Professional Documents

Culture Documents

Computer Aided Manufacturing Lab

Uploaded by

Mez Nacer0 ratings0% found this document useful (0 votes)

6 views4 pagesCOMPUTER-AIDED-MANUFACTURING-LAB

Original Title

COMPUTER-AIDED-MANUFACTURING-LAB

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCOMPUTER-AIDED-MANUFACTURING-LAB

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views4 pagesComputer Aided Manufacturing Lab

Uploaded by

Mez NacerCOMPUTER-AIDED-MANUFACTURING-LAB

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

The Computer Aided Manufacturing (CAM) Centre has 30 HP workstations and 30 DELL Precision T1700

with 21" monitors, high-end CAM softwares such as CATIA V6, Master CAM 2019 for Solidworks, See NC

TURN 10 and See NC Mill 10 for manual Part programming simulator, Solidworks 2018, Solid Cast 8,

COMSOL Multiphysics 5.2a, CNC MACHINE EMCO CONCEPT TURN-55 Trainer Lathe, CNC MACHINE

EMCO CONCEPT MILL-55 Trainer Milling.

CNC MACHINE EMCO CONCEPT MILL-55

Equipment Cost : EUR 29,646.12

Date of Purchase : 21-12-2010

Software : WinNC Fanuc 21-M

Technical Specifications:

Travel (X/Y/Z) : 190/140/260 mm

Milling Table (LxW) : 420 x 125 mm

Spindle Speed Range : 150-3500 R/min

Rapid Traverse : 0 - 2 m/min

Feed Rate : 0 - 2 m/min

Tool Turret : Programmable 8 station Automatic Tool

Changer – optional

Tool System : Similar to ISO 30

Power Supply : 115/230v, 50/60 Hz

Machine Dimensions (LxDxH) : 960 x 1000 x 980 mm

Machine weight : 190kg with ATC

Interchangeable Control System : Fanuc Siemens Heidenhain CAM Concept

Safety equipment : Compliance with CE regulations

Optional 4th Axis : CNC Programmable c/w 3 jaw chuck

CNC MACHINE EMCO CONCEPT TURN-55

Equipment Cost : EUR 15,861.49

Date of Purchase : 21-12-2010

Software : WinNC Fanuc 21-M

Technical Specifications:

Max turning diameter : 52 mm

Centre height : 65 mm

Distance between centre : 280 mm

Swing over bed : 130 mm

Swing over cross slide : 60 mm

Travel X Z : 48 x 236 mm

Spindle speed : 100 - 4000 R/min

Spindle bore : 16 mm

Constant surface speed : Programmable

Spindle motor : 0.75 kW ( 1 hp )

Rapid traverse : 2 m/min

Feed : 0 - 2 m/min

Tool Turret : 8 station automatic tool changer

Power supply : 230 V 50/60 Hz

Machine Dimensions (LxDxH) : 400 x 695 x 840 mm

Machine weight : 85 kg

Interchangeable Control System : Fanuc Siemens Heidenhain CAM Concept

Industrial design : 2 axes slant bed lathe

Safety equipment : Compliance with CE regulations

Software Details

Sl. No. of

Name of the Software Capabilities

No seats

Generative Drafting, Part Designing, Assembly

Designing, IGES Interface, Free Style Shaper &

Solid Works Version Optimizer, Analysis on Motion, Flow works & Load

1. 60

2018 application, Conversion of 2D drawing to 3D drawing,

Surface Modeling, Sheet metal works, Mould

manufacturing tools.

Master CAM Version CAD Modular, 2.5-axis Machining, 3-Axis Machining,

2. 2019 60 Simulation, c-Axis turning, 5-Axis Machining and

Generate the codes.

Generative Drafting, Part Designing, Assembly

CATIA Version Designing, IGES Interface, Free Style Shaper &

3. 60

V5R16 Optimizer, Analysis, 3-axis Machining, Prismatic

Machining, V4 Integration, Object Manager.

CADEM (CNC Lathe Tool for Simulation and Detecting flaws in Manual

4. & Milling Simulation) 50 CNC Part Programming. Cadem Technologies, 2010

2010

Mould filling, Solidification, Cooling and to predict the

5. Solid Cast 60 location of internal defects such as shrinkage porosity

and clod shuts.

Integrated user interface environment designed for cross

COMSOL Multi disciplinary product development with a unified

6. 1

Physics Software workflow for electrical, mechanical, fluid and chemical

applications.

Faculty associated with the lab

Lab In-Charge : Prof. T. SAMPATH KUMAR

Name of the Faculty Area of Expertise

Prof. Raja K Rapid Prototyping, CAD/CAM

Assembly Planning; New Product

Prof. Arun Tom Mathew

Development; FEM Motion Study

Prof. Denis Ashok Design and Automation, Machine Vision

Prof. E. Rajkumar Design and Automation, virtual reality

Rapid prototyping (medical and tooling),

Functionally Graded Material, Computer

Prof. Sugavaneswaran

aided design (automation and bio-cad),

Fea (Mechanics Of Multiple Material)

Metal Matrix composites, Material

Prof. Venkatesan S Characterization Design and analysis of

machine components

Prof. Oyyaravelu R Laser Welding, CAD/CAM, Manufacturing

Request form for using the CAM LAB facilities:

You might also like

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0From EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Rating: 5 out of 5 stars5/5 (1)

- Cam 1Document176 pagesCam 1bm713576No ratings yet

- CNC Router Essentials: The Basics for Mastering the Most Innovative Tool in Your WorkshopFrom EverandCNC Router Essentials: The Basics for Mastering the Most Innovative Tool in Your WorkshopRating: 5 out of 5 stars5/5 (3)

- 1 s2.0 S2214785322059521 MainDocument9 pages1 s2.0 S2214785322059521 MainfelipeNo ratings yet

- CAD Systems in Mechanical and Production EngineeringFrom EverandCAD Systems in Mechanical and Production EngineeringRating: 4.5 out of 5 stars4.5/5 (3)

- Design and Fabrication of Mini 5 Axis CNC Machine For Gemstone CarvingDocument5 pagesDesign and Fabrication of Mini 5 Axis CNC Machine For Gemstone CarvingBi LoNo ratings yet

- Vcta-Lc800-Lc810 - LC820Document5 pagesVcta-Lc800-Lc810 - LC820qeeNo ratings yet

- ME 408.01 - Computer Aided Manufacturing - Lab ManualDocument24 pagesME 408.01 - Computer Aided Manufacturing - Lab ManualOMKAR MUSHRIFFNo ratings yet

- Dsa 5500Document12 pagesDsa 5500Nguyen Van ToanNo ratings yet

- MillingDocument53 pagesMillingMuhammad Asif Shehzad KhanNo ratings yet

- C-Line 3D CMM: Portable Coordinate Measuring Machine for WorkshopsDocument8 pagesC-Line 3D CMM: Portable Coordinate Measuring Machine for WorkshopsaniketgunjalNo ratings yet

- Electronic CircuitsDocument91 pagesElectronic Circuitsvinay Shastry100% (6)

- SyllabusDocument3 pagesSyllabusAnonymous 4h9p1EIQYSNo ratings yet

- ULLASDocument36 pagesULLASKiranNo ratings yet

- Hurco VM2 ProposalDocument14 pagesHurco VM2 ProposalRonza129No ratings yet

- Implementation of CAD/CAM System CATIA V5 in Simulation of CNC Machining ProcessDocument8 pagesImplementation of CAD/CAM System CATIA V5 in Simulation of CNC Machining ProcessRay SaNo ratings yet

- Prototype CNC Machine Design Article Analyzes Modular SystemDocument6 pagesPrototype CNC Machine Design Article Analyzes Modular SystemTheng ChanntholNo ratings yet

- Prototype CNC Machine Design PDFDocument6 pagesPrototype CNC Machine Design PDFTheng ChanntholNo ratings yet

- Sarkar 2020 IOP Conf. Ser. Mater. Sci. Eng. 810 012066Document10 pagesSarkar 2020 IOP Conf. Ser. Mater. Sci. Eng. 810 012066Fahru ZainiNo ratings yet

- V. S. B Engineering College CAD/CAM Lab ManualDocument121 pagesV. S. B Engineering College CAD/CAM Lab ManualvinodkumarNo ratings yet

- V2i2 Ijertv2is2330Document5 pagesV2i2 Ijertv2is2330abdollahzadehNo ratings yet

- CNC-Cutting-Solutions CNC Controller For Cutting Machines WebDocument16 pagesCNC-Cutting-Solutions CNC Controller For Cutting Machines Webismet hyseniNo ratings yet

- ME1355-CAD / CAM Laboratory: Lab ManualDocument42 pagesME1355-CAD / CAM Laboratory: Lab ManualVeeria Chandran S100% (1)

- Darocha 2010Document5 pagesDarocha 2010Tahmidur FahimNo ratings yet

- IJRPR937Document8 pagesIJRPR937Prenank ChandrolNo ratings yet

- Ali 2021 IOP Conf. Ser. Mater. Sci. Eng. 1094 012005Document14 pagesAli 2021 IOP Conf. Ser. Mater. Sci. Eng. 1094 012005Yashvant SinghNo ratings yet

- Acknowledgement: Pathak (The Dean of Academic Affairs) For Providing Me A Platform Like KMT To IncreaseDocument29 pagesAcknowledgement: Pathak (The Dean of Academic Affairs) For Providing Me A Platform Like KMT To Increaseshivang poddarNo ratings yet

- Fifth Annual Electrical Engineering ExhibitionDocument6 pagesFifth Annual Electrical Engineering Exhibitionshafee001No ratings yet

- PC Fapt BrochureDocument2 pagesPC Fapt Brochurebabak671No ratings yet

- CNC Milling Machine FYP Final Report V1Document53 pagesCNC Milling Machine FYP Final Report V1Piyush NarkhedeNo ratings yet

- Venture Depliants Macchines For Industry - EngDocument9 pagesVenture Depliants Macchines For Industry - EngTanvon MalikNo ratings yet

- Atk Laser PPT CNCDocument10 pagesAtk Laser PPT CNCsurjitrajput8No ratings yet

- Stapper MotoresDocument3 pagesStapper Motoresnasser4858No ratings yet

- Me704 Cim (Cad)Document25 pagesMe704 Cim (Cad)ASHU KNo ratings yet

- Design and Fabrication of Low-Cost Polar CNC 2D PrinterDocument25 pagesDesign and Fabrication of Low-Cost Polar CNC 2D PrinterLovely AtchuthNo ratings yet

- Automatic Metal Sheet Cutting MachineDocument2 pagesAutomatic Metal Sheet Cutting MachinekothandapaniNo ratings yet

- CAM GuideDocument10 pagesCAM Guideio1_roNo ratings yet

- PLM Indishtech Pvt Ltd - Digital Twin and Virtual Commissioning ExpertsDocument16 pagesPLM Indishtech Pvt Ltd - Digital Twin and Virtual Commissioning ExpertsMounesh7No ratings yet

- 160TCLi PC Technical SpecificationDocument8 pages160TCLi PC Technical SpecificationChristina BassNo ratings yet

- Mee2007 Cad CamDocument2 pagesMee2007 Cad CamSrivathson EswaranNo ratings yet

- Online Millwright Fees DetailsDocument5 pagesOnline Millwright Fees DetailsAnup ShuklaNo ratings yet

- NX CAM Post Processing Errors Machine Data File Ge PDFDocument7 pagesNX CAM Post Processing Errors Machine Data File Ge PDFSHARAD CHANDRANo ratings yet

- Project CNC Par1Document11 pagesProject CNC Par1Gaurav JogiNo ratings yet

- Computer Integrated Manufacturing (PLTW) SyllabusDocument4 pagesComputer Integrated Manufacturing (PLTW) SyllabusmailmelakaNo ratings yet

- CNC Machine Design Prototype Developed by Brazilian ResearchersDocument5 pagesCNC Machine Design Prototype Developed by Brazilian Researchershasan alsarrafNo ratings yet

- Mold&dieDocument2 pagesMold&dieTRUNG QUOC LENo ratings yet

- Mechanical - VI. Sem Syllabus GtuDocument115 pagesMechanical - VI. Sem Syllabus GtukishormechNo ratings yet

- Courses Fees Detail Pamphlet PDFDocument2 pagesCourses Fees Detail Pamphlet PDFRajkumar ANo ratings yet

- P53说明书 EN1207Document19 pagesP53说明书 EN1207Yousif AlkhalilNo ratings yet

- Laser Solar A La WebadaDocument9 pagesLaser Solar A La Webada200901659No ratings yet

- Post ProcessingDocument12 pagesPost Processingsukhbir24No ratings yet

- Implementation and Control System of Foam Cutting MachineDocument32 pagesImplementation and Control System of Foam Cutting MachineKhant Wai YanNo ratings yet

- Dsa 5600 - Fresa CNCDocument12 pagesDsa 5600 - Fresa CNCxemante50% (2)

- CNC (VMC), Additive Manufacturing and RoboticsDocument27 pagesCNC (VMC), Additive Manufacturing and RoboticsB K Santosh SanthuNo ratings yet

- WhatsNew CimatronE 9.0 Version HighlightsDocument3 pagesWhatsNew CimatronE 9.0 Version HighlightsfaizNo ratings yet

- Design and Implementation of 3 Axis CNC Milling MachineDocument7 pagesDesign and Implementation of 3 Axis CNC Milling Machineအောင် ချစ်သူNo ratings yet

- Super Asia PresentationDocument23 pagesSuper Asia PresentationHajiNo ratings yet

- CNC Router Research PaperDocument7 pagesCNC Router Research Paperafeawqynw100% (1)

- Notas 2 CNC MACHINE TOOLSDocument5 pagesNotas 2 CNC MACHINE TOOLSArmandoNo ratings yet

- Cad Cam - 22.12.15-1 PDFDocument87 pagesCad Cam - 22.12.15-1 PDFGuru MaheshNo ratings yet

- Dokumen - Tips - Concept Mill 55 Operate 840d SL 828d Siemens 810d840d Fanuc Series 0Document20 pagesDokumen - Tips - Concept Mill 55 Operate 840d SL 828d Siemens 810d840d Fanuc Series 0Mez NacerNo ratings yet

- EMCO PC Turn 50 Electrical DocumentationDocument26 pagesEMCO PC Turn 50 Electrical DocumentationMez NacerNo ratings yet

- Kurzanleitung WinNC Update EN ADocument10 pagesKurzanleitung WinNC Update EN AMez NacerNo ratings yet

- CNC Milling Center Training Purposes Concept MILL 55Document4 pagesCNC Milling Center Training Purposes Concept MILL 55Mez NacerNo ratings yet

- FT5 ITCM enDocument18 pagesFT5 ITCM enMez NacerNo ratings yet

- Emco Concept Mill Techspec PDFDocument23 pagesEmco Concept Mill Techspec PDFprimayuwanaNo ratings yet

- Cherry 2020 Price List WsDocument64 pagesCherry 2020 Price List WsMez NacerNo ratings yet

- JCB 3CX, 4CX Eco Backhoe Loader PDF Specification PDFDocument24 pagesJCB 3CX, 4CX Eco Backhoe Loader PDF Specification PDFPMV DeptNo ratings yet

- Drive Circuit Basics: Industrial Circuits Application NoteDocument7 pagesDrive Circuit Basics: Industrial Circuits Application Notepokka20_pokkaNo ratings yet

- Step Motor BasicsDocument16 pagesStep Motor Basicsmarques1900No ratings yet

- SUSAN SCHOENIAN (Shāy-Nē-Ŭn) Sheep & Goat Specialist Western Maryland Research & Education CenterDocument49 pagesSUSAN SCHOENIAN (Shāy-Nē-Ŭn) Sheep & Goat Specialist Western Maryland Research & Education CenterMez NacerNo ratings yet

- JCB Backhoe Loader Product GuideDocument26 pagesJCB Backhoe Loader Product GuideMez Nacer0% (1)

- الطيور الرومية و أساليب تربيتهاDocument48 pagesالطيور الرومية و أساليب تربيتهاMez NacerNo ratings yet

- (2) الأعلاف المركزة و الخضراء و استعمالاتها في تغذية الحيوان -37Document29 pages(2) الأعلاف المركزة و الخضراء و استعمالاتها في تغذية الحيوان -37essamotabiNo ratings yet

- Parasites in GoatsDocument57 pagesParasites in GoatsMez NacerNo ratings yet

- Cessna 180 Skywagon: Key Black Cut Red 50% Cut Blue GuideDocument1 pageCessna 180 Skywagon: Key Black Cut Red 50% Cut Blue GuideMez NacerNo ratings yet

- Cessna 180 Skywagon: Iconic Small PlaneDocument1 pageCessna 180 Skywagon: Iconic Small PlaneMez NacerNo ratings yet

- N210 MD1GD3 PDFDocument1 pageN210 MD1GD3 PDFMez NacerNo ratings yet

- 12 Forging RollingDocument47 pages12 Forging RollingBitthal ParidaNo ratings yet

- Design and Fabrication of Power Scissor JackDocument39 pagesDesign and Fabrication of Power Scissor Jackmohamedovic100% (4)

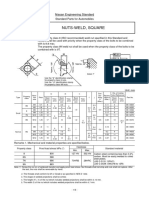

- Nes D2242Document6 pagesNes D2242prasannaNo ratings yet

- Prosprod I Casting Process (2) - Part2 PDFDocument36 pagesProsprod I Casting Process (2) - Part2 PDFPandu WibowoNo ratings yet

- Sheet Metal Gauge Size Chart-Stainless SteelDocument2 pagesSheet Metal Gauge Size Chart-Stainless Steellorenzinho290No ratings yet

- Fitting Workshop Manual2014Document35 pagesFitting Workshop Manual2014Sachi DhanandamNo ratings yet

- Material Data Sheet: Material Number Country DesignationsDocument2 pagesMaterial Data Sheet: Material Number Country DesignationsMogos PaulNo ratings yet

- Types of SpannersDocument6 pagesTypes of Spannerschandu maheshwariNo ratings yet

- Manual Guide I CNC Milling Made Easy ManualDocument126 pagesManual Guide I CNC Milling Made Easy ManualJasminNo ratings yet

- All Cad Files Group 1Document20 pagesAll Cad Files Group 1api-598255067No ratings yet

- MEE2001 Machine Drawing Digital AssignmentsDocument3 pagesMEE2001 Machine Drawing Digital Assignmentsdude_udit321771No ratings yet

- Zed Purlins Roll Forming LeafletDocument6 pagesZed Purlins Roll Forming LeafletTakis ApostolidesNo ratings yet

- PS 1804 (S)Document19 pagesPS 1804 (S)dzilioNo ratings yet

- Versatile Fence V SeriesDocument2 pagesVersatile Fence V SeriesWeng Hoe ChooNo ratings yet

- Design of Dies - Unit 5 PDFDocument178 pagesDesign of Dies - Unit 5 PDF210 SureshNo ratings yet

- Stamped Metal Jewelry: Creative Techniques & Designs For Making Custom JewelryDocument8 pagesStamped Metal Jewelry: Creative Techniques & Designs For Making Custom JewelryInterweave100% (1)

- A473 99 PDFDocument5 pagesA473 99 PDFJohano Araújo100% (1)

- Jonnesway Part Number CatalogDocument94 pagesJonnesway Part Number CatalogMikhaylovMikkelsenNo ratings yet

- Flekserica B&D BEG110 Spare PartsDocument2 pagesFlekserica B&D BEG110 Spare PartsEustahije BrzicNo ratings yet

- Gupilya Split Pins Splint: DIN 94-ISO 1234 A2-A4Document108 pagesGupilya Split Pins Splint: DIN 94-ISO 1234 A2-A4Arif AkbasNo ratings yet

- Making A Wooden Clockworks 2Document8 pagesMaking A Wooden Clockworks 2MiguelDelBarrioIglesisasNo ratings yet

- Heat Treatment Effects on Material PropertiesDocument5 pagesHeat Treatment Effects on Material PropertiesArgha DasNo ratings yet

- Cable TrayDocument27 pagesCable TrayRoron Wicaksono100% (1)

- Technology of Machine ToolsDocument60 pagesTechnology of Machine Toolsaly_wael71No ratings yet

- Val Caraig WPQTDocument1 pageVal Caraig WPQTMark Jason M. BrualNo ratings yet

- Hand Tools AMTDocument102 pagesHand Tools AMTboomscud33No ratings yet

- Torque For BoltDocument18 pagesTorque For BoltZoebairNo ratings yet

- WX100 Fastener Finish Speecification PDFDocument16 pagesWX100 Fastener Finish Speecification PDFJulion2009No ratings yet

- Astm F1554Document9 pagesAstm F1554CPA BTKNo ratings yet

- Cutting Tool - 0Document45 pagesCutting Tool - 0Sam SadaNo ratings yet