Professional Documents

Culture Documents

IMG - 0063 PSME Code 2008 52

Uploaded by

Master JaguarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IMG - 0063 PSME Code 2008 52

Uploaded by

Master JaguarCopyright:

Available Formats

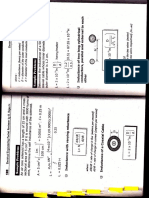

CHAPTER 4 - MACHINERY DANGER ZONE AND POTNTS OF OPERATION

c. -

Belt Guards fixed-mounted or movable 15.1 Electrical Safety Hazards shail be painted

guards or enclosures covering the length of red-orange color.

run of belts.

15.2 Outdoor installations shall be drip

d. Distance Rail'Guards - fixed-mounted or enclosure for weather protection.

movable . guards designed to prevent

personnel from moving into danger zones. 15.3 Motor terminal box covers shall

weatherproof.

e. Hood Guards fixed-mounted or

retractable enclosures covering the vicinity 15.4 ln wet workplaces, water splash motor

of the point of operation or danger zone. shallbe provided.

f. Water $Bhrh Gtards - fxed-mounted or 15.3 ln dusty environmefit, dust hoods shall

retractable water rerbtant encloeures placed on top of mcrtor but allowing

covering the vicinity of the point of the circulation of cooling air.

operation or dangrer zone and designed to

contain or direct lil;uid splashes and spills. 15.6 Electrical cable conduit pull boxes shall

weatherproof, liquid-t[ht, air-light

g. Expl,oslon Guards fixed+nounted when installed outdoors.

explosion resistant enclosures covering the

vicinity of the point of opqration or danger $ection 16.0 Personal Protection in

zone and designed to contain flying Workplaces

materials.

h. Firc Explosion troore - retractable type 16.1 Personal Protective Equipment.

explosion resistant enclosures covering Protective Equipment (PPE) shall be

vicinity of the point of operation of danger the last line of defense against hazards in

zone and designed to contain energy work environment. The engineer shall

bursts and flying materials. and require the use of PPE to protect personnd

from known or possible hazards in the

i. Rallinge and Screen Doors - Retractable workplace.

type railings or access doors resistant to

flying materials and encloses the vicinity of 16.2 Employers shall protect their employees

the point of operation or danger zone, and providing appropriate and approved protective

is designed to isolate the same without tools, devices, equipment and appliances such

impairing oculqr inspection. as, but not limited to the following:

14.2 Machine guardg provided for mechanical power Head Guards

transrnigsbn frorn the prime mover to the point Face Shields

of operatbn shall bG mde of enelosure that Eye Goggles

permlts yhffal kspedion at a distance while Ear Muffs

machine is running. Nose Aspirator

Hand Gloves

14.8 For eay identifaetion of sa&ty hazards, all Arm Sleeves Shbld

machine guards shell bo painted in yellow color, Body Apron Shield

and restrtcted floor area shall be painted with Leg Sleeve Shield

yellow strip line in walk aisles around the Foot Safety Shoes

machinery. Foot Rubber Boots

14.4 For automatic start-stop machines, a waming ' 16.3 Radiation hazards in workplaces shall be

sign, tag or nameplate shall be displayed in identified and appropriate warning signs shall be

strategic lscation in the workspace. posted.

$ectlon 15.0 Protgctlon for Electrical {6.4 Eye hazard from welding arc electricalflashes in

welding shop shall be shielded by wood panel

Maehlnory in Gontnloruial & lndustrial barrier as protection for observers and other

lnstallations personnel in the work area.

H

*

52

You might also like

- SWP-024 Usage of PPEDocument5 pagesSWP-024 Usage of PPEadrianlim13No ratings yet

- Guia de Laboratorio Resesate.Document8 pagesGuia de Laboratorio Resesate.WALTER CHOQUE COPARINo ratings yet

- Safety Light Curtains - OMRONDocument11 pagesSafety Light Curtains - OMRONnarshihNo ratings yet

- Group 10 - Cengr 425 - Safety EngineeringDocument5 pagesGroup 10 - Cengr 425 - Safety EngineeringtheDLordP15No ratings yet

- DM-PH&SD-P4-TG14 - (Guidelines For Personal Protective Equipment-Fall Protection-Safety Lines) PDFDocument3 pagesDM-PH&SD-P4-TG14 - (Guidelines For Personal Protective Equipment-Fall Protection-Safety Lines) PDFdemie figueroaNo ratings yet

- 21 Personal Protective EquipmentDocument4 pages21 Personal Protective EquipmentMohammed MinhajNo ratings yet

- JsaDocument13 pagesJsaArnold Roy Coballes Manalo100% (1)

- Electric Substation Personal Protective Equipment (PPE)Document2 pagesElectric Substation Personal Protective Equipment (PPE)KaranShindeNo ratings yet

- Onkyo HT-R430 Reciever User ManualDocument56 pagesOnkyo HT-R430 Reciever User ManualYoudont Knowme33% (3)

- User Manual: Quintessence HarmonizerDocument10 pagesUser Manual: Quintessence HarmonizerAlejandro Picco PlencovichNo ratings yet

- Landscaping Victoria SWMSDocument9 pagesLandscaping Victoria SWMScjNo ratings yet

- Quintessence Harmony - M - enDocument12 pagesQuintessence Harmony - M - enjorge gabriel delgadoNo ratings yet

- Hfe Onkyo Ht-r560 enDocument96 pagesHfe Onkyo Ht-r560 enKeith GruberNo ratings yet

- JSA DrillingDocument12 pagesJSA DrillingAbdus SamadNo ratings yet

- Hazard Identification Plan (Hip) & Site Visit:: 16"U/G Hwyh Gosp-3 Downstream Disposal Header (Asphalt Road)Document9 pagesHazard Identification Plan (Hip) & Site Visit:: 16"U/G Hwyh Gosp-3 Downstream Disposal Header (Asphalt Road)javithNo ratings yet

- Owner's Manual: CautionDocument170 pagesOwner's Manual: Cautionmichael hildebrandNo ratings yet

- Av Receiver: More User Manuals OnDocument80 pagesAv Receiver: More User Manuals OnMarcos ValerioNo ratings yet

- Risk Assess T-17 - Using Portable Hand ToolsDocument4 pagesRisk Assess T-17 - Using Portable Hand ToolsMAB AliNo ratings yet

- Manual Onkyo A-9070 enDocument44 pagesManual Onkyo A-9070 enJuan Pablo LarraínNo ratings yet

- bd-sp308 Manual e PDFDocument44 pagesbd-sp308 Manual e PDFAivaras MiliūnasNo ratings yet

- Chapter 7 Safety PolicyDocument29 pagesChapter 7 Safety Policyมิตร อันมาNo ratings yet

- Frontman 212RDocument20 pagesFrontman 212RGaragem SonoraNo ratings yet

- TXNR 414Document128 pagesTXNR 414aleixreyes28No ratings yet

- Manual Onkyo HTS3500 5.1 Channel Home Theater System HT-R391Document76 pagesManual Onkyo HTS3500 5.1 Channel Home Theater System HT-R391Marcus V SiqueiraNo ratings yet

- Safety in ConstructionDocument5 pagesSafety in ConstructionYash pawarNo ratings yet

- TXNR 616Document144 pagesTXNR 616jakeNo ratings yet

- Onkyo Onwer's Manual TX-SR803 703 PDFDocument96 pagesOnkyo Onwer's Manual TX-SR803 703 PDFVidiNo ratings yet

- HTR 648Document76 pagesHTR 648Kim Andre LeonardsenNo ratings yet

- Integrated and Power Amplifiers: HandbookDocument18 pagesIntegrated and Power Amplifiers: HandbookElla MariaNo ratings yet

- Compilation of PaesDocument203 pagesCompilation of PaesRyza MartizanoNo ratings yet

- Hot Rod III Deluxe and DeVille - Gamp - ManualDocument28 pagesHot Rod III Deluxe and DeVille - Gamp - Manuala personNo ratings yet

- NEW SOP 4.10 Working Under Adverse Weather Condition R6 FinalDocument6 pagesNEW SOP 4.10 Working Under Adverse Weather Condition R6 FinalVUNo ratings yet

- DeepMind 12D M enDocument162 pagesDeepMind 12D M enAndrea DellastaNo ratings yet

- Gamp Manual All Reve PDFDocument20 pagesGamp Manual All Reve PDFAngelLazarteNo ratings yet

- dv-sp405 Manual eDocument64 pagesdv-sp405 Manual eRicardo RodriguesNo ratings yet

- HDVD800 A4 549747 0313 en CDDocument19 pagesHDVD800 A4 549747 0313 en CDCharlesNo ratings yet

- DV-P745U: Important SafeguardsDocument24 pagesDV-P745U: Important SafeguardsjohndoemilNo ratings yet

- DrillingDocument22 pagesDrillingMandhatt KyleNo ratings yet

- Onkyo TX-SR706 A/V ReceiverDocument120 pagesOnkyo TX-SR706 A/V ReceiverMarlon Patrone100% (1)

- ht-s6200 Manual eDocument100 pagesht-s6200 Manual ederekbrch7No ratings yet

- Manual C 755 enDocument28 pagesManual C 755 enJerry ChengNo ratings yet

- User Manual: Deepmind 6Document164 pagesUser Manual: Deepmind 6xxpowercutxxNo ratings yet

- Marantz PM-7000 User GuideDocument17 pagesMarantz PM-7000 User Guidepeter11No ratings yet

- TX-sr307 Manual eDocument72 pagesTX-sr307 Manual eMRPITYINGER1No ratings yet

- Onkyo TX-8555Document48 pagesOnkyo TX-8555Juan Pablo LarraínNo ratings yet

- HT-S7300 HT-S6300: 7.1ch Home Theater SystemDocument76 pagesHT-S7300 HT-S6300: 7.1ch Home Theater SystemMarcelo AlmeidaNo ratings yet

- Onkyo TX-SR503 ManualDocument60 pagesOnkyo TX-SR503 ManualdivabananaNo ratings yet

- Downloaded From Manuals Search EngineDocument14 pagesDownloaded From Manuals Search EngineEryk Toro PerezNo ratings yet

- Integrated Amplifier Amplificateur Intégré Integrierter Verstärker Geïntegreerde VersterkerDocument17 pagesIntegrated Amplifier Amplificateur Intégré Integrierter Verstärker Geïntegreerde VersterkerElla MariaNo ratings yet

- Onkyo TX-SR600 Instruction ManualDocument80 pagesOnkyo TX-SR600 Instruction Manualkuko61No ratings yet

- VANTAGE 850dda ManualDocument32 pagesVANTAGE 850dda ManualRob SeamanNo ratings yet

- Inverted - Bucket - Steam - Traps IM 2 400 USDocument6 pagesInverted - Bucket - Steam - Traps IM 2 400 USMaarten VanwildemeerschNo ratings yet

- TX-nr609 Manual eDocument88 pagesTX-nr609 Manual eSrinivas Yugender TeraNo ratings yet

- Model: Service ManualDocument70 pagesModel: Service Manualbenitez leonel borinelliNo ratings yet

- Manual Onkyo TX-SR607Document108 pagesManual Onkyo TX-SR607liviugiurgiNo ratings yet

- 001 - Personal Protective Equipment Rev-03Document5 pages001 - Personal Protective Equipment Rev-03Rooney SharonNo ratings yet

- Confined Space Awareness: Hazard ControlDocument6 pagesConfined Space Awareness: Hazard ControljhoniNo ratings yet

- HD Integrator Box System: Service ManualDocument86 pagesHD Integrator Box System: Service ManualPușcă MartinNo ratings yet

- User Manual: Md3 Native Multiband DynamicsDocument24 pagesUser Manual: Md3 Native Multiband DynamicsMarco M. GualdiNo ratings yet

- IMG - 0069 MCQ EE Board Problem 2012 26Document1 pageIMG - 0069 MCQ EE Board Problem 2012 26Master JaguarNo ratings yet

- IMG - 0061 MCQ EE Board Problem 2012 18Document1 pageIMG - 0061 MCQ EE Board Problem 2012 18Master JaguarNo ratings yet

- IMG - 0066 MCQ EE Board Problem 2012 23Document1 pageIMG - 0066 MCQ EE Board Problem 2012 23Master JaguarNo ratings yet

- IMG - 0063 MCQ EE Board Problem 2012 20Document1 pageIMG - 0063 MCQ EE Board Problem 2012 20Master JaguarNo ratings yet

- IMG - 0064 MCQ EE Board Problem 2012 21Document1 pageIMG - 0064 MCQ EE Board Problem 2012 21Master JaguarNo ratings yet

- IMG - 0067 MCQ EE Board Problem 2012 24Document1 pageIMG - 0067 MCQ EE Board Problem 2012 24Master JaguarNo ratings yet

- IMG - 0062 MCQ EE Board Problem 2012 19Document1 pageIMG - 0062 MCQ EE Board Problem 2012 19Master JaguarNo ratings yet

- IMG - 0107 PSME Code 2008 98Document1 pageIMG - 0107 PSME Code 2008 98Master JaguarNo ratings yet

- IMG - 0105 PSME Code 2008 96Document1 pageIMG - 0105 PSME Code 2008 96Master JaguarNo ratings yet

- IMG - 0070 MCQ EE Board Problem 2012 27Document1 pageIMG - 0070 MCQ EE Board Problem 2012 27Master JaguarNo ratings yet

- IMG - 0136 ESAS 2001 Solved Problem Objectives 23-27Document1 pageIMG - 0136 ESAS 2001 Solved Problem Objectives 23-27Master JaguarNo ratings yet

- Img - 0055 MCQ For Power & Ipe 101Document1 pageImg - 0055 MCQ For Power & Ipe 101Master JaguarNo ratings yet

- Img - 0053 MCQ For Power & Ipe 97Document1 pageImg - 0053 MCQ For Power & Ipe 97Master JaguarNo ratings yet

- Img - 0060 MCQ For Power & Ipe 111Document1 pageImg - 0060 MCQ For Power & Ipe 111Master JaguarNo ratings yet

- Img - 0051 MCQ For Power & Ipe 93Document1 pageImg - 0051 MCQ For Power & Ipe 93Master JaguarNo ratings yet

- IMG - 0101 PSME Code 2008 92Document1 pageIMG - 0101 PSME Code 2008 92Master JaguarNo ratings yet

- IMG - 0103 PSME Code 2008 94Document1 pageIMG - 0103 PSME Code 2008 94Master JaguarNo ratings yet

- Img - 0059 MCQ For Power & Ipe 109Document1 pageImg - 0059 MCQ For Power & Ipe 109Master JaguarNo ratings yet

- Img - 0056 MCQ For Power & Ipe 103Document1 pageImg - 0056 MCQ For Power & Ipe 103Master JaguarNo ratings yet

- Img - 0052 MCQ For Power & Ipe 95Document1 pageImg - 0052 MCQ For Power & Ipe 95Master JaguarNo ratings yet

- Img - 0057 MCQ For Power & Ipe 105Document1 pageImg - 0057 MCQ For Power & Ipe 105Master JaguarNo ratings yet

- Img - 0058 MCQ For Power & Ipe 107Document1 pageImg - 0058 MCQ For Power & Ipe 107Master JaguarNo ratings yet

- Img - 0059 MCQ Ree Board Exam 107Document1 pageImg - 0059 MCQ Ree Board Exam 107Master JaguarNo ratings yet

- Img - 0054 MCQ For Power & Ipe 99Document1 pageImg - 0054 MCQ For Power & Ipe 99Master JaguarNo ratings yet

- Img - 0056 MCQ Ree Board Exam 101Document1 pageImg - 0056 MCQ Ree Board Exam 101Master JaguarNo ratings yet

- Img - 0058 MCQ Ree Board Exam 105Document1 pageImg - 0058 MCQ Ree Board Exam 105Master JaguarNo ratings yet

- Img - 0053 MCQ Ree Board Exam 95Document1 pageImg - 0053 MCQ Ree Board Exam 95Master JaguarNo ratings yet

- Img - 0055 MCQ Ree Board Exam 99Document1 pageImg - 0055 MCQ Ree Board Exam 99Master JaguarNo ratings yet

- Img - 0052 MCQ Ree Board Exam 93Document1 pageImg - 0052 MCQ Ree Board Exam 93Master JaguarNo ratings yet

- Img - 0054 MCQ Ree Board Exam 97Document1 pageImg - 0054 MCQ Ree Board Exam 97Master JaguarNo ratings yet

- QuinnmcfeetersresumeDocument1 pageQuinnmcfeetersresumeapi-510833585No ratings yet

- Project Manager PMP PMO in Houston TX Resume Nicolaas JanssenDocument4 pagesProject Manager PMP PMO in Houston TX Resume Nicolaas JanssenNicolaasJanssenNo ratings yet

- TRICARE Behavioral Health Care ServicesDocument4 pagesTRICARE Behavioral Health Care ServicesMatthew X. HauserNo ratings yet

- Lesson: The Averys Have Been Living in New York Since The Late NinetiesDocument1 pageLesson: The Averys Have Been Living in New York Since The Late NinetiesLinea SKDNo ratings yet

- Properties of LiquidsDocument26 pagesProperties of LiquidsRhodora Carias LabaneroNo ratings yet

- 1 - Laminar and Turbulent Flow - MITWPU - HP - CDK PDFDocument13 pages1 - Laminar and Turbulent Flow - MITWPU - HP - CDK PDFAbhishek ChauhanNo ratings yet

- T-Tess Six Educator StandardsDocument1 pageT-Tess Six Educator Standardsapi-351054075100% (1)

- Teks Drama Malin KundangDocument8 pagesTeks Drama Malin KundangUhuy ManiaNo ratings yet

- 2a Unani Medicine in India - An OverviewDocument123 pages2a Unani Medicine in India - An OverviewGautam NatrajanNo ratings yet

- Vedic Maths Edited 2Document9 pagesVedic Maths Edited 2sriram ANo ratings yet

- Centrifuge ThickeningDocument8 pagesCentrifuge ThickeningenviroashNo ratings yet

- Kefauver Harris AmendmentsDocument7 pagesKefauver Harris AmendmentsAnil kumarNo ratings yet

- Obara BogbeDocument36 pagesObara BogbeOjubona Aremu Omotiayebi Ifamoriyo0% (1)

- Vernacular ArchitectureDocument4 pagesVernacular ArchitectureSakthiPriya NacchinarkiniyanNo ratings yet

- The Minimum Means of Reprisal - China's S - Jeffrey G. LewisDocument283 pagesThe Minimum Means of Reprisal - China's S - Jeffrey G. LewisrondfauxNo ratings yet

- LicencesDocument5 pagesLicencesstopnaggingmeNo ratings yet

- How Can Literary Spaces Support Neurodivergent Readers and WritersDocument2 pagesHow Can Literary Spaces Support Neurodivergent Readers and WritersRenato Jr Bernadas Nasilo-anNo ratings yet

- P. E. and Health ReportDocument20 pagesP. E. and Health ReportLESSLY ABRENCILLONo ratings yet

- F5 Chem Rusting ExperimentDocument9 pagesF5 Chem Rusting ExperimentPrashanthini JanardananNo ratings yet

- Innovativ and Liabl :: Professional Electronic Control Unit Diagnosis From BoschDocument28 pagesInnovativ and Liabl :: Professional Electronic Control Unit Diagnosis From BoschacairalexNo ratings yet

- Amp DC, OaDocument4 pagesAmp DC, OaFantastic KiaNo ratings yet

- Laboratorio 1Document6 pagesLaboratorio 1Marlon DiazNo ratings yet

- Adverbs of Manner and DegreeDocument1 pageAdverbs of Manner and Degreeslavica_volkan100% (1)

- Mitsubishi FanDocument2 pagesMitsubishi FanKyaw ZawNo ratings yet

- Will Smith BiographyDocument11 pagesWill Smith Biographyjhonatan100% (1)

- M.Plan SYLLABUS 2022-24Document54 pagesM.Plan SYLLABUS 2022-24Mili DawsonNo ratings yet

- Topic Group Present (Week 8) Chapter 1:sociology and Learning ManagementDocument2 pagesTopic Group Present (Week 8) Chapter 1:sociology and Learning ManagementLEE LEE LAUNo ratings yet

- Onset Hobo Trade T Cdi 5200 5400 User ManualDocument3 pagesOnset Hobo Trade T Cdi 5200 5400 User Manualpaull20020% (1)

- Schneider Contactors DatasheetDocument130 pagesSchneider Contactors DatasheetVishal JainNo ratings yet