Professional Documents

Culture Documents

Proposal 1 Civil

Uploaded by

Saraj Gill0 ratings0% found this document useful (0 votes)

6 views2 pagescivil

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentcivil

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views2 pagesProposal 1 Civil

Uploaded by

Saraj Gillcivil

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

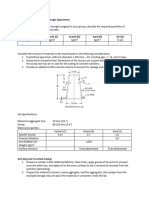

Sample Test

Cement a) Initial & Final Setting a) Vicat’s Apparatus

time b) 70.6 x 70.6 x 70.6 mm

b) Comp. Strength (at 7 moulds

day’s curing) c) Le-Chatelier Mould

c) at 28 day’s curing

d) Soundness

e) Fineness

f) Consistency

Cubes Comp. Strength a) 150 x 150 x 150 mm

Moulds

b) Compression Testing

Machine (Capacity

2000 kN)

c) Vibrating Table

d) Pan Mixer(40L)

Reinforcing Steel bar, Physical tests: a) Ultimate a) Universal Testing

Barbed Wire, Tensile Strength b) Percentage Machine (Capacity

Structural Angle, Flats & Tees Elongation c) Bend test d) 0.2 2000 kN)

Channel, Plates Proof Stress

Bricks a) Comp. Strength d) Compression Testing

b) Water Absorption Machine (Capacity

c) Efflorescence 2000 kN)

Concrete pavers blocks a) Comp. Strength a) Tile Abrasion Testing

b) Flexural Strength Machine

c) Water Absorption b) Paver Block Flexural

d) Abrasion Value testing Machine

Karb stone, precast concrete Comp. Strength Ready for a) Compression Testing

panels, Hollow and solid blocks testing Sample (Cylinder or Machine (Capacity

Cube 100 x 100 x 100 mm 2000 kN)

Coarse 1. Gradation a) 80 mm, 63 mm, 40

Aggregates/Gatka/Bajri) 2. Water Absorption mm, 20 mm, 16 mm,

3. Specific Gravity 12.5 mm, 10 mm, 4.75

4. Bulk Density mm, 2.36 mm Sieves

5. Elongation and Pan for Gradation

6. Flakiness of Aggregates

7. Abrasion b) Apparatus for testing

8. Crushing value Water Absorption and

9. Impact Value Specific Gravity of

aggregates

c) Tamping Rod and

cylindrical metal

measuring for Bulk

Density

d) Elongation Gauge and

Flakiness Gauge

e) Los Angeles Machine

f) Impact Testing

Machine

Fine Aggregates 1. Sieve Analysis a) 10 mm, 4.75 mm, 2.36

2. Fineness Modulus mm, 1.18 mm, 600-

3. Silt Content micron, 300-micron,

4. Moisture Content 150 micron and Pan

5. Liquid Limit & Plastic for gradation of Fine

Limit aggregates

6. Specific Gravity b) 50ML, 100ML, 250 ml ,

7. Bulk Density 500ML, 1000ML

8. Silt and Clay content measuring Cylinder

9. Bulking of Sand c) Pycnometer Bottle of

10. Bulk Density 1000 ml capacity

d) Tamping Rod and

cylindrical metal

measuring for Bulk

Density

e) Ventilated Oven

BM/PC 1. Bitumen Content a) Centrifuge Extractor

2. Gradation b) Ductility Testing

3. Bitumen (Ductility Machine

Value, Softening Point, c) Ring and Ball

Flash Point, Fire Point) Apparatus

d) Cleveland open cup

tester

e) Pensky Martens

Design of Structures Staad Pro (Software)=2

-- N A -- AutoCAD (Software)=2

Vetting of Structural Design

Desktop 3 (i7 with Graphic

card)=2

Laptop 1 (for presentation)=1

Laser Printer=1

Des

You might also like

- Machine Design AnswersDocument127 pagesMachine Design AnswersJoshua Gagate100% (1)

- HSE-BMS-011 Crane & Lifting SafetyDocument51 pagesHSE-BMS-011 Crane & Lifting SafetySatya NaiduNo ratings yet

- Drilling ConceptsDocument9 pagesDrilling ConceptsSamuel VelozNo ratings yet

- Test FacilitiesDocument2 pagesTest FacilitiesSaraj GillNo ratings yet

- Cidco Rate ListDocument1 pageCidco Rate ListKuldeep ChakerwartiNo ratings yet

- DDDDDDDocument10 pagesDDDDDDZardarHussainNo ratings yet

- Sanfoundry RCCDocument28 pagesSanfoundry RCCBishal ShahNo ratings yet

- Corrigendum To Notice No: 01/APTIDCO/AHP/PMAY/dated:08.11.2019 (2 Call)Document3 pagesCorrigendum To Notice No: 01/APTIDCO/AHP/PMAY/dated:08.11.2019 (2 Call)Thappetla SrinivasNo ratings yet

- River Training Works - Some Materal-SpecfcatonsDocument17 pagesRiver Training Works - Some Materal-SpecfcatonsWasifa NourinNo ratings yet

- CE 202: Material Sessional (Level-II/Term-I) Final-Term QuizDocument2 pagesCE 202: Material Sessional (Level-II/Term-I) Final-Term QuizAhmedArefinNo ratings yet

- Final Questions-Summer TrainingDocument24 pagesFinal Questions-Summer TrainingMostafa EldeebNo ratings yet

- Dental Materials: 1. Physical PropertiesDocument43 pagesDental Materials: 1. Physical PropertiesmohaNo ratings yet

- Es152 Strength of Materials 2019 2Document6 pagesEs152 Strength of Materials 2019 2Ben DostyNo ratings yet

- Machine Design ProblemsDocument16 pagesMachine Design ProblemsJustin MercadoNo ratings yet

- Questionnaire Fishing VesselsDocument2 pagesQuestionnaire Fishing VesselsSaturnino da Costa ParlanNo ratings yet

- Building Material Odisha JE AEE Previous Year Papers With SolutionDocument6 pagesBuilding Material Odisha JE AEE Previous Year Papers With SolutionaebsdNo ratings yet

- Testing of Geosynthetics-1Document2 pagesTesting of Geosynthetics-1ManilaNo ratings yet

- TGQC Set BDocument2 pagesTGQC Set Bbijal dedhiaNo ratings yet

- Visual Testing Qustion Level 3Document15 pagesVisual Testing Qustion Level 3Ashish SrivastavaNo ratings yet

- Cement Concrete Mix DesignDocument54 pagesCement Concrete Mix DesignAnimesh JainNo ratings yet

- Civil SOR QAP MasterDocument12 pagesCivil SOR QAP MasterKgnconstcorediffmail.com 557786No ratings yet

- MDSP SET 3 No AnswerDocument21 pagesMDSP SET 3 No AnswerEdelene BalitaosanNo ratings yet

- Attn.: Mr. Jamal Diab Managing Director: M/s. Survey & Test Consult International KuwaitDocument3 pagesAttn.: Mr. Jamal Diab Managing Director: M/s. Survey & Test Consult International Kuwaitraja qammarNo ratings yet

- Apparatus ListDocument1 pageApparatus ListSaraj GillNo ratings yet

- Experiment No: 3: Aim: PurposeDocument7 pagesExperiment No: 3: Aim: PurposeVikrant SinghNo ratings yet

- Assignment 1Document1 pageAssignment 1Sourav KayalNo ratings yet

- Ei HTH Mester B.E D: USN G Se - Eg eDocument2 pagesEi HTH Mester B.E D: USN G Se - Eg esrinivasa c vNo ratings yet

- Test Procedure-25-08-06Document49 pagesTest Procedure-25-08-06Hariom GuptaNo ratings yet

- LiveSession Anupama Week 5 05march2022Document8 pagesLiveSession Anupama Week 5 05march2022Umesh HuleNo ratings yet

- Construction Materials and TestingDocument4 pagesConstruction Materials and TestingNicole May Dela CruzNo ratings yet

- 200319-Final Exam - Machine DesignDocument2 pages200319-Final Exam - Machine DesignJoseph RefuerzoNo ratings yet

- Cswip 3.0 PDFDocument4 pagesCswip 3.0 PDFKianToro YeoNo ratings yet

- MDSP SET O3Document26 pagesMDSP SET O3BrilliantJohnMalandacRubiaNo ratings yet

- M.E ReviewerDocument14 pagesM.E ReviewerAlvin TusiNo ratings yet

- 1 - QuestionaireDocument3 pages1 - QuestionaireCharisse Ann Arado BadoriaNo ratings yet

- BMC Lab ManualDocument112 pagesBMC Lab ManualUaj AvhaNo ratings yet

- AppendixDocument31 pagesAppendixHimanshu MisraNo ratings yet

- B G192032 Pages:4: Assume Missing Data If Any and State It Answer Any Two Full Questions, Each Carries 15 MarksDocument4 pagesB G192032 Pages:4: Assume Missing Data If Any and State It Answer Any Two Full Questions, Each Carries 15 MarksirshadNo ratings yet

- Lab1 All Experiments Part2Document50 pagesLab1 All Experiments Part2Parth GuptaNo ratings yet

- JET Sample Paper MechanicalDocument4 pagesJET Sample Paper MechanicalDashrath MahatoNo ratings yet

- MDSP SET 1print No AnsDocument20 pagesMDSP SET 1print No AnsEdelene BalitaosanNo ratings yet

- Cswip 2.0Document3 pagesCswip 2.0KianToro YeoNo ratings yet

- Reviewer 7 - 755 QuestionsDocument34 pagesReviewer 7 - 755 QuestionsAndrei AlidoNo ratings yet

- Design Mix M 30Document4 pagesDesign Mix M 30SOIGNE ENGINEERING CONSULTANTSNo ratings yet

- GATE 2004 - Question Paper TF: Textile Engineering and Fiber ScienceDocument29 pagesGATE 2004 - Question Paper TF: Textile Engineering and Fiber ScienceChandra Deep MishraNo ratings yet

- Fluid Mechanics JE - Ac9016de d995 40a2 8a68 Aa7d2688e49eDocument63 pagesFluid Mechanics JE - Ac9016de d995 40a2 8a68 Aa7d2688e49efaroohaaris62No ratings yet

- In Trod 2Document13 pagesIn Trod 2Ahmed NabilNo ratings yet

- KMC 2018 PDFDocument11 pagesKMC 2018 PDFKailash Chaudhary100% (2)

- R09-Fatigue, Creep and Fracture MechanicsDocument2 pagesR09-Fatigue, Creep and Fracture MechanicsKiran KumarNo ratings yet

- QuestionsDocument9 pagesQuestionsNaveenkumarNo ratings yet

- Xperimental Study For Lexure Strength On Polypropylene Fiber Reinforced ConcreteDocument7 pagesXperimental Study For Lexure Strength On Polypropylene Fiber Reinforced Concretesamir aherNo ratings yet

- PSC Box Girder (Prestressing)Document51 pagesPSC Box Girder (Prestressing)ankit100% (3)

- Mix DesignDocument30 pagesMix DesignyogiforyouNo ratings yet

- Machine Ddesign ReviewDocument51 pagesMachine Ddesign ReviewMico Cañete100% (1)

- Section III (G)Document1 pageSection III (G)Kyle SchwartzNo ratings yet

- Walchand Institute of Technology, Solapur B.E. Part-II 2019-20 (CBCS Pattern) In-Sem. Examination - IIIDocument3 pagesWalchand Institute of Technology, Solapur B.E. Part-II 2019-20 (CBCS Pattern) In-Sem. Examination - IIIShashank SatheNo ratings yet

- CE 121 - Mix Design InstructionsDocument3 pagesCE 121 - Mix Design InstructionsjomifurungNo ratings yet

- PI-Metrology CRPQ PDFDocument57 pagesPI-Metrology CRPQ PDFRishav VermaNo ratings yet

- Chapter 3Document24 pagesChapter 3Md Ashiqur RahmanNo ratings yet

- RCC 01 Pratice SheetDocument3 pagesRCC 01 Pratice SheetPiyush DasNo ratings yet

- Lectures on Solid State Physics: International Series in Natural PhilosophyFrom EverandLectures on Solid State Physics: International Series in Natural PhilosophyRating: 4 out of 5 stars4/5 (1)

- Joint SecDocument1 pageJoint SecSaraj GillNo ratings yet

- 3rd Sem Attendance 2Document1 page3rd Sem Attendance 2Saraj GillNo ratings yet

- Engg GeologyDocument3 pagesEngg GeologySaraj GillNo ratings yet

- 5th Sem Attendance 2Document1 page5th Sem Attendance 2Saraj GillNo ratings yet

- 5th Sem Attendance 2Document1 page5th Sem Attendance 2Saraj GillNo ratings yet

- 5th Sem Attendance 2Document1 page5th Sem Attendance 2Saraj GillNo ratings yet

- 3rs Sem InternalDocument14 pages3rs Sem InternalSaraj GillNo ratings yet

- 3rd Sem Attendance 2Document1 page3rd Sem Attendance 2Saraj GillNo ratings yet

- Engg GeologyDocument3 pagesEngg GeologySaraj GillNo ratings yet

- Apparatus ListDocument1 pageApparatus ListSaraj GillNo ratings yet

- Abstract SarajDocument1 pageAbstract SarajSaraj GillNo ratings yet

- Aliyu NursefaDocument85 pagesAliyu NursefaSaraj GillNo ratings yet

- Future ScopeDocument4 pagesFuture ScopeSaraj GillNo ratings yet

- Adobe Scan 16 Mar 2022Document20 pagesAdobe Scan 16 Mar 2022Saraj GillNo ratings yet

- Shear Strength of Concrete Beam Cast Using Broken Bricks AggregatesDocument19 pagesShear Strength of Concrete Beam Cast Using Broken Bricks AggregatesSaraj GillNo ratings yet

- Important Instructions:: This Booklet Contains 24 PagesDocument24 pagesImportant Instructions:: This Booklet Contains 24 PagesPriyanshu MishraNo ratings yet

- Candidate Hall TicketDocument3 pagesCandidate Hall TicketSaraj GillNo ratings yet

- GillpdfDocument32 pagesGillpdfSaraj GillNo ratings yet

- Achla: Important InstructionsDocument24 pagesAchla: Important InstructionsSaraj GillNo ratings yet

- Guru Nanak Dev Engineering College Ludhiana: ProjectDocument15 pagesGuru Nanak Dev Engineering College Ludhiana: ProjectSaraj GillNo ratings yet

- Self-Compacting Concrete - Procedure For Mix DesignDocument11 pagesSelf-Compacting Concrete - Procedure For Mix Designramakrishna 1729123No ratings yet

- Candidate Hall TicketDocument3 pagesCandidate Hall TicketSaraj GillNo ratings yet

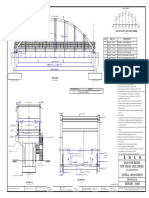

- 42m BowStringDocument1 page42m BowStringsorowareNo ratings yet

- Moga Road (NH-95), Ferozepur-152004 (Punjab) : Shaheed Bhagat Singh State Technical CampusDocument1 pageMoga Road (NH-95), Ferozepur-152004 (Punjab) : Shaheed Bhagat Singh State Technical CampusSaraj GillNo ratings yet

- Enginering All Report-MHRD, National Institutional Ranking Framework 2019Document16 pagesEnginering All Report-MHRD, National Institutional Ranking Framework 2019Saraj GillNo ratings yet

- Report On Radial Feeder ProtectionDocument20 pagesReport On Radial Feeder ProtectionSubhamGangdeb78% (9)

- Effect On Superhydrophobic Surfaces On ElectricalDocument12 pagesEffect On Superhydrophobic Surfaces On Electricalhadi ebrahimfathNo ratings yet

- Chapter 6 Mass Relationships in Chemical Reactions HandoutDocument6 pagesChapter 6 Mass Relationships in Chemical Reactions HandoutEugene MacapagalNo ratings yet

- Chapter 4 Radiation Heat TransferDocument22 pagesChapter 4 Radiation Heat TransferFarooq AhmadNo ratings yet

- L-27 Renewal Process, NHPPDocument9 pagesL-27 Renewal Process, NHPPAnisha GargNo ratings yet

- Base Plate IPE200 Fe250Document32 pagesBase Plate IPE200 Fe250Tejas SawantNo ratings yet

- DC002234-004 - Rev. 7 - EN - FR - ESDocument48 pagesDC002234-004 - Rev. 7 - EN - FR - ESAxl EslonNo ratings yet

- The Digital Oscilloscope and The Function Generator: Part I: Amplitude and Frequency MeasurementsDocument6 pagesThe Digital Oscilloscope and The Function Generator: Part I: Amplitude and Frequency MeasurementsNour ShamiNo ratings yet

- 1atoms Molecules and StoichiometryDocument95 pages1atoms Molecules and StoichiometryNurfarhah JohariNo ratings yet

- Lesson Plan 3 ChemistryDocument10 pagesLesson Plan 3 ChemistryLeslayy CelizNo ratings yet

- OPTI 370 Syllabus S22 (Updated)Document7 pagesOPTI 370 Syllabus S22 (Updated)AhmedphmaNo ratings yet

- The Effect of Rotating Atomizer Geometry On The SaDocument7 pagesThe Effect of Rotating Atomizer Geometry On The SamazaherramazaniNo ratings yet

- JNTUA Electrical Circuit Analysis Lab - PPT R20Document55 pagesJNTUA Electrical Circuit Analysis Lab - PPT R20naveenNo ratings yet

- System1 Plots - Machinery-Diagnostic - Part1Document16 pagesSystem1 Plots - Machinery-Diagnostic - Part1Thyagaraju PalisettyNo ratings yet

- Resonance: University of Babylon Basic of Electrical Engineering Lecture NotesDocument25 pagesResonance: University of Babylon Basic of Electrical Engineering Lecture NotesSaad AlwashNo ratings yet

- 0e89 PDFDocument7 pages0e89 PDFDamianCurcanNo ratings yet

- Energy Reports: Mostefa GhassoulDocument8 pagesEnergy Reports: Mostefa GhassoulEduardo DíazNo ratings yet

- Ch. 1 Electric Charges and Fields NCERT & PYQsDocument96 pagesCh. 1 Electric Charges and Fields NCERT & PYQsLakshya Jain100% (1)

- Tagore Engineering College Department of ECE: Unit Test - IIDocument1 pageTagore Engineering College Department of ECE: Unit Test - IIbhuvi2312No ratings yet

- FCE 412 Geotechnical Engineering IIB: Lecture NotesDocument81 pagesFCE 412 Geotechnical Engineering IIB: Lecture NotesLovian MagandaNo ratings yet

- Mechanical Engineering Principles, Bird and Ross, ISBN 9780415517850Document9 pagesMechanical Engineering Principles, Bird and Ross, ISBN 9780415517850Julius KipropNo ratings yet

- 56 - Isijint 2015 231 PDFDocument13 pages56 - Isijint 2015 231 PDFRaphael Mariano de SouzaNo ratings yet

- LTV 356t201505Document11 pagesLTV 356t201505ehsanNo ratings yet

- Pressure Transmitter With Ceramic Sensor, Accuracy 0,5%Document2 pagesPressure Transmitter With Ceramic Sensor, Accuracy 0,5%essameldinNo ratings yet

- BS 2nd Shift Time Table Wef 11-12-2023 (1st, 5th, 7th Semester)Document3 pagesBS 2nd Shift Time Table Wef 11-12-2023 (1st, 5th, 7th Semester)Samar Ameen SialNo ratings yet

- Dimensional AnalysisDocument13 pagesDimensional AnalysisTivani MphiniNo ratings yet

- 3va9988-0ba22-SHUNT TRIPDocument4 pages3va9988-0ba22-SHUNT TRIPLeonardo CAMARGO CAMARGONo ratings yet

- Cable CatologueDocument69 pagesCable CatologueJyoti ShekharNo ratings yet

- Clamp Overview: Standard SolutionsDocument32 pagesClamp Overview: Standard SolutionsArun JaisonNo ratings yet