Professional Documents

Culture Documents

DRE CAT Stepper Motors Catalogue

Uploaded by

Sendi Dika PrasendaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DRE CAT Stepper Motors Catalogue

Uploaded by

Sendi Dika PrasendaCopyright:

Available Formats

drylin®

Low Cost drylin® E | Stepper motors | Product overview

Automation

Various NEMA stepper motor options

Motor with stranded wires Motor with connector

Motors with stranded wires are the least expensive and The connector interface provides a high IP65 protection

the most common stepper motors. The connecting wires level (IP: International Protection). The higher the IP rating,

(length 30cm) for this type exit from the housing and will be the better the motor is protected from the ingress of dirt

configured with a JST connector. They are usually installed and water.

in machines and equipment that have an additional housing

or are used in clean environments.

Motor with connector and encoder Motor with connector, encoder and brake

The encoder (for increased machine reliability) sends signals The brake can hold the payload in position when the motor

from the motor to the motor control. The encoder verifies is not under power. This is used as a safety feature during

that the required linear motion has occurred precisely. power failures – recommended for vertically mounted

systems.

All motors are delivered with a machined

flat motor shaft (D-cut) for increased torque

resistance.

Installation sizes of NEMA stepper motors

NEMA11: Tiny but with plenty of power NEMA23XL: The power motor in the medium

This motor has very compact dimensions. Even so, heavy installation size

loads can be moved with the suitable lead screw pitch. This A development extension of the typical NEMA23 with nearly

motor is typically used on small test and analysis equipment twice the torque. The assembly dimensions are identical to

and miniature adjustments. the NEMA23, allowing many applications.

NEMA17: Small, but lots of power NEMA34: The power pack in the large installation size

This little motor has impressive torque and high RPMs. Applications with higher loads are implemented using the

Reliable operation at fast travel with low loads. largest installation size. Heavy-duty format adjustments or

parallel dual axis setups are among its primary duties.

NEMA23: The best known stepper motor size

Versatile choice due to the high torque and rotational speed.

This motor is the best choice for most applications with

medium loads.

1432 Online tools and more information www.igus.eu/drylinE-accessories

drylin®

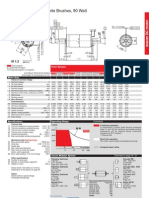

drylin® E | Stepper motors | Technical data automation

Technical data

Distance over hubs 28 42 56 60 86

Motor NEMA11 NEMA17 NEMA23 NEMA23XL NEMA34

Connection dimensions [mm] 28 x 28 42 x 42 56 x 56 60 x 60 86 x 86

Maximum voltage [VDC] 60 60 60 60 60

Nominal voltage [VDC] 24-48 24-48 24-48 24-48 24-48

Nominal current [A] 1.0 1.8 4.2 4.2 6.4

Holding torque [Nm] 0.13 0.5 2.0 3.5 5.9

Ratchet torque [Nm] 0.004 0.022 0.068 0.075 0.210

Step angle [°] 1.8 1.8 1.8 1.8 1.8

Resistance/phase [Ω] 2.30 ±10% 1.75 ±10% 0.5 ±10% 0.65 ±10% 0.33 ±10%

Inductivity/phase [mH] 1.40 ±20% 3.30 ±20% 1.90 ±20% 3.20 ±20% 3.00 ±20%

Moment of inertia - rotor [kgcm2] 0.02 0.08 0.48 0.84 2.70

Shaft load, axial [N] 7 7 15 15 65

Shaft load, radial [N] 20 20 52 63 200

Encoder

Operating voltage [VDC] 5

Signals/rotation [1/min] 500

Zero signal/index yes

Line driver RS422 Protocol

Signal shape [CW] A

(Clockwise A/

motor rotation)

B

B/

N/

Technical data

Plate size brake 28 42 56 60 86

NEMA11 NEMA17 NEMA23 NEMA23XL NEMA34

Operating voltage [VDC] – 24 ±10% 24 ±10% 24 ±10% 24 ±10%

Output rating [W] – 8 10 10 11

Holding torque [Nm] – 0.4 1.0 1.0 2.0

Mass moment of inertia [kgcm2] – 0.01 0.02 0.02 0.07

Mass moment 28 42 56 60 86

of inertia NEMA11 NEMA17 NEMA23 NEMA23XL NEMA34

Product weight [kg] 0.25 0.32 1.12 1.56 3.20

With encoder [kg] 0.27 0.34 1.14 1.58 3.30

With encoder and brake [kg] – 0.58 1.36 1.82 3.60

Operating data

Ambient temperature [°C] –10 to +50

Max. allowable temperature increase [°C] 80

Insulation class B

Air humidity

[%] 85

(non condensing)

IP rating - motor housing IP65 (shaft seal IP52, motor with stranded wires IP40)

CE conformity EMC directive

3D CAD files, prices and delivery times online www.igus.eu/drylinE-accessories 1433

drylin®

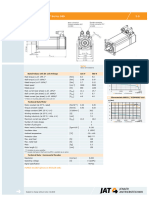

automation drylin® E | Stepper motors | Characteristic curves

Characteristic curves

Flange size 28 (NEMA11) Flange size 42 (NEMA17)

MOT-AN-S-060-001-028-… MOT-AN-S-060-005-042-…

0.14 0.6

0.12 0.5

0.10

0.4

0.08

0.3

0.06

0.2

0.04

M [Nm]

M [Nm]

0.02 0.1

0.00 0.0

10 100 1,000 10,000 10 100 1,000 10,000

n [rpm] n [rpm]

Flange size 56 (NEMA23) Flange size 60 (NEMA23XL)

MOT-AN-S-060-020-056-... MOT-AN-S-060-035-060-…

1.8 3.5

1.5 3.0

1.3 2.5

1.0 2.0

0.8 1.5

0.5 1.0

M [Nm]

M [Nm]

0.3 0.5

0.0 0.0

10 100 1,000 10,000 10 100 1,000 10,000

n [rpm] n [rpm]

Flange size 86 (NEMA34)

MOT-AN-S-060-059-086-…

6.0

5.0

4.0

3.0

2.0

M [Nm]

1.0

0.0

10 100 1,000 10,000

n [rpm]

------- 24VDC 48VDC

The characteristic curves are determined in quarter

step mode

1434 Online tools and more information www.igus.eu/drylinE-accessories

drylin®

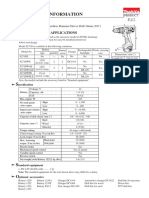

drylin® E | Stepper motors | Order key automation

Order key

MOT-AN-S-060-020-056-M-A-AAAA

Specification

AAAA: Standard

AAAC: Encoder

AAAD: Encoder & brake

Options

A: Without

C: Incremental encoder

D: Incremental encoder & brake

Motor connection

M: Metric connector

L: Stranded wires

Distance over hubs

028: 28mm (NEMA11)

042: 42mm (NEMA17)

056: 56mm (NEMA23)

060: 60mm (NEMA23XL)

086: 86mm (NEMA34)

Holding torque

001: 0.1Nm

005: 0.5Nm

020: 2.0Nm

035: 3.5Nm

059: 5.9Nm

Maximum voltage

060: 60V/DC

Motor type

S: Stepper motor

Type

AN: Design

Product type

MOT: Motor

More information www.igus.eu/drylinE

3D CAD files, prices and delivery times online www.igus.eu/drylinE-accessories 1435

You might also like

- Electrical and Electronic Principles: Volume 2From EverandElectrical and Electronic Principles: Volume 2Rating: 4 out of 5 stars4/5 (5)

- Advanced Coastal NavigationDocument302 pagesAdvanced Coastal NavigationHobbyLogic100% (3)

- Electrician Manual - CompleteDocument120 pagesElectrician Manual - CompleteidontlikeebooksNo ratings yet

- Design of Bunkers and SilosDocument15 pagesDesign of Bunkers and SilosSagarKasarla100% (1)

- Blockchain Unconfirmed Transaction Hack Script 3 PDF FreeDocument4 pagesBlockchain Unconfirmed Transaction Hack Script 3 PDF FreeSaifi Khan100% (3)

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- NEMA 17 & 23 Stepper Motor SpecsDocument4 pagesNEMA 17 & 23 Stepper Motor SpecsAmaranta AvilaNo ratings yet

- Fundamentals of AI Seismic InversionDocument30 pagesFundamentals of AI Seismic InversionYoggie Surya PradanaNo ratings yet

- Digital Power Electronics and ApplicationsFrom EverandDigital Power Electronics and ApplicationsRating: 3.5 out of 5 stars3.5/5 (3)

- Switched Reluctance MotorDocument52 pagesSwitched Reluctance Motorkoppulabro75% (8)

- Methods of Analysis and Solutions of Crack ProblemsDocument562 pagesMethods of Analysis and Solutions of Crack ProblemsgedysonlimaNo ratings yet

- Physics ART INTEGRATED PROJECTDocument24 pagesPhysics ART INTEGRATED PROJECTPRATHAM BANSAL67% (3)

- Compilation of Summative Test in Math 4 Ist QuarterDocument10 pagesCompilation of Summative Test in Math 4 Ist QuarterLYNE C. KE0% (1)

- Mot-St - enDocument9 pagesMot-St - encristian.rodriguezNo ratings yet

- Mot-Ec - enDocument8 pagesMot-Ec - enYERKO ANDRÉS GONZÁLEZNo ratings yet

- Mot-An-S en 20160403Document9 pagesMot-An-S en 20160403DARIONo ratings yet

- SIMOTICS S-1FL6 Low Inertia Motor Technical DataDocument4 pagesSIMOTICS S-1FL6 Low Inertia Motor Technical DataHamzaNo ratings yet

- Vrdm36x GBDocument15 pagesVrdm36x GBk4kh5svtstNo ratings yet

- AEROTECH Motor1210Document13 pagesAEROTECH Motor1210zhen yongjieNo ratings yet

- Melservo Jet Series Rotary Servo MotorDocument8 pagesMelservo Jet Series Rotary Servo MotorvermadelipNo ratings yet

- En 21 171Document1 pageEn 21 171pham tamNo ratings yet

- 2KJ3514-3KN38-9AR1-Z B33+C46+D11+K01+K06+L02+L75+M10+M59+N1S+P92 Datasheet enDocument2 pages2KJ3514-3KN38-9AR1-Z B33+C46+D11+K01+K06+L02+L75+M10+M59+N1S+P92 Datasheet encaukhoeoNo ratings yet

- Item:130ST Series Servo Motor: SpecificationsDocument4 pagesItem:130ST Series Servo Motor: Specificationsn13t0314No ratings yet

- Maxon RE35 Graphite Brushes 90wattDocument1 pageMaxon RE35 Graphite Brushes 90wattElectromateNo ratings yet

- SG40185HF SICOR 11KwDocument2 pagesSG40185HF SICOR 11KwMohammed Mahmoud EissaNo ratings yet

- F2140 Eng DatasheetDocument4 pagesF2140 Eng Datasheettngyew leeNo ratings yet

- Kaipor KDE12STA3 Silent Generator ManualDocument20 pagesKaipor KDE12STA3 Silent Generator ManualSergioPereyra64% (11)

- Maxon A-Max26 Precious Metal Brushes 7wattDocument1 pageMaxon A-Max26 Precious Metal Brushes 7wattElectromateNo ratings yet

- DCM5xxxx Series DC Brush Servo Motors SpecsDocument7 pagesDCM5xxxx Series DC Brush Servo Motors Specstuandtd2008No ratings yet

- Servomoteurs Brushless Ultract 13 - de 100 NM À 350 NM S1 PHASE AUTOMATIONDocument8 pagesServomoteurs Brushless Ultract 13 - de 100 NM À 350 NM S1 PHASE AUTOMATIONIBRAHIM MAKHLOUKANo ratings yet

- DS Linear Motors P02-23Sx80Document19 pagesDS Linear Motors P02-23Sx80Arturo GomezNo ratings yet

- Graphite Brushes, 60 Watt Maxon DC MotorDocument1 pageGraphite Brushes, 60 Watt Maxon DC MotorRatanieriNo ratings yet

- 30 MM, Graphite Brushes, 60 Watt: Order NumberDocument1 page30 MM, Graphite Brushes, 60 Watt: Order NumberRatanieriNo ratings yet

- ABB Servo Motors: 9C Series For ABB High Performance Machinery DrivesDocument8 pagesABB Servo Motors: 9C Series For ABB High Performance Machinery DriveseduantonioNo ratings yet

- Data Sheet: Three Phase Induction Motor - Squirrel CageDocument3 pagesData Sheet: Three Phase Induction Motor - Squirrel CageKamil KościelakNo ratings yet

- VRDM39x ManualDocument15 pagesVRDM39x ManualTamas RaduNo ratings yet

- RE50Document1 pageRE50Yhony Gamarra VargasNo ratings yet

- RE 50 50mm Graphite Brushes 200W MotorDocument1 pageRE 50 50mm Graphite Brushes 200W MotorJorge Alejandro Barrutia BorbollaNo ratings yet

- Rexroth HCS01Document5 pagesRexroth HCS01TFNo ratings yet

- Report Vibrasi Plant CP-2Document13 pagesReport Vibrasi Plant CP-2hafiz_hayat_44190215No ratings yet

- 2 Phase 60 (NEMA24) Easy Servo Motor Series: General SpecificationsDocument2 pages2 Phase 60 (NEMA24) Easy Servo Motor Series: General SpecificationsIonescuTeodoraNo ratings yet

- 180 Series Servo Motors: Dimension: Unit MMDocument1 page180 Series Servo Motors: Dimension: Unit MMMax QuintanillaNo ratings yet

- Gvx2000uk 6Document17 pagesGvx2000uk 6Michel BrailNo ratings yet

- Motor solo run test reportDocument2 pagesMotor solo run test reportKing SadNo ratings yet

- 90mm EC Brushless MotorDocument1 page90mm EC Brushless MotorLucas SuplinoNo ratings yet

- Datasheet DFV60A-22PC65536 1051309 enDocument9 pagesDatasheet DFV60A-22PC65536 1051309 enAdria PlayNo ratings yet

- Qmot Qbl4208 Family: V1.03 2010-Nov-03Document14 pagesQmot Qbl4208 Family: V1.03 2010-Nov-03etolockaNo ratings yet

- RE 35 35 MM, Graphite Brushes, 90 Watt: Part NumbersDocument1 pageRE 35 35 MM, Graphite Brushes, 90 Watt: Part Numbersasd3a1s65a13f5v06W83 846W84 T6W8E464No ratings yet

- Motor Maxon 323772Document1 pageMotor Maxon 323772Henry Daniel VerdugoNo ratings yet

- Maxon A-Max32 Graphite Brushes 20wattDocument2 pagesMaxon A-Max32 Graphite Brushes 20wattElectromateNo ratings yet

- Motor 30 WattDocument1 pageMotor 30 WattPRED4T0R85No ratings yet

- Ecospeed Motors / Series 80D 3-6Document2 pagesEcospeed Motors / Series 80D 3-6Vladimir StefanovicNo ratings yet

- Motor Data Sheet: Motor Part Code: 1.143TECAB5-IE3 Frame Size: 90S-4Document1 pageMotor Data Sheet: Motor Part Code: 1.143TECAB5-IE3 Frame Size: 90S-4s bNo ratings yet

- Motor data sheet 1.143TECAB5-IE3Document1 pageMotor data sheet 1.143TECAB5-IE3s bNo ratings yet

- Lureye SDMO T22KDocument4 pagesLureye SDMO T22KLuis Leiva Sanchez100% (1)

- 75 023teccb5-Ie2Document2 pages75 023teccb5-Ie2lê Văn QuangNo ratings yet

- Maxon EC20 Flat 3wattDocument1 pageMaxon EC20 Flat 3wattElectromateNo ratings yet

- Crouzet 24 V MotorDocument4 pagesCrouzet 24 V Motorth.wilbersNo ratings yet

- 8271D Te PDFDocument7 pages8271D Te PDF-Eq Wahyou-No ratings yet

- UntitledDocument120 pagesUntitledyair Enrique Romero OspinoNo ratings yet

- Maxon RE25 Precious Metal Brushes 10wattDocument1 pageMaxon RE25 Precious Metal Brushes 10wattElectromateNo ratings yet

- Danfoss VLT2800Document2 pagesDanfoss VLT2800omarNo ratings yet

- Dutymax HDSR Brochure PDFDocument7 pagesDutymax HDSR Brochure PDFGaith Ghaleb SharabatiNo ratings yet

- Catalogo Servo Motor AC Driver Policomp ComponentesDocument12 pagesCatalogo Servo Motor AC Driver Policomp ComponentesHI TEC SERVICE BAURUNo ratings yet

- Calcul LantDocument2 pagesCalcul LantDiana Maria CozmaNo ratings yet

- Locktronics Technical InformationDocument39 pagesLocktronics Technical InformationJulio Gutierrez ReyesNo ratings yet

- Silver Recovery From Waste X-Ray Photographic Films Collected From Hospitals in Addis AbabaDocument7 pagesSilver Recovery From Waste X-Ray Photographic Films Collected From Hospitals in Addis Ababamuftah76No ratings yet

- 3BSE041584-511 - En Compact Control Builder AC 800M 5.1.1 Getting StartedDocument174 pages3BSE041584-511 - En Compact Control Builder AC 800M 5.1.1 Getting StartedfranciscoproaNo ratings yet

- Artigo Fator de PotênciaDocument4 pagesArtigo Fator de PotênciaDiego FaenelloNo ratings yet

- Devialet Phantom English PDFDocument11 pagesDevialet Phantom English PDFSATYAM NAIDUNo ratings yet

- Class XII Monthly Test Revision on d-Block ElementsDocument6 pagesClass XII Monthly Test Revision on d-Block ElementsANUBHAV YADAVNo ratings yet

- Sky TowerDocument19 pagesSky TowerAlcohol You LaterNo ratings yet

- Class 3 Electron MU CalculationsDocument37 pagesClass 3 Electron MU CalculationsPanji Suryo KusumoNo ratings yet

- Short Questions... DbmsDocument10 pagesShort Questions... DbmsMuhammad Jamal ShahNo ratings yet

- Quick Disconnect Coupling DataDocument2 pagesQuick Disconnect Coupling DataEagle1968No ratings yet

- SPM Unit 3 NotesDocument13 pagesSPM Unit 3 Notes20kd1a05c1No ratings yet

- Srs Property Management System For ProgramersDocument16 pagesSrs Property Management System For ProgramersShah Alam100% (3)

- PLC Based Solar Panel With Tilting Arrangement: April 2016Document9 pagesPLC Based Solar Panel With Tilting Arrangement: April 2016Paul TodericNo ratings yet

- GATE Preparation Tips and Study PlanDocument3 pagesGATE Preparation Tips and Study PlanManish KushwahaNo ratings yet

- Soal Am 2023 - Bahasa InggrisDocument13 pagesSoal Am 2023 - Bahasa Inggrisfarukikamal48No ratings yet

- Data Communication: Lecturer: Tamanna Haque NipaDocument20 pagesData Communication: Lecturer: Tamanna Haque NipaAlokTripathiNo ratings yet

- Preparatory Guidance From Infosys - SP and DSE RolesDocument9 pagesPreparatory Guidance From Infosys - SP and DSE RolesSONALI MA80% (5)

- SPSS ImplicationsDocument3 pagesSPSS ImplicationsAnonymous MMNqiyxBUNo ratings yet

- Mapua Institute of Technology Experiment Validates Bernoulli's TheoremDocument16 pagesMapua Institute of Technology Experiment Validates Bernoulli's TheoremNadine Pascual100% (2)

- Testability Measures: Source: VLSI Test: Bushnell-AgrawalDocument38 pagesTestability Measures: Source: VLSI Test: Bushnell-AgrawalKartik singhNo ratings yet

- Understanding Physical Chemistry Author Dor Ben AmotzDocument35 pagesUnderstanding Physical Chemistry Author Dor Ben AmotzGintaNo ratings yet