Professional Documents

Culture Documents

Saudi Aramco Approved Coatings

Uploaded by

SUNIL RAJPUTOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Approved Coatings

Uploaded by

SUNIL RAJPUTCopyright:

Available Formats

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0(Standards Cutoff - Mar 2012) Rev 6 31-Mar-12

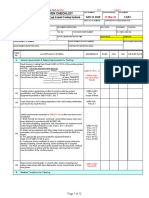

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

In-Process & Final Inspection of Internal coating SAIC-H-

30-Apr-13 MECH.

Application on Field Girth Welds 2060

PROJECT TITLE WBS / BI / JO NUM CONTRACTOR / SUBCONTRACTOR

Attachment- 1

REQUIREMENTS- SAUDI ARAMCO APPROVED PROTECTIVE COATING SYSTEMS for INTERNAL COATINGS

S.R. No APCS

Coating Specific Requirements for Coating Application

Type/Service Total DFT #1 #2

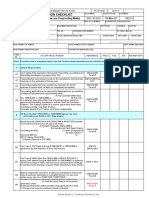

Specialty Liquid Coating Systems 1- Ceramic/Alloy Filled Epoxy 2- Glass Flakes Filled

for Pumps, Valves, Piping, Fitting Coatings Coatings

and Exchanger Boxes. Filler Coatings: Filler Coatings:

Service Temp: Up to 105C. Belzonas 1311/1111 Corroglass 100, 200,

Purchase Specifications: 09- Barrier Coatings: 600, Polyglass VEF

SAMSS-067 Belzonas 1341/1321/ 1391S/1391T Barrier Coatings & Top

1 APCS-28 750 – 1500 microns

SAMS Stock Numbers: N/A /5891 Coat:

Fluiglide and/or Veil

cote

Shop-Applied Fusion Bonded Epoxy APCS-102A shall not be used on the SAP M/N: (Refer to

for Internal Coating of Treated girth welds of any pipe and fittings SAES-H-002V)

Seawater and Potable Water coated with either APCS-28, APCS- Purchase Spec: 09-

Pipelines (Service Temp: Min. 0°C 375-625 117 or APCS-118. SAMSS-091.

2 APCS-102A

Max. 90°C ) microns

Shop-Applied Fusion Bonded Epoxy APCS-102B shall not be used on the SAP M/N: (Refer to

for Internal Coating of Formation girth welds of any pipe and fittings SAES-H-002V)

Water and Wet Crude Pipelines coated with either APCS-28, APCS- Purchase Spec: 09-

(Service Temp: Min. 0°C 375-625 117 or APCS-118. SAMSS-091.

3 APCS-102B Max. 95°C ) microns

Shop-Applied Fusion Bonded Epoxy Field Girth Weld Area: Crawler- Purchase Spec: (Refer

for Internal Coating of Sour/Sweet applied FBE or liquid coating APCS- to CSD. The coating

Gas Pipelines. 120 for internal girth welds of pipe shall be tested against

Pipe 625 – 750

(Primarily used for sour and sweet strings. the operating

microns

4 APCS-102C gas pipelines excluding girth welds. conditions.)

Girth Welds: As per

Temp: Min. 0°C

Coating Data sheets

Max. 95°C)

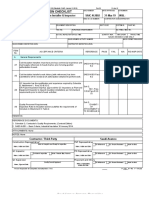

Internal coating for water, oil or gas The coating system for specific

service. For spools, valves, service shall be selected from the

elbows, tees, wyes, nozzles, flanges various SAP Material Numbers

and other associated pieces of specified in APCS-117. SAP M/N:

piping systems. When the coating is In this regard, CSD/Coatings Team 1000180021,

glass fiber/flake reinforced, a final shall be contacted 1000180023,

coat of flow coating should be used 1000180276,

5 APCS-117 500 to 1500 microns

to ensure a good flow property. 1000180279,

(Service Temp: depends on coating 1000180328 and

product) 100018033

Purchase Spec: N/A

Internal coating for water, oil or gas SAP M/N: N/A

service in the girth weld area Purchase Spec: N/A

applied by special semi-robotic 500 to 1,000 microns

6 APCS-120 machines.(Service Temp: depends (depending on product

on coating product) specification)

UMBER

TINGS

Coating Application

#2

2- Glass Flakes Filled

Coatings

Filler Coatings:

Corroglass 100, 200,

600, Polyglass VEF

Barrier Coatings & Top

Coat:

Fluiglide and/or Veil

cote

SAP M/N: (Refer to

SAES-H-002V)

Purchase Spec: 09-

SAMSS-091.

SAP M/N: (Refer to

SAES-H-002V)

Purchase Spec: 09-

SAMSS-091.

Purchase Spec: (Refer

to CSD. The coating

shall be tested against

the operating

conditions.)

SAP M/N:

1000180021,

1000180023,

1000180276,

1000180279,

1000180328 and

100018033

Purchase Spec: N/A

You might also like

- Saudi Aramco Inspection Checklist: In-Process Inspection of APCS-113 Coating Systems Application SAIC-H-2049 31-Mar-19Document3 pagesSaudi Aramco Inspection Checklist: In-Process Inspection of APCS-113 Coating Systems Application SAIC-H-2049 31-Mar-19harisNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- Saic W 2006Document1 pageSaic W 2006Abdelaziz MohamedNo ratings yet

- Saic L 2115Document4 pagesSaic L 2115khuram shahzadNo ratings yet

- Saic H 2082Document8 pagesSaic H 2082jerin100% (1)

- Tech Manual: Tech-5.12 10M Ec Combi Large SHRDocument260 pagesTech Manual: Tech-5.12 10M Ec Combi Large SHROvRrj AhmedNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistAnantha PadmanabhanNo ratings yet

- Inspection HandbookDocument127 pagesInspection HandbookWalter Rueda100% (2)

- SAIC-W-2006 Rev 8Document4 pagesSAIC-W-2006 Rev 8saravananmenmathiNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistYehia FelifelNo ratings yet

- Saudi Aramco welding inspection checklistDocument3 pagesSaudi Aramco welding inspection checklistManoj KumarNo ratings yet

- Pipe Coat & LiningDocument22 pagesPipe Coat & Liningjadav parixeet100% (3)

- Saic B 1002Document2 pagesSaic B 1002Hussain Nasser Al- NowiesserNo ratings yet

- Saic-M-1012 Rev 7 (Final)Document3 pagesSaic-M-1012 Rev 7 (Final)Satheesh Rama SamyNo ratings yet

- Aramcoinspectionhandbook 150311084705 Conversion Gate01 PDFDocument126 pagesAramcoinspectionhandbook 150311084705 Conversion Gate01 PDFMuhammed SulfeekNo ratings yet

- Inspection HandbookDocument126 pagesInspection Handbooksteffy18295% (21)

- SACIC-S-4098 Rev - Fit Layer Laminate of RTRGRE, GRV, and GRP PipingDocument2 pagesSACIC-S-4098 Rev - Fit Layer Laminate of RTRGRE, GRV, and GRP PipingShohrab JiNo ratings yet

- Saudi Aramco Inspection Checklist: Fireproofing Concrete Application Inspection SAIC-B-1002 1-Nov-09 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Fireproofing Concrete Application Inspection SAIC-B-1002 1-Nov-09 CivilWaleed MedhatNo ratings yet

- GB 2H Fills For Cross Flow CTDocument2 pagesGB 2H Fills For Cross Flow CTShahab Z AhmedNo ratings yet

- Schedule G - Attachment I-VII 3000953944Document18 pagesSchedule G - Attachment I-VII 3000953944xue jun xiangNo ratings yet

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Document3 pagesSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Abdul HannanNo ratings yet

- SAIC-K-4020 Rev 08 - Chilled Water Piping Lay-OutDocument4 pagesSAIC-K-4020 Rev 08 - Chilled Water Piping Lay-Outranausman1987No ratings yet

- Concrete Grade Inspection ChecklistDocument2 pagesConcrete Grade Inspection ChecklistShazab NawazNo ratings yet

- Epoxy Painting Cycle Requirements for SteelDocument9 pagesEpoxy Painting Cycle Requirements for SteelMaffone NumerounoNo ratings yet

- Rubia Fleet HD 400 15W 40Document2 pagesRubia Fleet HD 400 15W 40سالم دريديNo ratings yet

- Inspection Handbook PDFDocument20 pagesInspection Handbook PDFSamuel JohnNo ratings yet

- Apcs 117Document12 pagesApcs 117Ilyas AhmedNo ratings yet

- Liquid CoatingsDocument12 pagesLiquid CoatingsSUNIL RAJPUTNo ratings yet

- Saic M 1034Document2 pagesSaic M 1034noor mohamedazeezNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Codeline Drawing 80E30Document2 pagesCodeline Drawing 80E30hargote_2No ratings yet

- Saudi Aramco Inspection Checklist: Hood Installation SAIC-K-4036 25-Apr-18 HvacDocument3 pagesSaudi Aramco Inspection Checklist: Hood Installation SAIC-K-4036 25-Apr-18 HvacjunaidNo ratings yet

- Saes H 002vDocument33 pagesSaes H 002vGabrielNo ratings yet

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Document5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanNo ratings yet

- Dse9460 Dse9461 Data Sheet (Usa)Document2 pagesDse9460 Dse9461 Data Sheet (Usa)Marcelo Marcillo MielesNo ratings yet

- Shell Gadus S4 OGT Open Gear GreaseDocument2 pagesShell Gadus S4 OGT Open Gear GreaseMuhammad SaputraNo ratings yet

- MSASDocument2 pagesMSASFeby ZulkarnainNo ratings yet

- NPCL-YBP-RFI-TEL-000x Conduit Installation & Initial Mandrel Test SAIC-T-5709Document3 pagesNPCL-YBP-RFI-TEL-000x Conduit Installation & Initial Mandrel Test SAIC-T-5709afareenkhanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- SACIC-CV-0004 Rev.04 Electrical Resistivity TestDocument3 pagesSACIC-CV-0004 Rev.04 Electrical Resistivity TestEr Nizamuddin AliNo ratings yet

- Canusawrap™: Product Description ApplicationsDocument2 pagesCanusawrap™: Product Description ApplicationsolalekanNo ratings yet

- Saic-H-2029Document12 pagesSaic-H-2029mominNo ratings yet

- Gpcdoc Gtds Shell Tactic Emv Gadus s5 v100 2 (En) TdsDocument2 pagesGpcdoc Gtds Shell Tactic Emv Gadus s5 v100 2 (En) TdsEdgarNo ratings yet

- Saes H 004Document8 pagesSaes H 004kaleeswaran s100% (1)

- DWG REF QTY Number Description Material ShellDocument2 pagesDWG REF QTY Number Description Material ShellimtiyazNo ratings yet

- Saudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 30-Apr-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 30-Apr-17 Mechkarthi51289No ratings yet

- Saep 1200Document9 pagesSaep 1200Anonymous 4IpmN7On100% (1)

- ENOC ProductsDocument1 pageENOC ProductsjuanpaulobarbazaNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Highly Integrated Gate Drivers for Si and GaN Power TransistorsFrom EverandHighly Integrated Gate Drivers for Si and GaN Power TransistorsNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Saic-G - 2019Document2 pagesSaic-G - 2019SUNIL RAJPUTNo ratings yet

- Saic-N - 2007Document4 pagesSaic-N - 2007SUNIL RAJPUTNo ratings yet

- Saic-N - 2008Document2 pagesSaic-N - 2008SUNIL RAJPUTNo ratings yet

- Saic-N - 2017Document2 pagesSaic-N - 2017SUNIL RAJPUTNo ratings yet

- Saic-N - 2013Document2 pagesSaic-N - 2013SUNIL RAJPUTNo ratings yet

- Refractory Installation Qualification ChecklistDocument3 pagesRefractory Installation Qualification ChecklistSUNIL RAJPUTNo ratings yet

- Saic-Gi - 2102Document3 pagesSaic-Gi - 2102SUNIL RAJPUTNo ratings yet

- Saudi Aramco Inspection Checklist: Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 29-Dec-16 MechDocument23 pagesSaudi Aramco Inspection Checklist: Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 29-Dec-16 MechAbdul HafeezNo ratings yet

- Saic-N - 2005Document2 pagesSaic-N - 2005SUNIL RAJPUTNo ratings yet

- CBT 31Document9 pagesCBT 31SUNIL RAJPUT50% (2)

- Saic-N - 2002Document1 pageSaic-N - 2002SUNIL RAJPUTNo ratings yet

- Ph value shows acidity of solutionDocument3 pagesPh value shows acidity of solutionNidhin Joseph100% (1)

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGDocument5 pagesTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGvajidqcNo ratings yet

- Coating QuestionsDocument2 pagesCoating QuestionsSardar Muhamad Rashid100% (1)

- CBT 19Document3 pagesCBT 19SUNIL RAJPUTNo ratings yet

- Coating QuestionsDocument2 pagesCoating QuestionsSardar Muhamad Rashid100% (1)

- CBT 2Document2 pagesCBT 2SUNIL RAJPUT100% (1)

- CBT 22Document16 pagesCBT 22SUNIL RAJPUTNo ratings yet

- CBT 4Document9 pagesCBT 4SUNIL RAJPUTNo ratings yet

- Liquid CoatingsDocument12 pagesLiquid CoatingsSUNIL RAJPUTNo ratings yet

- CBT Coatings QuestionsDocument5 pagesCBT Coatings QuestionsSUNIL RAJPUTNo ratings yet

- Safety Requirements For Abrasive Blast CleaningDocument5 pagesSafety Requirements For Abrasive Blast CleaningHaleem Ur Rashid BangashNo ratings yet

- CBT 12Document7 pagesCBT 12SUNIL RAJPUT100% (1)

- Corrosion Prevention Surface Preparation Coating StandardsDocument9 pagesCorrosion Prevention Surface Preparation Coating StandardsSUNIL RAJPUT100% (1)

- Saes-H-004, 12.23.2018Document81 pagesSaes-H-004, 12.23.2018Rami ELLOUMINo ratings yet

- CBT QuestionsDocument20 pagesCBT Questionsmohammed amjad ali100% (1)

- CBT 25Document6 pagesCBT 25SUNIL RAJPUTNo ratings yet

- C - Quality Control Instrumention For Paint and Coating Installations - 2019Document67 pagesC - Quality Control Instrumention For Paint and Coating Installations - 2019SUNIL RAJPUTNo ratings yet

- Current SSPC Standards June2019Document7 pagesCurrent SSPC Standards June2019Aleksander Segura Tinoco100% (1)

- Design and Calculation AgitationDocument25 pagesDesign and Calculation Agitationibson045001256No ratings yet

- Fluid Mechanics Main File Paf 18-9-2020Document182 pagesFluid Mechanics Main File Paf 18-9-2020Gangesh SinghNo ratings yet

- Computational Fluid Dynamics (CFD) : A Seminar Report OnDocument16 pagesComputational Fluid Dynamics (CFD) : A Seminar Report OnAnil GöwđaNo ratings yet

- CST06 Capacity Improvement of A Large, Two Stage Diaphragm CompressorDocument19 pagesCST06 Capacity Improvement of A Large, Two Stage Diaphragm CompressorGustavoNo ratings yet

- Control Valves For Critical Applications PDFDocument8 pagesControl Valves For Critical Applications PDFonizuka-t2263No ratings yet

- Pilot operated pressure relief valve modular constructionDocument3 pagesPilot operated pressure relief valve modular constructionDillibabu RNo ratings yet

- VCS Guidelines Rev 10 01 2Document15 pagesVCS Guidelines Rev 10 01 2DMYTRO STRYZHKOVNo ratings yet

- KnjigaDocument671 pagesKnjigaIgor VasićNo ratings yet

- Stem Lesson Ld04 Aerodynamics SarradetDocument19 pagesStem Lesson Ld04 Aerodynamics SarradetYadana1No ratings yet

- Water Vapor and Humidity PowerpointDocument12 pagesWater Vapor and Humidity Powerpointapi-282246608100% (1)

- Edvard Kocbek PoetryDocument3 pagesEdvard Kocbek Poetry5h4d3No ratings yet

- Effect Injection On Air Lift PumpDocument6 pagesEffect Injection On Air Lift PumpDavid Fransiskus SimarmataNo ratings yet

- F1 12-Hydrostatic-Pressure DatasheetDocument1 pageF1 12-Hydrostatic-Pressure DatasheetBerlín LópezNo ratings yet

- Information Sheet For Rota Meter Test RigDocument7 pagesInformation Sheet For Rota Meter Test RigNayan BariNo ratings yet

- Ahmed 1984Document32 pagesAhmed 1984Jesus AguilarNo ratings yet

- JB00 B PPDC 020 0001 5Document1 pageJB00 B PPDC 020 0001 5tariq100% (1)

- Lab Report 2 - Head Loss in Pipe & BendsDocument20 pagesLab Report 2 - Head Loss in Pipe & BendsChris Ang76% (21)

- Neltex PVC PipesDocument2 pagesNeltex PVC Pipesyansen guyNo ratings yet

- Air Demand Behind Emergency Closure GatesDocument12 pagesAir Demand Behind Emergency Closure GatesSandeep JoshiNo ratings yet

- Hydraulics & RheologyDocument76 pagesHydraulics & RheologyMohamed Ahmed AlyNo ratings yet

- Cut-Back Asphalt (Rapid-Curing Type) : Standard Specification ForDocument1 pageCut-Back Asphalt (Rapid-Curing Type) : Standard Specification ForKaterin HernandezNo ratings yet

- BOQ For Cacl2 and New Tank240Document2 pagesBOQ For Cacl2 and New Tank240kasvikrajNo ratings yet

- Akron Style 753 High Pressure Trigger Shut OffDocument1 pageAkron Style 753 High Pressure Trigger Shut OffDercio CostaNo ratings yet

- Simulation of Water-Clay Flow in Dam Break with SPHDocument8 pagesSimulation of Water-Clay Flow in Dam Break with SPHGeorge CarmelNo ratings yet

- Unijin General Service Pressure Gauge Model: P110: Standard SpecificationDocument2 pagesUnijin General Service Pressure Gauge Model: P110: Standard Specificationdelvin26No ratings yet

- USDCM Volume 3 PDFDocument589 pagesUSDCM Volume 3 PDFSaga CastañedaNo ratings yet

- Design and Modeling of Fluid Power Systems: ME 597/ABE 591 Lecture 12Document22 pagesDesign and Modeling of Fluid Power Systems: ME 597/ABE 591 Lecture 12Elias80No ratings yet

- Drenage PDFDocument340 pagesDrenage PDFJoseNo ratings yet

- B.T.Yocum, Offshore Riser Slug Flow Avoidance Mathematical Models For Design and OptimizationDocument16 pagesB.T.Yocum, Offshore Riser Slug Flow Avoidance Mathematical Models For Design and OptimizationTrần Vũ HạNo ratings yet

- Designer's data sheet for distillation column internalsDocument4 pagesDesigner's data sheet for distillation column internalsTarun BhatiaNo ratings yet