Professional Documents

Culture Documents

Annexure - Equipment Inspection Check Sheet EESL

Uploaded by

aravindappiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Annexure - Equipment Inspection Check Sheet EESL

Uploaded by

aravindappiCopyright:

Available Formats

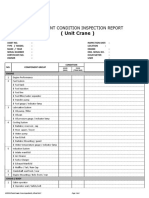

HEAVY EQUIPMENT INSPECTION

Owner name: MFG. /Model:

Year of MFG: Equipment No :

Maximum load: Result : OK / NOT OK

Inspection date: Due date:

Applicable For : Mobile Crane, Hydraulic Excavator, Bulldozer, Grader, Boom & Scissors Lifts

DETAILS OF INSPECTION

NOT

Check List OK OK NA Remark

1. Necessary Guards provided

2. Boom (limits switch) / Mechanical stopper

3. Hook (small, big), Safety Latch

4. Shelve, Roller

5. Rigging (Rope, Spherical)

6. Outrigger, Lock

7. Hydraulic line / Leakage

8. Condition of Petrol / Diesel storage tank

9. Condition of Tyre

10. Driving license of the operator

11. Test certificate / Fitness certificate

12. Hook should be certified

13. Rope/Sling test certificate

14. General physical condition of m/c

15. No black exhaust (PUC certificate)

Contractor Representative: _________________ Date: _____________

TML Request Team Representative : _________________ Date: ____________

TML Safety Representative: _________________ Date: ____________

CONCRETE CUTTING / PLATE COMPACTOR INSPECTION

Owner name: MFG. /Model:

Year of MFG: Equipment No :

Maximum load: Result : OK / NOT OK

Inspection date: Due date:

Applicable For : Concrete cutting machine, Plate compactor and Compactor

DETAILS OF INSPECTION

Check List OK NOT NA Remark

OK

1. Overall structure are safe

2. Moving part has guard

DIESEL OPERATED

3. Engine starter is safe

4. Engine has no crack, no leak

5. Engine control and emergency switch

is usable

6. Fuel tank has cover

7. No black exhaust (PUC certificate)

8. Switch condition

9. Shaft has a guard

10. Fuel tank leakage

ELECTRICALLY OPERATED

11. Earthing on m/c.

12. Starter in good condition

13. Earthing on motor

14. Guard available on motor.

15. Fuel tank leakage

16. Cable in good condition

17. Appropriate cable size

PNUMATIC OPERATED

18. Pnumatic hose condition and clamp

Contractor Representative: _________________ Date: _____________

TML Request Team Representative : _________________ Date: ____________

TML Safety Representative: _________________ Date: ____________

AIR COMPRESS0R INSPECTION

Owner name: MFG. /Model:

Year of MFG: Equipment No :

Maximum load: Result : OK / NOT OK

Inspection date: Due date:

Applicable For : Air Compressor

DETAILS OF INSPECTION

NOT

Check List OK OK NA Remark

1. Overall structure are safe

2. All control bottoNs and switches are in

good shape and usable

3. Distribution valve is good condition

4. Engine cover/Rotating shaft has good

Support

5. Tow connection is in good condition

6. Battery has cover

7. Air storage tank is in good condition with

approved

8. Engine has no crack, no leak

9. Air system has safety valve

10. Have wheel shock

11. Pressure Gauge condition

12. Safety valve has test certificate

13. Pressure relief valve

ELECTRICALLY OPERATED

14. Earthing on m/c.

15. Starter in good condition

16. Earthing on motor

17. Guard available on motor.

18. Fuel tank leakage

19. Cable in good condition

20. Appropriate cable size

Contractor Representative: _________________ Date: _____________

TML Request Team Representative : _________________ Date: ____________

TML Safety Representative: _________________ Date: ____________

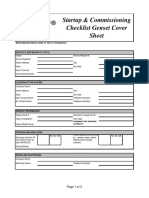

GENERATOR INSPECTION

Owner name: MFG. /Model:

Year of MFG: Equipment No :

Maximum load: Result : OK / NOT OK

Inspection date: Due date:

Applicable For : Generator

DETAILS OF INSPECTION

NOT

Check List OK

OK

NA Remark

1. Overall structure are safe

2. All control bottoms and switches are in

good shape and usable

3. Emergency switch is in place

4. Distribution point is in good shape

5. Equipped with ground cable connection

point

6. All cables are in good shape and certified

7. Fire extinguisher available

8. Lifting point or tow point is safe

9. Engine has no crack, no leak

10. AUM (Anti Vibration mounting) available

11. Alternator is totally enclosed

12. No live part shall be exposed

13. Control panel is certified

Contractor Representative: _________________ Date: _____________

TML Request Team Representative : _________________ Date: ____________

TML Safety Representative: _________________ Date: ____________

DISTRIBUTION PANEL INSPECTION

Owner name: MFG. /Model:

Year of MFG: Equipment No :

Maximum load: Result : OK / NOT OK

Inspection date: Due date:

Applicable For : Distribution Panel

DETAILS OF INSPECTION

NOT

Check List OK

OK

NA Remark

1. Panel cover water proof

2. Main circuit breaker is in good shape and

match with the load.

3. Equipped with electrical leak circuit

breaker (ELCB)

4. Use standard cable

5. Connecting point shall be terminated

using appropriate gland

6. Socket plug have cover and water proof

7. Ground cable size is 1/5 of feeding cable

8. Connect to grounding rod

9. Dangerous sign posted at panel

10. Field distribution panel is located in

dry area

11. Use cable tie to tight the cable

12. Erthing provision

13. Main incoming shall have entended

Rotary shaft with facility for pad locking

and defect interlock.

14. Outgoing feedus shall have facility for

lock-out.

Contractor Representative: _________________ Date: _____________

TML Request Team Representative : _________________ Date: ____________

TML Safety Representative: _________________ Date: ____________

WELDING MACHINE INSPECTION

Owner name: MFG. /Model:

Year of MFG: Equipment No :

Maximum load: Result : OK / NOT OK

Inspection date: Due date:

Applicable For : Welding Machine

DETAILS OF INSPECTION

Check List OK NOT OK NA Remark

1. Welding machine body has good condition

2. All of switches are in good condition

3. Voltage regulator is in good condition

4. Feeding cable size is 10 Sqm. at least

5. Use nut and bolt to tighten welding and grounding cable

6. Electrode welding holder is in good condition

7. Welding and grounding cables are good condition

8. Earthing privided

9. Welding earhting cable in good condition

10. ELCB with 30mA rating provided

11. Welding m/c earthing provided

12. Gland available on welding m/c

13. Colour of welding cable (Orange)

14. Colour of earthing cable (Black)

15. Welding cable terminated properly in the welding holder.

16. Termination of the return earthing

17. Cable from welding m/c to the point of weld piece. It should be

free from cut/damage. No joints shall be allowed in the cable.

18. Actul load No load output voltage of the welding m/c measured

between the earth and phase ( The phase tap shall be at 230 V )

19. Earthing clamp proper and suitable for the application

21. Welding m/c ISI Marked and certificated by authorized agencies.

Welding m/c Single/Two/Three

Contractor Representative: _________________ Date: _____________

TML Request Team Representative : _________________ Date: ____________

TML Safety Representative: _________________ Date: ____________

ELECTRIC DRILL / TORQUE WRENCH INSPECTION

Owner name: MFG. /Model:

Year of MFG: Equipment No :

Maximum load: Result : OK / NOT OK

Inspection date: Due date:

Applicable For : Electric Drill & Torque wrench

DETAILS OF INSPECTION

NOT

Check List OK

OK

NA Remark

1. Body structure is in good condition

2. Cable has double insulation

3. Cable and plug are in good condition

4. Remove speed lock control out

5. Minimum size of cable is 3 x 1.5 Sqm.

6. Moving part have guard cover

7. Industrial plug top available

8. Earthing provided

Contractor Representative: _________________ Date: _____________

TML Request Team Representative : _________________ Date: ____________

TML Safety Representative: _________________ Date: ____________

GAS CUTTING SET INSPECTION

Owner name: MFG. /Model:

Year of MFG: Equipment No :

Maximum load: Result : OK / NOT OK

Inspection date: Due date:

Applicable For : Gas cutting set

DETAILS OF INSPECTION

NOT

Check List OK

OK

NA Remark

1. Gas cylinders are in good condition

2. Gas cylinders vertically sitting on trolley

then tighten with chain

3. Gas regulators are inspected and

calibrated , no damage

4. Equipped with flash back arrester

(both oxygen and acetylene)

5. Use hose clamp at the connecting point

6. Hoses are in good condition and tied

properly

7.Ignition source available (Use approved

ignition torch)

8. Soapy water available

9. Fire extinguisher available

10. Gas cylinder cap available

11. Cylinder Key/Handle available

12. Colour code for hose (Blue)

13. Colour code for flammable gas.(Red)

14. Signage of cylinders

Contractor Representative: _________________ Date: _____________

TML Request Team Representative : _________________ Date: ____________

TML Safety Representative: _________________ Date: ____________

FULLBODY HARNESS INSPECTION

Owner name: MFG. /Model:

Year of MFG: Equipment No :

Maximum load: Result : OK / NOT OK

Inspection date: Due date:

Applicable For : Full body Harness

DETAILS OF INSPECTION

NOT

Check List OK

OK

NA Remark

1. Full body is in a good condition

do not have cut, tear, swollen or crack.

2. Clip lock at the chest and leg are in a

good condition.

3. D-RING do not have rust or bend.

4. Lanyard do not damage or tear.

5. Shock absorber is in a good condition

and covered.

6. Snap hook are in a good condition such

as bending, twisting, increased throat

opening, crack, nick and inoperative

latches.

7. Full Body Harness should be ISI marked

8. Locking arrangement of hooks

9. Rope condition

Contractor Representative: _________________ Date: _____________

TML Request Team Representative : _________________ Date: ____________

TML Safety Representative: _________________ Date: ____________

FORKLIFT INSPECTION

Owner name: MFG. /Model:

Year of MFG: Equipment No :

Maximum load: Result : OK / NOT OK

Inspection date: Due date:

Applicable For : Full body Harness

DETAILS OF INSPECTION

NOT

Check List OK

OK

NA Remark

1. Horn

2. Steering

3. Battery Indicator

4. Hand Brake

5. Direction Indicator

6. Accelarator

7. Tires & Wheels

8. Overhead Guard

9. Lights

10. Brake(s)

11. Reverse Horn

12. Forks, Mast, Chains,

13. Seat belt & Backrest

14. Hydraulic Cylinders

15. Hydraulic Hoses & Fittings

16. Fuel Leaks

17. Operator License

18. Elecric cable condition

19. Nuts & Bolts (Wheel & Fork)

20. Test Certificate

Contractor Representative: _________________ Date: _____________

TML Request Team Representative : _________________ Date: ____________

TML Safety Representative: _________________ Date: ____________

`

TOWTRUCK INSPECTION

Owner name: MFG. /Model:

Year of MFG: Equipment No :

Maximum load: Result : OK / NOT OK

Inspection date: Due date:

Applicable For : Full body Harness

DETAILS OF INSPECTION

NOT

Check List OK

OK

NA Remark

1. Horn

2. Steering

3. Elecric cable condition

4. Direction Indicator

5. Reverse Horn

6. Condition of Rear Hook

7. Condition of Key switch

8. Tires & Wheels

9. Lights

10. Brake(s)

11. Operator License

12. Seat Belt & Backrest

13. Hand Brake

14. Emergency Stop Switch

Contractor Representative: _________________ Date: _____________

TML Request Team Representative : _________________ Date: ____________

TML Safety Representative: _________________ Date: ____________

You might also like

- Construction Machinery Checklist-AllDocument14 pagesConstruction Machinery Checklist-Allpartha50% (2)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Dewatering PumpDocument14 pagesDewatering PumpparthaNo ratings yet

- Preuse Check List of Welding MachinesDocument1 pagePreuse Check List of Welding MachinesloganathanNo ratings yet

- INSP1 MobileCraneDailyInspectionDocument1 pageINSP1 MobileCraneDailyInspectionFuzail Ayaz100% (1)

- Sr. Nos. Inspection Items Yes No N/A: / HireDocument1 pageSr. Nos. Inspection Items Yes No N/A: / HireFuzail AyazNo ratings yet

- Saudi Aramco Pre-Commissioning Form: Dehydrator-Desalter TransformerDocument4 pagesSaudi Aramco Pre-Commissioning Form: Dehydrator-Desalter TransformerHaleem Ur Rashid BangashNo ratings yet

- Inspection Report Equipment Crawler CraneDocument4 pagesInspection Report Equipment Crawler CraneBryan Gates Avengedformyvalentine100% (1)

- Crawler Crane Inspection CheklistDocument2 pagesCrawler Crane Inspection CheklistALWI KARYANo ratings yet

- Welding Machine ChecklistDocument34 pagesWelding Machine ChecklistShahid BhattiNo ratings yet

- Periodical Insp of Portable Grinding MCDocument2 pagesPeriodical Insp of Portable Grinding MCloganathanNo ratings yet

- 18 - Fork Lift Defect - OptDocument4 pages18 - Fork Lift Defect - OptMoataz NazeemNo ratings yet

- Swab Tanker - Daily Checklist - Blue-WhiteDocument2 pagesSwab Tanker - Daily Checklist - Blue-WhitePCSL TransportNo ratings yet

- 25 - Checklist For Grinding MachineDocument1 page25 - Checklist For Grinding MachineMahmoud MoussaNo ratings yet

- Air Compressor PDFDocument1 pageAir Compressor PDFezuanNo ratings yet

- Alat Mobile CraneDocument2 pagesAlat Mobile CraneDebi NovitaNo ratings yet

- HSE Precheck List 1611927511Document22 pagesHSE Precheck List 1611927511sharathNo ratings yet

- Work Instructions For Rolling of PlatesDocument3 pagesWork Instructions For Rolling of PlatesPravin Patil100% (1)

- Diesel Generator Inspection Form: Doc. No. 26071-JO-HSE-PMOB-006 Effective Date 08 February 2021 Revision No. 1Document4 pagesDiesel Generator Inspection Form: Doc. No. 26071-JO-HSE-PMOB-006 Effective Date 08 February 2021 Revision No. 1Muhammad AlnurizzatiNo ratings yet

- Maintenance Schedule For SubstationDocument21 pagesMaintenance Schedule For SubstationSajid Shaikh100% (1)

- Crane Inspection: Leaks - Fuel, Lube, Oil, WaterDocument2 pagesCrane Inspection: Leaks - Fuel, Lube, Oil, WaterAlzaki AbdullahNo ratings yet

- Certificate For Examination of Overhead CraneDocument2 pagesCertificate For Examination of Overhead CraneAnisha MayaNo ratings yet

- WorkSafeBC - Forklift Inspection ChecklistDocument0 pagesWorkSafeBC - Forklift Inspection ChecklistjohnzepolNo ratings yet

- Check List For CraneDocument30 pagesCheck List For CraneMukesh KatarnavareNo ratings yet

- Toaz - Info Cat Compact Start Up and Commissioning Checklist PRDocument19 pagesToaz - Info Cat Compact Start Up and Commissioning Checklist PRKhaled Naseem Abu-SabhaNo ratings yet

- Commissioning Form - Crane TruckDocument2 pagesCommissioning Form - Crane TruckKurniawan PriambodoNo ratings yet

- Genset Startup and Commissioning Checklist C 175Document3 pagesGenset Startup and Commissioning Checklist C 175Dwi Mulyanti Dwimulyantishop100% (1)

- PrecommissioningSwitchgear GeneralDocument3 pagesPrecommissioningSwitchgear GeneralSatish ReddyNo ratings yet

- Gms Ele Itp 001 HV & LV SwitchgearDocument12 pagesGms Ele Itp 001 HV & LV Switchgearnidnitrkl051296100% (1)

- Check ListsDocument30 pagesCheck ListsAhmed Gomaa100% (1)

- 299 Service Vehicle ChecklistDocument1 page299 Service Vehicle ChecklistAlfred PabloNo ratings yet

- PPMG Engineering ServiceslimitedDocument6 pagesPPMG Engineering ServiceslimitedikponmwonsaNo ratings yet

- 007 Portable Hand GrindingDocument1 page007 Portable Hand Grindinghaslinda Abdul SahakNo ratings yet

- All ChecklistDocument31 pagesAll Checklistsunil KumarSwainNo ratings yet

- Sop For Motor Changing JobDocument10 pagesSop For Motor Changing JobT S Virdi50% (2)

- Boom Lift - Daily ChecklistDocument1 pageBoom Lift - Daily Checklistpawankumar100% (2)

- D.G.SETDocument5 pagesD.G.SETloganathanNo ratings yet

- Ee03100 Low Voltage SwitchboardDocument25 pagesEe03100 Low Voltage SwitchboardDeepak Verma100% (1)

- Mud Pump - High Pressure Lines PDFDocument7 pagesMud Pump - High Pressure Lines PDFKaleem UllahNo ratings yet

- Launcher WInch Machine Digital-1-5Document2 pagesLauncher WInch Machine Digital-1-5Girish PhalkeNo ratings yet

- VS - VPSP - DVL - DVSP - SSV - MSP - MVL Vertical Lift - Pre-Delivery and Frequent Inspection Report PDFDocument1 pageVS - VPSP - DVL - DVSP - SSV - MSP - MVL Vertical Lift - Pre-Delivery and Frequent Inspection Report PDFMaria Alejandra Peña LeonNo ratings yet

- Pre-Commissioning Check List Form Switchgear-General: October 2019Document3 pagesPre-Commissioning Check List Form Switchgear-General: October 2019xchannel28No ratings yet

- JAPL-F-HE-006-Paywelder ChecklistDocument1 pageJAPL-F-HE-006-Paywelder ChecklistAli HassanNo ratings yet

- PrecommissioningSwitchgear GeneralDocument3 pagesPrecommissioningSwitchgear GeneralPeter IyereNo ratings yet

- 008 Welding Machine InspectionDocument1 page008 Welding Machine Inspectionhaslinda Abdul SahakNo ratings yet

- Ve Chklist Lift Inspect-1Document2 pagesVe Chklist Lift Inspect-1RajaDurai Ramakrishnan0% (1)

- SOP Gnrater Room 1 and Room Gnrater2Document4 pagesSOP Gnrater Room 1 and Room Gnrater2Rami Aljaadi [Oman Aquaculture]No ratings yet

- 154 KV CIRCUIT BREAKER PDFDocument9 pages154 KV CIRCUIT BREAKER PDFCelil GOZELNo ratings yet

- Diesel Engine Generator Set Site Acceptance Test Procedure 48 JamDocument7 pagesDiesel Engine Generator Set Site Acceptance Test Procedure 48 Jambambang ismail100% (4)

- Dry TR TestDocument9 pagesDry TR Testamjaad100% (1)

- Inspeção DetalhadaDocument75 pagesInspeção DetalhadaHarry Wart WartNo ratings yet

- Truck Checklist InspectionDocument1 pageTruck Checklist InspectionMahar DikaNo ratings yet

- TPI WinchDocument2 pagesTPI Winchppandey84No ratings yet

- PRES-E-03 Electrical Equipment - Motor & GeneratorDocument2 pagesPRES-E-03 Electrical Equipment - Motor & GeneratorsalamlinNo ratings yet

- AlTamimi Heavy Equipment Checklist - ManliftDocument1 pageAlTamimi Heavy Equipment Checklist - ManliftGlenn ObregonNo ratings yet

- Test Report For Vaccum / Sf6 Gas Circuit BreakerDocument3 pagesTest Report For Vaccum / Sf6 Gas Circuit Breakerlokesh993100% (1)

- Instructions & Guidelines On Sampling of Oil From Oil Filled Electrical EquipmentDocument13 pagesInstructions & Guidelines On Sampling of Oil From Oil Filled Electrical EquipmentsorabhNo ratings yet

- Crawler Crane Inspection ChecklistDocument8 pagesCrawler Crane Inspection ChecklistMD RASID FAKIRNo ratings yet

- A1Z5L2 - Appendix VI - Valve Commissioning Checklist - USDocument1 pageA1Z5L2 - Appendix VI - Valve Commissioning Checklist - USAlpesh PatelNo ratings yet

- Laser SafetyDocument1 pageLaser SafetyaravindappiNo ratings yet

- General Safety Code of ConductDocument333 pagesGeneral Safety Code of ConductJaved KhanNo ratings yet

- Safety Mangagement System-IntroductionDocument3 pagesSafety Mangagement System-IntroductionaravindappiNo ratings yet

- Electrical Safety Manual Lockout TestDocument217 pagesElectrical Safety Manual Lockout TestOscar Leonardo Rincon PulidoNo ratings yet

- Sap User Id Creation FormDocument1 pageSap User Id Creation FormaravindappiNo ratings yet

- Annexure 1 Machine Safety Requirements For RFQDocument2 pagesAnnexure 1 Machine Safety Requirements For RFQaravindappiNo ratings yet

- Standard S Eci Cation of Multipurpose Fire TenderDocument9 pagesStandard S Eci Cation of Multipurpose Fire TenderaravindappiNo ratings yet

- 2 BHK Flat On Rent AvailableDocument1 page2 BHK Flat On Rent AvailablearavindappiNo ratings yet

- ARAVIND APPI RAJ.O, DGM - Central Safety Council: Role DescriptionDocument2 pagesARAVIND APPI RAJ.O, DGM - Central Safety Council: Role DescriptionaravindappiNo ratings yet

- SG-16 Safety Guideline For Fire SafetyDocument21 pagesSG-16 Safety Guideline For Fire SafetyaravindappiNo ratings yet

- Cognitive Ergonomics: This Chapter ProvidesDocument24 pagesCognitive Ergonomics: This Chapter ProvidesattaurrehmanNo ratings yet

- Elevating Safety Culture Through BBSDocument189 pagesElevating Safety Culture Through BBSaravindappiNo ratings yet

- Sqdcme & SDT TeamDocument16 pagesSqdcme & SDT Teamaravindappi100% (1)

- Quot B&S MR - Avinash Revise PDFDocument1 pageQuot B&S MR - Avinash Revise PDFaravindappiNo ratings yet

- 04 Consultation Services ADocument20 pages04 Consultation Services AkrissregionNo ratings yet

- NFPA 33 Paint Booth Check SheetDocument19 pagesNFPA 33 Paint Booth Check Sheetaravindappi100% (1)

- LOTO StepsDocument1 pageLOTO StepsaravindappiNo ratings yet

- Tripod TrainingDocument3 pagesTripod TrainingaravindappiNo ratings yet

- Understanding ATEXDocument14 pagesUnderstanding ATEXFavas KvpNo ratings yet

- Spirax Sarco Libro VaporDocument498 pagesSpirax Sarco Libro VaporvicasaznNo ratings yet

- Tacite: User's GuideDocument128 pagesTacite: User's GuideIra Carolina Bello Patiño100% (1)

- 4.9 OU500574930 Hydraulics SymbolsDocument19 pages4.9 OU500574930 Hydraulics SymbolsCristian Pulgar FabresNo ratings yet

- BHMN Valve Sizing HandbookDocument30 pagesBHMN Valve Sizing Handbookdj22500No ratings yet

- MacGREGOR Hydraulic DeckcranesDocument37 pagesMacGREGOR Hydraulic Deckcranesruslan100% (3)

- 06-3096B Innio Print 10-28-21Document10 pages06-3096B Innio Print 10-28-21Fernando SerangueliNo ratings yet

- DRG100 - Workshop Manual - VDRG02 - 01GB PDFDocument1,090 pagesDRG100 - Workshop Manual - VDRG02 - 01GB PDFNicolas Moyano100% (1)

- Parts Manual: Belt Drive Air CompressorDocument57 pagesParts Manual: Belt Drive Air CompressorestebanNo ratings yet

- 567-568 Butterfly Valve - IntroductionDocument8 pages567-568 Butterfly Valve - IntroductionHearnfar99No ratings yet

- Comissionamento Do Sistema de Pull in PDFDocument65 pagesComissionamento Do Sistema de Pull in PDFrfelippe8733No ratings yet

- SteeringDocument16 pagesSteeringLeonardo100% (1)

- CMIT-796-PIP-15.69-00-0008 - 0 3D Model Review ProcedureDocument10 pagesCMIT-796-PIP-15.69-00-0008 - 0 3D Model Review ProcedurenadaNo ratings yet

- SOP For Boiler Light Up ChecklistDocument9 pagesSOP For Boiler Light Up Checklistpradeep.selvarajan100% (1)

- Joh. Heinr. Bornemann GMBH Postfach 1162, D-31676 Obernkirchen Phone: +49 5724 390-0 Fax +49 5724 390 290Document6 pagesJoh. Heinr. Bornemann GMBH Postfach 1162, D-31676 Obernkirchen Phone: +49 5724 390-0 Fax +49 5724 390 290vuthanhNo ratings yet

- Basic Autolube SystemDocument25 pagesBasic Autolube SystemHydcon ServiceNo ratings yet

- Hydraulic Structure 2Document7 pagesHydraulic Structure 2Jl CarlNo ratings yet

- Types 168, 168H, and 68-2 Three-Way, Snap-Acting Switching ValvesDocument4 pagesTypes 168, 168H, and 68-2 Three-Way, Snap-Acting Switching ValvesHm HmNo ratings yet

- Study of Different Types of Pipe FittingsDocument17 pagesStudy of Different Types of Pipe FittingsIzi50% (2)

- NES 360 Guide To The Selection of Low Pressure Metric Standard Valves - Category 3Document244 pagesNES 360 Guide To The Selection of Low Pressure Metric Standard Valves - Category 3JEORJENo ratings yet

- Kidde Fire Protection FM200 GX20 Technical DatasheetsDocument56 pagesKidde Fire Protection FM200 GX20 Technical DatasheetsIndo AprilNo ratings yet

- 5.1 HRSG 11 12 SystemsDocument5 pages5.1 HRSG 11 12 SystemsM Moarraf Naeem100% (1)

- 3M78 HTDocument7 pages3M78 HTxdhawaiiNo ratings yet

- Chapter 7 SteeringDocument79 pagesChapter 7 SteeringZemariyam BizuayehuNo ratings yet

- ConECo Parts Catalog 2015Document200 pagesConECo Parts Catalog 2015viemey1952No ratings yet

- Galcon ProductDocument69 pagesGalcon Productapi-36492444No ratings yet

- Dubai Set To Create 1.5 L Jobs For Creative People: Dubai Launches New 3-Yr Visa For Freelance WorkDocument6 pagesDubai Set To Create 1.5 L Jobs For Creative People: Dubai Launches New 3-Yr Visa For Freelance WorkMustafa shaikhNo ratings yet

- SM Wa380-6 H60051-Up Vebm440101Document1,303 pagesSM Wa380-6 H60051-Up Vebm440101Ricardo Aguirre100% (7)

- Gammmsra 000049Document113 pagesGammmsra 000049Flyer FlyerNo ratings yet

- Troubleshooting ROD PUMPSDocument7 pagesTroubleshooting ROD PUMPSLeonardo Arzuza DuránNo ratings yet

- TFP1545 08 2018-ValveDocument12 pagesTFP1545 08 2018-ValveSenn OdrapmasdNo ratings yet