Professional Documents

Culture Documents

Saic-N - 2017

Uploaded by

SUNIL RAJPUTOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic-N - 2017

Uploaded by

SUNIL RAJPUTCopyright:

Available Formats

SAUDI ARAMCO ID/PIEU-31-January-2019 - REV.2019.01.

00 (Standards Cutoff - January 31,2019) Rev 39 31-Jan-19

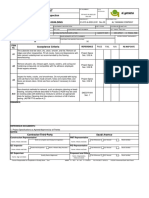

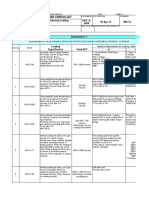

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Punch Listing of Hot Insulation Installation SAIC-N-2017 31-Mar-19 INSL-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A. General Requirements

The following Checklists are completed & accepted:

A) SAIC-N-2014 (Application Insp. of Cold Insulation)

C) SAIC-N-2015 (Insp. of Hot Insulation Installation prior to

A1 as referenced

Cladding) D) SAIC-N-2016 (Insp. of Cladding for

Hot Insulation)

Transfer the outstanding items on the FEIL .

INIH1000, Mandatory Hot Insulation Details are installed.

SAES-N-001,

A2 Perform final walkdown using detailed sketches. (See Note

Sec.3

1)

Vessel & Tank ultra violet resistant UT plugs fit snugly (vapor tight) & are

SAES-N-001

A3 opened & reclosed without disturbing the adjacent insulation. (See Note 2

Para. 8.2.2

(Items A - J) for UT Plugs)

Required removable/reusable Insulation covers are installed on Valve,

SAES-N-001,

A4 Flanges etc.

Sec.3

(INTG1000 Sec V-2)

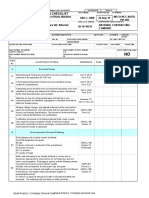

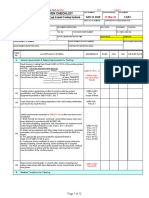

Clean-up is completed as follows:

A) After caulking, cleaned surfaces exhibit good workmanship

B) After mixing, thinning &

applying materials, all splatter is removed

SAES-N-001,

A5 C) After installing adjacent fireproofing all splatter is removed

Sec.3

D) Debris resulting from insulation application work are

removed from the work area.

(INSH2000, Sect. 5.12, INTG1000 Sec V-5)

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU-31-January-2019 - REV.2019.01.00 (Standards Cutoff - January 31,2019) Rev 39 31-Jan-19

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Punch Listing of Hot Insulation Installation SAIC-N-2017 31-Mar-19 INSL-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

REMARKS:

REFERENCE DOCUMENTS:

1. SAES-N-001 -- Basic Criteria, Industrial Insulation (16 January 2014)

2. PIP INSH2000 Installation of Cold Service Insulation Systems (Oct 1997)

3. PIP INTG1000 Insulation Inspection Checklist (Oct 2005)

NOTES: 1. Field copy of PIP INTG1000 & PIP INIH1000 (27 Details) is used on final walkdown (Not attached)

2. EXTREME CARE was used during UT plug installation as listed in "A through J" below. List outstanding items on Insulation Punch list.

A) UT plug hole cuts & metal surfaces beneath were inspected 100% for damage and Safety of Installation.

B) Cutting tools & pilot drills did not damage base metal or coating. Where this did occur, repairs were Company approved, performed & accepted.

C) All sharp edges were filed down or ground smooth & filings & sharp metal slivers were cleaned from inside UT plug holes for personnel safety.

D) Insulation damages beneath jacketing were repaired as necessary & final insulation beneath jacketing remains sound.

E) Gores, nozzle flashings & jacket securement (bands, etc) are neither damaged nor distorted (acceptable for service) after plug installation.

F) Inspector checked 100% of the plugs for a snug fit by placing UT plugs back into their respective holes.

G) Inspector identified loose plugs for repair by approved insulation patching methods and/or relocation of cut holes as necessary.

H) Inspector has verified that installation was per the plug manufacturer installation recommendations & precautions. (proper tools were used)

I) Baseline UT was completed prior to final caulking of plug locations (as necessary per orientation/location) & final inspection.

J) Plug installations are weatherproofed, sealed & undamaged. Verify serviceability (snug plugs do not fall out) at elevated operating temps.

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Saic-N - 2013Document2 pagesSaic-N - 2013SUNIL RAJPUTNo ratings yet

- Saic M 1014Document3 pagesSaic M 1014Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 1-Nov-09 CivilDocument1 pageSaudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 1-Nov-09 CivilWaleed MedhatNo ratings yet

- Saic D 2024Document9 pagesSaic D 2024Md ShariqueNo ratings yet

- Saic B 1004Document2 pagesSaic B 1004jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechDocument5 pagesSaudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechaamirapiNo ratings yet

- Saic B 2010Document2 pagesSaic B 2010usmanNo ratings yet

- 26 Saic A 2009Document5 pages26 Saic A 2009Naveed ShahNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistkartik_harwani4387No ratings yet

- Saic M 1060Document1 pageSaic M 1060Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistshahzadaNo ratings yet

- Ayc Inspection Checklist: Linolium Sheet Pre - Installation Inspection Industrial Support Facilities BuildingDocument6 pagesAyc Inspection Checklist: Linolium Sheet Pre - Installation Inspection Industrial Support Facilities Buildingmoytabura96No ratings yet

- Saudi Aramco Inspection Checklist: Depressurization of Pneumatic Test (Perform Leak Test) SAIC-A-2022 30-Apr-17 MechDocument1 pageSaudi Aramco Inspection Checklist: Depressurization of Pneumatic Test (Perform Leak Test) SAIC-A-2022 30-Apr-17 Mechkarthi51289No ratings yet

- Saic M 1053Document1 pageSaic M 1053Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 3-Jul-18 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 3-Jul-18 Civilkarthi51289No ratings yet

- Satr H 1003Document1 pageSatr H 1003Moghal AliNo ratings yet

- Saudi Aramco Inspection Checklist: Final Inspection of Intumescent Fireproofing Application SAIC-B-2010 30-Apr-13 MechDocument2 pagesSaudi Aramco Inspection Checklist: Final Inspection of Intumescent Fireproofing Application SAIC-B-2010 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saic N 2031Document4 pagesSaic N 2031aamirapi100% (1)

- SAIC-A-2022 Rev 6 Depressure PnematicDocument1 pageSAIC-A-2022 Rev 6 Depressure Pnematicpookkoya thangalNo ratings yet

- Saic H 1004Document4 pagesSaic H 1004NASIR SYEDNo ratings yet

- Ayc Inspection Checklist: Linolium Sheet Pre - Installation InspectionDocument1 pageAyc Inspection Checklist: Linolium Sheet Pre - Installation Inspectionmoytabura96No ratings yet

- Saic M 1052Document1 pageSaic M 1052Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistAnonymous S9qBDVkyNo ratings yet

- SAIC-W-2071 Selection of Welds For NDE (Vessels)Document2 pagesSAIC-W-2071 Selection of Welds For NDE (Vessels)KirubhakarPooranamNo ratings yet

- AYC CHECKLIST PAINTING Rev.01Document3 pagesAYC CHECKLIST PAINTING Rev.01moytabura96No ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistDilshad AhemadNo ratings yet

- Saic-G - 2019Document2 pagesSaic-G - 2019SUNIL RAJPUTNo ratings yet

- Saic N 2034Document4 pagesSaic N 2034aamirapiNo ratings yet

- Saic Q 1028Document2 pagesSaic Q 1028Qays YousefNo ratings yet

- Saic L 2008Document4 pagesSaic L 2008babjihanumanthuNo ratings yet

- Saic-N - 2002Document1 pageSaic-N - 2002SUNIL RAJPUTNo ratings yet

- Ayc Ic & Itp Roll Up DoorDocument10 pagesAyc Ic & Itp Roll Up Doormoytabura96No ratings yet

- Saudi Aramco Inspection Checklist: Receiving, Storage, Handling and Preservation of Filters SAIC-K-4028 HvacDocument2 pagesSaudi Aramco Inspection Checklist: Receiving, Storage, Handling and Preservation of Filters SAIC-K-4028 HvacshahzadaNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2003 30-Apr-13 MechDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2003 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saic e 2010Document3 pagesSaic e 2010sureshNo ratings yet

- Saic M 1008Document1 pageSaic M 1008Hussain Nasser Al- NowiesserNo ratings yet

- Saic-N - 2008Document2 pagesSaic-N - 2008SUNIL RAJPUTNo ratings yet

- SAIC N 2034 InspofRepairstoExtErosResistRefractInst EL RevDocument3 pagesSAIC N 2034 InspofRepairstoExtErosResistRefractInst EL RevAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 WeldDocument1 pageSaudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 Weldkartik_harwani4387No ratings yet

- Saic S 4054Document2 pagesSaic S 4054Jahanzeb MaharNo ratings yet

- SAIC-K-4039 Rev 7 Air-Cooled Condenser InstallationDocument2 pagesSAIC-K-4039 Rev 7 Air-Cooled Condenser InstallationshahzadaNo ratings yet

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Geotechnical Investigation Requirements SAIC-A-1007 30-Apr-13 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Geotechnical Investigation Requirements SAIC-A-1007 30-Apr-13 CivilJeffrey Lipata Jr.No ratings yet

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechDocument6 pagesSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechEagle SpiritNo ratings yet

- Saic L 2003Document9 pagesSaic L 2003MAZHARULNo ratings yet

- Saic e 2008Document4 pagesSaic e 2008usmanNo ratings yet

- Saudi Aramco Inspection Checklist: Review of SIS For Air Cooled Heat Exchanger SAIC-E-2004 15-Nov-17 MechDocument8 pagesSaudi Aramco Inspection Checklist: Review of SIS For Air Cooled Heat Exchanger SAIC-E-2004 15-Nov-17 MechmominNo ratings yet

- Ayc Ic & Itp SealerDocument6 pagesAyc Ic & Itp Sealermoytabura96No ratings yet

- Inspection and Test Plan For Fire Proofing Sealer ApplicationDocument6 pagesInspection and Test Plan For Fire Proofing Sealer Applicationmoytabura96100% (6)

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- Saic B 1001Document1 pageSaic B 1001Hussain Nasser Al- NowiesserNo ratings yet

- SAIC-H-2010 Rev 7Document1 pageSAIC-H-2010 Rev 7Satheesh Rama SamyNo ratings yet

- Saudi Aramco Inspection Checklist: Storage, Handling & Preservation of Relief Valves SAIC-J-2007 24-Jul-18 MechDocument6 pagesSaudi Aramco Inspection Checklist: Storage, Handling & Preservation of Relief Valves SAIC-J-2007 24-Jul-18 Mechnisha_khan100% (1)

- Saudi Aramco Inspection Checklist: Final Reinstatement After Mechanical & Chem Cleaning SAIC-G-2019 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Final Reinstatement After Mechanical & Chem Cleaning SAIC-G-2019 30-Apr-17 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Re-Instatement of Air Cooled Heat Exchanger SAIC-E-2008 15-Nov-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Re-Instatement of Air Cooled Heat Exchanger SAIC-E-2008 15-Nov-17 MechmominNo ratings yet

- SAIC-LT-2007 LeaK Testing-Vacuum BoxDocument3 pagesSAIC-LT-2007 LeaK Testing-Vacuum BoxKirubhakarPooranamNo ratings yet

- Saic-Gi - 2102Document3 pagesSaic-Gi - 2102SUNIL RAJPUTNo ratings yet

- Saic-N - 2007Document4 pagesSaic-N - 2007SUNIL RAJPUTNo ratings yet

- Saudi Aramco Inspection Checklist: Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 29-Dec-16 MechDocument23 pagesSaudi Aramco Inspection Checklist: Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 29-Dec-16 MechAbdul HafeezNo ratings yet

- Saic-G - 2019Document2 pagesSaic-G - 2019SUNIL RAJPUTNo ratings yet

- Saic-N - 2019Document3 pagesSaic-N - 2019SUNIL RAJPUTNo ratings yet

- Saic-N - 2008Document2 pagesSaic-N - 2008SUNIL RAJPUTNo ratings yet

- CBT 19Document3 pagesCBT 19SUNIL RAJPUTNo ratings yet

- Saic-N - 2002Document1 pageSaic-N - 2002SUNIL RAJPUTNo ratings yet

- Saic-N - 2005Document2 pagesSaic-N - 2005SUNIL RAJPUTNo ratings yet

- CBT 31Document9 pagesCBT 31SUNIL RAJPUT50% (2)

- Coating QuestionsDocument2 pagesCoating QuestionsSardar Muhamad Rashid100% (1)

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGDocument5 pagesTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGvajidqcNo ratings yet

- Coating QuestionsDocument2 pagesCoating QuestionsSardar Muhamad Rashid100% (1)

- CBT 8Document5 pagesCBT 8SUNIL RAJPUTNo ratings yet

- CBT 12Document7 pagesCBT 12SUNIL RAJPUT100% (1)

- InternalDocument2 pagesInternalSUNIL RAJPUTNo ratings yet

- CBT 2Document2 pagesCBT 2SUNIL RAJPUT100% (1)

- CBT 06.02.2020Document3 pagesCBT 06.02.2020Nidhin Joseph100% (1)

- Safety Requirements For Abrasive Blast CleaningDocument5 pagesSafety Requirements For Abrasive Blast CleaningHaleem Ur Rashid BangashNo ratings yet

- Liquid CoatingsDocument12 pagesLiquid CoatingsSUNIL RAJPUTNo ratings yet

- CBT 22Document16 pagesCBT 22SUNIL RAJPUTNo ratings yet

- CBT 3Document9 pagesCBT 3SUNIL RAJPUT100% (1)

- C - Quality Control Instrumention For Paint and Coating Installations - 2019Document67 pagesC - Quality Control Instrumention For Paint and Coating Installations - 2019SUNIL RAJPUTNo ratings yet

- CBT 25Document6 pagesCBT 25SUNIL RAJPUTNo ratings yet

- CBT 4Document9 pagesCBT 4SUNIL RAJPUTNo ratings yet

- Current SSPC Standards June2019Document7 pagesCurrent SSPC Standards June2019Aleksander Segura Tinoco100% (1)

- CBT QuestionsDocument20 pagesCBT Questionsmohammed amjad ali100% (1)

- Saes-H-004, 12.23.2018Document81 pagesSaes-H-004, 12.23.2018Rami ELLOUMINo ratings yet

- Linux and The Unix PhilosophyDocument182 pagesLinux and The Unix PhilosophyTran Nam100% (1)

- Ionic Bonding Worksheet - Type 1 PracticeDocument2 pagesIonic Bonding Worksheet - Type 1 Practicerichwenekylejc o Evaristo100% (6)

- DatuinMA (Activity #5 - NSTP 10)Document2 pagesDatuinMA (Activity #5 - NSTP 10)Marc Alen Porlaje DatuinNo ratings yet

- Bhavesh ProjectDocument14 pagesBhavesh ProjectRahul LimbaniNo ratings yet

- IoT Security Checklist Web 10 17 r1Document39 pagesIoT Security Checklist Web 10 17 r1SubinNo ratings yet

- Lesson 1 Concepts About Educational TechnologyDocument17 pagesLesson 1 Concepts About Educational TechnologyMarvin ContigaNo ratings yet

- MC4 CoCU 6 - Welding Records and Report DocumentationDocument8 pagesMC4 CoCU 6 - Welding Records and Report Documentationnizam1372100% (1)

- Icc Esr-2302 Kb3 ConcreteDocument11 pagesIcc Esr-2302 Kb3 ConcretexpertsteelNo ratings yet

- Do Now:: What Is Motion? Describe The Motion of An ObjectDocument18 pagesDo Now:: What Is Motion? Describe The Motion of An ObjectJO ANTHONY ALIGORANo ratings yet

- Design of Purlins: Try 75mm X 100mm: Case 1Document12 pagesDesign of Purlins: Try 75mm X 100mm: Case 1Pamela Joanne Falo AndradeNo ratings yet

- General Return Service Agreement (RSA) GuidelinesDocument2 pagesGeneral Return Service Agreement (RSA) GuidelinesJune Francis AngNo ratings yet

- WoundVite®, The #1 Most Comprehensive Wound, Scar and Post-Surgical Repair Formula Receives Amazon's Choice High RatingsDocument3 pagesWoundVite®, The #1 Most Comprehensive Wound, Scar and Post-Surgical Repair Formula Receives Amazon's Choice High RatingsPR.comNo ratings yet

- Unilever PakistanDocument26 pagesUnilever PakistanElie Mints100% (3)

- CESCOM 10 - Aircraft Status Report: Maintenance InspectionsDocument78 pagesCESCOM 10 - Aircraft Status Report: Maintenance InspectionsAlejandro BarradasNo ratings yet

- FIGMADocument22 pagesFIGMACessNo ratings yet

- Antenatal Care (ANC)Document77 pagesAntenatal Care (ANC)tareNo ratings yet

- Chain: SRB Series (With Insulation Grip)Document1 pageChain: SRB Series (With Insulation Grip)shankarNo ratings yet

- 3DS 2017 GEO GEMS Brochure A4 WEBDocument4 pages3DS 2017 GEO GEMS Brochure A4 WEBlazarpaladinNo ratings yet

- Hackerearth Online Judge: Prepared By: Mohamed AymanDocument21 pagesHackerearth Online Judge: Prepared By: Mohamed AymanPawan NaniNo ratings yet

- MCC333E - Film Review - Myat Thu - 32813747Document8 pagesMCC333E - Film Review - Myat Thu - 32813747Myat ThuNo ratings yet

- MSDS Leadframe (16 Items)Document8 pagesMSDS Leadframe (16 Items)bennisg8No ratings yet

- KM170, KM171, KM172, F3A21, F3A22: 3 SPEED FWD (Lock Up & Non Lock Up)Document4 pagesKM170, KM171, KM172, F3A21, F3A22: 3 SPEED FWD (Lock Up & Non Lock Up)krzysiek1975No ratings yet

- GNSS COrs SystemDocument20 pagesGNSS COrs SystemKostPutriMalangNo ratings yet

- Lahore Waste Management CompanyDocument45 pagesLahore Waste Management CompanyHadia NasirNo ratings yet

- Product Handbook Arendal 1961 Series SubwoofersDocument44 pagesProduct Handbook Arendal 1961 Series SubwoofersDomagoj KovacevicNo ratings yet

- Krishna TejaDocument71 pagesKrishna TejaHimanshu GaurNo ratings yet

- Some Studies On Structure and Properties of Wrapped Jute (Parafil) YarnsDocument5 pagesSome Studies On Structure and Properties of Wrapped Jute (Parafil) YarnsVedant MahajanNo ratings yet

- CryptogrophyDocument37 pagesCryptogrophyFarah EssidNo ratings yet

- 00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentDocument4 pages00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentFaizal AbdullahNo ratings yet

- Calendar of Activities A.Y. 2015-2016: 12 Independence Day (Regular Holiday)Document3 pagesCalendar of Activities A.Y. 2015-2016: 12 Independence Day (Regular Holiday)Beny TawanNo ratings yet