Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist

Uploaded by

kartik_harwani4387Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist

Uploaded by

kartik_harwani4387Copyright:

Available Formats

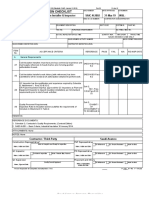

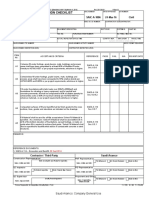

SAUDI ARAMCO ID/PID - 29/09/2017 - REV 0 (Standards Cutoff - January 2017 ) REV 0 29-Sep-17

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Seal Weld of faying surfaces and Threaded connections on

SAIC-W-1315 WELD

Offshore Structures

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

GENERAL REQUIREMENTS . Note:

A

Checklist applies to Offshore Structure (SAES-W-013) AWS D1.1

Unless specified otherwise, all faying surfaces should be sealed against

API

corrosion by continuous fillet welds. Seal welds should not be less than 3

RECOMMENDED

A1 mm (1/8 in.) but need not exceed 5 mm (3/16 in.) regardless of base

PRACTICE 2A-

metal thickness. Minimum preheat temperatures of AWS

WSD 13.3.4

D1.1/D1.1M:2010, Table 3.2 or Annex I should be applied.

All joints and faying surfaces, except for mudmats or those specifically

SAES-W-013

A2 designed and designated as removable bolted connections, shall be seal

10.15.1

welded by a continuous fillet weld.

Sealing compounds or tapes shall not be used on joints that are to be seal SAES-W-013

A3

welded. 10.15.2

Seal welding of threaded connections shall cover all exposed threads and SAES-W-013

A4

shall have a smooth contour between the two surfaces. 10.15.3

REMARKS: Faying Surface.The separation between faying surfaces of plug and slot welds, and of butt joints landing on a backing, shall not exceed

1/16 in [2 mm]. Where irregularities in rolled shapes occur after straightening do not allow contact within the above limits, the procedure necessary to

bring the material within these limits shall be subject to the approval of the Engineer.The use of filler plates shall be prohibited except as specified on

the drawings or as specially approved by the Engineer and made in conformance with 2.11.AWS D1.1 Clause 5.21.1.1.

ATTACHMENTS:

REFERENCE DOCUMENTS:

1. SAES-W-013 Welding Requirements for Offshore Structures (January 22 2015)

2.AWS D1.1 Structural welding code (Latest Edition)

3.API RP2A - WSD Planning, Designing and constructing fixed offshore Platform (Latest Edition)

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection:

T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Saudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 WeldDocument1 pageSaudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 Weldkartik_harwani4387No ratings yet

- SAIC-W-2084 Buttering or Build-Up of JointsDocument1 pageSAIC-W-2084 Buttering or Build-Up of Jointskarioke mohaNo ratings yet

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNo ratings yet

- SAIC-W-2071 Selection of Welds For NDE (Vessels)Document2 pagesSAIC-W-2071 Selection of Welds For NDE (Vessels)KirubhakarPooranamNo ratings yet

- SAIC-W-2077 Weld Joint Identification SystemDocument1 pageSAIC-W-2077 Weld Joint Identification Systemkarioke mohaNo ratings yet

- Saic H 1004Document4 pagesSaic H 1004NASIR SYEDNo ratings yet

- Saic S 4054Document2 pagesSaic S 4054Jahanzeb MaharNo ratings yet

- Saudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saic M 1014Document3 pagesSaic M 1014Hussain Nasser Al- NowiesserNo ratings yet

- Saic M 1070Document1 pageSaic M 1070Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection Checklist: Geotechnical Investigation Requirements SAIC-A-1007 30-Apr-13 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Geotechnical Investigation Requirements SAIC-A-1007 30-Apr-13 CivilJeffrey Lipata Jr.No ratings yet

- Saic B 1004Document2 pagesSaic B 1004jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Review of SIS For Air Cooled Heat Exchanger SAIC-E-2004 15-Nov-17 MechDocument8 pagesSaudi Aramco Inspection Checklist: Review of SIS For Air Cooled Heat Exchanger SAIC-E-2004 15-Nov-17 MechmominNo ratings yet

- Saic Q 1007Document2 pagesSaic Q 1007Hussain Nasser Al- NowiesserNo ratings yet

- Saic B 1001Document1 pageSaic B 1001Hussain Nasser Al- NowiesserNo ratings yet

- A A A A A A: Saudi Aramco Inspection ChecklistDocument2 pagesA A A A A A: Saudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saic A 1010Document1 pageSaic A 1010mohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Grounding - GES - Structural Steel Electrode Installation SAIC-P-3717 ElectDocument2 pagesSaudi Aramco Inspection Checklist: Grounding - GES - Structural Steel Electrode Installation SAIC-P-3717 Electmkalidas2006No ratings yet

- SAIC M 2007 Struct AlignDocument1 pageSAIC M 2007 Struct AlignAnonymous S9qBDVkyNo ratings yet

- SAIC-A-1006 - Final Fill InspectionDocument1 pageSAIC-A-1006 - Final Fill InspectionwalidNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 1-Nov-09 CivilDocument1 pageSaudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 1-Nov-09 CivilWaleed MedhatNo ratings yet

- Saic A 1006Document1 pageSaic A 1006Niel TanedoNo ratings yet

- Saic A 1009Document2 pagesSaic A 1009mohammadNo ratings yet

- Saic M 1031Document1 pageSaic M 1031Hussain Nasser Al- NowiesserNo ratings yet

- Saic A 1010Document1 pageSaic A 1010usmanNo ratings yet

- Saic-N - 2002Document1 pageSaic-N - 2002SUNIL RAJPUTNo ratings yet

- SAIC-A-1017 Rev 8 HDPE Liner Final Inspection FinalDocument1 pageSAIC-A-1017 Rev 8 HDPE Liner Final Inspection FinalGOSP3 QC MechanicalNo ratings yet

- Saic A 1006Document1 pageSaic A 1006Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection Checklist: Depressurization of Pneumatic Test (Perform Leak Test) SAIC-A-2022 30-Apr-17 MechDocument1 pageSaudi Aramco Inspection Checklist: Depressurization of Pneumatic Test (Perform Leak Test) SAIC-A-2022 30-Apr-17 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 MechDocument15 pagesSaudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Brazing Procedures SAIC-S-4048 30-Apr-13 PlumbDocument1 pageSaudi Aramco Inspection Checklist: Brazing Procedures SAIC-S-4048 30-Apr-13 PlumbKaranDinaNo ratings yet

- SAIC-RT-2001 Revw of RT ProcedureDocument1 pageSAIC-RT-2001 Revw of RT ProcedureKirubhakarPooranamNo ratings yet

- Saic A 1010Document1 pageSaic A 1010Naushad AlamNo ratings yet

- Saudi Aramco Inspection Checklist: Visual Insp of Air Test On Repads & Weld-Plus-Ends Cplgs SAIC-A-2016 30-Apr-13 MechDocument1 pageSaudi Aramco Inspection Checklist: Visual Insp of Air Test On Repads & Weld-Plus-Ends Cplgs SAIC-A-2016 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistAnonymous S9qBDVkyNo ratings yet

- Saic A 1017Document1 pageSaic A 1017jerinNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-L-1003 29-Jun-17Document1 pageSaudi Aramco Inspection Checklist: SAIC-L-1003 29-Jun-17Zia ur RehmanNo ratings yet

- Saic D 2024Document9 pagesSaic D 2024Md ShariqueNo ratings yet

- SAIC-A-2022 Rev 6 Depressure PnematicDocument1 pageSAIC-A-2022 Rev 6 Depressure Pnematicpookkoya thangalNo ratings yet

- Saudi Aramco Test Report: Adhesion Test of Fbe Coating SATR-H-2010 CoatDocument2 pagesSaudi Aramco Test Report: Adhesion Test of Fbe Coating SATR-H-2010 CoatnasirNo ratings yet

- Ayc Inspection Checklist: Linolium Sheet Pre - Installation InspectionDocument1 pageAyc Inspection Checklist: Linolium Sheet Pre - Installation Inspectionmoytabura96No ratings yet

- Saic A 1006Document1 pageSaic A 1006Saragadam DilsriNo ratings yet

- SAIC-L-2041 Rev 6 Storge & Inspection of ValvesDocument2 pagesSAIC-L-2041 Rev 6 Storge & Inspection of ValvesAhdal NoushadNo ratings yet

- Saic M 1052Document1 pageSaic M 1052Hussain Nasser Al- NowiesserNo ratings yet

- Saic e 2010Document3 pagesSaic e 2010sureshNo ratings yet

- Saudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechDocument1 pageSaudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechmominNo ratings yet

- Saic-N - 2017Document2 pagesSaic-N - 2017SUNIL RAJPUTNo ratings yet

- SAIC-H-2010 Rev 7Document1 pageSAIC-H-2010 Rev 7Satheesh Rama SamyNo ratings yet

- Aramco ChecklistDocument1 pageAramco ChecklistTayyab AchakzaiNo ratings yet

- SAIC-A-1014 - Preweld Qualification of HDPE WelderDocument1 pageSAIC-A-1014 - Preweld Qualification of HDPE WelderwalidNo ratings yet

- Saic B 2002Document1 pageSaic B 2002usmanNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- A Contractor's Guide to the FIDIC Conditions of ContractFrom EverandA Contractor's Guide to the FIDIC Conditions of ContractNo ratings yet

- Wiley Practitioner's Guide to GAAS 2016: Covering all SASs, SSAEs, SSARSs, PCAOB Auditing Standards, and InterpretationsFrom EverandWiley Practitioner's Guide to GAAS 2016: Covering all SASs, SSAEs, SSARSs, PCAOB Auditing Standards, and InterpretationsNo ratings yet

- (Compare Report) SAES-B-005Document14 pages(Compare Report) SAES-B-005kartik_harwani4387No ratings yet

- (Compare Report) SAES-A-502Document19 pages(Compare Report) SAES-A-502kartik_harwani4387No ratings yet

- (Compare Report) SAES-B-014Document39 pages(Compare Report) SAES-B-014kartik_harwani4387No ratings yet

- (Compare Report) SAES-B-018Document16 pages(Compare Report) SAES-B-018kartik_harwani4387No ratings yet

- (Compare Report) SAES-A-401Document42 pages(Compare Report) SAES-A-401kartik_harwani43870% (1)

- (Compare Report) SAES-B-009Document32 pages(Compare Report) SAES-B-009kartik_harwani4387No ratings yet

- Engineering Standard: SAES-A-008Document8 pagesEngineering Standard: SAES-A-008kartik_harwani4387No ratings yet

- Saes L 440Document14 pagesSaes L 440kartik_harwani4387100% (1)

- Saudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 WeldDocument1 pageSaudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 Weldkartik_harwani4387No ratings yet

- Saudi Aramco Inspection Checklist: Pre Welding Inspection - Offshore Structures SAIC-W-1312 WeldDocument1 pageSaudi Aramco Inspection Checklist: Pre Welding Inspection - Offshore Structures SAIC-W-1312 Weldkartik_harwani4387No ratings yet

- Saes L 136Document8 pagesSaes L 136kartik_harwani4387No ratings yet

- Saudi Aramco Inspection Checklist: Pre Welding Inspection - Offshore Structures SAIC-W-1312 WeldDocument1 pageSaudi Aramco Inspection Checklist: Pre Welding Inspection - Offshore Structures SAIC-W-1312 Weldkartik_harwani4387No ratings yet

- SAES-O-211: Personal Identification Verification CardsDocument6 pagesSAES-O-211: Personal Identification Verification Cardskartik_harwani4387No ratings yet

- SAES-O-310: Security Requirements For Railways at Industrial FacilitiesDocument8 pagesSAES-O-310: Security Requirements For Railways at Industrial Facilitieskartik_harwani4387No ratings yet

- Sabp J 902Document9 pagesSabp J 902kartik_harwani4387No ratings yet

- Saes o 203Document17 pagesSaes o 203kartik_harwani4387No ratings yet

- SAES-O-205: Security Systems For Industrial FacilitiesDocument18 pagesSAES-O-205: Security Systems For Industrial Facilitieskartik_harwani4387No ratings yet

- Saes o 313Document10 pagesSaes o 313kartik_harwani4387No ratings yet

- Saes o 203Document17 pagesSaes o 203kartik_harwani4387No ratings yet

- SAES-O-205: Security Systems For Industrial FacilitiesDocument18 pagesSAES-O-205: Security Systems For Industrial Facilitieskartik_harwani4387No ratings yet

- Sabp A 077Document13 pagesSabp A 077kartik_harwani4387No ratings yet

- Sa 6717Document1 pageSa 6717biplabpal2009No ratings yet

- Sabp J 900Document9 pagesSabp J 900kartik_harwani4387No ratings yet

- Saes y 301Document10 pagesSaes y 301kartik_harwani4387No ratings yet

- SAES-T-744 Design Criteria and Installation of Communication TowersDocument7 pagesSAES-T-744 Design Criteria and Installation of Communication TowersAbdul Rahim ShaikhNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection Perkartik_harwani4387No ratings yet

- Saudi Arabian Oil CompanyDocument2 pagesSaudi Arabian Oil CompanyBIPIN BALANNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection Perkartik_harwani4387No ratings yet

- Sosito Vs Aguinaldo Devt CorpDocument2 pagesSosito Vs Aguinaldo Devt CorpCali AustriaNo ratings yet

- DOLORES DE VERA v. ATTY. CENON J. NAVARRODocument5 pagesDOLORES DE VERA v. ATTY. CENON J. NAVARROFaustina del RosarioNo ratings yet

- Proceedings - of - The - Grand - Lodge - of - NY 1905 History of Lodges Including Hiram 105 PDFDocument573 pagesProceedings - of - The - Grand - Lodge - of - NY 1905 History of Lodges Including Hiram 105 PDFMark RobsonNo ratings yet

- RBV Energy LTD Purchase Order P12676-0000 Rev 1: To: Proclad International Forging LTDDocument2 pagesRBV Energy LTD Purchase Order P12676-0000 Rev 1: To: Proclad International Forging LTDsirjamlesNo ratings yet

- New Mangalore Port Trust Employees (Licensing of Stevedors) Regulations, 2009Document7 pagesNew Mangalore Port Trust Employees (Licensing of Stevedors) Regulations, 2009Latest Laws TeamNo ratings yet

- Employment Rights, Restriction and PoliciesDocument2 pagesEmployment Rights, Restriction and PoliciesRaidenhile mae VicenteNo ratings yet

- Elliot Dukke UsDocument7 pagesElliot Dukke UsNguyễn Phan Khánh LinhNo ratings yet

- Motobecane 1978 Sales BrochureDocument12 pagesMotobecane 1978 Sales BrochuremhiohaNo ratings yet

- Having The Mind of Christ During An Election: Message NotesDocument3 pagesHaving The Mind of Christ During An Election: Message NotesSams TabrizNo ratings yet

- Chapter 18 Reading OrganizerDocument3 pagesChapter 18 Reading OrganizerAnna SongNo ratings yet

- Evasco Vs Montanez Ruling On Substantive Due ProcessDocument2 pagesEvasco Vs Montanez Ruling On Substantive Due ProcessMacTavish PriceNo ratings yet

- Kuda - External Analysis Delta FinalDocument10 pagesKuda - External Analysis Delta Finalkays chapanda100% (2)

- Gabriel Simon Mnyele..appe VS The Repub..respo Crim Appe No4Document26 pagesGabriel Simon Mnyele..appe VS The Repub..respo Crim Appe No4DATIUS DIDACE(Amicus Curiae)⚖️100% (1)

- The OpsRamp Platform Security and ComplianceDocument9 pagesThe OpsRamp Platform Security and ComplianceJesus Huerta VilchisNo ratings yet

- Private Placement Program: Client Compliance ApplicationDocument13 pagesPrivate Placement Program: Client Compliance Applicationjoe andarestaNo ratings yet

- Concept Builders Vs NLRCDocument2 pagesConcept Builders Vs NLRCRachel Ann Katrina AbadNo ratings yet

- 1 Oblicon RealFamDocument31 pages1 Oblicon RealFamEfrean BianesNo ratings yet

- Secretary CertificateDocument2 pagesSecretary CertificateJanz CJNo ratings yet

- AFFIDAVITDocument4 pagesAFFIDAVITayyan communicationNo ratings yet

- The Lawyer OathDocument11 pagesThe Lawyer OathReymondNo ratings yet

- Motion To Dismiss Petition For ReviewDocument5 pagesMotion To Dismiss Petition For ReviewOzkar KalashnikovNo ratings yet

- Crane/Lifting Operations Supervisor A62: LOLER 1998 and BS 7212 Parts 1 To 3 During The Theory TestDocument7 pagesCrane/Lifting Operations Supervisor A62: LOLER 1998 and BS 7212 Parts 1 To 3 During The Theory TestMohamed FathyNo ratings yet

- Joaquin Vs DrilonDocument6 pagesJoaquin Vs DrilonJohn MenesesNo ratings yet

- Cartaspers PSM PDFDocument4 pagesCartaspers PSM PDFLUIS XVNo ratings yet

- Judicial Affidavit: Direct ExaminationDocument4 pagesJudicial Affidavit: Direct ExaminationXirkul TupasNo ratings yet

- Icc OpinionsDocument19 pagesIcc OpinionsJhoo AngelNo ratings yet

- Schedule - G 1Document6 pagesSchedule - G 1A RajaNo ratings yet

- SPPL 07 02 PDFDocument17 pagesSPPL 07 02 PDFFattia SyafiraNo ratings yet

- Section 194J: Fees For Professional or Technical ServicesDocument24 pagesSection 194J: Fees For Professional or Technical ServicesSAURABH TIBREWALNo ratings yet

- Hawkeye 360 Commercialising Space-Based Precision RF Detection and AnalyticsDocument13 pagesHawkeye 360 Commercialising Space-Based Precision RF Detection and AnalyticsCORAL ALONSONo ratings yet