100% found this document useful (1 vote)

5K views24 pagesFolded Plate Structure

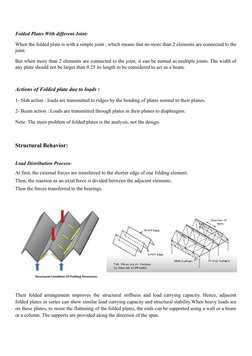

Folded plate structures are assemblies of flat plates or slabs inclined in different directions and joined along their edges. This allows them to carry loads without additional supporting beams. Some key points:

1. Folded plate roofs were first designed in 1923 and became popular for industrial and warehouse buildings in the 1920s-1930s due to their strength and ability to span long distances.

2. Loads are transmitted through both slab action of plates bending normal to their plane, and beam action of plates bending in their plane.

3. Folded plate structures are classified based on the shape of the final structure, which affects load transfer and direction of reliance, including linear, radial, and spatial types.

Uploaded by

patel shivanginiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

5K views24 pagesFolded Plate Structure

Folded plate structures are assemblies of flat plates or slabs inclined in different directions and joined along their edges. This allows them to carry loads without additional supporting beams. Some key points:

1. Folded plate roofs were first designed in 1923 and became popular for industrial and warehouse buildings in the 1920s-1930s due to their strength and ability to span long distances.

2. Loads are transmitted through both slab action of plates bending normal to their plane, and beam action of plates bending in their plane.

3. Folded plate structures are classified based on the shape of the final structure, which affects load transfer and direction of reliance, including linear, radial, and spatial types.

Uploaded by

patel shivanginiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Introduction

- Basic Principles of Folding Plate Structure

- Importance of the Folded Plate Structure

- Structural Behavior

- Application

- Analysis of Folded Plates

- Case Study: Air Force Academy Chapel, USA

- Case Study: Tagore Hall, Ahmedabad

- Case Study: Assembly Hall, University of Illinois, US

- References