Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist: Weld Overlay Chemical Composition Testing & Results SAIC-W-2025 24-Mar-16 Weld

Uploaded by

Rijwan MohammadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist: Weld Overlay Chemical Composition Testing & Results SAIC-W-2025 24-Mar-16 Weld

Uploaded by

Rijwan MohammadCopyright:

Available Formats

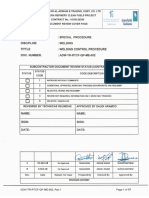

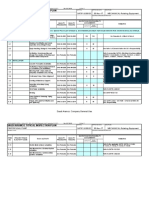

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.

01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Weld Overlay Chemical Composition Testing & Results SAIC-W-2025 24-Mar-16 WELD-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

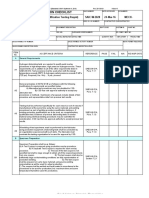

A General Requirements

Final weld overlay surface ( Machined surface as applicable) shall have

the chemical composition as required and checked prior to final PWHT or SAES-W-014,

A1

Para. 6.4

hydrotest.

Final weld overlay surface shall have the chemical composition checked

using :

A) Physical sample (drillings) removed for quantitative analysis OR

SAES-W-014,

A2 B) Portable spectrograph. With the specific approval of SA Insp, a

Para. 6.4

portable X-ray fluorescence machine may be used instead of a

spectrograph.All elements specified for deposit chemistry shall be

analyzed and reported, except for carbon when using the X-ray

fluorescence method.

Inspection has reviewed and approved chemical composition analysis

SAES-W-014,

A3 method & accuracy limits for each element.

Para. 6.4

B Extent of Testing

Automatic Welding:

One analysis for each overlay area or clad joint. Separate SAES-W-014,

B1 analyses shall be made for each heat/batch* of filler metal or electrode. Para. 6.5

Manual Welding (2 possible applications):

A) One analysis for each 1 m sq. of

SAES-W-014,

B2 area OR B) One analysis at intervals of 2 m

Para. 6.5

or less for overlay restoration of clad joints.

For service temps below 427°C, chemical analysis results shall be used

to calculate the ferrite content using the DeLong diagram.

SAES-W-014,

If calculated ferrite content is not between 3 & 10 FN, then:

Para. 6.6

B3 A) Utilize SAIC-W-2030 & SATR-W-2016

B) Take ferrite measurements on overlay welds.

(SAIC-W-2030)

C) Measured Ferrite Number shall be between

3 & 10 FN.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 24-Mar-2016 - REV. 2015.09.01 (Standards Cutoff - September 6, 2015) Rev. 2015.09.01 6-Sep-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Weld Overlay Chemical Composition Testing & Results SAIC-W-2025 24-Mar-16 WELD-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

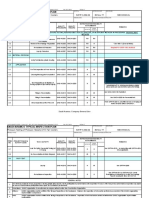

C TEST RESULTS

Following elements shall be analyzed for the deposit chemistry of SS &

Nickel-based alloy weld metal overlays:

C, Ni, Cr, Cu, Mo, Mn, Fe, plus (Ti, Nb, Cb)*,

C1

(* Ti, Nb & Cb are used in stabilized SS) SAES-W-014,

For overlay matls other than those listed above, Para. 5.6

elements to be analyzed shall be specified by CSD.

Note: Inspection shall review and approve the chemical composition

analysis method & accuracy limits for each element. (SAES-W-14 Para

4.6)

For welding procedure qualification, the chemistry of the overlay shall be

measured at 1.5 mm below the minimum specified overlay thickness. This

is regardless of the thickness of the as-welded deposited thickness in the SAES-W-014,

C2

procedure qualification. Inconel Alloy N06625 overlays shall have a Para. 5.7

maximum iron content of 10%. Monel overlays shall have a maximum iron

content of 4.5%.

REMARKS:

REFERENCE DOCUMENT: 1. SAES-W-010, Welding Requirements for Pressure Vessels, (30 June 2013).

2. SAES-W-014, Weld Overlays and Welding of Clad Materials, (11 March 2013)

3. AWS A4.2, Standard Procedures for Calibrating Magnetic Instruments to Measure Delta Ferrite …, 1997

4. ASTM A751, Standard Test Methods, Practices and Terminology for Chemical Analysis of Steel Products, 2001

ATTACHMENTS:

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Saudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Inspect Weld OverlaysDocument3 pagesInspect Weld OverlaysRijwan MohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-Y-2001 24-Mar-16 MechDocument2 pagesSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-Y-2001 24-Mar-16 MechRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- 1.1 Welder Test 86,350,000: PackageDocument2 pages1.1 Welder Test 86,350,000: PackageAhmad Dzulfiqar RahmanNo ratings yet

- GasketsDocument20 pagesGasketsParthiban NagarajanNo ratings yet

- CCK VNT DuplexDocument4 pagesCCK VNT DuplexNikki RobertsNo ratings yet

- Cash Flow (S-CURVE) : Monthly Cashout Monthly Cashin Cum Cashout Cum CashinDocument6 pagesCash Flow (S-CURVE) : Monthly Cashout Monthly Cashin Cum Cashout Cum CashinZahra NoorNo ratings yet

- Schedule of Price - 0050 - Jakarta Transportation (DA)Document2 pagesSchedule of Price - 0050 - Jakarta Transportation (DA)Asep FirmansyahNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 MechDocument15 pagesSaudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Boq Working JharkhandDocument36 pagesBoq Working JharkhandsmithNo ratings yet

- Heater Erection Procedure PDFDocument7 pagesHeater Erection Procedure PDFhasan_676489616No ratings yet

- KOC Guide to Cathodic Protection of Steel Tank BottomsDocument32 pagesKOC Guide to Cathodic Protection of Steel Tank BottomsJigarNo ratings yet

- SATIP-N-001-02 Rev. 4Document2 pagesSATIP-N-001-02 Rev. 4Anonymous 4e7GNjzGW100% (1)

- ES.0.08.0002 Rev.B - Engineering Data Request Form PDFDocument1 pageES.0.08.0002 Rev.B - Engineering Data Request Form PDFSaravanan VaradarajanNo ratings yet

- 32 Samss 005 PDFDocument33 pages32 Samss 005 PDFRajan SteeveNo ratings yet

- FIRENZE FPSO Preservation Maintenance Project EstimationDocument1 pageFIRENZE FPSO Preservation Maintenance Project EstimationSriNo ratings yet

- 1 SATIP-L-450-04 Cross Country Buried Pipeline-Rev 1Document4 pages1 SATIP-L-450-04 Cross Country Buried Pipeline-Rev 1Bighneswar PatraNo ratings yet

- Galvanic Technique: An Overview ofDocument11 pagesGalvanic Technique: An Overview ofAnnie TahirNo ratings yet

- Inspection OF Fired Heaters: For Restricted CirulationDocument59 pagesInspection OF Fired Heaters: For Restricted Cirulationasif rahim100% (1)

- Esab, Ok 309L (29.12.16)Document1 pageEsab, Ok 309L (29.12.16)RodrigoNo ratings yet

- Job Procedure For Hydrotest/Water Fillup Test: 1. ScopeDocument3 pagesJob Procedure For Hydrotest/Water Fillup Test: 1. ScopeRebecca SchultzNo ratings yet

- CV Mechanical Engineer Project Manager 11 Years ExperienceDocument2 pagesCV Mechanical Engineer Project Manager 11 Years ExperienceDARA SINGHNo ratings yet

- Daily progress and safety report for offshore oil and gas projectDocument9 pagesDaily progress and safety report for offshore oil and gas projectSivaramkumarNo ratings yet

- KLM Intro Storage Tanks Rev 3Document7 pagesKLM Intro Storage Tanks Rev 3Bonzibit ZibitNo ratings yet

- Evaluation of Smartphone Feature Preference by A Modified AHP ApproachDocument5 pagesEvaluation of Smartphone Feature Preference by A Modified AHP ApproachSeu Ze NinguemNo ratings yet

- Casing Design Overview GuideDocument33 pagesCasing Design Overview GuideGhebache OtakuNo ratings yet

- Erection Tank Settlement Check Schedule 103 110 165Document8 pagesErection Tank Settlement Check Schedule 103 110 165hrdsby100% (1)

- KKPE/PBHS/WPC11/GF021/Rev 01Document6 pagesKKPE/PBHS/WPC11/GF021/Rev 01collinNo ratings yet

- Pttep Painitng of Offshore FacilitiesDocument66 pagesPttep Painitng of Offshore FacilitiesSufianNo ratings yet

- 6 Contractor QC Resume Review ChecklistDocument1 page6 Contractor QC Resume Review ChecklistMudabbir HussainNo ratings yet

- The Salt Spray Corrosion of Polymer Coating On Ste PDFDocument8 pagesThe Salt Spray Corrosion of Polymer Coating On Ste PDFrifkifirdausNo ratings yet

- 20 Preservation of Piping MaterialsDocument45 pages20 Preservation of Piping MaterialsDamar WardhanaNo ratings yet

- PDO Approved Inspection BodiesDocument15 pagesPDO Approved Inspection BodiesMohammed Rizwan AhmedNo ratings yet

- 3 Steel Structure Installation CLDocument2 pages3 Steel Structure Installation CLwhah11No ratings yet

- WPS & SmawDocument12 pagesWPS & Smawnuke apriyaniNo ratings yet

- IP02-Bend Check List 01Document1 pageIP02-Bend Check List 01Laith SalmanNo ratings yet

- Shutdown Activity Schedule 4 DaysDocument1 pageShutdown Activity Schedule 4 DaysvaibhavNo ratings yet

- Evolutionary Developments of Thermal Desalination PlantDocument15 pagesEvolutionary Developments of Thermal Desalination PlantIsrar SyahrirNo ratings yet

- MOG-HSEQ-P-005 Rev A3 Corporate HSE Training Awarness and Competence ProcedureDocument18 pagesMOG-HSEQ-P-005 Rev A3 Corporate HSE Training Awarness and Competence ProcedureSamerNo ratings yet

- Painting Specification for Petrochemical ProjectDocument62 pagesPainting Specification for Petrochemical ProjectAnbu AlagupandianNo ratings yet

- The NEW Company ProfileDocument26 pagesThe NEW Company ProfilewisandhaNo ratings yet

- Conversion Chart of Vickers Hardness (HV) To Rockwell C (HRC)Document1 pageConversion Chart of Vickers Hardness (HV) To Rockwell C (HRC)selvamNo ratings yet

- Concrete Finishing ProcedureDocument11 pagesConcrete Finishing ProcedureGaneshNo ratings yet

- 8474l-000-Jsd-2310-001-2-Protective CoatingDocument31 pages8474l-000-Jsd-2310-001-2-Protective Coatinglebienthuy100% (1)

- Sky Climber SparesDocument7 pagesSky Climber SparesshambhoiNo ratings yet

- Inspectable MaterialsDocument2 pagesInspectable MaterialsMohamed RedaNo ratings yet

- Khadimally RT011215Document33 pagesKhadimally RT011215jkj_13874No ratings yet

- IQWQ-FT-BSPDS-00-120111 - 0 Packing SpecDocument27 pagesIQWQ-FT-BSPDS-00-120111 - 0 Packing Specjacksonbello34No ratings yet

- LEI Contractor QC Plan574264890Document32 pagesLEI Contractor QC Plan574264890Marzelino InoferioNo ratings yet

- Coke Crusher - Lubrication Pumps Run in TestDocument26 pagesCoke Crusher - Lubrication Pumps Run in TestsayedNo ratings yet

- Cost Effective ConnectionsDocument14 pagesCost Effective ConnectionsMarakan MaranNo ratings yet

- Project CharterDocument4 pagesProject CharterFrancisco Botelho CarlosNo ratings yet

- Daily Report by Supervisor P1-3Document14 pagesDaily Report by Supervisor P1-3PHAM PHI HUNGNo ratings yet

- WelderPOT 2009finalDocument160 pagesWelderPOT 2009finalMayo de la PazNo ratings yet

- SAEP - 306 Evaluating The Safe Operating Pressure of Corroded PipeDocument2 pagesSAEP - 306 Evaluating The Safe Operating Pressure of Corroded PipeSalik SiddiquiNo ratings yet

- Adw TR RTCF QP Me 002, Rev.1Document38 pagesAdw TR RTCF QP Me 002, Rev.1Rijwan MohammadNo ratings yet

- ISO9001-2015 Quality Management System Assessment ChecklistDocument37 pagesISO9001-2015 Quality Management System Assessment ChecklistAbrahamNdewingoNo ratings yet

- Assoc. Pip RESP003S: Data SheetDocument4 pagesAssoc. Pip RESP003S: Data SheetRijwan MohammadNo ratings yet

- Vertical Submerged Pump Data SheetDocument4 pagesVertical Submerged Pump Data SheetRijwan MohammadNo ratings yet

- ADW-TR-RTCF-QP-ME-021 Rev-01Document20 pagesADW-TR-RTCF-QP-ME-021 Rev-01Rijwan MohammadNo ratings yet

- Overseas Assignment 11 JuneDocument6 pagesOverseas Assignment 11 JuneRijwan MohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Hydrogen Disbonding Test (Qualification Testing Reqmt) SAIC-W-2020 24-Mar-16 MechDocument3 pagesSaudi Aramco Inspection Checklist: Hydrogen Disbonding Test (Qualification Testing Reqmt) SAIC-W-2020 24-Mar-16 MechRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestDocument4 pagesSaudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestRijwan MohammadNo ratings yet

- Technology Examination Questions (Multi-Cohice Exam) : Duties Before WeldingDocument6 pagesTechnology Examination Questions (Multi-Cohice Exam) : Duties Before WeldingvickyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Adw TR RTCF QP Me 021Document18 pagesAdw TR RTCF QP Me 021Rijwan MohammadNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Document2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Purchase Order .:: TR Ras Tanura Refinery Clean Fuels Project Electro-Mechanical Works - Ap4 & Ap5Document1 pagePurchase Order .:: TR Ras Tanura Refinery Clean Fuels Project Electro-Mechanical Works - Ap4 & Ap5Rijwan MohammadNo ratings yet

- Satip G 006 0122Document10 pagesSatip G 006 0122Rijwan MohammadNo ratings yet

- Satip A 104 03eeDocument10 pagesSatip A 104 03eeRijwan MohammadNo ratings yet

- Saep 29Document10 pagesSaep 29Rijwan MohammadNo ratings yet

- Satip F 001 04Document13 pagesSatip F 001 04Rijwan MohammadNo ratings yet

- Satip D 001 01Document11 pagesSatip D 001 01Rijwan Mohammad0% (1)

- Satip A 004 04JJDocument10 pagesSatip A 004 04JJRijwan MohammadNo ratings yet

- Satip H 002 02Document10 pagesSatip H 002 02Rijwan MohammadNo ratings yet

- Satip G 005 01Document11 pagesSatip G 005 01Rijwan MohammadNo ratings yet

- F3122 14Document6 pagesF3122 14senthilNo ratings yet

- Catalogo Secadores Spray - GEA (Niro)Document9 pagesCatalogo Secadores Spray - GEA (Niro)San ApolonioNo ratings yet

- Interference and Diffraction: Physics 112NDocument30 pagesInterference and Diffraction: Physics 112NPrashant BhajantriNo ratings yet

- Phy PPT FinalDocument29 pagesPhy PPT FinalReck OnNo ratings yet

- Computer Lab (Example Problems For SAP2000 v9)Document9 pagesComputer Lab (Example Problems For SAP2000 v9)deepak_karna_1No ratings yet

- CSIRO-RMIT Research Masters Project List: ID# Project Title RMIT Supervisors RMIT School Program Code Csiro Lab LocationDocument2 pagesCSIRO-RMIT Research Masters Project List: ID# Project Title RMIT Supervisors RMIT School Program Code Csiro Lab LocationRenzo FernandezNo ratings yet

- CRITICAL FLOW ANALYSISDocument31 pagesCRITICAL FLOW ANALYSISRobert BuiNo ratings yet

- S 9.29C - Pressure Vessel PermitDocument1 pageS 9.29C - Pressure Vessel PermitWILLIAMNo ratings yet

- ANSYS Theory Reference For The Mechanical APDL and Mechanical Applications R13 PDFDocument0 pagesANSYS Theory Reference For The Mechanical APDL and Mechanical Applications R13 PDFfrancisco_gil_510% (1)

- Fluid Mechanics 1St Edition Hibbeler Solutions Manual Full Chapter PDFDocument67 pagesFluid Mechanics 1St Edition Hibbeler Solutions Manual Full Chapter PDFfionaalexandrahukc100% (11)

- Simplified Modelling of Front Car StructuresDocument28 pagesSimplified Modelling of Front Car StructuresMane_SushilNo ratings yet

- Design Two-Way Slabs Using Coefficient MethodDocument8 pagesDesign Two-Way Slabs Using Coefficient MethodSL SPNo ratings yet

- Fuel Gas NGL (C3+) Recovery by Twister JTX ProcessDocument21 pagesFuel Gas NGL (C3+) Recovery by Twister JTX Processotis-a6866No ratings yet

- Compressor - EM2U60HLP (LBP) - DatasheetDocument4 pagesCompressor - EM2U60HLP (LBP) - DatasheetSamuel OsmagNo ratings yet

- 1.nano - Thin FilmDocument10 pages1.nano - Thin FilmTJPRC PublicationsNo ratings yet

- Modul 11 - Plate TectonicsDocument31 pagesModul 11 - Plate TectonicsAnwar Setio WidodoNo ratings yet

- Engg Mechanics Ques BankDocument68 pagesEngg Mechanics Ques BankUtkalNo ratings yet

- N8 .An-Introduction-to-Seismic-Isolation-R-Ivan-Skinnerl-William-H-Robinson-And-Graeme-H-McVerry PDFDocument190 pagesN8 .An-Introduction-to-Seismic-Isolation-R-Ivan-Skinnerl-William-H-Robinson-And-Graeme-H-McVerry PDFDaisy' Ruiz0% (1)

- 601 - Helicopter Turboshaft EngineDocument13 pages601 - Helicopter Turboshaft EngineVishnu SankarNo ratings yet

- 2 Methods of MeasurementDocument18 pages2 Methods of MeasurementSorayya Sangcopan OmarNo ratings yet

- SCC Initiation of Alloy 690Document11 pagesSCC Initiation of Alloy 690HASAN IZHAR KHANNo ratings yet

- Control Valves For Critical Applications PDFDocument8 pagesControl Valves For Critical Applications PDFonizuka-t2263No ratings yet

- Revision Worksheet - Chemical Bonding and Molecular Structure-2022-23Document2 pagesRevision Worksheet - Chemical Bonding and Molecular Structure-2022-23Malolan SriramNo ratings yet

- Compact Blue-Green Lasers for OEM ApplicationsDocument41 pagesCompact Blue-Green Lasers for OEM Applicationsdpiehler@alphion.comNo ratings yet

- Al Alloys Chemicals MechanicalsDocument1 pageAl Alloys Chemicals MechanicalsFactory FactoryNo ratings yet

- 9 Science Exemplar Chapter 9Document3 pages9 Science Exemplar Chapter 9Dev RajuNo ratings yet

- Unit IV Jet PropulsionDocument31 pagesUnit IV Jet PropulsionMuthuvel M100% (1)

- Physics ProjectDocument25 pagesPhysics Projectaryan sharrma100% (1)

- Mach ZenderDocument4 pagesMach ZenderGreeshmani GreeshNo ratings yet

- PHYSICS 1E Module 7 BBBB 3Document36 pagesPHYSICS 1E Module 7 BBBB 3Claire G. MagluyanNo ratings yet