Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist: Pre Welding Inspection - Offshore Structures SAIC-W-1312 Weld

Uploaded by

kartik_harwani4387Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist: Pre Welding Inspection - Offshore Structures SAIC-W-1312 Weld

Uploaded by

kartik_harwani4387Copyright:

Available Formats

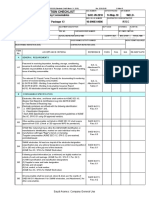

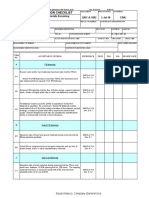

SAUDI ARAMCO ID/PID - 29/09/2017 - REV 0 (Standards Cutoff - January 2017 ) REV 0 29-Sep-17

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pre welding Inspection - Offshore Structures SAIC-W-1312 WELD

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

JOINT EDGE PREPARATION (INCLUDING FLAME CUTTING, ARC-AIR GOUGING, PLASMA CUTTING, BUTTERING, JOINT- WELD

A

METAL BUILD-UP)

An approved Welding Procedure (WPS) to be used is available at the SAES W-013

A1

weld site Para 7.1.8

Weld joint conform with the the weld joint details of the approved WPS as

follows:

a. Base material

As per WPS

b. Thickness

A2 SAES W-013

c. Bevel type

Para 9.0

d. Root Gap

Note:Permanent backing rings or strips shall not be used unless specified

in the design and approved by CSD

SAES W-013

A3 Internal misalignment of butt joints shall not exceed 3.0 mm.

Para 10.4

SAES W-013

A4 UT Lamination check conformed before TKY joint fit up. Table 2

Note 9

Weld number is marked adjacent to the weld joint and verified to conform

SAES W-013

A5 to the Weld Map. (Note : Markings shall be made with a suitable weather

Para 14.1

-proof marking material)

Weld joint identification markings confirmed to the requirements of the SAES W-013

A6

approved drawings. Para 14.2

API RP 2X

A7 Minimum Clearance between TKY joints shall be as per drawing. Para 7.2.5

IFC Drawing

Lifting Pad Eye materials shall be 100% UT Inspected and Through

SAES-M-005

Thickness inspected.All major lifting lugs shall be made with full

Table 8.1

A8 penetration groove welds. Unless specified otherwise, all intersecting and

SAES W-013

abutting parts to be welded shall be joined by complete penetration

Para 9.1 &9.2

groove welds

Mouse holes or weld access holes in webs are not permitted for welding

SAES W-013

A9 of beam splices. Joint design for the flanges shall be single-V from the

Para 9.7

side opposite to the web.

Saudi Aramco: Company General Use

You might also like

- Fitness RX For Women - December 2013Document124 pagesFitness RX For Women - December 2013renrmrm100% (2)

- Saes L 440Document14 pagesSaes L 440kartik_harwani4387100% (1)

- (Compare Report) SAES-B-005Document14 pages(Compare Report) SAES-B-005kartik_harwani4387No ratings yet

- Saes L 136Document8 pagesSaes L 136kartik_harwani4387No ratings yet

- Saudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechDocument1 pageSaudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechmominNo ratings yet

- Column FootingDocument57 pagesColumn Footingnuwan01100% (7)

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistJoni Carino SuniNo ratings yet

- Saic W 2036Document2 pagesSaic W 2036Neelam AhmadNo ratings yet

- Saes o 203Document17 pagesSaes o 203kartik_harwani4387No ratings yet

- Saes o 203Document17 pagesSaes o 203kartik_harwani4387No ratings yet

- (Compare Report) SAES-A-401Document42 pages(Compare Report) SAES-A-401kartik_harwani43870% (1)

- Sabp J 902Document9 pagesSabp J 902kartik_harwani4387No ratings yet

- dSPACE CLP1104 Manual 201663013420Document172 pagesdSPACE CLP1104 Manual 201663013420meghraj01No ratings yet

- Saudi Aramco Inspection ChecklistDocument23 pagesSaudi Aramco Inspection ChecklistjahaanNo ratings yet

- Bronchiolitis A Practical Approach For The General RadiologistDocument42 pagesBronchiolitis A Practical Approach For The General RadiologistTara NareswariNo ratings yet

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechJagdishNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-W-2032 24-Jul-18 Weld-Upgrade Aramco JNGLFP Propane System BI-21-00087 MacoDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-W-2032 24-Jul-18 Weld-Upgrade Aramco JNGLFP Propane System BI-21-00087 MacojahaanNo ratings yet

- SATIP-P-113-01 Rev 8 Final Induction Motor PDFDocument3 pagesSATIP-P-113-01 Rev 8 Final Induction Motor PDFSabheeh AliNo ratings yet

- Saic A 2011Document8 pagesSaic A 2011jerinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistMeraj HassanNo ratings yet

- Verify Saudi Aramco Test Equipment SafetyDocument6 pagesVerify Saudi Aramco Test Equipment SafetyEagle SpiritNo ratings yet

- Saes y 301Document10 pagesSaes y 301kartik_harwani4387No ratings yet

- SAES-T-744 Design Criteria and Installation of Communication TowersDocument7 pagesSAES-T-744 Design Criteria and Installation of Communication TowersAbdul Rahim ShaikhNo ratings yet

- Water Spray Nozzle: Fire Fighting Equipment Data SheetDocument7 pagesWater Spray Nozzle: Fire Fighting Equipment Data SheetJosef MadronaNo ratings yet

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Document2 pagesSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanNo ratings yet

- Saudi Aramco welding inspection checklistDocument3 pagesSaudi Aramco welding inspection checklistManoj KumarNo ratings yet

- Review PWHT Specs, Procedures and TablesDocument19 pagesReview PWHT Specs, Procedures and TablesIrshad IqbalNo ratings yet

- Aircraft Control Systems, Basic Construction, Wing and Fuselage ConstructionDocument146 pagesAircraft Control Systems, Basic Construction, Wing and Fuselage ConstructionTAMILSELVAM NALLUSAMYNo ratings yet

- SAES-O-211: Personal Identification Verification CardsDocument6 pagesSAES-O-211: Personal Identification Verification Cardskartik_harwani4387No ratings yet

- Blasting and Painting Technology Course: Presented by Technical Service PT. HEMPEL IndonesiaDocument128 pagesBlasting and Painting Technology Course: Presented by Technical Service PT. HEMPEL IndonesiaSugiati WidodoNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldDocument27 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldIrshad IqbalNo ratings yet

- SAUDI ARAMCO POST-WELDING VISUAL INSPECTION CHECKLISTDocument6 pagesSAUDI ARAMCO POST-WELDING VISUAL INSPECTION CHECKLISTManoj KumarNo ratings yet

- Saudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 WeldDocument1 pageSaudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 Weldkartik_harwani4387No ratings yet

- Installation of Main Steel Structure/ Platform & Steam SilencerDocument4 pagesInstallation of Main Steel Structure/ Platform & Steam SilencerzhangNo ratings yet

- Saic W 2011Document3 pagesSaic W 2011munnaNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 Mechkarthi51289No ratings yet

- Saudi Aramco PMI Program ReviewDocument18 pagesSaudi Aramco PMI Program ReviewejazNo ratings yet

- Saic D 2024Document9 pagesSaic D 2024Md ShariqueNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 Weldm4metzNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002karthi51289No ratings yet

- SAUDI ARAMCO PRESSURE TESTING PROCEDURE REVIEWDocument27 pagesSAUDI ARAMCO PRESSURE TESTING PROCEDURE REVIEWNaushad AlamNo ratings yet

- Final Cleanliness InspectionDocument2 pagesFinal Cleanliness Inspectionkarthi51289No ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportJagdishNo ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- Saudi Aramco HDPE Liner Inspection PlanDocument10 pagesSaudi Aramco HDPE Liner Inspection PlanJagdishNo ratings yet

- Saic LPT 2006Document12 pagesSaic LPT 2006jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 WeldMAZHARULNo ratings yet

- Saic e 2002Document10 pagesSaic e 2002jerinNo ratings yet

- Section Subject: Shaybah CPF Expansion ProjectDocument21 pagesSection Subject: Shaybah CPF Expansion ProjectAdhie Waelacxh100% (1)

- SATIP-T-492-01 Ver 08Document1 pageSATIP-T-492-01 Ver 08thezaidNo ratings yet

- QM07 QuestionsDocument7 pagesQM07 Questionskta_87100% (1)

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerEagle SpiritNo ratings yet

- Saic L 2139Document9 pagesSaic L 2139Kumar RNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerSathish Kumar SelvarajNo ratings yet

- Chem-Wps - PQR - WPQ-003 CS-CS 08-08 Gtaw-SmawDocument5 pagesChem-Wps - PQR - WPQ-003 CS-CS 08-08 Gtaw-Smawvijay padaleNo ratings yet

- Fully Deployable. Completely Retrievable.: Solitaire ABDocument6 pagesFully Deployable. Completely Retrievable.: Solitaire ABneureportNo ratings yet

- SATIP-H-002-05 Epoxy For Atmospheric Up To 150CDocument2 pagesSATIP-H-002-05 Epoxy For Atmospheric Up To 150ChossamalsherbinyNo ratings yet

- Saudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportDocument2 pagesSaudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportJoni Carino Suni100% (1)

- 01-SAMSS-048 PDF Download - CRA Clad or Lined Steel PipeDocument4 pages01-SAMSS-048 PDF Download - CRA Clad or Lined Steel PipeZahidRafiqueNo ratings yet

- Electrode Issue SlipDocument1 pageElectrode Issue SlipHasan ShahriarNo ratings yet

- Saudi Aramco Inspection Checklist: Vent Piping Connection SAIC-S-4041 18-May-05 PlumbDocument2 pagesSaudi Aramco Inspection Checklist: Vent Piping Connection SAIC-S-4041 18-May-05 PlumbUzair AhmadNo ratings yet

- Saudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechDocument3 pagesSaudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechmominNo ratings yet

- Schedule B - Attachment IVDocument29 pagesSchedule B - Attachment IVAbdul Ahad LoneNo ratings yet

- SAUDICHECK - WELD TRACKING DATABASEDocument5 pagesSAUDICHECK - WELD TRACKING DATABASEManoj KumarNo ratings yet

- SAES-M-009 PDF Download - Design Criteria For Blast Resistant Buildings - PDFYAR - Engineering Notes, Documents & LecturesDocument7 pagesSAES-M-009 PDF Download - Design Criteria For Blast Resistant Buildings - PDFYAR - Engineering Notes, Documents & LecturesZahidRafiqueNo ratings yet

- Mandatory Appendix e Asme BPVC Sec Ix 2023Document3 pagesMandatory Appendix e Asme BPVC Sec Ix 2023mr.bakhtiari.mahmoudNo ratings yet

- Saic B 1004Document2 pagesSaic B 1004jerinNo ratings yet

- Define of WPS & PQRDocument16 pagesDefine of WPS & PQRThanh Hua100% (1)

- Weld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020Document3 pagesWeld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020bishalNo ratings yet

- Asme CodesDocument14 pagesAsme CodesSaidFerdjallahNo ratings yet

- SAUDI ARAMCO RADIOGRAPHIC TESTING INSPECTIONDocument24 pagesSAUDI ARAMCO RADIOGRAPHIC TESTING INSPECTIONmunnaNo ratings yet

- SAIC-W-C014-Post Weld Visual Inspection - Offshore StructuresDocument4 pagesSAIC-W-C014-Post Weld Visual Inspection - Offshore StructuresVinu MadhavanNo ratings yet

- (Compare Report) SAES-B-009Document32 pages(Compare Report) SAES-B-009kartik_harwani4387No ratings yet

- (Compare Report) SAES-B-018Document16 pages(Compare Report) SAES-B-018kartik_harwani4387No ratings yet

- (Compare Report) SAES-A-502Document19 pages(Compare Report) SAES-A-502kartik_harwani4387No ratings yet

- Engineering Standard: SAES-A-008Document8 pagesEngineering Standard: SAES-A-008kartik_harwani4387No ratings yet

- Saudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 WeldDocument1 pageSaudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 Weldkartik_harwani4387No ratings yet

- Saudi Aramco Inspection Checklist: Pre Welding Inspection - Offshore Structures SAIC-W-1312 WeldDocument1 pageSaudi Aramco Inspection Checklist: Pre Welding Inspection - Offshore Structures SAIC-W-1312 Weldkartik_harwani4387No ratings yet

- (Compare Report) SAES-B-014Document39 pages(Compare Report) SAES-B-014kartik_harwani4387No ratings yet

- SAUDI ARAMCO SEAL WELD INSPECTIONDocument1 pageSAUDI ARAMCO SEAL WELD INSPECTIONkartik_harwani4387No ratings yet

- Saudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 WeldDocument1 pageSaudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 Weldkartik_harwani4387No ratings yet

- Saes o 313Document10 pagesSaes o 313kartik_harwani4387No ratings yet

- SAES-O-310: Security Requirements For Railways at Industrial FacilitiesDocument8 pagesSAES-O-310: Security Requirements For Railways at Industrial Facilitieskartik_harwani4387No ratings yet

- SAES-O-205: Security Systems For Industrial FacilitiesDocument18 pagesSAES-O-205: Security Systems For Industrial Facilitieskartik_harwani4387No ratings yet

- SAES-O-205: Security Systems For Industrial FacilitiesDocument18 pagesSAES-O-205: Security Systems For Industrial Facilitieskartik_harwani4387No ratings yet

- Sabp J 900Document9 pagesSabp J 900kartik_harwani4387No ratings yet

- Saudi Aramco Power Circuit Breaker Inspection RequirementsDocument2 pagesSaudi Aramco Power Circuit Breaker Inspection Requirementskartik_harwani4387No ratings yet

- Sa 6717Document1 pageSa 6717biplabpal2009No ratings yet

- Sabp A 077Document13 pagesSabp A 077kartik_harwani4387No ratings yet

- Saudi Arabian Oil CompanyDocument2 pagesSaudi Arabian Oil CompanyBIPIN BALANNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection Perkartik_harwani4387No ratings yet

- Accepted Manuscript: Process Safety and Environment ProtectionDocument51 pagesAccepted Manuscript: Process Safety and Environment Protectionimran shaukatNo ratings yet

- Mec 323Document68 pagesMec 323VINAY B.SNo ratings yet

- MODULE-2-VETTECH325 (2)Document31 pagesMODULE-2-VETTECH325 (2)cejproiloNo ratings yet

- Orac Charts - BuenisimoDocument92 pagesOrac Charts - BuenisimosanthigiNo ratings yet

- Concept of StateDocument10 pagesConcept of StateAryansh ShuklaNo ratings yet

- Mini ProjectDocument6 pagesMini Projectirene0% (1)

- 2024 Drik Panchang Telugu Calendar v1.0.1Document25 pages2024 Drik Panchang Telugu Calendar v1.0.1Sreekara GsNo ratings yet

- 07 - Structural Organisation in AnimalsDocument31 pages07 - Structural Organisation in AnimalsKamala Kannan XANo ratings yet

- Chapter 3Document58 pagesChapter 3hasanNo ratings yet

- Siemens 810dDocument13 pagesSiemens 810dAdo ŠehićNo ratings yet

- Airway Management in The Critically Ill: ReviewDocument9 pagesAirway Management in The Critically Ill: ReviewQuarmina HesseNo ratings yet

- Marketing 5 0Document23 pagesMarketing 5 0gmusicestudioNo ratings yet

- Make A Selection: Choose An Alloy and Correlating Casting ProcessDocument5 pagesMake A Selection: Choose An Alloy and Correlating Casting ProcessSarath ChandraNo ratings yet

- FV10 Excel Flux Tutorial en 2Document36 pagesFV10 Excel Flux Tutorial en 2Ahcene BouzidaNo ratings yet

- Theoretical Development of The Brooks-Corey CapillDocument7 pagesTheoretical Development of The Brooks-Corey CapillDiana Vanessa PedrazaNo ratings yet

- Rotating Sharp Shooting Multi Target Mechanism Improves Military AimDocument13 pagesRotating Sharp Shooting Multi Target Mechanism Improves Military AimVishal GNo ratings yet

- Oxygen Concentrator SpecificationsDocument3 pagesOxygen Concentrator Specificationsmino pharmNo ratings yet

- AAB 075323 EPDM Waterproofing Membrane (For RC Roof Build-Up Inc. Insulation)Document3 pagesAAB 075323 EPDM Waterproofing Membrane (For RC Roof Build-Up Inc. Insulation)tewodrosNo ratings yet

- Vitamin and Mineral Contents of Gongronema Latifolium LeavesDocument3 pagesVitamin and Mineral Contents of Gongronema Latifolium LeavesFrida Febriani IsnanisafitriNo ratings yet

- A Study On Renewable Energy Resources in IndiaDocument39 pagesA Study On Renewable Energy Resources in IndiaDevendra SharmaNo ratings yet

- Fundamental Calculations To Convert Intensities Into Concentrations in Optical Emission Spectrochemical AnalysisDocument14 pagesFundamental Calculations To Convert Intensities Into Concentrations in Optical Emission Spectrochemical AnalysisPYDNo ratings yet

- Char Lynn 104 2000 Series Motor Data SheetDocument28 pagesChar Lynn 104 2000 Series Motor Data Sheetsyahril boonieNo ratings yet

- Example of Gcse Science CourseworkDocument7 pagesExample of Gcse Science Courseworkbcrbcw6a100% (2)

- November 2010 (v1) QP - Paper 3 CIE Biology A-Level PDFDocument12 pagesNovember 2010 (v1) QP - Paper 3 CIE Biology A-Level PDFWiji NingNo ratings yet