Professional Documents

Culture Documents

Manual Book Osp-22-37m (S) A (R) 1

Manual Book Osp-22-37m (S) A (R) 1

Uploaded by

Ageng A. Poo0 ratings0% found this document useful (0 votes)

56 views72 pagesOriginal Title

MANUAL BOOK OSP-22-37M(S)A(R)1

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

56 views72 pagesManual Book Osp-22-37m (S) A (R) 1

Manual Book Osp-22-37m (S) A (R) 1

Uploaded by

Ageng A. PooCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 72

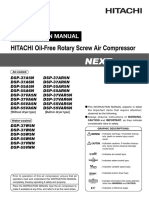

INSTRUCTION MANUAL HITACHI

HITACHI ROTARY SCREW COMPRESSOR

Air-Cooled Type, HISCREW =3500-Series

Model : OSP-22S5AI OSP-22S5ARI

OSP-22S6AI OSP-22S6ARI

OSP-22M5AI OSP-22M5ARI

OSP-22M6AI OSP-22M6ARI

OSP-37S5AI OSP-37S5ARI

OSP-37S6AI OSP-37S6ARI

OSP-37M5AI OSP-37M5ARI

OSP-37M6AI OSP-37M6ARI

[Without a built-in air dryer] [With a built-in air dryer]

sure fovea tis anal earful

in order to operate the machine

safely and properly.

‘Also, prepare the manual near

the machine to make it available

at anytime, and refer to it as the

need arises.

© This manual expresses the matters that need your attention as below.

© Do not fail to observe “WARNING” and “CAUTION,” as they assume considerable

importance to safety.

What Marks Say:

A WARNING : pes is a warming. This aseumes possible 8 This means prohibition,

leath or severe injury to the operator if

fandcieeea

[ENO + This means convenient information

ZA CAUTION. : Tisisa cauton.this assumes possible toknow.

injury to the operator and physical

damage, if handled wrongly. [GSS THis shows reteronce page number.

mor] ‘This means the tings that need attention rye. This shows he information specific to

RAT Gertnen WARNING ard cauion. EDV

the modets with a builtin air dryer.

Characteristics of this Manual

© This manual serves daily operators and maintenance personnel of the compressor as an

instructive materials including its introduction, operation, daily control and periodic ser

vicing

© Before insiallation of the compressor, read the manual carefully and understand its con-

tent and follow the instructions given by it when in use.

Also, prepare the manual near the machine to make it available at anytime, and refer to it

as the need arises.

@ If you have anything unclear or any question, please ask your dealer or your nearest

Hitachi regional office.

© tis convenient for ordering spare part, periodic maintenance and overhaul if type and

serial number of the compressor are filled into the back cover of the manual.

A WARNING

Never remove a protective device from the air compressor or

modify the air compressor.

Never fail to install an earth leakage circuit breaker on the power

cable. It prevents a ground fault burning accident.

Never use the HISCREW as a respiratory appliance by which a

person breathes the compressed air directly.

‘Type I (2000 Series)

Oil Flooded Type With a builtin Air Dryer

SCREW Type Air Cooled Type

Package Type Frequency (5:50Hz, 6:60H2)

S$: FIype Control Ms P-Type Conto!

Output (a)

@ International System of Units (SI):

For the unit of pressure the International System of Units (SI) is used throughout this

manual. To convert it into the conventional system of units, use the following conversion

formula:

7 kgf/em? = 0.69 MPa or 1 kgf/cm? =

.098 MPa

@ Hitachi may make improvements and/or changes in the products described in this publication at any time without notice.

CONTENTS

1. TO USE IN SAFETY 2

2. PARTS DESCRIPTION AND THEIR FUNC-

TIONS - 4

2.1 Appearance“ 4

2.2 Main Component Units

and their Functions

3. HOW TO OPERATE ~~~

38.1 Air Compressor Instrumentation

3.2 How to Use the Digital Monitor

and its Controls =~

3.3 Initial Start-Up ~~

3.4 Setting of the Contro Functions ~~

3.5 Daily Operation

4, DAILY CHECK

4.1 Daily Operation Management ~~~

4.2 Control of Condensate

4.3 Lubricant Management ~~

DAILY CHECK

5, TROUBLESHOOTING |

5.1 When ALARM or SHUTDOWN is |

Displayed 20]

|

| szoveride Operation

| ss sHUTDOWN/ALARM Indications onthe

Instrument Panel

5.4 A List of SHUTDOWNS Not Displayed on

Instrument Panel

6, SYSTEM OF EACH COMPONENT «

6.1 Compressed Air/Lubricant System --- 28

6.2. Capacity Control System 29

6.3. Dryer System

INSTRUCTIONS FOR INSTALLATION.

a4 |g.)

| 7.1 Verification of Components 34 |B2

7.2 Instructions When Conveying 34/85

7.3 Instructions When Installing 38 (Eg

7.4 Piping Insturuction ~ 36 [SE

7.5 Compressor Room Ventilation a7 |g

7.6 Instructions of Electrical Wiring a8 [2°

8, PERIODIC MAINTENANCE

8.2 Typical Maintenance Standard (A)

of Air Compressor

8.3 Typical Maintenance Standard (B)

of Air Compressor

8.4 Typical Maintenance Standard of

‘Air Dryer, Auto Drain Trap for Dryer

8.6 Performance Check of

Capacity Control System

8.7 Replacement of Oil Filter Element

8.8 Cleaning and Replacement of

Air Intake Filter Element

8.9 Cleaning of Cooler

8.10 Inspection and Replacement of

Mi

8.11 Replacement of Oil Separetor Element

8.12 Inspection of Belt

um Pressure/Check Valve

‘9, WHEN IT IS NOT USED FOR LONG TIME ---

10. PARTS LIST ~~~

11. OPERATION RECORD LOGBOOK:

12. LIMITED WARRANTY AND AFTER-

SALES SERVICE

13. STANDARD SPECIFICATION

8.1 Periodic Maintenance for Compressor “=:

8.5 Performance Check of Relief Valve

PERIODIC MAINTENANCE

7

67

1. TO USE IN SAFETY

In order to operate the machine properly and safely, it is indispensable to read care-

fully and follow warnings and instructions hereunder mentioned prior to its use.

The warnings and instructions on labels are attached to the places shown in the figure

below.

4 WARNING

ROTATING PARTS UNDER

‘THE INCOMING-AIR LOUVERS!

esp your

incoringaouvers because the col an fs

‘onderaath,

hands and any obec away rom the

AX WARNING

DETERIORARTED OR FLAMMABLE OIL!

1 Replace the oi andthe i separator (element

‘and housing) regula as schedsed by the

Insiction Manal Faure ocbserve this may

p.13). Refer tothe IMPORTANT (1).

peor

Becomes on (non-lashing}

‘when the HISCREW is load:

ng under the standard | ype

capacity contra. Refer tothe

IAPORTANT G3

ERE _ RUNNING WODE,

ross the ECOMODE buon o enable an

respectively enabled and activated,

‘SELECT Button

DRYER Button & Light (red)

[Bross the SELECT bution (0

splay some operating data

‘and. shutdownvalarm codes

fon the digital monitor (G3.

8.

‘Undor manual operation mode for the bull

air dryer, press the DRYER button to manual

ly start and stop, Under eny operation

‘modes forthe built-in air dyer, the DRYER.

light becomes on (nor-flashing and lashing)

when itis operating respectively normally and

Abnormally. Refer to the IMPORTANT (2),

Buttons/Lights for

‘ALARM Light (red) _

Shutdown and

6

th

‘Becomes on (lashing) whon an alarming prob

lem arses. At the same tie the digital monitor

plays a corresponding alarm code. Rete

IMPORTANT (1),

Bee AOSNODE_

(ete Je Bee |

ECOMODE Button and Light (yeliow) |

ECOMODE function that tomporafly roduces tho

cutout pressures. THe ECOMODE light bacomes

[on (non-fashing and lashing) when this function is.

Becomes on (lashing oF non-

lashing) when a remote oper

bled.

[PORTANT]

(1) If you want to permanently enable a

remote operation with the REMOTE

light on (non-tashing), place the DIP

s5wteh SW1 No. 4 in an on position. tt

You want to use an external setting

Switch for enabling!dsabling a remote

‘operation with the REMOTE light on

tHlashing), connect the wires between

the external setting switch and the

starterfoontol box. For more informa:

tion, se page 13.

(2) Before shipping the models with a

builtin air ever, Hitachi presets op

‘ation mode to automatic you want

to enable manual operation mode,

change the setings ofthe DIP switch

SW2 No.1 & 2.For more information,

‘300 page 14.

Before disconnecting the power from

the HISCREW under manual opera

tion mode, pross the DRYER bution

to manualty stop tho builtin alr dryor.

Ifyou disconnect the power before

‘manually stopping tho bul air dyer,

‘restarts as soon as you roconnoct

the power, thats, you cannot manu-

Tt before starting the ar

(8) The LOAD light bocomes on (lashing)

when the ISCREW is loading under

{he alternative [type capacity control.

For more information, see page 32.

Remote and local operation means starting

and stopping the HISCREW respectively

with external control signals from other than

the builtin starter/eontrol box and

with the START and STOP buttons on the

builtin instrument panel.

[arora]

SHUTDOWN Light (red)

(1) The digital monitor displays a dis-

charge air temperature, instead of

‘Bocomes on (ashing) when a shutdown

problem arses, At the same Ume the ig

tal monitor deplays a comesponding shut-

down cod Refer tothe IMPORTANT (1).

the alarmishutdown code, when

the alarm/shutdown light be:

‘comes on (flashing) due to high

RESET Button

| Releases a self-hoid circuit made |

when an alarmishutdowin problem |

arose (ES pp.29-28).

____ Digital Monitor

Displays an alarm’shutdown code

when a coresponding ight becomes

on (lashing) (E3" pp.23-24). Refer to

[he IMPORTANT (2)

(or abnormally high discharge alr

temperature.

(2) Atthe same time the DRYER light

becomes on (flashing) when the

builtin air dryer causes an alarm?

shutdown problem (63° p.25).

3. HOW TO OPERATE [How to Use Digital Monit

3.2 How to Use the Digital Monit

jor and its Controls)

or and its Controls

| (1) Displaying the Operating Hours, Pressi

| 22 rests tng ta petra

(Operating Hours (x 10%)

: Pressure in MPa (Unused.)

[raeserearensy

[a estrone sn

| Us Tota loading ime (x 10,000)

E: Alarm/shutdown code

(Avalane ony han an slamishatown

rotor hes happoned}

ure, Discharge Air Temperature,

Loading Rate, Total Loading Time, and Alarm or Shutdown Code

When you connect the power, the digital monitor displays the

total operating hours. To display other data, do as fellows:

© Press the SELECT button. The screen displays “P0.00"

‘This sereen is unused.

@® Press the SELECT button. The sereon displays “C”

together with the discharge air temperature.

© Pross the SELECT button. The sereon displays “L?

together with the loading rate. The system flushes

figures when in calculation,

@ Press the SELECT button. The screen displays “U"

together with the total loading time (x 10,000)

Rofer to the IMPORTANT:

© Press the SELECT button, When the alarm/shutdown

light is:

+ on (flashing), the sereen displays “B” (lashing)

together with the alarm/shutdown code (Ea pp.

23-24), Press the SELECT button to return to the

original sereen of total operating hours.

+ off, you directly return to the original sereen of

total operating hours.

=

IMPORTANT]

It you want to display the exact total loading

time (« 10), hold down the SELECT button

and press the RESET button

(2) Displaying the Shutdown History

Newest shutdown

EXX|

op

Digital Monitor

7

serene | een |

sem omen |

XX: Shutdown code

‘To display other data, do as follows:

@ Hold down the SELECT button, The seroon displays

“FO” together with the shutdown ende (63° pp. 23-24).

‘The “0” indicates the newest shutdown.

@ Pross the SELECT button. The screen displays “F1"

togother with the shutdown code. The “1” indicates the

second newest shutdown.

@ Press the SELECT button. The screen displays “F2”

togother with the shutdown code. The “2” indicates the

oldest shutdown,

@ Press the RESET button. The screen returns to what

‘you have left with the action @ above. If you press the

SELECT button instead, the sereen displays “F3" (and

the further numbers) which are not to be used by the

[NPORTANT]

Displaying the *c)"in the action (D indicates that no shut-

downs are stored in the memory.

3. HOW TO OPERATE (How to Use Digital Monitor and its Controls]

(3) Displaying the Capacity Control Settings

Hod down the RESET buon

oo, wna teste SELECT BuO ‘To display the capacity control setings, do as

Digital Monitor| & & follows:

@ Hold down the RESET button and press the

[ae pce ee ne tease

| displays “DL” as an example (see the IMPOR-

ach new screen TANT below),

ene | © Press for each new sereen to display the standard

ee and alternative cutoff and cutin pressures and the

reference time for sifting to ECOMODE control

No2:Cutn Pressure | @ Press the RESET button. The screen returns to

Goto the 08, 0s0ra what you have left with the action ©D above

section (4)

Changing 03: Prsse ovownl | ¢— GROUT

the 006: 0.08 ese)

‘Tho first screen displays the capacity conto! mode

Stony mmm rare situ tatinoes comes paso

eae Rereeetate | | ty contol typos as flows:

Settings. | con: 30 secon A UsksP Type

105: Atemative Cu ue ps)

ee emus U:UType

ooo. osie The frst serge also dleplays the “#" that may vary

depending onthe specticatons.

Nos: Atomaive cutn | | depending on the sp

Peon

ao ose. ose

Prose to retum,

: . . ‘To change the capacity control settings, do as follows:

(4) Changing the Capacity Control Settings 4) ‘Display the eutolf pressure screen

Follow the section (3) Displaying the Capacity Control Settings @ Hold down the SELECT button and press the RESET

{0 clay ha soron where you wane charge tho soting. ‘button. The first decimal place ofthe current cutoff pres-

‘cut Prssur Son sure setting flashes to indicate that itis changeable.

(an example) Hold down te SELECT buton @) Press the SELECT button as many times as required

Pinca nd press he RESET buen, until a desired numbor is displayed

Moo @® Five seconds lates, the first decimal place stops flash

ing and the second decimal place flashes. Press the

SELECT button as many times as required until a

desired number is displayed.

® Press the RESET button to return to the cutoff pres-

oan © Press the SELECT button to move tothe eutin pres-

pated sure screen. Repeat the above actions @ through @

Soeen to change the eutin pressure setting. Press the RE-

‘SET button. The screen returns to what you have lft

" with the action © above.

(iB J Press. ‘Standard Factory Settings (in MPa without decimal point)

THSOREW Speseatins[0.59 Pa [0.99 MPa [0.92 mPa] Rena

= swartcanem 1.[ 069 | 089 | 092

cOSd | sunutcunPeve —2.| 069” | 074 | 082

renmiQimets—3-| 008 | 008 | 008

[Eeialeama™® ¢.[" 090 {090 | o90

ma Z Aen OetPe 5. 080 022

MPORTAN] Aes CaP 6-| 059 | 07a] 082

1. Do not change the reference time for siting to ea

ECOMODE conto. See page 31.

2, Toenable te alternative cuotcutn pressure fune- itachi presets the standard cutoff pressure to the cor

tion, turn on the external switch that you installed responding specification pressure. Always set the cut-

to onabledisabe this function cf and culin pressures o between O50 and the spect

fication pressure 069, 083, of 092.

3. HOW TO OPERATE [Initial Start-Up]

3.3 Initial Start-Up

A\ CAUTION

Before turn the power ON, make sure if

installation, (2ipiping and [3lelectrical wir-

ing have been properly completed.

(WeonTanr]

Every button such as START, STOP and RESET will

‘not function unless the switch held down more than 0.3

second.

After the installation, or after long unused time (over a week),

run the machine by way of initial start-up.

3.3.1 Before power on

a

4\ CAUTION

Oil has been filled in the oll case by the

factory before delibery.

3.3.2 Power on

® @@ Sail

T oO

a wr : a

= l|

[comes [nae '

4

10

© Be sure the power is OFF.

@ Be sure that grounding is firmly connected.

© Be sure the discharge pressure gauge indicates 0.

@ Detach the door (for the 22 kW models) or the

front enclosure panel (for the 37 kW models)

and remove the starter/control box cover.

‘Make sure that the DIP switches SW1 and

‘$W2 on the printed circuit board are correctly

set. (ESF pp. 12-14)

© Check if oil level is kept around the upper red

line on the oil level gauge.

(Oil level lowers while operation)

ror)

Capacity control of S-type is preset to I-type contol,

land MHtype isto P-type (AUTO) control.

ter to page 12 for the seting of controt function when

the control type is changed.

‘Compressor shifts repeatedly between ful-load and no-

{oad operation within the range of its discharge pres-

sure between 0.69 MPa and 0.59 MPa.

@® Connect the power.

@ See if POWER light glows on the compressor’s

instrument panel.

@ Digital monitor displays run hour in 10 hours

as a unit.

@ Fully open the valve on discharge side.

(Wontar)

For safety, the unit will not operate for 5 seconds after,

the power is ON, even START button is pressed.

3. HOW TO OPERATE [Initial Start-Up]

3.3.3 Operation

@ Press the START button.

g a @ START light glows and the compressor starts.

| ® Gradually closing the discharge side valve,

f and keep running-in of the machine at the dis-

[ioe | Olea! charge pressure of 0.49-0.59 MPa for an hour.

= @© Be sure that the oil level is kept between two

red lines during operation.

H © Press the SELECT button on the instrument

panel to display the discharge air tempera-

ture. Make sure that it is stable between 65°C

and 100°C.

nln te! |

‘J © Make sure that, 5 to 10 minutes after starting,

4 the refrigerant pressure gauge reads 0.41 to

0.73 MPa.

@® Make sure that, about 20 minutes after start-

ing, the automatic condensate trap starts drain-

ing the condensate.

3.3.4 Stop

© Press the STOP button,

‘The compressor stops.

Power

® D Suppiy @® Be sure that the pressure at DISCHARGE AIR

@ PRESSURE GAUGE indicates 0 (It returns to

© for about 1 or 2 minutes after stop.)

4s

@ Fully close the valve on discharge side.

@ Disconnect the power.

"

3. HOW TO OPERATE [Setting of the Control Functions}

3.4 Setting of the Control Functions

Power If

® — Supaly

a

(EELEEED ~ ZIZED

OP Switch

‘owe.

ot

3.4.1 Setting of Capacity Control Mode

As listed in the table below:

+ The S- and M-type HISCREWs provide two ca-

pacity control modes each.

+ You can select either one of them by setting the

No. 3 & 4 pins of the DIP switch SW2 located

on the printed cireuit board.

__S4ype

cae |

(U ype) (UL Type) UTE Type) (U+1 Type)

Seren gt [nos] oN [ON [ON | ON

Bwa"" |Noa| OFF [ON

DaprnDgiatinie] Uae | Oicax

ase | oles

NOTES:

1. The shaded cells indicate a standard factory seting

2. The + mark indicates that the CPU automatically selects

either of the 2 or 3 capacity control types whichever is

‘appropriate,

3, Do not get the SW2 No. 3 & 4 to other than the above.

For more information on the capacity control sys-

tem, see pages 29 through 30.

FSatso saa

Printed Circuit Board

12

When you use an external air dryer under the’ mode

ot capacity contro (Uype + I4ype + P-type) enable t

to keep operating even when the HISCREW automat-

cally stops. Ths prooct the external ar dryer rom ston-

ing and restating frequently

3.4.2 How to Set Capacity Control Type

tou

© Disconnect the power.

@® Remove the starter/eontrol box cover.

@ Place the No. 4 pin of the DIP switch SW2 in

an off position,

@® Return the starter/eontrol box cover to its origi-

nal place.

© Reconnect the power.

© Display the capacity control setting screen on

the digital monitor (G3 p. 9). Make sure that

the U as 0.U:** is displayed.

[PORTANT]

Do not select the U-type when your KISCREW spectties

the discharge of 0.92 MPa,

3. HOW TO OPERATE [Setting of the Control Functions}

O@ 2D 309

Ero feoreon [Pena Orin

se en

JON tig nad | Ma he

owns |S Saye

lorF [Domes

\ (1) To nae ba eno peraton

Gest sa \ ome SCRE nen panel

via dob RESET ton

{tres me ESOMDDE Suton,

3.4.3 Enabling the Remote Operation

‘The following 3 methods (1), (2), and (3) are avail-

able to enable the remote operation. Usually em-

ploy the method (1).

Method (1); On the HISCREW's Instrument Panel

@ Connect the power.

@® Hold down the RESET button and press the

ECOMODE button.

© Make sure that the REMOTE light is on to indi-

ato a remote operation enabled.

@ To disable the remote operation, hold down the

RESET button and press the ECOMODE button.

Make sure that the REMOTE light is off to indi-

cate a remote operation disabled or a local opera-

tion enabled.

Method (2): On the Starter

© Disconnect the power.

@ Remove the starter/control box cover

Connect the wires between the HISCREW's starter!

control box and an external control panel. For in-

formation on a wiring diagram, see pages 40

through 43.

@ Place the No.4 pin ofthe DIP switch SW1 (on the

printed cireuit board) in an on position.

© Return the starter/control box cover to its original

place,

© Reconnect the power.

@® Make sure that the REMOTE light is on to indi-

2@ cate a remote operation enabled.

. CAUTION a

a ee aOR

Dr owen oy Shanne the sander istry With thie method, usualy, you may intend to permaneniy

eo n setings tor tre. 58 pie use a remote operation Ifyou want o disable or some

ong ‘Sinisa proper cont a ‘reason you need place the No.4 pin ofthe DIP omc

Specter OT gorithm is fst ‘8W1 in an off position.

Sy Bon

SSaoe ae Se ‘Method (3): On an External Setting Switch

Sa Co @® Disconnect the power.

smote operation, always use

the method used when in enabling. If you enabled it

with the method (2) or (3), for example, you cannot

disable it withthe method (1).

+ You can stop the remotely started MISCREW even

by pressing the STOP button on the HISCREW's in-

strument panel.

“Asan optional function, you can externally output the

remote operation salting signal.

@® Remove the starter/eontrol box cover.

©® Connect the wires:

between the HISCREW’s starter/eontrol box and an

external control panel, and

between the HISCREW's starterfeontrol box and the

external setting switch.

For information on a wiring diagram, see pages 40

through 43.

@® Make sure that the No. 4 pin of the DIP switch

‘SW1 (on the printed circuit board) isin an off posi-

tion,

© Return the starter/control box cover to its original

place.

@ Reconnect the power.

@ Turn on the external setting switch.

@® Make sure that the REMOTE light flashes to indi-

cate a remote operation enabled.

@ Todisable the remote operation, turn off the ex:

temal setting switch. Make sure that the REMOTE

light is off to indicate a remote operation disabled

ora local operation enabled.

13

3. HOW TO OPERATE [Setting of the Control Functions}

(Dryer

This page describes for the models with a

built-in air dryer.

Without

XSCREW Modots | Buin

Ar Dryer

DIP Sween [Not] OFF [OFF [ONT

Win Bustin Ait Oeyae

sw2 [No.2] OFF ‘ON ‘OFF

aa Ea

One ne

Seo woe cen a

Pe the power! | evens}

nvenion | ort [oi entanen.cenataas"|

OTE Te ehdedcle ae « mac cry ang

wove none

a ow gu

eon

i) SSERTTTTIL sy TT ert omy

sya SH al

ce? !

3.4.4 Setting of Air Dryer

(1) Operation Modes.

As listed in the table left, the models with a built-in

air dryer provide 8 operation modes. You can select

either one of them by setting the No. 1 & 2 pins of the

DIP switch $W2 located on the printed eircuit board

Ifyou want to enable an air dryer prestart function,

always select the automatic mode.

Ifyou want to start and stop the built-in air dryer with

the DRYER button, always select the manual mode.

‘The settings are saved in the memory when you have

stopped the HISCREW.

(2) Air Dryer Prestarting

‘To enable the air dryer prestart function, set:

DIP switch SW2 No.1 & 2 to ON & OFF respec-

tively, and

DIP switch SW1 No.1 to ON.

‘When you press the START button under the air dryer

prestart funtion,

+ ‘The START light and DAYER light become on (non-

flashing),

+ The AUTO START light becomes on (flashing), and

+ The air dryer prestarts.

‘Three minutes later,

+ The AUTO START light becomes off, and

+ The air compressor automatically starts

‘This chills the built-in air dryer sufficiently in advance,

and thus enables to discharge the dry compressed air

from the beginning.

‘When you use an external automatic control

panel (muttiple-nit controller two-unit controller, etc):

* Set the DIP switch SW2 No.1 & 2 to ON & ON

respectively (to enable the manual mode), and

the DIP switch SW1 No.1 to OFF (to disable

the air dryer prestart function).

‘Thus you can protect the air dryer from stopping

and restating frequently.

Power | |

‘Supply u

©} (]

se

PORTANT]

‘When the power is instantaneously interrupted and then

Uninterrupted, the air compressor and the air dryer start

simultaneously.

(8) Air Dryer Warning (Shutdowr/Alarm)

‘To enable the air dryer warning function, set the DIP

switch SW1 No.2 to:

ON for an alarm, and

OFF for a shutdown.

When the air dryer fails,

+ The SHUTDOWN or ALARM light becomes on

(Sashing),

+ The DRYER light begins flashing, and

+ Thedigital monitor displays the shutdown or alarm

code.

When the SHUTDOWN light flashes, the air compres-

sor is automatically shut down, When the ALARM light,

flashes, the air compressor is not shut down but keeps

operating. In either case, usually, the air dryer is shut

down,

(4) Setting Procedure

When setting the DIP switches SW1 and SW2:

© Disconnect the power.

@ Detach the door (forthe 22 KW models) or the front,

enclosure panel (for the 37 KW models), and then

remove the starter/eontrol box cover,

@ Set the DIP switches SW1 and SW2 as required.

@ Return the door or front enclosure panel and the

starter/control box cover to their original places.

3.5 Daily Operation

3. HOW TO OPERATE [Daily Operation}

A\ CAUTION

© Donot operate the machine with the pressure excess of its rated pressure. Excessive pressure gives

overload to the motor and may damage some parts or even cause SHUTDOWN of the compressor.

any question,

@ Investigate the cause and take necessary measures when the Relief Valve functions or the compres-

sor stops by other safety device. Ask your dealer or your nearest Hitachi Service Station if there is

@ When the HISCREW automatically stops and restarts frequently, or the ambient temperature and

humidity are high, open the oll/condensate drain vaive of the oll case to drain the condensate from

time to time. If you do not observe this instruction, the alr end (rotors, bearings, etc.) and the compo-

\__nents rust internally to cause a failure and/or the oll deteriorates. For more Information, see page 17.

3.5.1 Before power on

Boor

Oil Level Gauge il Filing

Port

3.5.2 Power on

@ Check if oil level is kept within the range be-

tween upper and lower red lines. However,

since the oil level may lower a little while op-

eration of the unit, chock again the level when

the unit is in operation.

© Connect the power.

@ POWER light on the instrument panel glows.

@® Folly open the vaive on discharge side,

@ Fully open the valve for the condensate drain

trap,

15

3. HOW TO OPERATE [Daily Operation]

3.5.3 Operation

a

3.5.4 Stop

16

© Press the START button.

Make sure that the air compressor starts,

+ For the air dryer prestarting (2° p. 14) disabled:

‘Make sure that the built-in air dryer starts

simultaneously.

+ For the air dryer prestarting enabled:

‘Make sure that the built-in air dryer prestarts,

the AUTO START light flashes for 3 minutes,

and then the air compressor starts.

© Make sure that the oil level during operation

is kept within the range between the red lines.

© [fit is below the lower line, follow the proce-

dure on page 18 and replenish the genuine

synthetic oil (NEW HISCREW OIL 2000).

@ Digital monitor displays run hour in 10 hours

as a unit.

Press the SELECT button on the instrument

panel and check if the discharge temperature

is within the range between 65°C and 100°C.

(After temperature stabled)

© Make sure that, 5 to 10 minutes after starting,

the refrigerant pressure gauge reads 0.41 to

0.73 MPa.

© Make sure that, about 20 minutes after start-

ing, the automatic condensate trap starts drain-

ing the condensate.

© Press the STOP button.

‘The compressor stops,

@ Be sure that the pressure at DISCHARGE AIR

PRESSURE GAUGE indicates 0 (It returns to

0 for about 1 or 2 minutes after stop.)

© Fully close the valve on discharge side.

@© Disconnect the power.

4. DAILY CHECK

{ 4. WARNING

1, Before check and maintenance of the compressor, carefully read “TO USE IN SAFETY” (ES p. 2)

again.

2, Be sure to turn OFF the POWER when check or maintenance is carried out.

3. Never touch rotating parts of the compressor (Motor Shaft, M-Sheave, V-Pulley, V-Belt and Cooling

Fan).

4.1 Daily Operation Management

Record the operation status of the day in OPERA-

TION RECORD LOGBOOK (8S p.67). Mainte-

nance must be carried out if checked values show

excess over allowable criteria,

4.2 Control of Condensate

‘The oil temperature control valve controls the oil

temperature and thus prevents the condensate

from being produced in the oil case under the nor-

mal operating conditions.

Under the following operating conditions, however,

the condensate may be produced in the oil case.

1. The ambient temperature and relative humidity is

as high as:

30°C and more than 80%, and

40°C and more than 50%.

2. The HISCREW stops and restarts repeatedly.

3. The oil cooler cools the oil excessively.

If this is the case, open the oil draining valve and

check if the condensate comes out. Drain the con-

densate as required.

A\ CAUTION

@ Running the compressor for long time

without draining may cause not only

‘troubles to the Rotor and Bearings in its

air end, but other majour troubles like

rusting inside equipments.

© Incase of multiple unit operation, itis rec-

ommended to attach an oil cleaner to the

unit. Ask your dealer or Hitachi's service

station for this information.

® Do not open the oil-draining valve when

the HISCREW is operating. Otherwise the

hot oil gushes out and you may be injured

or burnt.

Draining the Condensate before Starting

the HISCREW

@Make sure that the HISCREW is not operating

and the discharge pressure gauge reads 0 MPa.

@Close, and then unplug, the oil-draining valve

on the pipe extended from the oil case.

@Place the oil pan under the oil-draining valve.

@ Open the oil-draining valve.

®The oil comes out and the condensate follows.

@©When the oil starts to come out again, close and

plug the oil-draining valve.

IMPORTANT]

li the condensate isnot diseriminable from the lubricant,

‘check its viscosity by your finger tips while draining. Be

‘sure the condensate is wall cooled before touching it. If

the condensate sticks to your fingers, the lubricant is.

‘coming out,

Take this

Saucer

(Furnished by user)

17

4. DAILY CHECK [Lubricant Management]

4.3 Lubricant Management

{ 4 WARNING

1. When deteriorated lubricant is used without replacement, some of it adhere to the Oil Separator Ele-

‘ment and accumulate heat caused by its oxidization. This may bring even fire in the worst case.

2. Change lubricant and Oil Separator Element constantly according to the standard given by the Main

tenance Standard (ES pp. 45-46). Deteriorated Lubricant may result fire to the Oil Separator.

3. Use genuine synthetic oil (NEW HISCREW OIL 2000) for lubricant. Avoid use of other brand or mix use

with it

tion),

lines.

4.3.1 Oil level check

‘Check lubricant level by the oil level gauge on the

oil case while the unit is working (loaded opera-

It is normal if the level is kept between two red

‘The level over the upper line is too much. Stop

the compressor and after check of no residual

pressure is left inside, discharge off the surplus

from the valve at oil case drain port.

If the level is lower than the lower red line, itis in

short. Stop the compressor and after check of no

residual pressure left inside, turn OFF the power

and replenish some more of lubricant.

Twe| OSP-22SA(R)I | OSP-37SA(R)I Ask your dealer or Hitachi's service station for replace-

item OSP-22MA(R)I | OSP-37MA(R)I ment of the genuine synthetic of (NEW HISCREW OIL 2000).

Oliv | titers | 2.6 ters 4 ter ll can: Part No 386]

between | 20 titers oil can: Part No.[332]

red ines _| (0.34 liters / 1m) | (0.51 liters / 1¢m) ‘The genuine synthetic oil may get darkened dus to its

or | Biiters 13 liters

4\ CAUTION

@ Replenish the oit (genuine synthetic oil) periodically to

maintain the proper oil level. Long time operation without

‘the oi replenishment at low oil level, can cause the shorter

ail life or olf deterioration.

@ Oil replenishment shail be carried out every 1500 to 2000

‘operating hours. Replenish amount might be;

2 to 3 liters for 22 KW, and 3 to 4 liters for 37 KW.

(Actual replenish amount shalt be determined by the oil

level, as itis varied by the load rate of the compressor.)

®@ Sampling analysis of the oll at every 3000 hours interval

recommended. Earlier oll replacement might be nec

sary, depending on the result of the analysis.

Consult HITACHI dealer for the sampling analysis.

18

4, DAILY CHECK [Lubricant Management]

4.3.2 How to change oil

@ Press the STOP button.

}@ Disconnect the power.

}@ Be sure that the pressure in the compressor is

decreased io the ambient pressure level (Check i

the Pressure Gauge indicates © MPa).

]@ Detach the door and the right enclosure panel

© Unptug the oi-drining pipe on the pipe extended

{rom the oit case.

|@ Place the oi pan undor the oi draining valve. Open|

the oikdraining valve, Lat the ol be totally drained

from the oil case. Close and plug the oi-draining|

valve.

I@ Pace tha ol pan under the oil coole’s plug. Un+|

il Cooler Drining Port

Qocated under th plug the oll cooler. Let the oil be totally drained

‘ight enclosure panel) {rom the oil cooler. Plug the ol cooler.

(@ Unplug the ol fling port. Fil the genuine synthetic

cil (NEW HISCREW OIL 2000) into the ol coor,

Lnti the oil reaches the upper red line on the oi

level gauge,

1@ Make sure that all the plugs are tightly screwed,

‘and return the door and the right enclosure panel

to thoir original places.

[@ Tum the POWER ON. Press the START bution

and siop it7 or 8 seconds later.

16 Check the oif level with the oll gauge of the oi

case. The level wil ower because some of itis

‘ircuating in pipes or ol cooter.

|@ Confirm that the pressure decreases to the level

of the ambient air pressure, Then tuen the

POWER OFF end replenish some more lubricant

into he replenish port.

1&3 After replenishment, fasten the plug on the re-]

plenish port securely

|@ Proes the START button again to chock the ol ove

wen the compressors ats ful foad.

Discharge

il Case

Draining Pon Oil Filing Port

Fitting the oll

Ay CAUTION

@ Replace the lubricant in whole every two

Check and Replenishment

( A CAUTION

© If olf Is 80 deteriorated as to produce the sludge or to be gresn, you can not recover the system's

function even by cleaning the all cooler, oll case and oll piping. You may fave to replace the olf cooler

and overhaul the entire aystem (Including the air ond).

© Optional Low Oi! Levet Alarming Feature:

if the ALARM light flashes and the error code E-22 Is displayed on the digital moniter, stop the

HISCREW, make sure that the system has been depressurized, and turn off the main power; then add

oll, Restart and fully load the HISCREW; then press the RESET button,

19

5. TROUBLESHOOTING

{ A\ CAUTION

In case where ALARM is given or a SHUTDOWN happens, remove its causes before restart the unit.

Ask your dealer or your nearest Hitachi Service Station if you have any question or unclear point.

5.1 When ALARM or SHUTDOWN is Displayed

) Discharge Ar

Temperature

tent can be checked by pressing the SELECT

button for more than 7 seconds.

B® See page 8 for this operation.

20

The unit memorizes three items of shutdown

history with different shutdown code. {ts con-

IFC] arm

SHUTDOWN

5.1.1 ALARM Light Flashing

(The HISCREW keeps operating.)

Alarm is given (Ex: Temperature sensor detects

high discharge temperature ofthe compressor.).

@The ALARM light flashes. The digital monitor

displays the discharge air temperature.

@Remove the causes of alarm,

(Refer to pages 23 through 24 “SHUTDOWN/

ALARM Indications on the Instrument Panel" for

countermeasures.)

5.1.2 SHUTDOWN Light Flashing

(The HISCREW stops operating.)

Shutdown happens (Ex: Temperature sensor de-

tects excessive in the discharge temperature of

‘the compressor.)

@The SHUTDOWN light flashes. The digital

‘monitor displays the discharge air temperature.

@Remove the causes of shutdown.

(Refer to pages 23 through 24 “SHUTDOWN/

ALARM indications on the Instrument Pane!” for

countermeasures.)

@Press the RESET button.

@The SHUTDOWN light becomes off

5.1.3 When SHUTDOWN code is

displayed on the digital monitor

‘The ALARM or SHUTDOWN light flashes, Take the

similar actions as above.

(Reorran]

Procedure to reset ALARM and SHUTDOWN depends

‘on what brought the ALARM or SHUTDOWN.

(Gee Reset Procedure in pages 23 through 24 "SHUT:

DOWN/ALARM Indications on the Instrument Panel’)

Rei ae

5. TROUBLESHOOTING [Override Operation]

5.1.4 Automatic Restart after Power Supply

Interruption (Equipped to M-Type)

M-type unit is equipped with a function of auto-

matic restart after power supply interruption.

When an interruption of power supply in which

electromagnetic contactor turns OFF happens,

this function detects it. Make AUTO START light

blink and wait until pressure drops down to 0,

thon the unit automatically restarts.

@POWER INTERRUPTION occurs.

@The unit stops automatically.

@When the power supply is interrupted, AUTO

START light on the operation panel blinks.

@The compressor will automatically restart 60

seconds after POWER recovery.

(1) Power supply interruption moans the instantaneous

{drop of voltage to 0 V.

(2) The compressor continues its normal operation without

stop if the said drop time is shorter than 20 ms.

(3) When such time is longer than 5 seconds, the sensor

detects it as a power failure and stops the unt. In such

case, the unit will not restart automatically. So, press

the START button to start the unit again.

5.2 Override Operation

When the digital monitor displays a shutdown

code, first check the wires and connectors and take

corrective measures against any abnormal or loose

wires/eonnectors. Sometimes this may solve the

problem, If the problem persists or the shutdown

code is still displayed, proceed to enable an over-

Tide operation.

‘The override operation allows only the U-type ca-

pacity control. You should use the override opera-

tion as a temporary solution until you can finish

fixing the HISCREW.

A\ CAUTION

While you proceed to an override operation,

contact your Hitachi distributor to fix the

HISCREW as early as possit

24

5. TROUBLESHOOTING [Override Operation]

Power

De

sing IP Switch

® Sr operat ps

2sesere — CulT I (tno ape

DIP Switch on Call

Printed Greit Board

ve amoscorea,

®

Indicating of

Overtide Operation

Enabled

22

5.2.1 Enabling Override Operation

Press the RESET button.

@Disconnect the power.

@Detach the door (for the 22 kW models) or the

front enclosure panel (for the 37 kW models),

and remove the starter cover.

@Reset the DIP switches (on the printed circuit

board located in the starter/control box) as fol-

lows:

SW1 No. &: ON (setting of override operation)

‘$W2 No.3 & 4: ON & OFF

(Getting of U-type capacity control)

Return the door or the front enclosure panel to

their original places.

@Reconnect the power.

‘The digital monitor displays EE indicating that

the override operation is successfully enabled.

[Beorran)

(Override operation disables the following functions:

= To display the digital monitor (except for EE)

~ To turn on (elther flashing or not flashing) the ALARM

or SHUTDOWN light

= To select a scroon by pressing the SELECT button

~ To externally output the control signals through the |

dry contacts

5.2.2 When Override Operation is not

Allowed

‘The override operation is not allowed to the fol-

lowing error codes:

E-31: The thermistor TH1 is disconnected or

loosely connected

E-82: The thermistor TH2 is disconnected or

loosely connected

E-41; ROM error (failure of PCB)

1-42; RAM error (failure of PCB)

E43: E,ROM error (failure of PCB)

If this is the case, see pages 23 through 24 to take

corrective measures.

[NPORTANT]

For the error code E33 (failure of prossure sensor)

‘After enabling an override operation, hold down the

‘SELECT button and connect the power, and press the

START button, Note that this clears the shutdown

history

5. TROUBLESHOOTING [SHUTDOWN/ALARM Indications on the Instrument Panel]

5.3 SHUTDOWN/ALARM Indications on the Instrument Panel

‘When a problem oceurs, the SHUTDOWN, ALARM or AUTO START light flashes and the digital monitor displays

a corresponding ALARM or SHUTDOWN (as ‘A/S! below) code. If this is the case, refer to the following table to

identify the cause. If you cannot identify the cause, or for the problem with a ( mark in the table, contact a

Hitachi distributor.

RS] tone | Gacgono" FSEEN] — oy ve [what andiiow | Howto ms

|Code} Action Problem |shutgow | me ree [tere] 40 Dotoot Reset History|

7 [amToown| rena | Yoo |Fahecipamer |iacrnopowraipoy brave Gap] —[tepraat [Prose rom | 7

onan Sep) |anemtaanen comin trogued” | [aera [buonote

[High discharge | Greck and conect te capaiy oni stings and’ }overioad voley | thera

pressure or wads the modular wale, he discharge pms | overioad relay.

tie tbe eons

TGR aRS | choo opr some Fer

remure aati come &

ava —| Chek the moo Sao ance

naan |e &

ao | Cre ao i

ve amuToownr [righ dectage] Yer |ionanden’ |\ensne ti won beau te arbon| [oma |asete | 8

Jon ash) | mipenhse'(9| — |tpertae semper oso. femomecre | RESET oun

[Low oil evel | Addo (Dscoenect the poner are make sure tat the | over 110°C

curs nga ta}

yo Sse’ [Cen be cong na Se pape

elcolr

yr gg | Rosa a a Bas page 8.

eter

23 [marin [gh dectame] to [Sane a2 [Sanear Fee Teo Becta | atoatcaiy | 28

fontating |tanpomnae¢)| |e e8 ate fewwmecre | roe

om 0s

10 | soToGwnr | Fada doar | Yor] Wein oan |e pow g [Drowenswi[Pmone | 8

tas) layers pec Noe et Ort | RESET son

ALARM: No | devioe during g DIP switch Sw1 | Press the. 19

On (Hashing) rere |No2 settoON | RESET bution.

Ear srTooWn:| Rr pase| Yer ]Povr maces [Daan powscanachage 2a | —|ovtacedara |Oucomectand |

naan) [comecten recreate 3 power co res pects ator |recomeat be

ecmectea me | poner

rower

az | SARDWE | Phase-acing] Yew | we cemaded |S he pver ain Thy anneal] —|Danceaior®|Dacomactand | 08

On tang) [comecion stnaiaca |e power corte recrete aber |e

as comectng te | poner

rower

57 [ srvToGwn [ign dechane] Yew [Faire cot [Repaon he tema aomertandiho| [omc |Prsete | 17

Enea [torpomtre 20] fsoparor fo g|tencemae2 [Reser non

eran oer ior

[e-12 | SHUTDOWN | Abnormally ‘Yes |Falture of ol | Check the oil separator element. Replace | [Detected during | Press the 2

Joncming) [ror ascrarge |" |eeparioe [rogue 6 lost pwan [nese baton.

rere eran

Fane ot | Banc verano 2

contactor 62 _|the 62 was &

1a | TBO | Opn ve

fon acing

Es [sToOWn[Ansver enor] Yer |fanrect — [Dcowecinw pore andiecrme <2] —|Dneseranna frowns [1

on tena contact eonsco42 | ray eine t2wsee epncethe| |Get opeaton | RESET buon

tt ane | nce

Er SATDOWN[Anower ars] Yor |Foirct [Dicom rove an hac 62 | | Deioded ug [Psst AY

on tang) [eonmcors2 eonacors2 | Toy cinnedtne Stes pptcethe|_|Raropanton | RESET bon

L starve | at ncesay

5. TROUBLESHOOTING [SHUTDOWN/ALARM indications on the Instrument Panel]

E-St | SHUTDOWN: |Falea or decor | Yes [Fatureor _|Discornec\ the poner and checkihe THT.| [Operating [Auionatcaly | 1

On ashing) | nacesterpertue| Jasconnecton of | Replace it necessary Tiny recamect| (% |lemperaire | rece

sort ermiieTHt | ine TH wins. beiow -90°e

[E2 [SMUTDOWNE [Failed or dscon-| Ves |Fatueor | Disownecl fe power and checkihe TH2.| Operating | Aulomatealy | 52

Jon tasting) |neseetunpotine Jasconnecton ot | Replace it necessary Tigh reccnnect| (4 |iemporature | esa.

noo? ormioeTH2 | tbe THE whee. below 30°C

[E39 | SHUTDOWN |Faiea oF "Yes. Faure or dco | Disconneat ho power ana chock tne PS. | [O(er) MPa [Automatcaly | 28

}On fasting) | cisconnected recientes | Replace tt necessary. Tghtyreconnect| (9 |euring rose.

Pressure sensor senserPS | the PS wires operation

[E43 [SHUTDOWN | Foles cane) | Ves [Fale of ROM |Dizcomec and recannectthe power | [Retnngacion |Oisoonned and | 41

Jon ashing) | device (ocorted | probir sit occurs, replace the printed recoroect he

eur board) | cet boar. owe:

‘E42 [SHUTDOWEE [Foiled contol | Yes | Faire of RAM [Dlconcecl and reconnect the power ta| —[Retyingacton |Disconectond | a2

‘om (hashing) | devee (orpraisa | problem sit occurs, replace the pried reconnect he

ut beard) | eteut boar owe

'E@3 | SAUTDOWn:|Faled cna) | Ves Faure of BRON |Dioconnect and roconneciine power ia| — [Retyingacton |Dwoowectand | 12

}On fasring) | devew (ores creut| problern cil occurs, replace the printed recomact ne

boar) rat board Power.

E21 [ALARW —_|Goggedar | No | Ccggng ofa |oan he arte mr eiement pressure | Presathe 2

}On (asring) | iaka ter nike ter fiorenta ot | RESET buton.

74 KPa

G0 | ALARM [Excessheioaa’ | No | Wal 7,000,000 [Replace ih consunatle parts of suction) | 000,000 tes | Hod down =

Jon tasting) | unis ties oaded | rote vaive SELECT and

| rloaded press RESET.

[E22 [ALARM |Uowaiewei | No |Lowotlevet 2

}On tasting) | (option)

[E55 [SHUTDOWN | Opton Yer 6

[on tasting)

E64 ALARM: [Open Wo o

On ashing)

= [asTo stam: [instantaneous | No [IPS olbaiow 5 [Check he power soppy PS ozs ro

Jon (tasting) | powec seconds Ss00onds

rterupton TPS of below S| Check he power saph- Sof below 20 o

ws seconde ns

24

* Discharge empareure 1: Temperate atthe ole ofthe aie

Diecrarge temperature 2: Temperature a the cule f ho ol soparaor element

5. TROUBLESHOOTING [SHUTDOWN/ALARM Indications on the Instrument Panel]

ier

® Troubleshooting after the DRYER Light Fiashes

‘When a problem occurs on the built-in air dryer, the DRVER light flashes and the digital monitor displays a

corresponding ALARM or SHUTDOWN code. If this is the case, refer to the following table to identify the cause.

After solving the problem, press the RESET button to reset the control circuit.

Symptoms Causes ‘What to Check What Actions to Take [Mark]

[@) Operation of harmal | Operating curren: High | Check ihe powo’ supply votage, | Keap the operaing vliage ao apociod

‘overload relay AFC ‘Check the PS1 for an operation. Rofer to the (2). G

Power cables: Connected | Check the power supply terminal | Regan the teminal screws

Ina single phase. s2res for looseness.

‘Check the contactors for roughness of | Replace the contactor. e

their contacts

Pans of retigerant Check ogee compres brent | Replace the rtigorant compressor. te

compressor: Failed. [Check he ineutaton resistance. [Replace the rfigorant compressor | |

OFC: Fal. ‘Check the operating curent. place the 49°C. ©

‘Chock he wires for looseness “Ti reconnect the wis. ©

Operation of Incoming compressed alr: | Check the amblent temperature, | Reduce the anbint onperaturiobeiow 0°.

igh-ressure High in temperature. [Chacth cong ion lta compress | Clan cen donee nd repoe fe cot.

pressure ich PS1 gas pace vavet | Reed the eigen pressure gage. | Adhuahe hot gee pase vane ocorecly |,

Fale. seta religorant pressure.

alco ages bse ae Teoma |

‘Gondonser fn: Dirty. | Check the condenser fin for dines. | Clean the condenser fs.

‘Cooling fan motor or | Check ten cal ontch PS eau, | Replace the PS2. g

cenderaar Nt endor | Choc the 48°C fr conny Replace the 49°. ©

ee ‘Chock tho andor WIS or contnly | Replace the IM and/or. ©

‘Check the contactors fora falure. | Replace the contactors. @

Noncondansable gas: | Chckthe evaporator for a efigerant ak | Clean te refigerant pas and replace the

Mozed in the retigerant pats, air cooler, G

Pars of pressure swiches | Check the coninaly Feplace he PST andlor PSR

PSI andlor PS2: Faled, ¢

[&) Operation of Refigorant Leaked. | Oheakihe system fora refigerantioak | Takes coeae menue, rd wpe heretigoant |

reiigomnt [OH Fated ‘Check the OH for continuity Replace tho OR. xa

Incoming rtigerant High valve for | Adjust the ho-gas bypass vahe to correctly

in temperature. ‘set a refrigerant pressure, G

4X WARNING

The built-in air dryer uses non-flammable, non-toxic, and odorless refrigerant (Freon gas R-407C). The

Freon gas leak from the system, however, may generate toxic gas by contact with fire and it may irritate

the eyes and throats. In addition, it covers the floor because it is larger in specific weight than the air,

which may cause oxygen deficit to the personnel. When the Freon gas leaks, therefore, extinguish the fire,

ventilate the room with @ sweep-the-floor motion, and contact a Hitachi distributor.

25

5. TROUBLESHOOTING [A List of SHUTDOWNS Not Displayed on Instrument Panel]

5.4 A List of SHUTDOWNS Not Displayed on Instrument Panel

Ask your dealer or Hitachi's Service Station if the cause of malfunction is unknown or with {¥ mark shown in a

REMARKS column.

SHPTOWS AND TROUBLES] POSSIBLE CAUSES SOLUTIONS aed

Wire breaking Replace of wire &

Si Motor noise | print circuit board, relays, failures, fuse | Replace

B| inaudible | blown-out, transformer failure.

= Motor matfunction Repair ar replace ©

g Voltage drop Change Trait Capacity when POWER CAPACITY to sal

| motor notes | Wites {00 thin Replace Wires to ones of standard size

5) audible Motor abnormal Repair or replace &

Start Solenoid Valve": Failed. Replace &

Compressor’s revolution unable Disassemble and inspection of the Compressor Main Body | (

‘Modulator Valve Biow-af Solenoid Valve faut_| Readjust or Replace &

Discharge Pressure Gauge Indication fault Replace ©

Pressure Leak in Pipes Refastening/Packing change

decreased Intake Filter clogging ‘Clean or Replace Element

Oil Separator clogging Replace Element &

Pressure Regulating Valve fault Readjustment &

pare Suction Throttle Valve fault Disassemble and check/Packing change &

ieareasea ‘Mechanical Sealing damage Replace @

Pressure Gauge Indication fault Replace e

Relief Valve Excess Over Rated Pressure ‘See “Discharge pressure increased” above. | (+

operated Relief Valve: Incorrectly adjusted or faiied.| Readjust, Repair or Replace &

Discharge Temp. | Poor operation of Oi Temperature Control Valve | Replace a

too high Suetion Air Temperature too high More Ventilation

Lubricant Oil Scavenge Pipe System clogging | Clean or Replace Recovery Orifice

consumption il Separator clogging Replace Element &

exceesn) Oi level: Not between the red nes on oi level gauge] Keep oil level between the red lines.

¥] Current value | Lowered or unbalanced voltage Adjustment of power and voltage

large | Reualabaie esis being pa lean stan) | Inspection, flashing, oll change e

i tiatiarayeasrommlaivec ow | Roast g

S| erst intake Fier clogging Clean or Replace Element

& Over-voltage ‘Adjustment of power and voltage

26

To be continued on page 27.

5. TROUBLESHOOTING [A List of SEUTDOWNS Not Displayed on Instrument Panel

SMPTONS AND TROUBLES POSSIBLE CAUSES SOLUTIONS es

‘Adjustment failure of Modulator Valve _| Readjust @ |

‘Stat Solenid Valve" andor Blow ff Sonoid Var Failed | Replace &

Capacity Contro | Air-leak or clogging in plumbing system | Cleaning and refastening of Plumbing Equipments | (%

maifunction Cap Seal damaged Replace @

‘Suction Thvatile Valve's rubber seat damaged or deformed | Replace @

Inappropriate pressure setting Resatting ©

‘sof aera gone stool PEW HESOREW on 209 | Replace with the appropriate one ©

pri “Ambient Air Temperature too high Replace it wth genuine sya ashing nse is eed)

too early Water in the system ‘Check of Drain Suction Port and drainage

Deteriorated Lubricant stil left Flushing at Lubricant change &

‘Strange noiee from | Compressor grips Foreign Particle _| Disassemble/Repair ©

the Main Body | Inappropriate friction or damage of Bearing | Replace ©

Other unfamiliar | Loose Bolts or Screws Retastening _|

nolees Fault installation ‘Aad some mortar to settle the foundation evelly

‘Stange noise fom Bet | Beit slipping ‘Adjust Belt Tension or replace it &

Loose Bolts or Screws Refastening

Exceesive Vibration | Fault installation ‘Add some mortar to sell the foundation lovely

‘Unbalnco of tho uit deo Gooing Fan contaminaion | Clean Fins &

Drain trap clogging Clean

Refrigerant Drain discharge system clogging ‘Clean dren discharge system then drain ftom under ait cooler. | |

feumaas ‘Air cooler frozen ‘just ot as bypass ve be 041 Wa oor. |”,

| gather at outet. Replace bypass valve if unadjustable,

& Refrigerant leak Repair then fill refrigerant. ¢

3 High intake air temperature ‘Keep ambient temperature below 40°C.

Refrigerant lean cooler and replace fan.

ae emerdrete | Noncondensing gas mind in cle ‘Wash cyole then replace evaporator. @

gather at outlet | Hot gas bypass vaive fault ‘Adjust bypase valve tobe the specie pressure. |,

Replace if unadjustable.

* Only forthe 37 KW models.

* Only if you installed an ammeter on the power supply

A\ WARNING

1. Running the unit with deteriorated lubricant unchanged or in a very hot condition brings the lubricant

ignites and this may cause serious accident.

Keep the lubricant well controlled (See pages 18 through 19).

2. Do not operate the unit without protective equipment. In case of SHUTDOWN, read this section “5.

TROUBLESHOOTING" to remove the cause. If the cause is unknown, inform and ask your dealer or

Hitachi Service Station.

4 CAUTION

© Running the unit with its foose belt brings not only lowered discharge alr capacity due to its slipping,

but also life of belt shortened. If belt is broken during the operation, the lubricant blows out of the

Suction Throttle Valve. Be sure to carry out your constant check on belt.

@ If the unit stops due to the function of Temperature Relay, check leakage in the mechanical seal and

replace it if lubricant leak is found there.

27

6. SYSTEM OF EACH COMPONENT

6.1 Compressed Air/Lubricant System

Air Exhausted from Air Dryer

Cooing Fan

15/0" daze J

Air Sucked

‘Condanser

Compressed Air ox

Discharged Sr

condersate I

wegen ee

aay

sal

VE

Air Exhausted from Air Compressor

n

' | Air Sucked onto

Tatercooier

| Aoroote

£74 Air Sucked onto

rf il Cooler

Jowett ton 2 Congress tow tuba ow

TH! : Thermistor (discharge temp. 1)

‘THO : Thermsto dacharge temo. 2)

PS(1): A pressure sensor (for capacity control)

6.1.1 Compressed air flow

The air under atmospheric pressure is taken in

the unit through Air Intake Filter and is com-

pressed by a compressor to the specified pressure

This Compressed Air flows in the Oil Case to-

gether with Lubricant, and by which Compressed

Air and Lubricant are separated. Segregated

Compressed Air is cooled in the Aftercooler and

then discharged out.

28

63E : Pressure switch

638V : Pressure differential sensor of alr intake fiter

6.1.2 Lubricant flow

The Lubricant circulates in the unit by means of

pressure difference between the pressure in the

Oil Case and the one in the suction side of the

Compressor. The mixture of Compressed Air and

Heat Exchanged Lubricant are separated in the

Oil Separator into the Compressed Air and the

Lubricant. Segregated Lubricant is cooled in the

Oil Cooler afterwards and returns to the suction

side of Compressor, then it makes Heat Exchange

with another Compressed Air again.

6. SYSTEM OF EACH COMPONENT [Capacity Control System]

6.2. Capacity Control System

Confort 22 mode

‘On forth 97M mode

6.2.1 Types of Capacity Control

Operation air flow

‘Risin: 20P (NO-COM) Sai et

20US (NC-cOM) — wahecbset

oad: 20° (NC-COM) — Susi a

‘20us (wo-com) —F~ wae con.

Uiype Prossuro or

modulator opens. roe ses a

Types20P (NO-COM) San ote

‘2005 (NO-COM) —7 ate dna.

‘Alstop: 20° (NO-COM) —~ Sin rte

(NO-coM) —}~ aed

it Separator

BF See page 12 for setting of capacity control mode,

page 9 for changing the capacity control settings.

Type of capacity control

Purpose Stype | Mtype

T-type (integral unioad type): Fully closes the suction,

throttle valve when discharge pressure reaches to cut-

off pressure, and fully opens by cutin pressure. At fall

close, pressure inside the oil separator is discharged

until it reaches to the atmosphere and economize

power consumption more

‘The discharge pressure of the compressor is variable

the pressure range as follows: (Rach pressure

value is set by digital monitor on the panel)

[Speciation

discharge pressure

[Cutott pressure

wpa | 069 | 0.83 | 0.92

mPa | 069 | 0.83

g\é

[Cutin pressure | MPa | 0.50 | 0.74

Pressure sensor detects pressure salting and micro

‘computer makes judgement thereto.

‘This is applicable when air con-

sumption is less and the unit is in

continuous use, and when the

power consumption at unload op-

‘eration must be kept less,

3

| standra stn

‘Atdaiery fem

fect.

P-type (Motor ON-OFF control type): In addition to

Ustype and I-type control, the system automatically

stops the motor when a consumed air capacity is less.

(This type fluctuates pressure like I-type.)

‘This is applicable when the unit

is very often operated unloaded,

or when the air consumption in-

termittently fluctuates.

Ustype (Suction unload type): Gradually controls dis-

charge air capacity by opening or closing the suction

throttle valve according to the increase in discharge

pressure,

This is applicable when fluctua-

tion of discharge pressure must

be kept less.

29

6. SYSTEM OF EACH COMPONENT (Capacity Control System]

6.2.2 L-Type Capacity Control

(Standard setting for S-type at delivery

from the factory)

This controls the capacity as a flow chart in the

right figure.

(1) When “pressure fluctuation cycle: t” is less

than 28 seconds, U-type (suetion unload type)

control is adopted.

(2) When “pressure fluctuation cycle: t” is

longer than 28 seconds, T-type (integral un-

load type) control is adopted.

6.2.3 P-Type Capacity Control

(Standard setting for M-type at delivery

from the factory)

This controls the capacity as a flow chart in the

right figure,

(1) If “pressure fluctuation oyole: t” is less than

28 seconds, U-Type control (Suction Unload

‘Type) is adopted.

(2) If “pressure fluctuation cycle: t” is over 28

seconds and the air consumption is larger

than 30% of its rated capacity, E-Type control

integral Unload Type) is adopted.

(3) If “pressure fluctuation cycle:

seconds and the air consumption is less than

80% of its rated capacity, P-Type control (Mo-

tor ON-OFF Control Type) is adopted.

‘However, the number of stops the motor makes

is limited to 8 times during 30 minutes

(4) When the I-type unloading operation contin-

ues for 8 minutes, the P-type capacity contrat

is activated.

In case of P-Type (Motor ON-OFF Control Type),

(1) The Motor will not start again for 48 seconds when

it stops.

(2) Inetall an external air receiver tank. if you fal to ob-

‘serve ths instruction, the plant airline pressure may

cetically drop within 48 seconds (or before the mo-

tor can restart). When you want to use the

ECOMODE function, select a larger air recel

tank. For appropriate air receiver tank capacity, s86

page 26.

over 28

30

®

(sams ious

| say

|

|

sul ©

i of

a ZL a

6, SYSTEM OF EACH COMPONENT (Capacity Control System)

6.2.4 Condensate Control Function

Condensate control is a standard feature of the

M-type HISCREW. This function works so that the

condensate can be minimally produced when the

air compressor repeats an automatic stop/restart.

Because the condensate is nevertheless produced

and collected in the oil case when the air compres-

sor is in an automatic stop, the condensate control

function also works so that the condensate can be

‘evaporated and carried over together with the com-

pressed air.

(1) The condensate control function is activated

not when you press the START button but

when the HISCREW (in an automatic stop) re-

starts automatically.

(2) The memory stores a condensation tempera-

ture that depends on the discharge pressure

(e.g, 70°C for 0.69 MPa). Based on the operat

ing pressure and temperature detected by the

sensors, the CPU checks whether the operat-

ing temperature is lower or higher than the

stored condensation temperature. If lower, al-

ways the U-type capacity control is selected to

increase the operating temperature and thus

‘minimize the condensate production. If higher,

always the I-type capacity control is selected.

Afterwards, the P-type capacity control may

be selected and, when the conditions are sat-

isfied, the motor may be automatically stopped.

(eo

Even when the automatic.stop conditions are satistied,

the condensate control function (i.e, some ambient and

‘operating factors) may cause the motor to continue op-

erating, Ths is not abnormal,

6.2.5 ECOMODE Function

ECOMODE function is a standard feature of the

S- and M-type HISCREW. It is disabled, however,

by Hitachi before shipping the HISCREW.

(1) How ECOMODE Function Works

If you want to enable the ECOMODE function

‘under the I-type capacity control, press the

ECOMODE button. Make sure that the

ECOMODE light becomes on (non-flashing).

‘When a load-unload eycle is below 80 seconds

(a reference time) for shifting to the

ECOMODE function, the standard cutoff pres-

sure is used with the ECOMODE light non-

flashing.

When a load-unload cycle is 30 seconds or over,

the ECOMODE function begins to work and

thereby the optional lower cutoff pressure is

No. —

vaype'

ECOMODE Light

‘Off wen disabled

‘On (non-fashing) when enabled

‘On (ashing) when worked

ECOMODE Button

10 enable or disable

31

6. SYSTEM OF EACH COMPONENT [Capacity Control System}

automatically used with the ECOMODE light

flashing. The cutoff pressure shifts from stan-

dard to optional step-by-step until it reaches

the cutin pressure + 0.05 MPa or a load-un-

load eycle decreases to below 30 seconds. Thus

you can save the power as indicated by the

shaded areas in the illustration.

(2) Precautions

« When you use the ECOMODE function, in-

stall an air receiver tank that has a larger

capacity than otherwise required. For more

information, see page 36.

+ Do not change the reference time of 30 sec-

onds although it is accessible on the fourth

of the capacity control setting screens.

+ This funetion eannot work when (1) the

HISCREW is operating under the P- or U-

type capacity control and (2) you have

changed the preset standard cutoff pressure.

6.2.6 Alternative Cutoff/Cutin

Pressure Function

Alternative cutofi/eutin pressure function is an op-

tional feature of the S- and M-type HISCREW un-

der the I-type capacity control. Alternative cutoff

and cutin pressures are lower than the standard

ones. You may use this function, when a com-

pressed air demand is less (i.e. during overtime),

and thus save the power as indicated by the shaded

areas in the illustration.

If you want to use this function, contact your

Hitachi distributor to modify the control circuit,

install an external owoff switch, and set the cutoff

and cutin pressures to as required.

‘To activate this function, turn on the external on/

off'switch. Make sure that the LOAD light becomes

on (flashing) and off when the HiSCREW is respec-

tively loading and unloading. (Note that this ac-

tion of the LOAD light is different from when the

standard cutoff and cutin pressures are used.) To

deactivate this function (or to return to the stan-

dard cutoff and cutin pressures), turn off the ex-

ternal on/off switch.

INPORTANT]

+ The ECOMODE function does not work when the al

ternative cutolicutin pressure function is activated,

+ The alternative cutofticutin pressure function does not

work when the compressed air demand causes the

{U-type (not the type) to be selected.

32

je Siting oF

[Gut Preseure om

Standard to Optional

Power Saving Effects [Adonai

Cutoff

{Pressure

(cutin

Prossure

Tne

Preset CutofiiCutin Ditferentiat: 0.1 MPa

Optional Cutoff Pressure: Cutin Pressure + 0.05 MPa

CCutott pressure automatically shifts from standard to optional

until 2 cycle time decreases to 30 seconds or below.

Power Saving Effects

|

6.3 Dryer System [jpiyer

SYSTEM OF EACH COMPONENT [Dryer System]

‘Compressed air inlet

<5 | Aitflow % Compressed air

ae mene LE"

+ :rotieantton || ge LE Sd

a Hustla

Heat exchanger

a )

low-pressure siae) gem TTT ULL"

P

‘cooler @)

coma ©

>) High-pressure switch

Capitary tube t

®

6.3.1 Compressed Air Flow

Compressed air precooled by the aftercooler is

heat-exchanged with low-temperature com-

pressed air by the precooter ® of heat exchanger,

and then with refrigerant by the air cooler

this time, the steam contained in the compressed

air is condensed and automatically discharged as

drain from the auto drain trap ©. The cooled

compressed air is returned to the precooler ®,

heat-exchanged with compressed air cooled by

the aftercooler, and then discharged.

6.3.2 Refrigerant Flow

‘The high-temperature and high-pressure refrig-

erant ges discharged from the refrigerating com-

pressor © gets into the condenser ©. It is

cooled by the fan © and turns into high-pressure

liguid refrigerant.

‘The high-pressure refrigerant is squeezed by the

capillary tube @ and sent to the air cooler ®) as a

low-pressure liquid refrigerant. The refrigerant

is heat-exchanged with compressed air and

evaporated. It is sucked as overheated steam into

the refrigerating compressor ©), recompressed

and then discharged. This cycle is repeated.

The hot gas bypass vaive © works automatically

depending on a load and an ambient temperature,

and controls the evaporation temperature of re-

frigerant to be kept constant in order to prevent

condensed water from freezing by overcooling at a

low temperature and at no load.

33

7. INSTRUCTIONS FOR INSTALLATION

7.1 Verification of Components

Machine Standard

Nameplate Check -Accesstory

Foundation Bracket, Foundation Bolts (M12, M418) 2 sets

Fork Slot Covers 4 pieces

M6 Bolts 8 pieces

Condensate Trap (only forthe models witha built-in al dryer) 1 set

Output (KW)

Moc

Frequency (Hz)

7.2 Instructions When Conveying

Fork itt Crane

Fics oc pcan

‘Spee be pcage 7

iemeindton” | gf aml aT

K [ramernoe Sen

= proses cu eecee ta

fomennae etsceens

Ur corr

()

(

Use acesive apse

{proven he tent

| Georrom dotched

Frets y

(aon wr

22x fio be

Model Total Weight (kg)

OSP-22S/M5AI 540

OSP-22S/M6AL

‘OSP-22S/MSARI = Holsting Jigs

OSP-22S/M6ARL For the 22 kW models: One wooden tie frame and two wooden

OSP-S7S/M5AL 760 tie bars are located in a packing cat.

__osp-s7smeal | aa For the 37 kW models: One wooden tie frame and two steel tie

OSP-37S/M5ARI 830 channels are located in a packing crate.

OSP-37S/M6ARI

34

7. INSTRUCTIONS FOR INSTALLATION [Instructions When installing)

7.3 Instructions When Instailing

{ Ay WARNING

1. Never put anything inflammable (inflammable solvent etc.) near the Compressor, or such material

may be compressed by the unit and brought explosion.

2. Never allow the operation which uses fire near the compressor. Sparks may get in the unit and

damage inside.

Never use the HISCREW in the environments

Place where powder of metal, cement Place where inflammable,

and other dust or bits of down is found combustible or explosive gas or

affluently or other dusty place particles exists and hazardous,

Ay CAUTION

@ Use the compressor in a room. Moisture or powder dust will demage the compressor when it Is installed outside,

@ Install the compressor in @ room equipped with both intake alr port and discharge air port and where enough

ventilation is available. Otherwise, discharged hest from the compressor makes room temperature rise and will

cause shutdown to the compressor,

Fan pen

If the location 18 not roomy

‘onough, provide a ventilation

aintenance Space (Backspace)

fas elaine tial Keep asic 08m ore

seater

Fe Founda

Sen aes cs de te vvaton a aon

rope arp ana sweets bm svn

Sito tat a one

ea servicing (0.6m or

os the unit. Such vibration may

mor)

Keep a space of 0.5 m or more reach the compressor and dam

before setting up a pipe around age iis bearings.

the unt.

TW Aad Waltenance Spans

(fight hand eda space)

Koop a space of 0.5 mor more

Cover folk slots with noise-proof are

Plates attached tothe unit, taintenance Space (Font space) ] Belov setting up @ power nes

Keep a space of 0.6 m or more.

Install tho unit on a lovet floor.

(Horizontality should be kept less than 1 rm/t m.)

IW there is a space between the common base and the

floor, or reflecting noise from wall or ceiling, noise will

become louder.

35

7. INSTRUCTIONS FOR INSTALLATION [Instructions When Piping]

7.4 Instructions When Piping

7.4.1. Air Receiver

When your plant airline has the volume of more than

40 liters, you can operate the HISCREW without an air

receiver tank. In order to prevent the plant airline

pressure from fluctuating or to effectively control the

HISCREW capacity for saving the power, however,

install an external air receiver tank of the minimum

capacity such as

ECOMODE Function | 22kW Models | S7KW Models

Not used 0.43 mF Ora

Used oT a 2a

(D) Do not install a check valve between the air reveiver

tank and the HISCREW.

@When you want to use the ECOMODE function,

install an air receiver tank that has a larger capacity

than otherwise required. When you install an exter-

nal air dryer and filters under the ECOMODE func

tion, place them after the air receiver tank so that

the ECOMODE function can effectively save the

power.

7.4.2. Discharging Air pipe

(1) Discharging pipes must be joined with an union or a

flanged joint, and a stop valve must be fixed to them

for maintenance and i

cx)

Dich A

4 wp

(2) If there is concaved or upright piping in the run,

install a drain valve at the bottom of the run to pre-

vent the accumulation of the drain. To connect the

‘harge pipe to your horizontal plant airline, keep

a space of more than 600 mm between the horizon-

tal plant airline and the AUSCREW top cover so that