Professional Documents

Culture Documents

Inspect Weld Overlays

Uploaded by

Rijwan MohammadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspect Weld Overlays

Uploaded by

Rijwan MohammadCopyright:

Available Formats

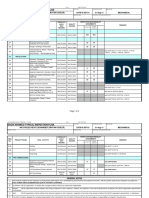

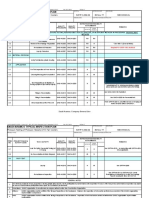

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.

01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WELD-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A General Requirements

First layer of multi-layer overlays shall be liquid penetrant examined per

SAES-W-014,

ASME SEC VIII D1, App 8 (equivalent to ASME SEC VIII D2, Art 9-2).

A2 Para. 6.7.1

Area examined shall be a 10 percent random coverage. If rejectable

indications are found, then the entire area shall be 100% examined.

Final layer, incl. single layer overlays shall be PT'd, over the entire area

(100%) per the same code criteria above (item A2).

The examination shall be conducted on the surface in its

final SAES-W-014,

A3 condition, i.e., as-welded or machined. Examination shall be Para. 6.7.2

conducted after the final PWHT, if PWHT is specified.

Commentary Notes: Perform an additional

examination prior to

PWHT in order to find and repair any defects prior to PWHT.

PT Examination shows extensive cracking or fissuring:

Ferroxyl test is performed to identify nature, location & extent SAES-W-014,

of cracking and should be documented. Para. 6.7.2

A4 Note: Ferroxyl or ferricyanide test is an iron contamination test to

determine if the cracking extends upto the base metal.

SAES-W-014,

If Ferroxyl or ferricyanide test shows iron contamination then the Para. 6.7.2

A5 overlay shall be repaired by complete removal of the overlay to base

metal in the area of fissuring prior to rewelding.

B Repair of weld overlay /Cladding

Repairs to overlays were performed by:

A) Removing the defect by machining or grinding only

(thermal methods are prohibited). SAES-W-014,

B) Removal of the overlay defect did not reduce Para. 6.8

B1

the base metal thickness below minimum design thickness. (UT or

measurement)

C) Repair area overlay was approved overlay procedure with a nominal

composition that matched original overlay composition.

Saudi Aramco: Company General Use

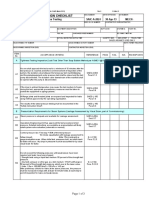

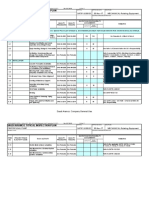

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WELD-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Each Repair was described on a Weld Description form SAES-W-010,

B2

(See SAES-W-014, Attachment 3). See Attachment 1 Para. 7.1.2

Each Repair area shall be welded back as per the applicable WPS and

the restored weld overlay shall undergo chemical analysis check, ferrite SAES-W-010

B3

no check and penetrant testing as required per original testing plan and Para 16.5

should be documented

REMARKS:

REFERENCE DOCUMENT: 1. SAES-W-010, Welding Requirements for Pressure Vessels, (08 September 2012).

2. SAES-W-014, Weld Overlays and Welding of Clad Materials, (13 Decembeer, 2011)

3. ASME SEC VIII D1 Pressure Vessels (2005 Edition)

4. ASME SEC VIII D2 Pressure Vessels, Alternative Rules (2005 Edition)

5. ASME SEC IX Welding and Brazing Qualifications (2005 Edition)

ATTACHMENTS:

Attachment 1 - SAES-W-010, Attachments A & B Weld Map & Weld Description Table ... Utilize to locate & identify defects

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

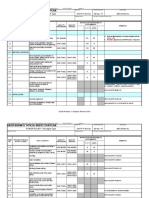

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WELD-

Attachment 1 - SAES-W-010, ATT. 3 Weld Map

Saudi Aramco: Company General Use

You might also like

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Weld Overlay Chemical Composition Testing & Results SAIC-W-2025 24-Mar-16 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Weld Overlay Chemical Composition Testing & Results SAIC-W-2025 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Document2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadNo ratings yet

- Radiographic Examination Engineering ProcedureDocument30 pagesRadiographic Examination Engineering Proceduredanielpradeep100% (1)

- Saep 306Document15 pagesSaep 306nadeem shaikh100% (1)

- Saep 325Document43 pagesSaep 325AbdullahNo ratings yet

- Auxiliary Piping SpecificationDocument11 pagesAuxiliary Piping SpecificationZubair RaoofNo ratings yet

- Saes M 009Document55 pagesSaes M 009Shanmugapriya BalaramanNo ratings yet

- Preparing Saudi Aramco Engineering StandardsDocument9 pagesPreparing Saudi Aramco Engineering StandardsDemac SaudNo ratings yet

- Sabp J 902Document9 pagesSabp J 902kartik_harwani4387No ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Sabp D 002Document16 pagesSabp D 002engforever AdnanNo ratings yet

- Saes Q 004Document24 pagesSaes Q 004AasimNo ratings yet

- RFI (Blank)Document1 pageRFI (Blank)SajjadPervaizNo ratings yet

- 01 Samss 031Document3 pages01 Samss 031Awais CheemaNo ratings yet

- 00 Saip 06Document4 pages00 Saip 06Selvakpm06No ratings yet

- Saep 31Document5 pagesSaep 31Anonymous 4IpmN7OnNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument3 pagesSaudi Aramco Typical Inspection PlanOmer aliNo ratings yet

- 02 Samss 012Document10 pages02 Samss 012bmkaleNo ratings yet

- Satip e 007 01Document2 pagesSatip e 007 01Anonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistSajid ShaikhNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- Saep 12Document39 pagesSaep 1269badbutchNo ratings yet

- SAUDI ARAMCO BOILER INSPECTION PLANDocument4 pagesSAUDI ARAMCO BOILER INSPECTION PLANAnonymous 4e7GNjzGWNo ratings yet

- Inspection Procedure EDRDocument8 pagesInspection Procedure EDRaamirtec301No ratings yet

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-Y-2001 24-Mar-16 MechDocument2 pagesSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-Y-2001 24-Mar-16 MechRijwan MohammadNo ratings yet

- Sabp A 001Document22 pagesSabp A 001kuse2456No ratings yet

- 09 Samss 030Document8 pages09 Samss 030Kalanithi KasirajanNo ratings yet

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapNo ratings yet

- 17 Samss 006Document13 pages17 Samss 006Ahamedulla KhanNo ratings yet

- SP-1176 V4.0Document45 pagesSP-1176 V4.0Ghulam HusainNo ratings yet

- AIE-PR-PRJ-005 - in Service Pipework Inspection Procedure Rev 01Document20 pagesAIE-PR-PRJ-005 - in Service Pipework Inspection Procedure Rev 01faraz_muslimNo ratings yet

- Norsok Standard m0012004 Materials SelectionDocument34 pagesNorsok Standard m0012004 Materials SelectionФокусник с нуляNo ratings yet

- Saep 324Document13 pagesSaep 324Up WeldNo ratings yet

- 175-026600 10312016Document2 pages175-026600 10312016Prasanna UmapathyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saep 1144Document23 pagesSaep 1144Amit shahNo ratings yet

- Saudi Aramco Hardness Testing Procedure ReviewDocument3 pagesSaudi Aramco Hardness Testing Procedure ReviewphilipyapNo ratings yet

- SAUDI ARAMCO INSPECTION CHECKLIST FOR LEAK TESTINGDocument3 pagesSAUDI ARAMCO INSPECTION CHECKLIST FOR LEAK TESTINGpookkoya thangalNo ratings yet

- Clad and Lined Pipe Specification: Company SpecificationsDocument59 pagesClad and Lined Pipe Specification: Company SpecificationsrachedNo ratings yet

- Cathodic Protection of Buried StructuresDocument22 pagesCathodic Protection of Buried StructuresPhilip OjugohNo ratings yet

- Saudi Aramco Air Cooled Heat Exchanger Inspection PlanDocument2 pagesSaudi Aramco Air Cooled Heat Exchanger Inspection PlanAnonymous S9qBDVkyNo ratings yet

- Aa 036531 001Document1 pageAa 036531 001narutothunderjet2160% (1)

- 00 Saip 72Document6 pages00 Saip 72Erin JohnsonNo ratings yet

- Saes L 130Document5 pagesSaes L 130Ahmed Kabel100% (1)

- ES.0.08.0002 Rev.B - Engineering Data Request Form PDFDocument1 pageES.0.08.0002 Rev.B - Engineering Data Request Form PDFSaravanan VaradarajanNo ratings yet

- EXAMPLE SIZING OWS Calculation Per API 421 PDFDocument1 pageEXAMPLE SIZING OWS Calculation Per API 421 PDFAnonymous hbEfEuPNo ratings yet

- Ir 175-010000Document2 pagesIr 175-010000Abu Anas M.SalaheldinNo ratings yet

- Saes L 108Document26 pagesSaes L 108Muhammad AwaisNo ratings yet

- SATIP B 019 01 (Revision 4)Document2 pagesSATIP B 019 01 (Revision 4)Anonymous 4e7GNjzGWNo ratings yet

- 09 Samss 101Document9 pages09 Samss 101GOSP3 QC MechanicalNo ratings yet

- Saep 744Document7 pagesSaep 744Anonymous 4IpmN7OnNo ratings yet

- SAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTDocument2 pagesSAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTnisha_khanNo ratings yet

- Human Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveFrom EverandHuman Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveNo ratings yet

- ISO9001-2015 Quality Management System Assessment ChecklistDocument37 pagesISO9001-2015 Quality Management System Assessment ChecklistAbrahamNdewingoNo ratings yet

- Assoc. Pip RESP003S: Data SheetDocument4 pagesAssoc. Pip RESP003S: Data SheetRijwan MohammadNo ratings yet

- Vertical Submerged Pump Data SheetDocument4 pagesVertical Submerged Pump Data SheetRijwan MohammadNo ratings yet

- SAEP - 306 Evaluating The Safe Operating Pressure of Corroded PipeDocument2 pagesSAEP - 306 Evaluating The Safe Operating Pressure of Corroded PipeSalik SiddiquiNo ratings yet

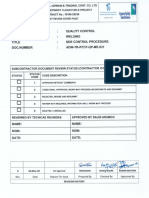

- Adw TR RTCF QP Me 002, Rev.1Document38 pagesAdw TR RTCF QP Me 002, Rev.1Rijwan MohammadNo ratings yet

- Overseas Assignment 11 JuneDocument6 pagesOverseas Assignment 11 JuneRijwan MohammadNo ratings yet

- ADW-TR-RTCF-QP-ME-021 Rev-01Document20 pagesADW-TR-RTCF-QP-ME-021 Rev-01Rijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestDocument4 pagesSaudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestRijwan MohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-Y-2001 24-Mar-16 MechDocument2 pagesSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-Y-2001 24-Mar-16 MechRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Hydrogen Disbonding Test (Qualification Testing Reqmt) SAIC-W-2020 24-Mar-16 MechDocument3 pagesSaudi Aramco Inspection Checklist: Hydrogen Disbonding Test (Qualification Testing Reqmt) SAIC-W-2020 24-Mar-16 MechRijwan MohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Satip F 001 04Document13 pagesSatip F 001 04Rijwan MohammadNo ratings yet

- Technology Examination Questions (Multi-Cohice Exam) : Duties Before WeldingDocument6 pagesTechnology Examination Questions (Multi-Cohice Exam) : Duties Before WeldingvickyNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Document2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadNo ratings yet

- Purchase Order .:: TR Ras Tanura Refinery Clean Fuels Project Electro-Mechanical Works - Ap4 & Ap5Document1 pagePurchase Order .:: TR Ras Tanura Refinery Clean Fuels Project Electro-Mechanical Works - Ap4 & Ap5Rijwan MohammadNo ratings yet

- Adw TR RTCF QP Me 021Document18 pagesAdw TR RTCF QP Me 021Rijwan MohammadNo ratings yet

- Satip A 104 03eeDocument10 pagesSatip A 104 03eeRijwan MohammadNo ratings yet

- Satip A 004 04JJDocument10 pagesSatip A 004 04JJRijwan MohammadNo ratings yet

- Saep 29Document10 pagesSaep 29Rijwan MohammadNo ratings yet

- Satip G 006 0122Document10 pagesSatip G 006 0122Rijwan MohammadNo ratings yet

- Satip D 001 01Document11 pagesSatip D 001 01Rijwan Mohammad0% (1)

- Satip H 002 02Document10 pagesSatip H 002 02Rijwan MohammadNo ratings yet

- Satip G 005 01Document11 pagesSatip G 005 01Rijwan MohammadNo ratings yet

- Gunnebo - Shackles and Rigging ScrewsDocument18 pagesGunnebo - Shackles and Rigging ScrewsJorgeLopezNo ratings yet

- Spot Welding GuidelinesDocument5 pagesSpot Welding GuidelinesCaínCastilloNo ratings yet

- Gear Heat TreatmentDocument40 pagesGear Heat TreatmentvishnuNo ratings yet

- Design of Fit Between Die and InsertDocument4 pagesDesign of Fit Between Die and InsertInnovative Research PublicationsNo ratings yet

- Pamphlet 165 Edition 2 FINALDocument26 pagesPamphlet 165 Edition 2 FINALmbtcpNo ratings yet

- UTP Chemical GBDocument12 pagesUTP Chemical GBajaychackotecsoNo ratings yet

- Walworth-Pressure - Seal 2011 1Document76 pagesWalworth-Pressure - Seal 2011 1einhaw1985No ratings yet

- Aluminum Dome Roof SpecDocument4 pagesAluminum Dome Roof SpecMaribel Isaura Cunurana YapuchuraNo ratings yet

- LP Iii I Mech 55019 (2012-2013)Document22 pagesLP Iii I Mech 55019 (2012-2013)Rahul Kumar KNo ratings yet

- Misc Hetating PaperDocument14 pagesMisc Hetating PaperdhruvNo ratings yet

- Api 571 PDFDocument3 pagesApi 571 PDFumnartkhNo ratings yet

- Arc Welding Equipment and ProcessesDocument40 pagesArc Welding Equipment and Processesali100% (1)

- Is - 4503 Specification For Shell and Tube Type Heat ExchangersDocument69 pagesIs - 4503 Specification For Shell and Tube Type Heat Exchangerssrtools1980y100% (3)

- European Steel and Alloy Grades: X14Crmos17 (1.4104)Document2 pagesEuropean Steel and Alloy Grades: X14Crmos17 (1.4104)farshid KarpasandNo ratings yet

- Material GradesDocument20 pagesMaterial GradesEmreNo ratings yet

- MINISTRY HOUSING METAL RAILINGSDocument4 pagesMINISTRY HOUSING METAL RAILINGSmasoodaeNo ratings yet

- Sampling Procedure For Impact Testing of Structural SteelDocument5 pagesSampling Procedure For Impact Testing of Structural Steeljoy gultomNo ratings yet

- Drill Pipe CorrosionDocument2 pagesDrill Pipe Corrosionfbiagent008No ratings yet

- China StahlDocument8 pagesChina StahldstifterNo ratings yet

- Pressure Vessel Lecture Notes Online PDFDocument2 pagesPressure Vessel Lecture Notes Online PDFAdrian Selgas100% (1)

- Sound Velocity Chart PDFDocument1 pageSound Velocity Chart PDFIman NutnumNo ratings yet

- Iron and Steel Products Update 27mac2014Document13 pagesIron and Steel Products Update 27mac2014mfakhrudNo ratings yet

- Job Methodology For Fabrication & Erection of TankDocument22 pagesJob Methodology For Fabrication & Erection of TankBIPIN BALANNo ratings yet

- Teck 90 Armoured Power Cable SpecsDocument4 pagesTeck 90 Armoured Power Cable SpecsJames Ernes Llacza CarmeloNo ratings yet

- ALTIGDocument5 pagesALTIGbokugairuNo ratings yet

- A 985 - A 985M - 03 Qtk4ns9botg1tq - PDFDocument14 pagesA 985 - A 985M - 03 Qtk4ns9botg1tq - PDFMung Duong XuanNo ratings yet

- Data Sheet FBEDocument4 pagesData Sheet FBEAnonymous Xaf2033No ratings yet

- Reaction TypesDocument10 pagesReaction TypesaqibazizkhanNo ratings yet

- SIFL Training ReportDocument26 pagesSIFL Training Reportahmadmashhoorum100% (3)

- Guide To Pressure Vessel CodesDocument61 pagesGuide To Pressure Vessel Codespradeepbt100% (1)