easy recognition

of dissimilar layers and even thin strata by the observed variation in the penetration resistance.

The JKR/Mackintosh Probe Test is a lightweight and portable penetrometer. It is considerably

facter and cheaper tool than boring equipment especially when the depth of exploration is

moderate and the soils under investigation are soft and loose. The JKR/Mackintosh Probe Test

is a simple and economic testing method to gather preliminary data on sub surface conditions.

The data will use for designing the shallow foundation. This test only suitable for the soft and

loose soil such as clay and peat soil layer. The rods consists of 16mm diameter High Yield

Steel each of length approximately 120 cm. Then the rods are connected to each other by 25

mm outer diameter couplings.

The main advantages of the Mackintosh Probe include:

a) Speed of operation;

b) Use in difficult terrain where access is poor;

c) Minimal equipment and personnel are required;

d) Equipment is very low cost;

e) Simplicity of operation and data recording/analysis;

f) Use in the interpolation of soil strata and properties between trial pits and

boreholes;

g) Reduces the number of boreholes required.

4.0 EQUIPMENTS

a. Penetration rod (120 cm long)

b. Coupling

c. Pipe wrenches

d. Penetration cone

e. Hammer nut

f. Drop hammer

g. Lifting handle

Fig 1 : Probe test equipment

Fig. 2 : The set-up and dimensions of Mackintosh Probe.

(source : A. Fakher ET AL, 2006)

5.0 PROCEDURES

1. Identify the point place on the surface area.

2. After the point have been identify, equipment for probe test are assembled.

3. The penetration rods and drop hammer are joint using the rod coupling. Grease is sweep up

for an easy dissembles later.

4. A distance of 300mm on rod is mark and used as a pit stop of blowing when the soil depth

has reached at 300 mm.

5. The equipment is set up on the ground. The hammer is pulled until it reached the

maximum. The hammer is dropped freely to driven the cone into the soils.

6. The sum of the number of blows for penetration of 300 mm depth is recorded in the data

sheet.

7. The hammer is taken off on the last 300 mm of each rod and joined the existing rod with

another rod and lastly the hammer.

8. The probing is continued and stopped when ;

~ the resistance has reached 400 blows/300 mm or

~ the depth has reached 15.0 m, whichever is reached earlier.

9. Pull the rods using lifitng tools after the penetration reached the requirement.

10. The equipment is dissembled and cleaned before storing.

6.0 RESULT AND CALCULATIONS

The related formula to find the value of safe pressure are shown below:

For blows > 40 use:

P = [2860 + 550(R − 40)1/2 ] x 0.04788 kN/m2 , where, P = Bearing capacity

R = Num. blows

For blows < 40 use chart as appendix A

Depth (m) Number of blows, R (num.) Bearing capacity, P (kN/m2)

7.0 QUESTIONS

1. Plot a graphs of:

a. Bearing capacity versus number of blows for each point hole.

b. Soil depth versus number of blows.

c. Soil depth versus cummulative number of blows

2. Analyse the graphs to determine the types of soil and suitablity for development.

3. Explain the differences between JKR Probe Test and Mackintosh Probe Test.

You might also like

- Instruments, Measurement Principles and Communication Technologies for Downhole Drilling EnvironmentsFrom EverandInstruments, Measurement Principles and Communication Technologies for Downhole Drilling EnvironmentsNo ratings yet

- Experiment 3 Sieve AnalysisDocument5 pagesExperiment 3 Sieve AnalysisNur BazilahNo ratings yet

- Engineering Surveying: Theory and Examination Problems for StudentsFrom EverandEngineering Surveying: Theory and Examination Problems for StudentsRating: 4.5 out of 5 stars4.5/5 (24)

- Experiment 1 Site InvestigationDocument6 pagesExperiment 1 Site InvestigationNur BazilahNo ratings yet

- EXPERIMENT 4 Atterberg LimitDocument5 pagesEXPERIMENT 4 Atterberg LimitNur BazilahNo ratings yet

- Dcc30112 Geotechnical and Highway Engineering Laboratory: Clo 1 P3 DK6 DP1, DP4 DK6Document5 pagesDcc30112 Geotechnical and Highway Engineering Laboratory: Clo 1 P3 DK6 DP1, DP4 DK6muhammad nur imanNo ratings yet

- Sesi II 2021 2022 Full Lab Sheet and FormatDocument75 pagesSesi II 2021 2022 Full Lab Sheet and FormatMasni MasniNo ratings yet

- UT-Flaw1 Detection Procedure R1 - 2Document25 pagesUT-Flaw1 Detection Procedure R1 - 2George OgbecheNo ratings yet

- Tensile Test Report on Mild Steel SpecimenDocument16 pagesTensile Test Report on Mild Steel SpecimenEngr.Hamid Ismail CheemaNo ratings yet

- DCPT TestDocument10 pagesDCPT TestMonirul Islam BadalNo ratings yet

- Metallurgy Lab 2021 Lab Manual: List of ExperimentsDocument23 pagesMetallurgy Lab 2021 Lab Manual: List of ExperimentsPrashant D BijayNo ratings yet

- Building Tecnology Studio I RES 201 Project TitleDocument13 pagesBuilding Tecnology Studio I RES 201 Project Titlekian hongNo ratings yet

- Geo Lab 2 (A&b) ShanDocument24 pagesGeo Lab 2 (A&b) ShanShavinassh VijayanNo ratings yet

- Field Density Testing with Nuclear GaugeDocument10 pagesField Density Testing with Nuclear GaugedavethiyaguNo ratings yet

- A Comprehensive Study On The Precision and Accuracy of In-Lab and On-Site Measurement of Pavement Acoustic AbsorptionDocument12 pagesA Comprehensive Study On The Precision and Accuracy of In-Lab and On-Site Measurement of Pavement Acoustic AbsorptionLaboratorio StradeNo ratings yet

- Interpretation of Laboratory and Field Test Results For DesignDocument113 pagesInterpretation of Laboratory and Field Test Results For DesignKhairul Azmil75% (4)

- PDA Method StatementDocument22 pagesPDA Method StatementChezy629100% (2)

- 8.material Finer Than 75 MicronDocument3 pages8.material Finer Than 75 MicronSamrendra UdgirkarNo ratings yet

- Tajarb PDFDocument67 pagesTajarb PDFbilalNo ratings yet

- Fire Protection System Inspection ReportDocument10 pagesFire Protection System Inspection ReportAishah SeiniNo ratings yet

- Soil Mechanics Laboratory ManualDocument288 pagesSoil Mechanics Laboratory ManualAref MalkawiNo ratings yet

- Highway Lab Manual 2021Document119 pagesHighway Lab Manual 2021ISMAILA AMOTOTONo ratings yet

- AGES - Method Statement For PDADocument8 pagesAGES - Method Statement For PDAResearcherNo ratings yet

- Lab 3 MseDocument5 pagesLab 3 MseYohannes Earran Amin Anak Roger MambuNo ratings yet

- Your Name ID# - Practical Project 1 - Module 3 - 7.5%Document12 pagesYour Name ID# - Practical Project 1 - Module 3 - 7.5%Harinder SinghNo ratings yet

- Soil Mechanics Lab Manual 1692706655Document165 pagesSoil Mechanics Lab Manual 1692706655Neha Reddy HoneyNo ratings yet

- 2003 Verhaeghe VandermeerDocument13 pages2003 Verhaeghe Vandermeermadhumster1240No ratings yet

- P4 MNOpenpitdesignby Emma AppianingDocument10 pagesP4 MNOpenpitdesignby Emma AppianingGbenga AdewumiNo ratings yet

- College of Engineering Civil Engineering Program: Self-Instructional Manual (SIM) For Self-Directed Learning (SDL)Document3 pagesCollege of Engineering Civil Engineering Program: Self-Instructional Manual (SIM) For Self-Directed Learning (SDL)REX IAN BONGALESNo ratings yet

- CIV 4100 Assignment No3Document13 pagesCIV 4100 Assignment No3tamooseNo ratings yet

- SL-B Lab Script 2023-2024Document7 pagesSL-B Lab Script 2023-2024AyeshaNo ratings yet

- DCC 30112 – GEOTECHNICAL AND HIGHWAY LABORATORYDocument2 pagesDCC 30112 – GEOTECHNICAL AND HIGHWAY LABORATORYIrfan SyazwanNo ratings yet

- Field Calibration and Spatial Analysis of CompactiDocument24 pagesField Calibration and Spatial Analysis of CompactiEgika AgungNo ratings yet

- 2D and 3D Profile MeasurementDocument5 pages2D and 3D Profile MeasurementMim HartanahNo ratings yet

- Lab SheetDocument3 pagesLab Sheetshahril shaharoniNo ratings yet

- ACUREN Thickness Measurement ProcedureDocument15 pagesACUREN Thickness Measurement ProcedureAhmed Ben Nouma0% (1)

- Lab 1 Metrology (Measurement of Screw Thread) (FKM PENANG)Document4 pagesLab 1 Metrology (Measurement of Screw Thread) (FKM PENANG)jojoNo ratings yet

- Wangetal 2016Document36 pagesWangetal 2016Patrícia FiguereidoNo ratings yet

- Consolidation TestDocument9 pagesConsolidation Testdatonizam0% (1)

- AHCDRG301 Install Drainage Systems Assessment V1 5jul17 4Document10 pagesAHCDRG301 Install Drainage Systems Assessment V1 5jul17 4Dylan McpaulNo ratings yet

- IME 241 Manufacturing Processes Laboratory: Revised October, 2007Document34 pagesIME 241 Manufacturing Processes Laboratory: Revised October, 2007Foisal Ahmed MirzaNo ratings yet

- METHOD OF STATEMENT-Mackintosh Probe TestDocument3 pagesMETHOD OF STATEMENT-Mackintosh Probe TestAzmi SabriNo ratings yet

- Manufacturing Technology Lab IIDocument55 pagesManufacturing Technology Lab IIdheenathayalNo ratings yet

- Lab Manual For UTMDocument200 pagesLab Manual For UTMDesmond TongNo ratings yet

- Estimating Ground Impedance Parameters from Field MeasurementsDocument10 pagesEstimating Ground Impedance Parameters from Field MeasurementstanjalazarNo ratings yet

- RJE - SC - URUP - P1, P2, P3, P4&P5 (Hlawga, 33KV GIS)Document18 pagesRJE - SC - URUP - P1, P2, P3, P4&P5 (Hlawga, 33KV GIS)Htun SoeNo ratings yet

- Hard Rock Tunnel Boring Vol. 6 - Performance Data and Back-MappingDocument96 pagesHard Rock Tunnel Boring Vol. 6 - Performance Data and Back-MappingDavide AgnellaNo ratings yet

- Articulo DCPDocument6 pagesArticulo DCPFernando GuerreroNo ratings yet

- Measurement: W. Zurowski, J. Zepchło, D. Kana Ska, M. RuckiDocument7 pagesMeasurement: W. Zurowski, J. Zepchło, D. Kana Ska, M. RuckiSonja KostićNo ratings yet

- New Test DeviceDocument10 pagesNew Test DeviceMoezselmi.12 SelmiNo ratings yet

- Construction Material - Lab ManualDocument100 pagesConstruction Material - Lab ManualMohammed JberNo ratings yet

- Highway Engineering PDFDocument54 pagesHighway Engineering PDFKreesthu ReddyNo ratings yet

- Course Outcomes Course Intended Learning Outcome: ConsolidationDocument5 pagesCourse Outcomes Course Intended Learning Outcome: ConsolidationRaffy OrialNo ratings yet

- App E - Noise Assessment ReportsDocument27 pagesApp E - Noise Assessment ReportsLama JTNo ratings yet

- Dca20072 Practical - LevellingDocument6 pagesDca20072 Practical - LevellingHanaAnuarNo ratings yet

- Drilling MachineDocument5 pagesDrilling MachineJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Soil Mechanics Laboratory Manual 6th Edition by Das B M PDFDocument165 pagesSoil Mechanics Laboratory Manual 6th Edition by Das B M PDFperfectotejeda100% (2)

- CEE 214L Engineering Materials Laboratory ManualDocument45 pagesCEE 214L Engineering Materials Laboratory ManualcheggNo ratings yet

- DCG2043 - Engineering 1Document17 pagesDCG2043 - Engineering 1noor syazanaNo ratings yet

- Chapter 4 Site Exploration Part IIDocument54 pagesChapter 4 Site Exploration Part IIVhaun AzonNo ratings yet

- 40257-Article Text-143957-1-10-20190417Document17 pages40257-Article Text-143957-1-10-20190417Rica ParillaNo ratings yet

- Written Modes of Professional Communication: Genres Across ProfessionsDocument13 pagesWritten Modes of Professional Communication: Genres Across ProfessionsSean Deanyel RamosNo ratings yet

- Econometricstutorials Exam QuestionsSelectedAnswersDocument11 pagesEconometricstutorials Exam QuestionsSelectedAnswersFiliz Ertekin100% (1)

- Economic Impact of Lamu Cultural Festival 2016Document58 pagesEconomic Impact of Lamu Cultural Festival 2016BURAC INSIGHTNo ratings yet

- Risk Management Plan TemplateDocument4 pagesRisk Management Plan TemplateAnish AmatyaNo ratings yet

- Brain Tumor Detection Using Machine Learning TechniquesDocument7 pagesBrain Tumor Detection Using Machine Learning TechniquesYashvanthi SanisettyNo ratings yet

- (Law and Global GovernanceDocument504 pages(Law and Global GovernancehoniNo ratings yet

- Site SurveyingDocument245 pagesSite SurveyingTatenda PaduzeNo ratings yet

- Managing Presales - Div C - Group 9 - RFP - Cloud TechDocument31 pagesManaging Presales - Div C - Group 9 - RFP - Cloud TechAsish KumarNo ratings yet

- Unconditional Self-Acceptance Among The Psychology Students of University X, Malaysia: The Role of Mattering, Perceived Social Support and State Self-EsteemDocument10 pagesUnconditional Self-Acceptance Among The Psychology Students of University X, Malaysia: The Role of Mattering, Perceived Social Support and State Self-EsteemIJPHSNo ratings yet

- 4-Childhood Attachment With Parents As Predictor of Subjective Well Being in Young AdultsDocument25 pages4-Childhood Attachment With Parents As Predictor of Subjective Well Being in Young AdultsClinical and Counselling Psychology ReviewNo ratings yet

- JNTU THESIS GUIDELINESDocument7 pagesJNTU THESIS GUIDELINESHOD (MVGR Civil)No ratings yet

- Conservation of Historic Buildings: DR. K. N. Modi University Newai, Rajasthan. 304021Document5 pagesConservation of Historic Buildings: DR. K. N. Modi University Newai, Rajasthan. 304021Aliaa Ahmed ShemariNo ratings yet

- Leibniz's Early Concepts in Medicine and Healthcare ReformDocument6 pagesLeibniz's Early Concepts in Medicine and Healthcare ReformRicardo PeresNo ratings yet

- The Mental Workload Analysis of Safety Workers in An Indonesian Oil Mining IndustryDocument4 pagesThe Mental Workload Analysis of Safety Workers in An Indonesian Oil Mining IndustryJhoni putraNo ratings yet

- CareerCarve Activity ListDocument4 pagesCareerCarve Activity ListireneNo ratings yet

- Microbial Ecology in Growing AnimalsDocument504 pagesMicrobial Ecology in Growing AnimalsFernando CruzNo ratings yet

- Integer Programming Part 2Document41 pagesInteger Programming Part 2missMITNo ratings yet

- Chapter 1 of Tagay Dzai! The Lived Experience of Female Adolescents in Filipino Tagay CultureDocument2 pagesChapter 1 of Tagay Dzai! The Lived Experience of Female Adolescents in Filipino Tagay CultureThea QuibuyenNo ratings yet

- Impact of COVID on Academic PerformanceDocument33 pagesImpact of COVID on Academic PerformanceKristine RilleraNo ratings yet

- Chapter 3 Research ProcessDocument30 pagesChapter 3 Research ProcessagegnehubezieNo ratings yet

- Assignment QuestionDocument4 pagesAssignment Questionhdsasdad0% (1)

- Lesson 2 q4Document16 pagesLesson 2 q4Luna LedezmaNo ratings yet

- Mangvwat, Et. Al.Document11 pagesMangvwat, Et. Al.Abdul OGNo ratings yet

- Project Management & Challenges-1Document10 pagesProject Management & Challenges-1Sonika VermaNo ratings yet

- Parenting Style and Psychological ProblemsDocument24 pagesParenting Style and Psychological ProblemsJason BealsNo ratings yet

- The Continuing Embarrassment of CultureDocument22 pagesThe Continuing Embarrassment of CultureNadia RebigNo ratings yet

- A Study To Evaluate The Effectiveness of Structured Teaching Program On Chemotherapy Administration in Terms of Knowledge Among Student Nurses in A Selected Institution at HubballiDocument3 pagesA Study To Evaluate The Effectiveness of Structured Teaching Program On Chemotherapy Administration in Terms of Knowledge Among Student Nurses in A Selected Institution at HubballiInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Improving Vocabulary Ability by Using Comic JournalDocument11 pagesImproving Vocabulary Ability by Using Comic JournalViophiLightGutNo ratings yet

- CAPE 2003 Caribbean StudiesDocument11 pagesCAPE 2003 Caribbean Studiesmjamie12345No ratings yet