Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist

Uploaded by

Rijwan MohammadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist

Uploaded by

Rijwan MohammadCopyright:

Available Formats

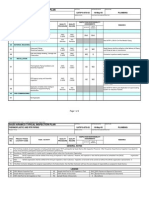

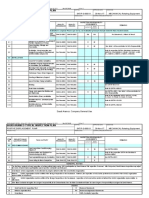

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.

01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review Supplemental Procedure - Method Statements

SAIC-W-2018 24-Mar-16 MECH-

related to Overlay Welding, Cladding Restoration, Repair

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A General Requirements

Welding procedures for corrosion resistant weld overlay have been

SAES-W-014,

A1 prepared & qualified in accordance with ASME SECTION IX & SAES-W-

Para. 5.1

014 and CSD has approved the Welding Package. (Refer SAIC-W-2017)

All corrosion-resistant weld overlays, including clad restoration, shall

conform with ASME SEC VIII reqts (Div. 1 or Div. 2) & W-014. SAES-W-014,

A2

Commentary Note: Refer to ASME SEC VIII D1, Part UCL and ASME Para. 4.1

SEC VIII D2, Article F-5 for specific requirements.

Repairs to integrally clad material shall not be done without the specific

SAES-W-014,

A3 approval of CSD. Any weld repairs to the cladding shall meet the

Para. 4.7

requirements for weld overlays.

The required deposit thickness of overlay as required by specific design

requirement is known and procedure relates how it shall be accomplished SAES-W-014,

A4

(for all surfaces & types of overlay).The deposited overlay thickness shall Para. 4.2

not be less than 3 mm for corrosion-resistant overlays.

Single layer overlays require prior approval by CSD. Additional

SAES-W-014,

A5 qualification and production tests may be required, as determined by

Para. 4.9

CSD.

Weld deposit chemistry shall be specified in engineering design. Where a

nominal alloy designation for overlay or cladding is listed (e.g., 316L), then SAES-W-014,

A6

overlay deposit shall meet equivalent filler metal composition reqmts Para. 4.4

unless otherwise specified or exempted.

The direction of overlay deposition shall be circumferential unless

otherwise approved by CSD. (Some components and geometries, such SAES-W-014

A7

as small diameter nozzles, or special applications may not permit welding Para. 4.3

in a circumferential direction.)

The WPS shall indicate the minimum deposit thickness qualified and the

minimum number of layers required. The number of layers used for the SAES-W-014,

A9

Procedure Qualification Record (PQR) shall be recorded and shall be the Para. 5.2

minimum number of layers specified on the WPS and used in production.

Method of Weld Overlay identification (to be supplemented by the weld SAES-W-010,

A10

map - see SAES-W-010, Para. 7.1.2). MARKING METHODS! Para. 15.1/15.2

Saudi Aramco: Company General Use

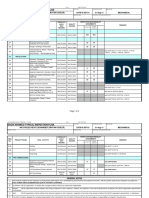

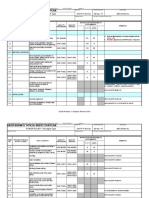

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review Supplemental Procedure - Method Statements

SAIC-W-2018 24-Mar-16 MECH-

related to Overlay Welding, Cladding Restoration, Repair

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

B Requirements for production welding inspection and testing

Production welding shall conform to the WPS, including all supplementary

SAES-W-014,

B1 essential variables and restrictions specified in this standard, such as heat

Para. 6.1

input restrictions , flux brand , and bead overlap (Also refer SAIC-W-2017)

Base metal shall be cleaned and this requires removal of the mill scale

SAES-W-014,

B2 and any adherent corrosion products. Caution: Repairs may require

Para. 6.2

special cleaning such as grit blasting or mechanical cleaning

Cladding restoration portion of weld joints between clad materials or

SAES-W-014,

B3 attaching clad materials to other materialsls shall meet requirements for

Para. 4.5

weld overlays.

Joint preparation & details for weld joints in clad vessels (incl weld SAES-W-014,

B4

overlays) shall be per SASD AB-036367. Para. 4.6

Ferrite measurements are per AWS A4.2.

Note: Calculation of the ferrite content using Schaeffler or DeLong

SAES-W-014,

B5 diagrams based on the chemical composition is not sufficient for critical

Para. 4.8

applications (CSD to determine). Actual measurements using methods

specified in AWS A4.2 are required. (SAIC-W-2030)

Actual overlay thickness achieved, after any machining, shall be

measured by ultrasonic methods or by physical measurement.

SAES-W-014,

B6 Note: A detailed procedure shall be submiited to

Para. 6.3

Inspection for review and approval. Minimum final thickness shall not be

less than thickness specified in the engineering design.

Final weld overlay surface shall have the chemical composition checked

prior to final PWHT or hydrotest. Chemistry is tested as described below.

All elements specified for deposit chemistry shall be analyzed and

reported (except for carbon when using the X-ray fluorescence method) :

A) Physical sample (drillings) removed for quantitative analysis OR

B) Portable spectrograph. With the specific approval of SA Insp, a SAES-W-014,

B7

portable X-ray fluorescence machine may be used instead of a Para. 6.4

spectrograph.

Note:

1) Analysis method & accuracy limits for each element shall be submitted

to Inspection for review & approval.

2) Repair method for

areas where samples have been removed shall be submitted to

Inspection for review and approval.

Frequency of chemical composition analyses shall be as follows:

A) Automatic welding - One analysis for each overlay

area or clad joint. Separate analyses shall be made for each heat/batch of SAES-W-014,

B8

filler metal or electrode. Para. 6.5

B) Manual - One analysis for each 1 m sq. of area or one analysis at

intervals of 2 m or less for overlay restoration of clad joints.

Saudi Aramco: Company General Use

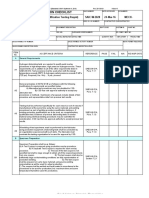

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review Supplemental Procedure - Method Statements

SAIC-W-2018 24-Mar-16 MECH-

related to Overlay Welding, Cladding Restoration, Repair

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Ferrite measurements shall be made for austenitic SS welds when the

design temp exceeds 427°C: A) Ferrite

SAES-W-014,

content shall be checked in the as-welded condition.

Para. 6.6

B9 B) Ferrite Number shall be between 3 and 10

FN. C) Ferrite number

(SAIC-W-2030)

checks shall be performed at the same frequency as specified above

(Item B8) for chemical composition analyses.

For service temperatures below 427°C, the chemical analysis results shall

SAES-W-014,

be used to calculate the ferrite content using the DeLong diagram. If

Para. 6.6

B10 calculated ferrite content is not between 3 & 10 FN, then actual ferrite

measurements shall be taken on production piece. The measured Ferrite

(SAIC-W-2030)

Number shall be between 3 and 10 FN.

First layer of multi-layer overlays shall be PT examined per ASME SEC

SAES-W-014,

VIII D1, App 8 (equivalent to ASME SEC VIII D2, Art 9-2). Area examined

B11 Para. 6.7.1

shall be a 10 percent random coverage. If rejectable indications are found,

then the entire area shall be 100% examined.

Final layer, incl. single layer overlays shall be PT'd, over the entire area

(100%) per the same code criteria above (item B11).

The examination shall be conducted on the surface in its

SAES-W-014,

final

B12 Para. 6.7.2

condition, i.e., as-welded or machined. The examination shall be

conducted after the final PWHT, if PWHT is specified.

Notes: Perform an additional examination prior to

PWHT in order to find and repair any defects prior to PWHT.

SAES-W-014,

Ferroxyl test, shall be performed to determine the extent and nature of the

B13 Para. 6.7.2

cracking if determined that extensive cracking or fissuring has occurred.

Requirement for Repair Disposition (Ferroxyl Test)

A ferroxyl or ferricyanide test is an iron contamination test to determine if

SAES-W-014,

the cracking extends to the base metal. If iron contamination is found,

Para. 6.7.2

then the overlay shall be repaired by complete removal of the overlay to

B14

base metal in the area of fissuring prior to rewelding. If iron contamination

(SAIC-W-2026)

is not found, then only localized repairs are required (i.e., the excavations

only need to be large enough to completely remove the defect

indications).

REPAIRS TO OVERLAYS:

Repairs to overlays shall be performed by removing the defect by

machining or grinding (thermal methods are not permitted). Removal of SAES-W-014,

B15 the overlay defect shall not reduce the base metal thickness below the Para. 6.8

minimum design thickness. The repair area shall be welded using an

approved overlay procedure with a nominal composition that shall match

the original overlay composition.

VISUAL INSPECTION CRITERIA:

Finished overlay surface shall be free of overlaps, SAES-W-014,

B16 undercutting, & notches & shall be relatively smooth. All flux & slag are Para. 6.9

removed completel. Only SS brushes, ceramic (glass) beads, iron-free

grit, or SS grit shall be used to mechanically clean the overlay surfaces.

Saudi Aramco: Company General Use

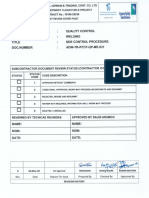

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review Supplemental Procedure - Method Statements

SAIC-W-2018 24-Mar-16 MECH-

related to Overlay Welding, Cladding Restoration, Repair

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Base Metal cladding or Overlay shall be stripped back 10 mm from each

side of weld joint prior to welding base metal portion of weld. Complete

SAES-W-014,

removal of the cladding/overlay shall be verified by a suitable etching test

B17 Para. 6.10

or chemical analysis of stripped back surface.

Note: Suitable etchants incl nitric acid or nital.

SAES-W-014,

After welding base metal portion of the joint, the side of the weld to be

B18 Para. 6.10

overlaid shall be ground flush using mechanical methods.

Hardness Testing shall be in accordance with standard drawing AB-

036386.The amximum allowable hardness is VHN 250 for the base metal.

For sour service, SAES-A-301 reqmts for weld metal overlay (Production

Hardness Testing) must be met. SAES-W-014,

Hardness testing is required for weld overlays in: Para

B19 A) Hydrogen service components of any wall thickness. 5.11.2

B) Sour service components of any wall thickness. (SAIC-W-

C) For pressure vessels in any service if the base metal wall thickness is 2012)

greater than 38 mm.

Only CSD may waive Production Hardness Testing Reqmts

Hydrogen Disbonding Test Supplement:

In high temperature, high pressure hydrogen service, the SAES-W-014,

B20 special requirements of SAES-W-014, Section 7 shall be met Section 7

REFER TO SAIC-W-2020 for Details.

REMARKS:

REFERENCE DOCUMENT: 1. SAES-W-010, Welding Requirements for Pressure Vessels, (08 September 2012)

2. SAES-W-014, Weld Overlays and Welding of Clad Materials, (11 March 2013)

3. ASME SEC VIII D1 Pressure Vessels (2013 Edition)

4. ASME SEC VIII D2 Pressure Vessels, Alternative Rules (2013 Edition)

5. ASME SEC IX Welding and Brazing Qualifications (2013 Edition)

6. AWS A4.2 Std Proc for Calibrating Magnetic Instr to Measure Delta Ferrite Content of Austenitic & Duplex Austenitic-Ferritic SS Weld Metal

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Me2207 Manufacturing Technology I Lab ManualDocument71 pagesMe2207 Manufacturing Technology I Lab ManualKarthick N91% (11)

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapNo ratings yet

- SAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTDocument2 pagesSAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTnisha_khanNo ratings yet

- Welding Journal 1960 5Document157 pagesWelding Journal 1960 5AlexeyNo ratings yet

- Perform Brazing-Silver Soldering PDFDocument33 pagesPerform Brazing-Silver Soldering PDFtereve100% (1)

- Saudi Aramco piping inspection planDocument2 pagesSaudi Aramco piping inspection planMuhammad Farukh Manzoor100% (1)

- Wave Solder TaguchiDocument6 pagesWave Solder TaguchivictoreaNo ratings yet

- Saep 324Document13 pagesSaep 324Up WeldNo ratings yet

- Technology Examination Questions (Multi-Cohice Exam) : Duties Before WeldingDocument6 pagesTechnology Examination Questions (Multi-Cohice Exam) : Duties Before WeldingvickyNo ratings yet

- Saudi Aramco Precast Concrete Installation PlanDocument10 pagesSaudi Aramco Precast Concrete Installation PlanNaushad AlamNo ratings yet

- Duston - Radio Construction For The AmateurDocument41 pagesDuston - Radio Construction For The AmateurLeon Ziegler100% (1)

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsFrom EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsNo ratings yet

- SAUDI ARAMCO BOILER INSPECTION PLANDocument4 pagesSAUDI ARAMCO BOILER INSPECTION PLANAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatDocument3 pagesSaudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatMoghal AliNo ratings yet

- ISO9001-2015 Quality Management System Assessment ChecklistDocument37 pagesISO9001-2015 Quality Management System Assessment ChecklistAbrahamNdewingoNo ratings yet

- SAEP-321 Performance Qualification Testing and Certification of Saudi Aramco WeldersDocument28 pagesSAEP-321 Performance Qualification Testing and Certification of Saudi Aramco WeldersSergey KichenkoNo ratings yet

- Satip D 001 01Document11 pagesSatip D 001 01Rijwan Mohammad0% (1)

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Document2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Document2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadNo ratings yet

- 17 Samss 006Document13 pages17 Samss 006Ahamedulla KhanNo ratings yet

- Saudi Aramco Inspection Checklist: Weld Overlay Chemical Composition Testing & Results SAIC-W-2025 24-Mar-16 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Weld Overlay Chemical Composition Testing & Results SAIC-W-2025 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Tle CSS Module 5 - Terminating and Connecting Electrical Wiring and Electronic CircuitDocument31 pagesTle CSS Module 5 - Terminating and Connecting Electrical Wiring and Electronic CircuitCrauxz de TraxNo ratings yet

- Saep 306Document15 pagesSaep 306nadeem shaikh100% (1)

- 09 Samss 030Document8 pages09 Samss 030Kalanithi KasirajanNo ratings yet

- III. Applicable Codes & Standards for Aramco ProjectsDocument5 pagesIII. Applicable Codes & Standards for Aramco ProjectsZain Ali KidwaiNo ratings yet

- Saep 119Document12 pagesSaep 119brecht1980No ratings yet

- SCH.Q - Contract No.6600044663 (IK)Document81 pagesSCH.Q - Contract No.6600044663 (IK)kamilNo ratings yet

- Assoc. Pip RESP003S: Data SheetDocument4 pagesAssoc. Pip RESP003S: Data SheetRijwan MohammadNo ratings yet

- Gold RecoveryDocument9 pagesGold RecoveryJoe MartinNo ratings yet

- Welding Standards for Corrosion-Resistant Piping MaterialsDocument10 pagesWelding Standards for Corrosion-Resistant Piping MaterialsRaj AryanNo ratings yet

- Other NDT TechniquesDocument12 pagesOther NDT TechniquesabyNo ratings yet

- Inconel 600 PDFDocument16 pagesInconel 600 PDF孙俊磊100% (1)

- Engineering Encyclopedia: Protective Coating ApplicationDocument24 pagesEngineering Encyclopedia: Protective Coating ApplicationAnonymous S9qBDVkyNo ratings yet

- Project Report On Aluminium Ingot ScrapDocument9 pagesProject Report On Aluminium Ingot ScrapSachin Sharma67% (3)

- Saudi Aramco Typical Inspection Plan: Fireproofing Concrete SATIP-B-006-01 14-May-18 CivilDocument11 pagesSaudi Aramco Typical Inspection Plan: Fireproofing Concrete SATIP-B-006-01 14-May-18 CivilKhurram ShehzadNo ratings yet

- Adw TR RTCF QP Me 002, Rev.1Document38 pagesAdw TR RTCF QP Me 002, Rev.1Rijwan MohammadNo ratings yet

- A A A A A A: Saudi Aramco Inspection ChecklistDocument2 pagesA A A A A A: Saudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Preparing Saudi Aramco Engineering StandardsDocument9 pagesPreparing Saudi Aramco Engineering StandardsDemac SaudNo ratings yet

- SATIP B 019 01 (Revision 4)Document2 pagesSATIP B 019 01 (Revision 4)Anonymous 4e7GNjzGWNo ratings yet

- Inspect Weld OverlaysDocument3 pagesInspect Weld OverlaysRijwan MohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- Auxiliary Piping SpecificationDocument11 pagesAuxiliary Piping SpecificationZubair RaoofNo ratings yet

- Saep 119Document11 pagesSaep 119Demac SaudNo ratings yet

- Saes X 800Document12 pagesSaes X 800SIVANo ratings yet

- RFI (Blank)Document1 pageRFI (Blank)SajjadPervaizNo ratings yet

- Saep 325Document43 pagesSaep 325AbdullahNo ratings yet

- Radiographic Examination Engineering ProcedureDocument30 pagesRadiographic Examination Engineering Proceduredanielpradeep100% (1)

- 01 Samss 031Document3 pages01 Samss 031Awais CheemaNo ratings yet

- Saes Q 004Document24 pagesSaes Q 004AasimNo ratings yet

- Saep 351Document24 pagesSaep 351Raj KumarNo ratings yet

- Saes A 114Document26 pagesSaes A 114abaanNo ratings yet

- SAIC-Q-1041 Asphalt Pavement Prime Coat & Tack Coating InspectionDocument10 pagesSAIC-Q-1041 Asphalt Pavement Prime Coat & Tack Coating InspectionAbdul HannanNo ratings yet

- Saudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliDocument5 pagesSaudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliShahbaz AhmadNo ratings yet

- Satip e 007 01Document2 pagesSatip e 007 01Anonymous 4e7GNjzGWNo ratings yet

- Inspection Procedure for Determining Retirement Thickness of PipingDocument6 pagesInspection Procedure for Determining Retirement Thickness of Pipingmalika_00No ratings yet

- 175-026600 10312016Document2 pages175-026600 10312016Prasanna UmapathyNo ratings yet

- Saudi Aramco tank inspection requirementsDocument2 pagesSaudi Aramco tank inspection requirementssridhar100% (1)

- Saudi Aramco Inspection Checklist: Gravity Sewer Piping Installation Inspection SAIC-L-2138 25-May-05 PlumbDocument3 pagesSaudi Aramco Inspection Checklist: Gravity Sewer Piping Installation Inspection SAIC-L-2138 25-May-05 PlumbHesham HelalNo ratings yet

- Inspection Procedure EDRDocument8 pagesInspection Procedure EDRaamirtec301No ratings yet

- Satip - S-050-01Document4 pagesSatip - S-050-01LIJINNo ratings yet

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNo ratings yet

- Schedule B - Attachment IVDocument29 pagesSchedule B - Attachment IVAbdul Ahad LoneNo ratings yet

- SATIP S 070 02 Irrigation PipingDocument2 pagesSATIP S 070 02 Irrigation PipingMuhammad Farukh ManzoorNo ratings yet

- Saes H 201Document9 pagesSaes H 201heartbreakkid132No ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- Saep 397Document9 pagesSaep 397munnaNo ratings yet

- Saudi Aramco Inspection Checklist: FBE Rebar & Embedments Receiving Inspection SAIC-Q-1007 15-Nov-17 MAH-SA-CDocument3 pagesSaudi Aramco Inspection Checklist: FBE Rebar & Embedments Receiving Inspection SAIC-Q-1007 15-Nov-17 MAH-SA-CAbdul HannanNo ratings yet

- Asset Integrity Management A Complete Guide - 2020 EditionFrom EverandAsset Integrity Management A Complete Guide - 2020 EditionNo ratings yet

- SAEP - 306 Evaluating The Safe Operating Pressure of Corroded PipeDocument2 pagesSAEP - 306 Evaluating The Safe Operating Pressure of Corroded PipeSalik SiddiquiNo ratings yet

- Vertical Submerged Pump Data SheetDocument4 pagesVertical Submerged Pump Data SheetRijwan MohammadNo ratings yet

- ADW-TR-RTCF-QP-ME-021 Rev-01Document20 pagesADW-TR-RTCF-QP-ME-021 Rev-01Rijwan MohammadNo ratings yet

- Overseas Assignment 11 JuneDocument6 pagesOverseas Assignment 11 JuneRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-Y-2001 24-Mar-16 MechDocument2 pagesSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-Y-2001 24-Mar-16 MechRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Hydrogen Disbonding Test (Qualification Testing Reqmt) SAIC-W-2020 24-Mar-16 MechDocument3 pagesSaudi Aramco Inspection Checklist: Hydrogen Disbonding Test (Qualification Testing Reqmt) SAIC-W-2020 24-Mar-16 MechRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestDocument4 pagesSaudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestRijwan MohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Adw TR RTCF QP Me 021Document18 pagesAdw TR RTCF QP Me 021Rijwan MohammadNo ratings yet

- Purchase Order .:: TR Ras Tanura Refinery Clean Fuels Project Electro-Mechanical Works - Ap4 & Ap5Document1 pagePurchase Order .:: TR Ras Tanura Refinery Clean Fuels Project Electro-Mechanical Works - Ap4 & Ap5Rijwan MohammadNo ratings yet

- Satip G 006 0122Document10 pagesSatip G 006 0122Rijwan MohammadNo ratings yet

- Satip A 104 03eeDocument10 pagesSatip A 104 03eeRijwan MohammadNo ratings yet

- Saep 29Document10 pagesSaep 29Rijwan MohammadNo ratings yet

- Satip F 001 04Document13 pagesSatip F 001 04Rijwan MohammadNo ratings yet

- Satip A 004 04JJDocument10 pagesSatip A 004 04JJRijwan MohammadNo ratings yet

- Satip H 002 02Document10 pagesSatip H 002 02Rijwan MohammadNo ratings yet

- Satip G 005 01Document11 pagesSatip G 005 01Rijwan MohammadNo ratings yet

- Litz Wire Termination GuideDocument5 pagesLitz Wire Termination GuideBenjamin DoverNo ratings yet

- Introduction to Welding Processes and ApplicationsDocument34 pagesIntroduction to Welding Processes and ApplicationsPierre NorrisNo ratings yet

- Adm1602k Nsa Fbs 3.3vDocument22 pagesAdm1602k Nsa Fbs 3.3vHer ManTokNo ratings yet

- UTP Chemical GBDocument12 pagesUTP Chemical GBajaychackotecsoNo ratings yet

- Developments in Blast Furnace Process Control at Port Kembla BaseDocument13 pagesDevelopments in Blast Furnace Process Control at Port Kembla BaseBinod Kumar PadhiNo ratings yet

- Hot rolled steel cleaning method between rolling operations quizDocument6 pagesHot rolled steel cleaning method between rolling operations quizRuthNo ratings yet

- 001-CEN Welding and Allied Processes - CEN TC 121Document17 pages001-CEN Welding and Allied Processes - CEN TC 121Pradip Tapan BanerjeeNo ratings yet

- Product Catalog: Bavaria SchweisstechnikDocument152 pagesProduct Catalog: Bavaria SchweisstechnikFilipe CordeiroNo ratings yet

- Glass Beads by Borate Fusion - tcm50-54735Document60 pagesGlass Beads by Borate Fusion - tcm50-54735Hernán Alejandro Rosero VegaNo ratings yet

- M2 CorrosionDocument13 pagesM2 CorrosionMalvika RkNo ratings yet

- Aoyue 936a 936Document12 pagesAoyue 936a 936rabas_No ratings yet

- Blazing Vs SolderingDocument2 pagesBlazing Vs SolderingAsif HassanNo ratings yet

- IRSM-46-13 With Amendment 2016Document29 pagesIRSM-46-13 With Amendment 2016Våïbhäv Çhåühåñ100% (1)

- TB 870-25 FluxDocument2 pagesTB 870-25 FluxBéla BődiNo ratings yet

- Non-Ferrous Extractive MetallurgyDocument79 pagesNon-Ferrous Extractive MetallurgyArindam BhowmickNo ratings yet

- Strip Cladding EngDocument24 pagesStrip Cladding EngVassoula DarNo ratings yet

- Computer Systems Servicing 1st Semester Module 3 Wires and Cables Tools Jointing and SolderingDocument12 pagesComputer Systems Servicing 1st Semester Module 3 Wires and Cables Tools Jointing and SolderingJoyNo ratings yet

- Joining ProcessesDocument10 pagesJoining ProcessesSachin KhotNo ratings yet

- Principles of Metallurgical OperationsDocument38 pagesPrinciples of Metallurgical OperationsMuhammad Saim100% (1)

- Mft-I Two & 13 Marks QuestionDocument16 pagesMft-I Two & 13 Marks QuestionrahulNo ratings yet

- KOBE Steel SS Weld Filler Tables and Comparison SMAW GTAW SAW FCAW KWT - SUS - 3edDocument22 pagesKOBE Steel SS Weld Filler Tables and Comparison SMAW GTAW SAW FCAW KWT - SUS - 3edlram70No ratings yet