Professional Documents

Culture Documents

PT4205 30V 1.2A Step-down HB LED Driver

Uploaded by

Jose ReyesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PT4205 30V 1.2A Step-down HB LED Driver

Uploaded by

Jose ReyesCopyright:

Available Formats

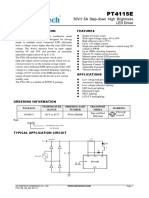

PT4205

30V, 1.2A Step-down HB LED Driver

GENERAL DESCRIPTION FEATURES

The PT4205 is a continuous conduction mode inductive Simple low parts count

step-down converter, designed for driving single or Wide input voltage range: 5V to 30V

Up to 1.2A output current

multiple serie connected LEDs efficiently from a

Single pin on/off and brightness control using DC

voltage source higher than the total LED chain voltage. voltage or PWM

The device operates from an input supply between 5V Typical 3% output current accuracy

and 30V and provides an externally adjustable output Inherent open-circuit LED protection

current of up to 1.2A. Depending upon the supply High efficiency (up to 97%)

voltage and external components, the PT4205can Hysteretic Control: No Compensation

Adjustable Constant LED Current

provide more than tens of watts of output power. Soft over temperature protection

The PT4205 includes the power switch and a high-side ESOP8 package for large output power application

output current sensing circuit, which uses an external RoHS compliant

resistor to set the nominal average output current, and a

dedicated DIM input accepts either a DC voltage or a APPLICATIONS

wide range of pulsed dimming. Applying a voltage of Low voltage halogen replacement LEDs

0.3V or lower to the DIM pin turns the output off and Automotive lighting

switches the device into a low current standby state. LED back-up lighting

The PT4205 is available in SOT89-5 and ESOP8 Illuminated signs

packages.

ORDERING INFORMATION

TEMPERATURE ORDERING PART TRANSPORT

PACKAGE MARKING

RANGE NUMBER MEDIA

Tape and Reel PT4205

SOT89-5 -40 oC to 85 oC PT4205E89E

1000 units xxxxxX

Tape and Reel PT4205

ESOP8 -40 oC to 85 oC PT4205EESH

2500 units xxxxxX

Note:

xxxxxX

Assembly Factory Code

Lot Number

TYPICAL APPLICATION CIRCUIT

RS

VIN

0.28Ω

DC5-30V LED

D

3W

L=47uH

5 4

CIN 100uF

AC12- VIN CSN

18V

PT4205

SW GND DIM

1 2 3

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 1

PT4205_DS Rev EN_1.2

PT4205

30V, 1.2A Step-down HB LED Driver

PIN ASSIGNMENT

CSN 1 8 DIM

PT4205

VIN 2 7 NC

SW 3 6 GND

NC 4 5 NC

ESOP8

PIN DESCRIPTIONS

PIN

PIN No. DESCRIPTION

NAMES

1 SW Switch Output. SW is the drain of the internal N-Ch MOSFET switch.

2 GND Signal and power ground. Connect directly to ground plane.

Logic level dimming input. Drive DIM low to turn off the current regulator.

3 DIM

Drive DIM high to enable the current regulator.

4 CSN Current sense input

5 VIN Input Supply Pin. Must be locally bypassed.

- Exposed PAD Internally connected to GND. Mount on board for lower thermal resistance.

ESOP8 4,5,7 NC No connection

ABSOLUTE MAXIMUM RATINGS (note1)

SYMBOL ITEMS VALUE UNIT

VIN Supply Voltage -0.3~40 V

SW Drain of the internal power switch -0.3~40 V

CSN Current sense input (Respect to VIN) +0.3~(-6.0) V

DIM Logic level dimming input -0.3~30 V

ISW Switch output current 1.5 A

PDMAX Power Dissipation (Note 2) 1.5 W

PTR Thermal Resistance, SOT89-5 (θJA) 45 o

C /W

o

PTR Thermal Resistance, ESOP8 (θJA) 40 C /W

Operation Junction Temperature Range -40 to 150 o

TJ C

o

TSTG Storage Temperature -55 to 150 C

ESD(note3) HBM 2 kV

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 2

PT4205_DS Rev EN_1.2

PT4205

30V, 1.2A Step-down HB LED Driver

RECOMMENDED OPERATING RANGE

SYMBOL ITEMS VALUE UNIT

VIN VDD Supply Voltage 0 ~ 30 V

o

TOPT Operating Temperature -40 to +85 C

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Recommended

Operating Range indicates conditions for which the device is functional, but do not guarantee specific performance

limits. Electrical Characteristics state DC and AC electrical specifications under particular test conditions which

guarantee specific performance limits. This assumes that the device is within the Operating Range. Specifications are

not guaranteed for parameters where no limit is given, however, the typical value is a good indication of device

performance.

Note 2: The maximum power dissipation must be derated at elevated temperatures and is dictated by TJMAX, θJA,

and the ambient temperature TA. The maximum allowable power dissipation is PDMAX = (TJMAX - TA)/ θJA or the

number given in Absolute Maximum Ratings, whichever is lower.

Note 3: Human body model, 100pF discharged through a 1.5kΩ resistor.

ELECTRICAL CHARACTERISTICS (Note 4, 5, 6)

The following specifications apply for V IN=12V, TA=25 oC, unless specified otherwise.

SYMBOL ITEMS CONDITIONS Min. Typ. Max. UNIT

VIN Input Voltage 5 30 V

VUVLO Under voltage lock out VIN falling 4.5 V

VUVLO, HYS UVLO hysterisis VIN rising 200 mV

FSW Max. Switching Frequency 1 MHz

Current Sense

Mean current sense

VCSN VIN-VCSN 194 200 206 mV

threshold voltage

VCSN_hys Sense threshold hysteresis ±15 %

ICSN CSN Pin Input Current VIN-VCSN=50mV 8 µA

Operating Current

Quiescent supply current

IOFF VDIM<0.3V 130 µA

with output off

DIM Input

VDIM DIM floating voltage DIM floating 4.7 V

VDIM_H DIM input voltage High 2.5 V

VDIM_L DIM input voltage Low 0.3 V

VDIM_DC DC brightness control 0.5 2.5 V

fDIM(note 6,7) Max. DIM Frequency fOSC=500kHz 50 kHz

DIM pin internal pull up

IDIM VDIM=0 20 uA

current

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 3

PT4205_DS Rev EN_1.2

PT4205

30V, 1.2A Step-down HB LED Driver

ELECTRICAL CHARACTERISTICS (Continued) (Note 4, 5)

SYMBOL ITEMS CONDITIONS Min. Typ. Max. UNIT

Output Switch

RSW SW On Resistance VIN=12V 0.6

Ω

VIN=24V 0.4

ISWmean Continuous SW Current 1.2 A

ILEAK SW Leakage Current 0.5 5 µA

Thermal Shutdown

TPROT Soft temperature protection 135 ℃

Threshold

TMAX Maximum operating junction 150 ℃

temperature

Note 4: Typical parameters are measured at 25˚C and represent the parametric norm.

Note 5: Datasheet min/max specification limits are guaranteed by design, test, or statistical analysis.

Note6: The maximum dimming frequency is limited by operating frequency, because operating frequency varies with supply

voltage, output voltage and inductor selection, to achieve the best dimming linearity, the dimming frequency is recommended to

limited less than 1% of operating frequency.

Note 7: When PWM dimming is used, the minimum on duration of PWM signal should not less than 1uS。

SIMPLIFIED BLOCK DIAGRAM

⑤ ①

5V

VIN LDO TSD SW

④ Current

CSN

Sense

-

1.25V

Driver

Reference +

OC

5V comparator

21u ②

③ A DIM GND

DIM

Buffer

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 4

PT4205_DS Rev EN_1.2

PT4205

30V, 1.2A Step-down HB LED Driver

OPERATION DESCRIPTION

The device, in conjunction with the coil (L1) and from 0.5V to 2.5V. When the dc voltage is higher than

current sense resistor (RS), forms a self oscillating 2.5V, the output current keeps constant. The LED

continuous-mode buck converter. current also can be adjusted by a resistor connected to

the DIM pin. An internal pull-up current source is

When input voltage VIN is first applied, the initial

connected to a 5V internal regulator. Connect a resistor

current in L1 and RS is zero and there is no output from

to DIM and GND sets the voltage of DIM:

the current sense circuit. Under this condition, the

VDIM=20uA*RDIM.

output of CS comparator is high. This turns on an

internal switch and switches the SW pin low, causing The DIM pin is pulled up to the internal regulator (5V)

current to flow from VIN to ground, via RS, L1 and the by a current source. It can be floated at normal

LED(s). The current rises at a rate determined by VIN operation. When a voltage applied to DIM falls below

and L1 to produce a voltage ramp (VCSN) across RS. the threshold (0.3V nom.), the switch is turned off. The

When (VIN-VCSN) > 230mV, the output of CS internal regulator and voltage reference remain

comparator switches low and the switch turns off. The powered during shutdown to provide the reference for

current flowing on the RS decreases at another rate. the shutdown circuit. Quiescent supply current during

When (VIN-VCSN) < 170mV, the switch turns on again shutdown is nominally 130uA and switch leakage is

and the mean current on the LED is determined by below 5uA.

0.17 0.23

I OUT 0.2 / Rs . Additionally, to ensure the reliability, the PT4205 is

2 Rs

built with a thermal shutdown (TSD) protection and a

The high-side current-sensing scheme and on-board thermal pad. The TSD protests the IC from over

current-setting circuitry minimize the number of temperature, when junction temperature more than

external components while delivering LED current with 135 ℃ the output current begin to decrease

±3% accuracy, using a 1% sense resistor. until to zero at 150℃. With the analog dimming

The PT4205 allow dimming with a PWM signal at the function via DIM pin, LED over temperature can easily

DIM input. A logic level below 0.3V at DIM forces be realized by connecting a NTC resistor to DIM pin

PT4205 to turn off the LED and the logic level at DIM and GND.

must be at least 2.5V to turn on the full LED current.

The frequency of PWM dimming ranges from 100Hz to

more than 20 kHz.

The DIM pin can be driven by an external DC voltage

(VDIM) to adjust the output current below the nominal

average value defined by RS. The DC voltage is valid

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 5

PT4205_DS Rev EN_1.2

PT4205

30V, 1.2A Step-down HB LED Driver

TYPICAL PERFORMANCE CHARACTERISTICS

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 6

PT4205_DS Rev EN_1.2

PT4205

30V, 1.2A Step-down HB LED Driver

TYPICAL PERFORMANCE CHARACTERISTICS(continued)

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 7

PT4205_DS Rev EN_1.2

PT4205

30V, 1.2A Step-down HB LED Driver

TYPICAL PERFORMANCE CHARACTERISTICS(continued)

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 8

PT4205_DS Rev EN_1.2

PT4205

30V, 1.2A Step-down HB LED Driver

TYPICAL PERFORMANCE CHARACTERISTICS(continued)

Operation waveform: (Vin=12V,L=47uH,3xLED)

CH2:SW 5V/div

CH3:Iout 200mA/div

PWM dimming (Vin=12V, L=47uH, 3xLED) PWM dimming (Vin=12V, L=47uH, 3xLED)

CH1: Vdim 5V/div F=200Hz D=1% CH1: Vdim 5V/div F=200Hz D=99%

CH2: SW 10V/div

CH2: SW 10V/div

CH3: Iout 200mA/div CH3: Iout 200mA/div

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 9

PT4205_DS Rev EN_1.2

PT4205

30V, 1.2A Step-down HB LED Driver

TYPICAL PERFORMANCE CHARACTERISTICS(continued)

PWM dimming (Vin=12V, L=47uH,3xLED) PWM dimming (Vin=12V, L=47uH, 3xLED)

CH1: Vdim 5V/div F=20KHz D=10% CH1: Vdim 5V/div F=20KHz D=10%

CH2: SW 10V/div CH2: SW 10V/div

CH3: Iout 200mA/div

CH3: Iout 200mA/div

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 10

PT4205_DS Rev EN_1.2

PT4205

30V, 1.2A Step-down HB LED Driver

APPLICATION NOTES

Setting nominal average output current with 0.2 D

I OUT

external resistor RS Rs

The nominal average output current is determined by

the value of the external current sense resistor (RS)

(0 D 100%,2.5V V pulse 5V )

connected between VIN and CSN and is given by:

V pulse 0.2 D

I OUT 0.2 / Rs ( Rs 0.17) I OUT

2.5 Rs

This equation is valid when DIM pin is float or applied

with a voltage higher than 2.5V (must be less than 5V). (0 D 100%,0.5V V pulse 2.5V )

Actually, RS sets the maximum average current which

can be adjusted to a less one by dimming.

RS

Output current adjustment by external DC control VIN

0.28Ω LED

voltage 3W

The DIM pin can be driven by an external dc voltage L

(VDIM), as shown, to adjust the output current to a 68uH

D

value below the nominal average value defined by RS.

VIN CSN SW

RS

VIN

0.28Ω LED

3W

DIM PT4205

L

68uH GND

D

VIN CSN SW

PWM dimming provides reduced brightness by

DIM PT4205 modulating the LED’s forward current between 0% and

100%. The LED brightness is controlled by adjusting

GND

the relative ratios of the on time to the off time. A 25%

brightness level is achieved by turning the LED on at

full current for 25% of one cycle. To ensure this

switching process between on and off state is invisible

by human eyes, the switching frequency must be

The average output current is given by: greater than 100 Hz. Above 100 Hz, the human eyes

0.0935 VDIM average the on and off times, seeing only an effective

I OUT (0.5V VDIM 1.9V ) brightness that is proportional to the LED’s on-time

2.5 Rs

duty cycle. The advantage of PWM dimming is that the

0.071 VDIM 1.9

I OUT (1.9V VDIM 2.5V ) forward current is always constant, therefore the LED

Rs 0.6 color does not vary with brightness as it does with

Note that 100% brightness setting corresponds to: analog dimming. Pulsing the current provides precise

brightness control while preserving the color purity.

(2.5V VDIM 5V ) The dimming frequency of PT4205 can be as high as 20

kHz.

Output current adjustment by PWM control

Shutdown mode

A Pulse Width Modulated (PWM) signal with duty Taking the DIM pin to a voltage below 0.3V will turn

cycle PWM can be applied to the DIM pin, as shown off the output and the supply current will fall to a low

below, to adjust the output current to a value below the standby level of 130μA nominal.

nominal average value set by resistor RS:

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 11

PT4205_DS Rev EN_1.2

PT4205

30V, 1.2A Step-down HB LED Driver

Soft-start resistance connections to the SW and VIN pins.

An external capacitor from the DIM pin to ground will The chosen coil should have a saturation current higher

provide additional soft-start delay, by increasing the than the peak output current and a continuous current

time taken for the voltage on this pin to rise to the rating above the required mean output current.

turn-on threshold and by slowing down the rate of rise Following table gives the guideline on inductor

of the control voltage at the input of the comparator.

selection:

Adding capacitance increases this delay by

approximately 0.125ms/nF. Saturation

5V-10V 10V-20V 20V-30V

Vin current

Inherent open-circuit LED protection

1 LED 47uH 68uH 100uH

If the connection to the LED(s) is open-circuited, the

coil is isolated from the SW pin of the chip, so the 2 LED 68uH 100uH

device and LED will not be damaged. When the LED(s) 3 LED 68uH 100uH 1.3-1.5

load is connected the device will enter normal 4 LED 68uH 68uH times of

operation. 5 LED 47uH 68uH load

Capacitor selection 6 LED 47uH 68uH current

A low ESR capacitor should be used for input 7 LED 68uH

decoupling, as the ESR of this capacitor appears in 8 LED 68uH

series with the supply source impedance and lowers

Suitable coils for use with the PT4205 are listed in the

overall efficiency. This capacitor has to supply the

relatively high peak current to the coil and smooth the table below:

current ripple on the input supply. A minimum value of Part L DCR ISAT

Manufacturer

4.7uF is acceptable if the DC input source is close to No. (uH) (Ω) (A)

the device, but higher values will improve performance

MSS1038-473 47 0.128 2

at lower input voltages, especially when the source CoilCraft

impedance is high. For the rectified AC input, the MSS1038-683 68 0.213 1.6

www.coilcraft.com

capacitor should be higher than 100uF and the tantalum MSS1038-104 100 0.304 1.3

capacitor is recommended. The input capacitor should

be placed as close as possible to the IC. The inductor value should be chosen to maintain

For maximum stability over temperature and voltage, operating duty cycle and switch 'on'/'off' times within

capacitors with X7R, X5R, or better dielectric are the specified limits over the supply voltage and load

recommended. Capacitors with Y5V dielectric are not current range.

suitable for decoupling in this application and should The following equations can be used as a guide.

NOT be used. SW Switch 'On' time

A suitable Murata capacitor would be L I

GRM42-2X7R475K-50. TON

The following web sites are useful when finding VIN VLED I avg ( Rs rL Rsw )

alternatives:

SW Switch 'Off' time

www.murata.com

www.t-yuden.com L I

www.avxcorp.com TOFF

VLED VD I avg ( Rs rL)

Inductor selection

Where:

Recommended inductor values for the PT4205 are in

the range 47uH to 100uH. L is the coil inductance (H)

Higher values of inductance are recommended at lower rL is the coil resistance (Ω )

output current in order to minimize errors due to RS is the current sense resistance (Ω )

switching delays, which result in increased ripple and Iavg is the required LED current (A)

lower efficiency. Higher values of inductance also

Δ I is the coil peak-peak ripple current (A) {Internally

result in a smaller change in output current over the

supply voltage range. (See graphs). The inductor should set to 0.3 x Iavg}

be mounted as close to the device as possible with low VIN is the supply voltage (V)

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 12

PT4205_DS Rev EN_1.2

PT4205

30V, 1.2A Step-down HB LED Driver

VLED is the total LED forward voltage (V) be achieved with higher capacitor values. Note that the

RSW is the switch resistance (Ω ) {=0.6Ω nominal} capacitor will not affect operating frequency or

efficiency, but it will increase start-up delay and reduce

VD is the diode forward voltage at the required load

the frequency of dimming, by reducing the rate of rise

current (V) of LED voltage.

By adding this capacitor the current waveform through

Diode selection

the LED(s) changes from a triangular ramp to a more

For maximum efficiency and performance, the rectifier

sinusoidal version without altering the mean current

(D1) should be a fast low capacitance Schottky diode

value.

with low reverse leakage at the maximum operating

voltage and temperature. Operation at low supply voltage

They also provide better efficiency than silicon diodes, The internal regulator disables the drive to the switch

due to a combination of lower forward voltage and until the supply has risen above the startup threshold

reduced recovery time. (VUVLO). Above this threshold, the device will start to

It is important to select parts with a peak current rating operate. However, with the supply voltage below the

above the peak coil current and a continuous current specified minimum value, the switch duty cycle will be

rating higher than the maximum output load current. It high and the device power dissipation will be at a

is very important to consider the reverse leakage of the maximum. Care should be taken to avoid operating the

diode when operating above 85°C. Excess leakage will device under such conditions in the application, in

increase the power dissipation in the device and if close order to minimize the risk of exceeding the maximum

to the load may create a thermal runaway condition. allowed die temperature. (See next section on thermal

The higher forward voltage and overshoot due to considerations). The drive to the switch is turned off

reverse recovery time in silicon diodes will increase the when the supply voltage falls below the under-voltage

peak voltage on the SW output. If a silicon diode is threshold (VUVLO-0.2V).

used, care should be taken to ensure that the total This prevents the switch working with excessive 'on'

voltage appearing on the SW pin including supply resistance under conditions where the duty cycle is

ripple, does not exceed the specified maximum value. high.

The following web sites are useful when finding

alternatives: www.onsemi.com Thermal considerations

When operating the device at high ambient

Reducing output ripple temperatures, or when driving maximum load current,

Peak to peak ripple current in the LED(s) can be care must be taken to avoid exceeding the package

reduced, if required, by shunting a capacitor CLED power dissipation limits. The graph below gives details

across the LED(s) as shown below: for power derating. This assumes the device to be

RS mounted on a 25mm2 PCB with 1oz copper standing in

VIN still air.

0.28Ω LED

3W

Max. Power Dissipation

L 1600

68uH

D 1400

1200

Power (mW)

VIN CSN SW 1000

800

DIM PT4205 600

400

GND

200

0

-40 -20 0 20 40 60 80 100 120 140

Ambient Temperature (Deg C)

A value of 1uF will reduce the supply ripple current by

a factor three (approx.). Proportionally lower ripple can

increase if the efficiency of the circuit is low. This may

Note that the device power dissipation will most often

result from the use of unsuitable coils, or excessive

be a maximum at minimum supply voltage. It will also

parasitic output capacitance on the switch output. When

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 13

PT4205_DS Rev EN_1.2

PT4205

30V, 1.2A Step-down HB LED Driver

the application is limited by the internal power Thermal shutdown protection

dissipation of the device, the ESOP8 package is To ensure the reliability, the PT4205 is built with a soft

recommended because of its enhanced power over temperature protection function. when junction

temperature more than 135℃ the output current

dissipation ability.

begin to decrease until to zero at 150℃. The

Thermal compensation of output current soft over temperature function protects the IC and avoid

the flicker when operation at high temperature.

High luminance LEDs often need to be supplied with a

temperature compensated current in order to maintain Layout considerations

stable and reliable operation at all drive levels. The Careful PCB layout is critical to achieve low switching

LEDs are usually mounted remotely from the device losses and stable operation. Use a multilayer board

whenever possible for better noise immunity. Minimize

so,for this reason, the temperature coefficients of the

ground noise by connecting high-current ground returns,

internal circuits for the PT4205 have been optimized to the input bypass-capacitor ground lead, and the

minimize the change in output current when no output-filter ground lead to a single point (star ground

compensation is employed. If output current configuration).

compensation is required, it is possible to use an SW pin

external temperature sensing network - normally using The SW pin of the device is a fast switching node, so

Negative Temperature Coefficient (NTC) thermistors PCB tracks should be kept as short as possible. To

and/or diodes, mounted very close to the LED(s). The minimize ground 'bounce', the ground pin of the device

should be soldered directly to the ground plane.

output of the sensing network can be used to drive the

DIM pin in order to reduce output current with Coil and decoupling capacitors and current sense

increasing temperature. resistor

It is particularly important to mount the coil and the

RS input decoupling capacitor as close to the device pins as

VIN

possible to minimize parasitic resistance and inductance,

0.28Ω LED

3W which will degrade efficiency. It is also important to

L minimize any track resistance in series with current

68uH sense resistor RS. It’s best to connect VIN directly to

D

one end of RS and CSN directly to the opposite end of

VIN CSN SW

RS with no other currents flowing in these tracks. It is

important that the cathode current of the Schottky diode

does not flow in a track between RS and VIN as this

DIM PT4205

may give an apparent higher measure of current than is

actual because of track resistance.

GND

NTC

LED current compensation use

NTC

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 14

PT4205_DS Rev EN_1.2

PT4205

30V, 1.2A Step-down HB LED Driver

TYPICAL APPLICATION CIRCUIT

RS

VIN

0.57Ω

DC5-30V LED

D

3*1W

L=47uH

5 4

CIN 100uF

AC12- VIN CSN

18V

PT4205

SW GND DIM

1 2 3

Fig1 :3X1W application

RS

VIN

0.28Ω

DC5-30V LED

D

3*3W

L=47uH

5 4

CIN 100uF

AC12- VIN CSN

18V

PT4205

SW GND DIM

1 2 3

Fig 2: 3X3W application

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 15

PT4205_DS Rev EN_1.2

PT4205

30V, 1.2A Step-down HB LED Driver

TYPICAL APPLICATION CIRCUIT (Continued)

Fig 3 DEMO board for mass production

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 16

PT4205_DS Rev EN_1.2

PT4205

30V, 1.2A Step-down HB LED Driver

PACKAGE INFORMATION

SOT89-5 Package

D1 A

E

E1

b1

b c

e

L

e1

MILLIMETERS INCHES

SYMBOL

MIN MAX MIN MAX

A 1.400 1.600 0.055 0.063

b 0.320 0.520 0.013 0.020

b1 0.360 0.560 0.014 0.022

c 0.350 0.440 0.014 0.017

D 4.400 4.600 0.173 0.181

D1 1.400. 1.800 0.055 0.071

E 2.300 2.600 0.091 0.102

E1 3.940 4.250 0.155 0.167

e 1.500 TYP. 0.060 TYP.

e1 2.900 3.100 0.114 0.122

L 0.900 1.100 0.035 0.043

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 17

PT4205_DS Rev EN_1.2

PT4205

30V, 1.2A Step-down HB LED Driver

PACKAGE INFORMATION

ESOP-8 Package

DIMENSIONS IN MILLIMETERS DIMENSIONS IN INCHES

SYMBOL

MIN MAX MIN MAX

A 1.350 1.750 0.053 0.069

A1 0.050 0.150 0.004 0.010

A2 1.350 1.550 0.053 0.061

b 0.330 0.510 0.013 0.020

c 0.170 0.250 0.006 0.010

D 4.700 5.100 0.185 0.200

D1 3.202 3.402 0.126 0.134

E 3.800 4.000 0.150 0.157

E1 5.800 6.200 0.228 0.244

E2 2.313 2.513 0.091 0.099

e 1.270(BSC) 0.050(BSC)

L 0.400 1.270 0.016 0.050

θ 0° 8° 0° 8°

China Resources Powtech (Shanghai) Limited WWW.CRPOWTECH.COM Page 18

PT4205_DS Rev EN_1.2

You might also like

- 30V, 1.2A Step-Down High Brightness LED Driver With 5000:1 DimmingDocument18 pages30V, 1.2A Step-Down High Brightness LED Driver With 5000:1 DimmingJaPan LifeNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- PT4115 LED Step-DownDocument18 pagesPT4115 LED Step-DownNandor KermeciNo ratings yet

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- 50V/1.5A Step-Down High Brightness LED Driver: General Description FeaturesDocument11 pages50V/1.5A Step-Down High Brightness LED Driver: General Description FeaturesKwun Hok ChongNo ratings yet

- DS NAU8220 DataSheet EN Rev2.0Document21 pagesDS NAU8220 DataSheet EN Rev2.0Fay AgodoloNo ratings yet

- High Voltage Linear LED Driver in TO252-3 PackageDocument6 pagesHigh Voltage Linear LED Driver in TO252-3 PackageEzequiel A O VillegasNo ratings yet

- High Precision PSR Constant Current LED Driver Description FeaturesDocument2 pagesHigh Precision PSR Constant Current LED Driver Description FeaturesVictorUrbinaNo ratings yet

- TD1583_TechcodeDocument13 pagesTD1583_Techcodedavid.gjeorgevskiNo ratings yet

- Order Parts and Request Quotation Online for Low-Drop Voltage RegulatorDocument15 pagesOrder Parts and Request Quotation Online for Low-Drop Voltage RegulatorDidier DoradoNo ratings yet

- Description Features: Maximizing IC PerformanceDocument6 pagesDescription Features: Maximizing IC PerformanceHernan De OtoNo ratings yet

- High Precision PSR Constant Current LED Driver Description FeaturesDocument8 pagesHigh Precision PSR Constant Current LED Driver Description FeaturesDusmantha AnandaratneNo ratings yet

- High Precision LED Driver Controls Constant CurrentDocument9 pagesHigh Precision LED Driver Controls Constant CurrentDimitar TodorovNo ratings yet

- MT7830A MaxicTechnologyDocument8 pagesMT7830A MaxicTechnologyKamran AzamNo ratings yet

- Non-isolated Buck Constant Current LED Driver ICDocument2 pagesNon-isolated Buck Constant Current LED Driver ICchaghoufNo ratings yet

- BP2833D DatasheetDocument8 pagesBP2833D DatasheetVenegas GamaNo ratings yet

- High Precision Buck Constant Current LED Driver BP2866XJDocument2 pagesHigh Precision Buck Constant Current LED Driver BP2866XJEo GpNo ratings yet

- Ic LedDocument7 pagesIc LedDokter LampuNo ratings yet

- MT7613 Optimizes LED PerformanceDocument6 pagesMT7613 Optimizes LED PerformanceVishal dtuNo ratings yet

- BP9833A Non-isolated Buck LED Driver DatasheetDocument8 pagesBP9833A Non-isolated Buck LED Driver DatasheetnguyenthucsnterNo ratings yet

- Acer v193hq Rc185ac-Anu-Ae01Document52 pagesAcer v193hq Rc185ac-Anu-Ae01sebastinNo ratings yet

- Nithya Electronics Tiruchendur 2A 1.4M 5.5V Synchronous Buck ConverterDocument6 pagesNithya Electronics Tiruchendur 2A 1.4M 5.5V Synchronous Buck ConverterSonu KumarNo ratings yet

- BP2328DDocument2 pagesBP2328DMaslikan AdemNo ratings yet

- 3 A Low Drop Positive Voltage Regulator: Adjustable and FixedDocument27 pages3 A Low Drop Positive Voltage Regulator: Adjustable and FixedTT DVNo ratings yet

- LED Step-Up Converter Drives White LEDs from BatteryDocument7 pagesLED Step-Up Converter Drives White LEDs from BatteryM'handAyoubiNo ratings yet

- BP2857D LED DriverDocument8 pagesBP2857D LED DriverPruebas de funcionamientoNo ratings yet

- AL8861EV1 User GuideDocument8 pagesAL8861EV1 User GuideHans ClarinNo ratings yet

- TRIAC Dimmable Offline LED Driver: TechnologyDocument8 pagesTRIAC Dimmable Offline LED Driver: TechnologyCanerNo ratings yet

- Silergy Corp SY8213FCC - C178246Document9 pagesSilergy Corp SY8213FCC - C178246Thai LamNo ratings yet

- MT7842 MaxicTechnologyDocument6 pagesMT7842 MaxicTechnologyHeart of mountainNo ratings yet

- Non-Isolated Buck APFC LED Driver Description FeaturesDocument9 pagesNon-Isolated Buck APFC LED Driver Description FeaturesRisoSilvaNo ratings yet

- La 4282Document7 pagesLa 4282michelNo ratings yet

- MT7638 DS-EN - Rev1.00Document8 pagesMT7638 DS-EN - Rev1.00Vishal dtuNo ratings yet

- sc4525c 1278277Document23 pagessc4525c 1278277Paulo OliveiraNo ratings yet

- Led Tubelight Driver CircuitDocument22 pagesLed Tubelight Driver CircuitSarvadnya AmbareNo ratings yet

- Description Features: High Accuracy, Dual Winding PSR AC-DC LED DriverDocument8 pagesDescription Features: High Accuracy, Dual Winding PSR AC-DC LED Driverjohnbad36No ratings yet

- Description Features: High Efficiency High Precision Buck Constant Current DriverDocument9 pagesDescription Features: High Efficiency High Precision Buck Constant Current DriverThiagoAlmeidaNo ratings yet

- Bd9423efv e 1223519 PDFDocument61 pagesBd9423efv e 1223519 PDFVươngNo ratings yet

- BD9423EFVDocument61 pagesBD9423EFVIoan TivgaNo ratings yet

- AL5815EV1 User GuideDocument8 pagesAL5815EV1 User GuideJuan Vicente Hernandez LogytelNo ratings yet

- Mains Dimmable Liner LED Driver Description Features: Is A High Current PrecisionDocument7 pagesMains Dimmable Liner LED Driver Description Features: Is A High Current PrecisionMechín Rodriguez Ejvr100% (1)

- Features Description: Ltc4290/Ltc4271 8-Port Poe/Poe+ Pse ControllerDocument32 pagesFeatures Description: Ltc4290/Ltc4271 8-Port Poe/Poe+ Pse ControllerVladimir MartynovNo ratings yet

- MP3388Document12 pagesMP3388mirandowebsNo ratings yet

- Bd9470xxx eDocument38 pagesBd9470xxx eJose GargaglioneNo ratings yet

- DS8510 07Document12 pagesDS8510 07CALINo ratings yet

- Power Converters Lab ManualDocument89 pagesPower Converters Lab ManualHari PrasadNo ratings yet

- RT8577ADocument18 pagesRT8577ASamuel SamTechNo ratings yet

- NCR320PAS / NCR321PAS: 1. Product ProfileDocument18 pagesNCR320PAS / NCR321PAS: 1. Product ProfileЕвгений ИвановNo ratings yet

- Features and Benefits: CMOS High Sensitivity LatchDocument6 pagesFeatures and Benefits: CMOS High Sensitivity LatchJoão AlmeidaNo ratings yet

- pt1301_r3.2_powtechDocument9 pagespt1301_r3.2_powtechOscar Caetano FontNo ratings yet

- TSCR420CX6 / TSCR421CX6: Taiwan SemiconductorDocument11 pagesTSCR420CX6 / TSCR421CX6: Taiwan SemiconductorJuan CecconiNo ratings yet

- Chipown: Low Standby-Power Quasi-Resonant Primary-Side ConverterDocument10 pagesChipown: Low Standby-Power Quasi-Resonant Primary-Side ConverterJoaquin Andres AlarconNo ratings yet

- Description Features: Current Mode PWM ControllerDocument9 pagesDescription Features: Current Mode PWM ControllerAlex GerasimenkoNo ratings yet

- PT4226A/27A/29A Primary Side CC Regulator GuideDocument15 pagesPT4226A/27A/29A Primary Side CC Regulator GuideHenry PalNo ratings yet

- Is Now Part ofDocument9 pagesIs Now Part ofviyikitoNo ratings yet

- BP2325AJ High-Efficiency Non-Isolated Buck LED DriverDocument2 pagesBP2325AJ High-Efficiency Non-Isolated Buck LED DriverFlavio Tonello TavaresNo ratings yet

- MT7605B DSDocument7 pagesMT7605B DSVishal dtuNo ratings yet

- Engine Simulator Board V1.4 ManualDocument7 pagesEngine Simulator Board V1.4 ManualKi Rekso Aljero50% (2)

- EmpowerCTA+ User GuideDocument177 pagesEmpowerCTA+ User GuideJose ReyesNo ratings yet

- Complementary Silicon Power Darlington TransistorsDocument4 pagesComplementary Silicon Power Darlington TransistorsJose ReyesNo ratings yet

- Dokumen - Tips - Soft Key Solutions Hasp4 Hasp HL Hardlock Dongle Emulator For Aladdin HardwareDocument4 pagesDokumen - Tips - Soft Key Solutions Hasp4 Hasp HL Hardlock Dongle Emulator For Aladdin HardwareJose ReyesNo ratings yet

- ICONOS R200 Gen AdjustmentDocument108 pagesICONOS R200 Gen Adjustmentnik100% (1)

- Electrolux Assistent N10 Manual DownloadDocument4 pagesElectrolux Assistent N10 Manual DownloadJose ReyesNo ratings yet

- Compatibilite Des KP Gamme LUST - ENDocument1 pageCompatibilite Des KP Gamme LUST - ENJose ReyesNo ratings yet

- Radiation Medicine Cat en 58721100 12Document100 pagesRadiation Medicine Cat en 58721100 12Jose ReyesNo ratings yet

- TN526D V1 LUST ServoC E0Document9 pagesTN526D V1 LUST ServoC E0Jose ReyesNo ratings yet

- EN - User Manual Collimator R302 Without Filterselection - RevL - 2007-05Document78 pagesEN - User Manual Collimator R302 Without Filterselection - RevL - 2007-05Jose ReyesNo ratings yet

- Kp100 Panel Lust ManualDocument45 pagesKp100 Panel Lust ManualNiwrad MontillaNo ratings yet

- Compact Low-Cost Hybrid Potentiometer with International PatentsDocument1 pageCompact Low-Cost Hybrid Potentiometer with International PatentsJose ReyesNo ratings yet

- UP-D72XR: Digital Film ImagerDocument4 pagesUP-D72XR: Digital Film ImagerJose ReyesNo ratings yet

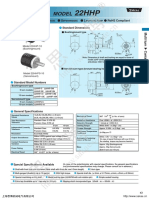

- 22HHPDocument1 page22HHPJose ReyesNo ratings yet

- NCR18650B PanasonicDocument7 pagesNCR18650B PanasonicJose ReyesNo ratings yet

- AMRA Relay Catalog 2016 ENG - 4Document180 pagesAMRA Relay Catalog 2016 ENG - 4Jose Reyes100% (1)

- CAT24C01, CAT24C02, CAT24C04, CAT24C08, CAT24C16 1-Kb, 2-Kb, 4-Kb, 8-Kb and 16-Kb I C CMOS Serial EepromDocument20 pagesCAT24C01, CAT24C02, CAT24C04, CAT24C08, CAT24C16 1-Kb, 2-Kb, 4-Kb, 8-Kb and 16-Kb I C CMOS Serial EepromJose ReyesNo ratings yet

- CAT24C01, CAT24C02, CAT24C04, CAT24C08, CAT24C16 1-Kb, 2-Kb, 4-Kb, 8-Kb and 16-Kb I C CMOS Serial EepromDocument20 pagesCAT24C01, CAT24C02, CAT24C04, CAT24C08, CAT24C16 1-Kb, 2-Kb, 4-Kb, 8-Kb and 16-Kb I C CMOS Serial EepromJose ReyesNo ratings yet

- FLEXlm Reference ManualDocument47 pagesFLEXlm Reference ManualJose ReyesNo ratings yet

- CAT24C01, CAT24C02, CAT24C04, CAT24C08, CAT24C16 1-Kb, 2-Kb, 4-Kb, 8-Kb and 16-Kb I C CMOS Serial EepromDocument20 pagesCAT24C01, CAT24C02, CAT24C04, CAT24C08, CAT24C16 1-Kb, 2-Kb, 4-Kb, 8-Kb and 16-Kb I C CMOS Serial EepromJose ReyesNo ratings yet

- FLEXlm Reference Manual PDFDocument318 pagesFLEXlm Reference Manual PDFJose ReyesNo ratings yet

- TIP Entire ManualDocument105 pagesTIP Entire ManualmuratNo ratings yet

- PIDim Rev 0 Issue For Design 20221025Document58 pagesPIDim Rev 0 Issue For Design 20221025Tommy MurphyNo ratings yet

- Sonar 2076Document2 pagesSonar 2076Henrique NetoNo ratings yet

- Tesks List EksportDocument19 pagesTesks List EksportcvyunaallexamedikaNo ratings yet

- Oracle Big Data SQL Installation GuideDocument139 pagesOracle Big Data SQL Installation Guidepedro.maldonado.rNo ratings yet

- Elements of Industrial Automation (22526) : A Laboratory Manual ForDocument65 pagesElements of Industrial Automation (22526) : A Laboratory Manual ForBihari MathurNo ratings yet

- Trendnxt HTML 5 l1 PDFDocument3 pagesTrendnxt HTML 5 l1 PDFSanjay ShindeNo ratings yet

- UTF-8'en'QRadar SIEM and ZscalerDocument20 pagesUTF-8'en'QRadar SIEM and ZscalerDens Can't Be PerfectNo ratings yet

- Visiview Web Visualisation ToolDocument4 pagesVisiview Web Visualisation ToolNATHANNo ratings yet

- Fuel Injector Cleaner: Form No. 107340Document4 pagesFuel Injector Cleaner: Form No. 107340Leandro Nikko ReintarNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument3 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyAboozar FathinejadNo ratings yet

- Lab 1 - Code Conversion.: A. IntroductionDocument22 pagesLab 1 - Code Conversion.: A. IntroductionAishwarya JSNo ratings yet

- Standard Thermal Store Dec 21Document2 pagesStandard Thermal Store Dec 21ErikNo ratings yet

- IMAGEnet I-Base en New CIDocument6 pagesIMAGEnet I-Base en New CISamuel DJOSSOUNo ratings yet

- 001 - Understanding Convergence in An Autodesk Nastran In-CAD Nonlinear Analysis - Nastran - Autodesk Knowledge NetworkDocument12 pages001 - Understanding Convergence in An Autodesk Nastran In-CAD Nonlinear Analysis - Nastran - Autodesk Knowledge NetworkEquitus EngNo ratings yet

- MGT 625 Talent Management: Case Analysis - The Perfect CEODocument3 pagesMGT 625 Talent Management: Case Analysis - The Perfect CEOMasumiNo ratings yet

- Rotary Actuator and Gripper Selection GuideDocument63 pagesRotary Actuator and Gripper Selection GuideAlexandre DomingosNo ratings yet

- Siemens Energy Company Presentation en 2022 PDF Original FileDocument29 pagesSiemens Energy Company Presentation en 2022 PDF Original FileSunil DashoraNo ratings yet

- C5 X7 Fuses LegendDocument9 pagesC5 X7 Fuses LegendmirelNo ratings yet

- Mighty Press Hat PressDocument9 pagesMighty Press Hat PressJudy NeenaNo ratings yet

- (BURNDY) SectionD Grounding06Document94 pages(BURNDY) SectionD Grounding06María José CucanchonNo ratings yet

- ALE of GL Accounts V 1.0Document21 pagesALE of GL Accounts V 1.0chongNo ratings yet

- Hyundai Motors: Operations and Sourcing of Hyundai ProductsDocument15 pagesHyundai Motors: Operations and Sourcing of Hyundai ProductsAditya JaiswalNo ratings yet

- CS Practical File - Term IDocument6 pagesCS Practical File - Term ITanay MaheshwariNo ratings yet

- Neutral Quick Installation Guide (For Dome CMIP70x2W-28MA) - 20210413Document1 pageNeutral Quick Installation Guide (For Dome CMIP70x2W-28MA) - 20210413Marvin Caballero ZelayaNo ratings yet

- Ferro/Rebar Scanning Report For Agrabad WASA Staff Quarter (East Side Building)Document21 pagesFerro/Rebar Scanning Report For Agrabad WASA Staff Quarter (East Side Building)Biprojit HoreNo ratings yet

- Prso KM S - : Durgapur Public SchoolDocument2 pagesPrso KM S - : Durgapur Public SchoolPrasoon Singh RajputNo ratings yet

- References LinkdnDocument15 pagesReferences LinkdnJamie JordanNo ratings yet

- FCR Prima T2 RS KARYA HUSADADocument18 pagesFCR Prima T2 RS KARYA HUSADAreihan.romanovNo ratings yet

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (543)

- Complete Electronics Self-Teaching Guide with ProjectsFrom EverandComplete Electronics Self-Teaching Guide with ProjectsRating: 3 out of 5 stars3/5 (2)

- Practical Electronics for Inventors, Fourth EditionFrom EverandPractical Electronics for Inventors, Fourth EditionRating: 4 out of 5 stars4/5 (3)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 5 out of 5 stars5/5 (8)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsFrom EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsRating: 3.5 out of 5 stars3.5/5 (2)

- The Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026From EverandThe Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Rating: 5 out of 5 stars5/5 (1)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesFrom EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesRating: 5 out of 5 stars5/5 (1)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersFrom Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersRating: 5 out of 5 stars5/5 (1)

- C++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingFrom EverandC++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingRating: 4 out of 5 stars4/5 (1)

- Winning in 2025: Digital and Data Transformation: The Keys to SuccessFrom EverandWinning in 2025: Digital and Data Transformation: The Keys to SuccessNo ratings yet

- Ramblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowFrom EverandRamblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowNo ratings yet

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)From EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Rating: 4.5 out of 5 stars4.5/5 (2)

- ARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)From EverandARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)No ratings yet

- Current Interruption Transients CalculationFrom EverandCurrent Interruption Transients CalculationRating: 4 out of 5 stars4/5 (1)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesFrom EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesRating: 5 out of 5 stars5/5 (1)

- Foundations of Western Civilization II: A History of the Modern Western World (Transcript)From EverandFoundations of Western Civilization II: A History of the Modern Western World (Transcript)Rating: 4.5 out of 5 stars4.5/5 (12)

- Teach Yourself Electricity and Electronics, 6th EditionFrom EverandTeach Yourself Electricity and Electronics, 6th EditionRating: 3.5 out of 5 stars3.5/5 (15)