Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist

Uploaded by

Rijwan MohammadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist

Uploaded by

Rijwan MohammadCopyright:

Available Formats

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.

01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

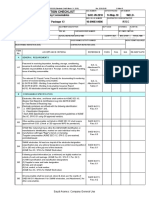

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A General requirements

All weld documents shall be submitted to SA for technical approval

prior to start of work (per SAEP-352). The Welding documents

SAES-W-010,

include the Welding Procedure Specifications (WPS), Qualification

A1 Section 7.1.1 &

Test Records (PQR), Weld Description & Weld Map (Attachment 3)

7.1.9

See Attachment 1.

Originals of all test records, mill certificates, etc. including records

SAES-W-010,

A2 from independent test laboratory shall be made available for review

Para. 7.1.11

by Saudi Aramco upon request.

WPSs, PQRs, Weld Maps, & Weld Descriptions shall be available at SAES-W-010,

A3

work site for verification at any time by authorized SA inspector. Para. 7.1.8

For shop fabrication In-Kingdom and all field fabrication and

installation, the Welding Procedure Specifications (WPSs) and

Procedure Qualification Records (PQRs) shall be prepared as per

SAES-W-010,

A4 format of ASME Section IX (NMA App. B). See Attachment 2.

Para. 7.1.3

Commentary Note: Standardized PQR forms from an approved

independent test laboratory are acceptable. Equivalent WPS form

from a contractor may be acceptable if approved by CSD.

All corrosion-resistant weld overlays, including clad restoration, shall

conform with ASME SEC VIII reqts (Div. 1 or Div. 2) & W-014. SAES-W-014,

A5

Commentary Note: Refer to ASME SEC VIII D1, Part UCL and Para. 4.1

ASME SEC VIII D2, Article F-5 for specific requirements.

Repairs to integrally clad material shall not be done without the

SAES-W-014,

A6 specific approval of CSD. Any weld repairs to the cladding shall

Para. 4.7

meet the requirements for weld overlays.

The minimum deposit thickness shall be specified in the engineering

SAES-W-014,

A7 design but shall not be less than 3 mm for corrosion-resistant

Para. 4.2

overlays.

The direction of overlay deposition shall be circumferential unless

otherwise approved by CSD.

SAES-W-014,

A8 Commentary Note: Some components and geometries, such as

Para. 4.3

small diameter nozzles, or special applications may not permit

welding in a circumferential direction.

Single layer overlays require prior approval by CSD. Additional

SAES-W-014,

A9 qualification and production tests may be required, as determined by

Para. 4.9

CSD.

Ferrite measurements shall be performed in accordance with AWS SAES-W-014,

A10

A4.2 Para. 4.8

SAES-W-014,

A11 All chemical analysis methods shall conform to ASME/ASTM A751.

Para. 4.11

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

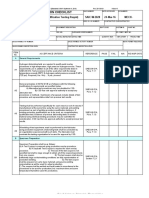

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

B Overlay Procedure Qualification Requirements

All weld overlays shall be qualified in accordance with ASME SEC SAES-W-014,

B1

IX. Para. 5.1

The WPS shall indicate the minimum deposit thickness qualified and

the minimum number of layers required. The number of layers used

SAES-W-014,

B2 for the Procedure Qualification Record (PQR) shall be recorded and

Para. 5.2

shall be the minimum number of layers specified on the WPS and

used in production.

For all processes and all layers, the heat input specified on the WPS

SAES-W-014,

B3 shall not exceed the heat input recorded on the PQR by more than

Para. 5.3

10%.

For the SAW and Electro-slag processes, any change in the flux

SAES-W-014,

B4 brand, trade name, or designation shall be considered an essential

Para. 5.4

variable.

For single layer weld overlays, any decrease in overlap (As stated in

PQR) between adjacent beads needs requalification. SAES-W-014,

B5

Note: The overlap or spacing must be measured and recorded on Para. 5.5

the PQR and specified on the WPS.

The following elements shall be analyzed and specified for the

deposit chemistry for all stainless steel and nickel-based alloy weld

metal overlays:

SAES-W-014,

B6 C, Ni, Cr, Cu, Mo, Mn, Fe, plus any other significant elements that

Para. 5.6

are intentionally added to either the base metal or filler metal (e.g.,

Nb or Ti for stabilized stainless steel grades).

The chemistry of the overlay shall be measured at 1.5 mm below the

minimum specified overlay thickness. This is regardless of the SAES-W-014,

B7

thickness of the as-welded deposited thickness in the procedure Para. 5.7

qualification.

Inconel Alloy N06625 overlays shall have a maximum iron content of

SAES-W-014,

B8 10%.

Para. 5.7

Monel overlays shall have a maximum iron content of 4.5%.

The chemical composition of weld deposit shall be within the range

SAES-W-014,

B9 specified for the UNS number of the CRA clad material except for

Para. 5.8

the iron.

For PMI, the chemistry shall be checked on the final finished surface

of the production weld overlay.

SAES-W-014,

B10 Commentary Note:

Para. 5.9

Note: For overlay materials other than those listed above, the

elements to be analyzed shall be specified by CSD.

For austenitic stainless steel weld overlays, the ferrite content shall

SAES-W-014,

B11 be checked in the as-welded condition and shall be between 3 and

Para. 5.10

10 FN.

PQR hardness testing is required for weld overlays in:

a) Hydrogen service components of any wall thickness.

b) Sour service components of any wall thickness. SAES-W-014,

B12

c) For pressure vessels in any service if the base metal wall Para. 5.11

thickness is greater than 38 mm.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

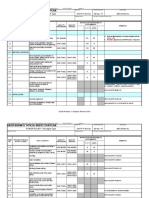

Hardness testing shall be in accordance with Standard Drawing AB-

036386. The maximum allowable hardness is VHN 250 for the base

metal and HAZ of all overlays and for the weld metal deposit of

austenitic stainless steel corrosion-resistant overlays.

Note: The hardnesses for the weld deposit of hardfacing overlays

SAES-W-014,

B13 and nickel-based corrosion-resistant overlays will depend on the

overlay material and the application. For sour service applications, Para. 5.11

NACE MR0175/ISO 15156 requirements for the weld metal overlay

must be met.

Hydrogen disbonding tests are additionally required to qualify weld

overlay procedures when both the design temperature exceeds

SAES-W-014,

B14 350°C and the hydrogen partial pressure exceeds 5 MPa. (Also see

Para. 7.1.1

SAIC-W-2020)

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

C Qualification of Welders & Welding operators for Weld Overlays

SAES-W-014,

All welders & welding operators for weld overlays shall be qualified

C1 Para. 4.10;

per ASME SEC IX QW-380.

ASME Sec IX

REMARKS:

REFERENCE DOCUMENT: 1. SAES-W-010, Welding Requirements for Pressure Vessels, (08 September 12.)

2. SAES-W-014, Weld Overlays and Welding of Clad Materials, (11 March 2013)

3. ASME SEC VIII D1 Pressure Vessels (2013 Edition)

4. ASME SEC VIII D2 Pressure Vessels, Alternative Rules (2013 Edition)

5. ASME SEC IX Welding and Brazing Qualifications (2013 Edition)

6. AWS A4.2 Std Proc for Calibrating Magnetic Instr to Measure Delta Ferrite Content of Austenitic & Duplex Austenitic-Ferritic SS Weld Meta

ATTACHMENTS:

Attachment 1 - SAES-W-010, Attachments A & B Weld Map & Weld Description Table

Attachment 2 - ASME IX, NMA APP. B, SAMPLE WPS & PQR FORMS

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

Attachment 1 - SAES-W-010, ATT. 3 Weld Map

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

Attachment 2 - ASME IX, NMA APP. B, SAMPLE WPS & PQR FORMS

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

Attachment 2 - ASME IX, NMA APP. B, SAMPLE WPS & PQR FORMS

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

Attachment 2 - ASME IX, NMA APP. B, SAMPLE WPS & PQR FORMS

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

Attachment 2 - ASME IX, NMA APP. B, SAMPLE WPS & PQR FORMS

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

Attachment 2 - ASME IX, NMA APP. B, Additional Forms (Info Only)

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

Attachment 2 - ASME IX, NMA APP. B, Additional Forms (Info Only)

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review of Welding documents - WPS, PQR and WPQ

related to Overlay Welding & Cladding SAIC-W-2017 24-Mar-16 WELD-

Restoration/Repair

Saudi Aramco: Company General Use

You might also like

- Spark Plug Material and Manufacturing ProcessDocument10 pagesSpark Plug Material and Manufacturing Processerrvent ensoiNo ratings yet

- Materials System SpecificationDocument11 pagesMaterials System Specificationimranb_001100% (1)

- Saep 321Document25 pagesSaep 321AbdullahNo ratings yet

- Assoc. Pip RESP003S: Data SheetDocument4 pagesAssoc. Pip RESP003S: Data SheetRijwan MohammadNo ratings yet

- B 36 - B 36M - 13Document9 pagesB 36 - B 36M - 13Ahmed BilalNo ratings yet

- Precipitation Hardening of Aluminum AlloysDocument7 pagesPrecipitation Hardening of Aluminum AlloysJen Astoveza100% (2)

- SAIC-W-2085 Pre-Welding Inspection PDFDocument4 pagesSAIC-W-2085 Pre-Welding Inspection PDFkarioke mohaNo ratings yet

- SAIC W 2069 in Process Welding InspectionDocument8 pagesSAIC W 2069 in Process Welding InspectionAbdul Gafoor ShaikhNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistJoni Carino SuniNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Inspect Weld OverlaysDocument3 pagesInspect Weld OverlaysRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco welding checklistDocument13 pagesSaudi Aramco welding checklistAnonymous S9qBDVky100% (1)

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- SAUDI ARAMCO POST-WELDING VISUAL INSPECTION CHECKLISTDocument6 pagesSAUDI ARAMCO POST-WELDING VISUAL INSPECTION CHECKLISTManoj KumarNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalpravinNo ratings yet

- SAIC-W-2015 Rev 7 (NDE Selection)Document17 pagesSAIC-W-2015 Rev 7 (NDE Selection)vijayachiduNo ratings yet

- Saudi Aramco Hardness Testing Procedure ReviewDocument3 pagesSaudi Aramco Hardness Testing Procedure ReviewphilipyapNo ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- 175 010300 PDFDocument2 pages175 010300 PDFAbu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistJoni Carino Suni100% (1)

- Saudi Aramco Inspection ChecklistDocument23 pagesSaudi Aramco Inspection ChecklistjahaanNo ratings yet

- Saudi Aramco Pipe Inspection RequirementsDocument2 pagesSaudi Aramco Pipe Inspection RequirementsAbu Anas M.Salaheldin100% (1)

- Saep 324Document13 pagesSaep 324Up WeldNo ratings yet

- Saic RT 2007Document9 pagesSaic RT 2007munnaNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-W-2032 24-Jul-18 Weld-Upgrade Aramco JNGLFP Propane System BI-21-00087 MacoDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-W-2032 24-Jul-18 Weld-Upgrade Aramco JNGLFP Propane System BI-21-00087 MacojahaanNo ratings yet

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechDocument3 pagesSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidNo ratings yet

- Saic W 2003Document14 pagesSaic W 2003Mohammed IlliasuddinNo ratings yet

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-Y-2001 24-Mar-16 MechDocument2 pagesSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-Y-2001 24-Mar-16 MechRijwan MohammadNo ratings yet

- Satr-W-2008 Atyb TRDocument6 pagesSatr-W-2008 Atyb TRDeo MNo ratings yet

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNo ratings yet

- Saep 31Document5 pagesSaep 31Anonymous 4IpmN7OnNo ratings yet

- Saic A 2011Document8 pagesSaic A 2011jerinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistAli AhmedNo ratings yet

- Oxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupsDocument6 pagesOxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupssanketNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection - Bolts, Nuts & Washers For Structural ConnectionsDocument6 pagesSaudi Aramco Inspection Checklist: Receiving Inspection - Bolts, Nuts & Washers For Structural ConnectionsAbdul HannanNo ratings yet

- SATIP-H-100-01 Rev 7Document2 pagesSATIP-H-100-01 Rev 7Satheesh Rama SamyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection ChecklistAli AhmedNo ratings yet

- 175 010700 PDFDocument2 pages175 010700 PDFAbu Anas M.SalaheldinNo ratings yet

- Saep 324 PDFDocument13 pagesSaep 324 PDFArvind ShakyaNo ratings yet

- SAUDI ARAMCO RADIOGRAPHIC TESTING INSPECTIONDocument24 pagesSAUDI ARAMCO RADIOGRAPHIC TESTING INSPECTIONmunnaNo ratings yet

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapNo ratings yet

- Saic D 2024Document9 pagesSaic D 2024Md ShariqueNo ratings yet

- Inspection Procedure EDRDocument8 pagesInspection Procedure EDRaamirtec301No ratings yet

- QW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) ExaminationDocument8 pagesQW-193 Tube To Tube-Sheet Mock Up and Macro (Etching) Examinationডঃ শুভম চ্যাটার্জীNo ratings yet

- SAUDI ARAMCO LPT INSPECTION PLANDocument3 pagesSAUDI ARAMCO LPT INSPECTION PLANDurga Jagan PuppalaNo ratings yet

- SAUDICHECK - WELD TRACKING DATABASEDocument5 pagesSAUDICHECK - WELD TRACKING DATABASEManoj KumarNo ratings yet

- SAIC-H-2010 Rev 7Document1 pageSAIC-H-2010 Rev 7Satheesh Rama SamyNo ratings yet

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- SAIC-L-2014 Flange Joint Insp PDFDocument7 pagesSAIC-L-2014 Flange Joint Insp PDFAnonymous S9qBDVkyNo ratings yet

- Review PWHT Specs, Procedures and TablesDocument19 pagesReview PWHT Specs, Procedures and TablesIrshad IqbalNo ratings yet

- Saep 351Document24 pagesSaep 351Raj KumarNo ratings yet

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Finishing and Curing Inspection SAIC-Q-1015 15-Nov-17 MAH-SA-CDocument4 pagesSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Finishing and Curing Inspection SAIC-Q-1015 15-Nov-17 MAH-SA-CAbdul HannanNo ratings yet

- Saudi Aramco Test ReportDocument4 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saes D 008Document21 pagesSaes D 008Shajin Mohammed ShamsudhinNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Document2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadNo ratings yet

- 175 014301 PDFDocument2 pages175 014301 PDFAbu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatDocument3 pagesSaudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatMoghal AliNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestDocument4 pagesSaudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldDocument27 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldIrshad IqbalNo ratings yet

- ISO9001-2015 Quality Management System Assessment ChecklistDocument37 pagesISO9001-2015 Quality Management System Assessment ChecklistAbrahamNdewingoNo ratings yet

- Vertical Submerged Pump Data SheetDocument4 pagesVertical Submerged Pump Data SheetRijwan MohammadNo ratings yet

- SAEP - 306 Evaluating The Safe Operating Pressure of Corroded PipeDocument2 pagesSAEP - 306 Evaluating The Safe Operating Pressure of Corroded PipeSalik SiddiquiNo ratings yet

- Adw TR RTCF QP Me 002, Rev.1Document38 pagesAdw TR RTCF QP Me 002, Rev.1Rijwan MohammadNo ratings yet

- Inspect Weld OverlaysDocument3 pagesInspect Weld OverlaysRijwan MohammadNo ratings yet

- Overseas Assignment 11 JuneDocument6 pagesOverseas Assignment 11 JuneRijwan MohammadNo ratings yet

- ADW-TR-RTCF-QP-ME-021 Rev-01Document20 pagesADW-TR-RTCF-QP-ME-021 Rev-01Rijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestDocument4 pagesSaudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestRijwan MohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Weld Overlay Chemical Composition Testing & Results SAIC-W-2025 24-Mar-16 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Weld Overlay Chemical Composition Testing & Results SAIC-W-2025 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-Y-2001 24-Mar-16 MechDocument2 pagesSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-Y-2001 24-Mar-16 MechRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Hydrogen Disbonding Test (Qualification Testing Reqmt) SAIC-W-2020 24-Mar-16 MechDocument3 pagesSaudi Aramco Inspection Checklist: Hydrogen Disbonding Test (Qualification Testing Reqmt) SAIC-W-2020 24-Mar-16 MechRijwan MohammadNo ratings yet

- Satip F 001 04Document13 pagesSatip F 001 04Rijwan MohammadNo ratings yet

- Technology Examination Questions (Multi-Cohice Exam) : Duties Before WeldingDocument6 pagesTechnology Examination Questions (Multi-Cohice Exam) : Duties Before WeldingvickyNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Document2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadNo ratings yet

- Purchase Order .:: TR Ras Tanura Refinery Clean Fuels Project Electro-Mechanical Works - Ap4 & Ap5Document1 pagePurchase Order .:: TR Ras Tanura Refinery Clean Fuels Project Electro-Mechanical Works - Ap4 & Ap5Rijwan MohammadNo ratings yet

- Adw TR RTCF QP Me 021Document18 pagesAdw TR RTCF QP Me 021Rijwan MohammadNo ratings yet

- Satip A 104 03eeDocument10 pagesSatip A 104 03eeRijwan MohammadNo ratings yet

- Satip A 004 04JJDocument10 pagesSatip A 004 04JJRijwan MohammadNo ratings yet

- Saep 29Document10 pagesSaep 29Rijwan MohammadNo ratings yet

- Satip G 006 0122Document10 pagesSatip G 006 0122Rijwan MohammadNo ratings yet

- Satip D 001 01Document11 pagesSatip D 001 01Rijwan Mohammad0% (1)

- Satip H 002 02Document10 pagesSatip H 002 02Rijwan MohammadNo ratings yet

- Satip G 005 01Document11 pagesSatip G 005 01Rijwan MohammadNo ratings yet

- ASTM A352 18aDocument7 pagesASTM A352 18aKelly BatesNo ratings yet

- DT13 PDFDocument328 pagesDT13 PDFRaul CostiniucNo ratings yet

- Welding DefectsDocument36 pagesWelding DefectsAmit SharmaNo ratings yet

- Pure Substances:: Elements and CompoundsDocument51 pagesPure Substances:: Elements and CompoundsMaria Kristelle Alejandro PaltaoNo ratings yet

- Ingles 3Document6 pagesIngles 3DIEGO ALEJANDRO PRADA ACOSTANo ratings yet

- SG Acicular Martensitic Iron PropertiesDocument2 pagesSG Acicular Martensitic Iron PropertiesTarun ChakrabortyNo ratings yet

- GalvInfoNote - 3 - 1 How Zinc Protects SteelDocument6 pagesGalvInfoNote - 3 - 1 How Zinc Protects SteelKYAW SOE100% (1)

- 7 Skarn Deposits PDFDocument24 pages7 Skarn Deposits PDFFerdinand Torres100% (2)

- VNT Brochure NewDocument5 pagesVNT Brochure Newda vin ciNo ratings yet

- Allowable Stresses of Typical ASME Materials - Carbon Steel SA 516 Gr.70Document3 pagesAllowable Stresses of Typical ASME Materials - Carbon Steel SA 516 Gr.70Muhammed Mudafi ElhaqNo ratings yet

- MCQ SOET DE MINING BRANCH 5TH SEM Advance Mining GeologyDocument8 pagesMCQ SOET DE MINING BRANCH 5TH SEM Advance Mining GeologyPRAVEEN YADAWNo ratings yet

- Astm A36 Chapa Grossa Ate 19mm PDFDocument1 pageAstm A36 Chapa Grossa Ate 19mm PDFHugo RodriguezNo ratings yet

- Spring MaterialsDocument3 pagesSpring MaterialsS. VeeravelNo ratings yet

- Kesterite, Cu2 (ZN, Fe) SNS+, and Stannite, Cuz (Fezn) $nsa, Structurally Similar But Distinct MineralsDocument7 pagesKesterite, Cu2 (ZN, Fe) SNS+, and Stannite, Cuz (Fezn) $nsa, Structurally Similar But Distinct MineralsrohitmahaliNo ratings yet

- B197B197M-07 (Reapproved 2013)Document6 pagesB197B197M-07 (Reapproved 2013)AtlanticNo ratings yet

- EnDOtec Welding Cored WireDocument12 pagesEnDOtec Welding Cored WirecriuvosNo ratings yet

- Astm B 98M-98Document5 pagesAstm B 98M-98Fa ChNo ratings yet

- Glass Ceramics QuizDocument3 pagesGlass Ceramics QuizRon Pascual100% (1)

- MAT 3421 Data SheetDocument3 pagesMAT 3421 Data SheetDiógenes da Silva Pereira100% (1)

- Convert WT% To At% (And Reserve) in An Alloy-Ver.2Document13 pagesConvert WT% To At% (And Reserve) in An Alloy-Ver.2HanLe DuyNo ratings yet

- Wall Colmonoy Corp Colmonoy 200 Series TDS April2020Document3 pagesWall Colmonoy Corp Colmonoy 200 Series TDS April2020santiago aguileraNo ratings yet

- 1.2210 115crv3Document2 pages1.2210 115crv3Eduardo DelfinoNo ratings yet

- MINERALS AND ROCKS. DemoDocument32 pagesMINERALS AND ROCKS. DemoChrisma BehaganNo ratings yet

- Please Pay 600rs For Three Month For Gold Rate ServiceDocument2 pagesPlease Pay 600rs For Three Month For Gold Rate ServiceMuhammad AbdullahNo ratings yet

- SDSDFSDDocument1 pageSDSDFSDrajuNo ratings yet

- Ceramic Injection Molding (CIM)Document3 pagesCeramic Injection Molding (CIM)Metal PartsNo ratings yet

- Quiz 1 MED 201Document4 pagesQuiz 1 MED 201Himanshu PathakNo ratings yet