Professional Documents

Culture Documents

SMS 04. Busduct - Rev.00 Y2023.02.10

Uploaded by

thancvOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SMS 04. Busduct - Rev.00 Y2023.02.10

Uploaded by

thancvCopyright:

Available Formats

DHG PHARMACEUTICAL PLANT (PHASE 1)

E&I PACKAGE

Project name : DHG PHARMACEUTICAL PLANT (PHASE 1)

WORK METHOD STATEMENT

Installation of Busduct

Revision: 00

Submitted by SC VIETPHAT Date :

Approved by, Reviewed by, Prepared by,

Approved by TVC Date:

Approved by, Reviewed by, Prepared by,

Approved by DHG Date:

Busduct 1/20 Version:00-Effective date: 10-02-2023

DHG PHARMACEUTICAL PLANT (PHASE 1)

E&I PACKAGE

Contents

1. Introduction............................................................................................................................3

2. Scope........................................................................................................................................3

3. Standards................................................................................................................................3

4. References...............................................................................................................................3

5. Definitions And Abbreviations..............................................................................................4

6. Specification Clauses..............................................................................................................4

7. Resources Mobilization Plan.................................................................................................4

8. Construction Equipment.......................................................................................................4

9. Personnel.................................................................................................................................5

10. Materials..............................................................................................................................5

11. Construction Procedure and Construction Methods......................................................6

12. Description Method for Installation of Busduct..............................................................8

13. Responsibility....................................................................................................................18

14. Design & Drawings...........................................................................................................18

15. Statutory Consents............................................................................................................18

16. Work Program..................................................................................................................18

17. Quality Assurance.............................................................................................................18

18. Health & Safety.................................................................................................................18

19. Environmental Policy.......................................................................................................18

20. Relevant documentation...................................................................................................18

21. Subcontractor....................................................................................................................19

22. Risk & Hazard Assessment..............................................................................................19

23. Organization Chart..........................................................................................................19

24. Inspection...........................................................................................................................19

Busduct 2/20 Version:00-Effective date: 10-02-2023

DHG PHARMACEUTICAL PLANT (PHASE 1)

E&I PACKAGE

1. Introduction.

This is a guide for the safe and proper handling, installation, operation and maintenance of

busway and associated fittings. Since the construction sites are usually of poor conditions,

proper planning and coordination between different trades are important for a good busway7

installation. Furthermore, proper handling installation, operation and maintenance, coupled

with proper design and fabrication are important to the long term reliability and safe

operation of busway. Neglecting certain fundamental requirements could to personal injury,

failure of the busway and damage to other property. Some useful points are listed below for

consideration.

This document defines the methods to be adopted to ensure that the works conducted at site

are in compliance with the approved designs and material approvals. That the materials are

installed in accordance with the approved design and using recognized installation practices

that are safe and compliant with the Project Safety Plan and associated Safety Procedures.

That the inspection and testing of the works are in compliance with the Project Quality Plan,

its associated Quality Procedures and approved Inspection and Test Plan for the work.

The method statement describes the procedure for Material Delivery Inspection, Installation,

Inspection and Testing of the Busway.

2. Scope.

This document is concerned with on site inward inspection, installation and testing methods

to be adopted to ensure that all Busduct and fittings are supplied, installed, tested and

inspected for the works is in accordance with the Project requirements. It applies for the

laying of Busduct, testing & commissioning of the Busduct.

The work methods are summarized as follows:

2.1 Preparation of the works

2.2 Delivery and inspection of Busduct and fittings.

2.3 Setting out of the works.

2.4 Laying of Busduct as per approved shop drawing.

2.5 Termination of Busduct.

2.6 Testing & Commissioning of Busduct.

3. Standards

3.1 BS 159; BS EN60439

3.2 TCVN 4766:1989; TCVN 6610:2000; TCVN 5699:2002; TCVN 5064:1995;TCVN

5935:1995

4. References

This document has been prepared with reference to the following documents:

4.1 Project Safety Plan and associated procedures

4.2 Project Environmental Plan and associated procedures

4.3 Project Quality Plan and associated procedures

4.4 Specifications issued

Busduct 3/20 Version:00-Effective date: 10-02-2023

DHG PHARMACEUTICAL PLANT (PHASE 1)

E&I PACKAGE

4.5 Relevant design document approvals

4.6 Relevant materials approvals

4.7 Local Regulations and Codes and Standards

5. Definitions And Abbreviations

BS British Standard

TCVN Vietnam Standard

DCP Design Control Point

DTLL Drop to Low Level

DWP Detailed Works Program

ENG The Engineer

EHS Environmental Health Standard

F/A From Above

F/B From Below

F&E Feed and Expansion

HL High Level

ITP Inspection and Test Plan

N/A Not applicable

RM Rising Main

RTHL Rise to High Level

PPE Personal Protective Equipment

R/A Rise to Above

T/A To Above

T/B To Below

TP Test Point

VFD Variable Frequency Drive

NCR Non-Conformance Report

6. Specification Clauses

Referring to the general specification of electrical system.

7. Resources Mobilization Plan

According to the work program, and planned site access availability at the respective work

sites, appropriate staff, labor, equipment and materials will be mobilized to the site to install

the Busduct in accordance with the approved design shop drawing.

The actual mobilization of staff, labor and equipment and the materials delivery schedule will

be dependent on site access. Actual site access dates will need to be notified at least four

weeks ahead of targeted handing over of the site and confirmation of site access date one

week before the access date. Notification and confirmation of site access dates shall be

provided as required.

It is understood that sub-contractor will be responsible for the provision of appropriate types

and quantities of cranes, cradles, working platforms and scaffoldings. Temporary ventilation,

power supplies and lighting systems will be provided to all works locations.

Aspects of the mobilization of the various resources are described in detail in the following

sections of this method statement.

8. Construction Equipment

It is envisaged that no major plant or equipment will be required to be provided for the

activities involved in the supply and installation of the Busduct. The typical construction

equipment requirements is as listed below, and will be used for erection activities at site.

Busduct 4/20 Version:00-Effective date: 10-02-2023

DHG PHARMACEUTICAL PLANT (PHASE 1)

E&I PACKAGE

8.1 PPE for all staff and labor

8.2 Measuring tapes and setting out markers

8.3 Electrician's Tool Box

8.4 Other Hand Tools

8.5 Certified Megger (Insulation Resistance Tester)

8.13 Hole Saw Cutter

8.14 Certified Mobile Scaffolds and step Ladders.

Note: All powered tools shall be suitable for use with a 220 volt power supply.

9. Personnel

Installation of the Busduct will be organized from a central location by the project

management team. It is envisaged that the installation of Busduct on site will be conducted

by the following:

One installation team shall be responsible for setting out the termination works and shall

have more installation groups based on the work load. Each installation team will comprise

of a supervisor for every installation groups. One installation group shall have two skilled

electricians/ fitters and two laborers.

Busduct installed team shall be responsible for setting out the Busduct, fitting and support

installation works and shall have more installation groups based on work load. Each

installation team will comprise of a supervisor for one to three installation groups. One

installation group shall have one electrician/ fitter and seven laborers.

The installation team and/or Busduct installer team will report to the site construction

management organization, in general, and the Site Electrical Engineer in particular.

The personnel on site will be fully competent to carry out the setting out and installation and

all related works associated with the project to the relevant standards.

The site personnel will have attended the required contractors induction safety and/ or

competency training and will abide by the health & safety plans, policy and procedures as

well as Environmental Plan.

Personnel will be deployed to the various sites on the basis of program requirement and site

access availability. It is intended that the works teams will be organized by geographical

areas.

Refer to the organization chart as per Project QA plan for further details.

10. Materials

The Busduct and fittings will be according to the site requirement and in accordance with the

approved design/ shop drawings. The Busduct materials will be inspected at the factory

before being delivered to the site.

The unloading of the Busduct materials will be carried out at site using a resident crane,

forklift provided, if available at site, a licensed operator under project safety rules and

regulation will operate it. If a crane or forklift is not available at site, the materials will be

manually unloaded at the job-site either using a chain block, forklift. For short lengths and

lighter fittings, it will be manually lifted

Busduct 5/20 Version:00-Effective date: 10-02-2023

DHG PHARMACEUTICAL PLANT (PHASE 1)

E&I PACKAGE

It should be noted that the materials used in this work are of valuable nature and that they

shall be stored in a secured location and access to these materials shall be strictly controlled.

All materials delivered to the site will first be inspected by the store in charge/ site in charge,

to check that it is in accordance with the site requirements, the approved design and approved

material submittals. The materials are free from any damage caused during delivery to site.

Delivery documents shall be checked for completeness. Defective or damaged material/s

shall either be returned to their supplier's facility or stored on site at a suitable quarantine

location. Allowance of reasonable period to remove this damage material/s from the site will

be given. The inward inspection of materials will be carried in accordance with the relevant

QA/ QC procedure.

The site engineer has the authority to perform any inspection for the stored materials from his

own point of view, to check the material quality or quantity whatever.

No materials will be permitted to enter the work locations without being inspected upon

arrival to the site.

11. Construction Procedure and Construction Methods

The construction procedures and methods described here are based upon the scope and

application of the method statement summarized in Section 2 of this method statement and

the work methods structured accordingly.

11.1 Preparation of the works

Before the commencement of installation, the following are required to be carried out:

11.1.1 Check the designs of the Bustduct shop drawings are approved, and

that the drawings for the installation are issued with "Issued for

Construction" status, in accordance with document control procedures.

11.1.2 Check the design of the Builder's Work and requirements, as applicable, is

approved, and the Builder's Work and requirements drawings, if applicable,

are issued with "Issued for Construction" status, in accordance with

document control procedures.

11.1.3 Check the available site access to the work area for installation, the work

area is clean and safe, and the available temporary services are provisions.

Check the applicable builder's works and requirements works are complete.

If these provisions are available and adequate, a joint inspection undertaking

shall be conducted and recorded.

11.1.4 Check that the Busduct materials have been ordered and inspected at the

suppliers' facility and available for delivery to store/ warehouse.

11.2 Delivery and inspection of busduct and fittings on arrival at store.

11.2.1 All delivered material shall be inspected upon arrival at the store/ warehouse.

The inspection shall be advised, in advance, as required by the ITP.

11.2.2 The delivered materials shall be inspected in accordance with the appropriate

QA/QC and project procedures.

11.2.3 The delivered materials shall be in accordance with the approved design,

approved shop drawings; materials approvals and all applicable

documentation and certification shall be available with the delivery.

11.2.4 The materials shall be free from defects or damages.

Busduct 6/20 Version:00-Effective date: 10-02-2023

DHG PHARMACEUTICAL PLANT (PHASE 1)

E&I PACKAGE

11.2.5 Any material delivered to the site that do not conform to the above shall

either be returned to the point of supply or stored on site at a suitable

quarantine store. A NCR shall be raised for all such materials.

11.2.6 No materials will be permitted to enter the works locations without being

inspected on arrival to the site.

11.3 Installation Procedure: Pre-check.

11.3.1 Generally prior to commencement of the delivery of the Busduct materials,

the setting out of the installation shall be conducted to determine the location

of any equipment.

11.3.2 The setting out of the works shall be on the basis of an "Issued for

Construction" installation shop drawings. And the setting out shall be from a

common reference point to be provided at the site. The common reference

point shall also be included in the “issued for construction" installation

drawings, with all setting out dimensions relative to the common reference

point.

11.3.3 Any discrepancy between the common reference point on the "Issued for

Construction" installation drawings and the actual site provisions shall be

notified to the Project Manager and a NCR shall be raised.

11.3.4 Installation of Busduct and fittings is clear & as per approved drawings.

11.4 Installation Procedure:

11.4.1 It is highly recommended that Busduct erection shall only commence when

the builder works for busway room/duct has been completed. The room/duct

shall be in a dry and clean condition with lockable door and kerb.

11.4.2 Latest approved drawing shall be made available to site personnel or

supervisor.

11.4.3 Do not drag the busduct across the roads/ floors.

11.4.4 Handle the busduct with great care to avoid damage to internal components,

the enclosure and its finish. Never subject the busduct to twisting, denting,

impact or rough handling.

11.4.5 Follow manufacturer’s recommendation to provide busduct support to secure

an installation.

11.4.6 Align vertically and horizontally before the final tightening of all joint bolts.

11.4.7 Joint assembly must clean contact surface so that it is free from contaminant

before jointing.

11.4.8 If joints and joint assemblies are exposed to moisture, plaster, or any other

type of contaminant, they shall be properly covered during installation.

11.4.9 All plug-in openings that are not in use must be covered.

11.4.10 Busduct shall not run close to or underneath any water pipe work. Otherwise.

Weatherproof type busduct shall be adapted.

11.4.11 If there is possible leakage, sheet metel shield or appropriate protective cover

shall be provided to prevent contamination of busway.

Busduct 7/20 Version:00-Effective date: 10-02-2023

DHG PHARMACEUTICAL PLANT (PHASE 1)

E&I PACKAGE

11.4.12 List for proposed Busduct and fittings which shall be laid in each area shall

be prepared.

11.4.13 Required sizes of Busduct shall be shifted to work area site by means of

crane, forklift & trailer/ trucks

11.4.14 Lift Busduct to designated level by using crane. Refer to illustration below

for proper lifting of the drum.

11.4.15 After unloading of Busduct and fittings near working area, Insulation

Resistance Test shall be carried out for complete quantity to ensure there is

no damage occurred during transportations

11.4.16 Assigned personnel to guide the Busduct while it passes through every

succeeding floor to avoid jamming with the building's structure.

11.4.17 Horizontal Busduct and fitting Pull Set Up

11.4.18 Inspection and Testing of busduct and fitting terminations

11.4.19 Upon completion of the busduct installations, the same shall be offered up

for inspection and, if necessary, testing, in accordance with the project

requirement.

11.4.20 Notice of testing shall be advised to the ENG. for their discretionary

attendance and witnessing. Notice shall be advised at least 24 hours prior

to the proposed inspection and testing.

11.4.21 The installation shall be inspected as per the attached check list.

12. Description Method for Installation of Busduct

12.1 Sequence of works

Busduct 8/20 Version:00-Effective date: 10-02-2023

DHG PHARMACEUTICAL PLANT (PHASE 1)

E&I PACKAGE

Method of Statement/Materials/Shop Drawings Via RFA/CDT to Electrical Engineer’s Approval

Submission

Rejected

Decision

Electrical Engineer's Comment

Engineer's Verdict

Approved

Material Procurement & Delivery

Rejected

Material Inspection

Approved

Preparation Busduct

Approved

Requisition

Confirming Insert layout and Making Anchor/Expansion location IR/AFI 24 hours in Advance

Electrical Engineer's inspection

Rejected

Decision

Engineer's Verdict Electrical Engineer's Site Inspection

Approved

Drilling hole/Setting Anchor or Expansion Bolt

Installation of Hanger Rod and Support Bracket

Installation of Busduct

Requisition

IR/AFI 24 hours in Advance

Identification

Electrical Engineer's inspection

Rejected

Decision

Engineer's Verdict Electrical Engineer's Site Inspection

Approved

Proceed cabling work

Busduct 9/20 Version:00-Effective date: 10-02-2023

DHG PHARMACEUTICAL PLANT (PHASE 1)

E&I PACKAGE

12.2 Methodology

12.2.1 General:

a. Storage

- All unit numbers shall be checked against the packing this upon arrival of

the goods/consignment.

- Also to check for any damages on busduct units that may occur during

transportation.

- Store the busduct in a dry place to protect it from being soiled or

damaged. If necessary, cover the busduct with water proof sheets

- Do not lay the busduct directly on the ground. Always place pieces of

wood under the busduct and stack up firmly as shown below. Never put it

upright during storage or installation.

- Cover the ends of the busduct unit with a vinyl sheet sill immediate

installation to prevent it from being soiled.

b. Preparation:

- Check the busduct laying route thoroughly to see if there are any

obstacles, i.e. heat source, water leakage, etc.

- To standardized the installation of the busduct, the hanger pitch should be

set to support two sections to one unit.

- Site conditions are to be investigated before handing to determine the

most appropriate laying order. The installation starts from connecting of

busduct to transformer or switchboard. If the position of elbows T-branch

could not be determined precisely, then the selection on another

position/point would have to be determined for.

c. Laying :

- Fork lift or similar is used for transportation and lifting. The weight per

one meter of SCm Busduct System is given in the table on page 11.

However, special busduct sometimes may weigh more than those shown

in the table.

- To prevent the busduct from being damaged when hanging it with a rope,

insert thick pieced of tag or corrugated cardboard between them. For

copper busduct rated 2500A and above, a piece of strong wood is

recommended to be used to withstand the weight.

- Ensure that there are no damaged to the conductor contact surface and

insulating materials before jointing of the busduct. Also to ensure they are

Busduct 10/20 Version:00-Effective date: 10-02-2023

DHG PHARMACEUTICAL PLANT (PHASE 1)

E&I PACKAGE

not soiled with debris and other foreign matter, if there is any, clean them

thoroughly with dry cloth.

- Make loose joint of busducts over the whole run. After measuring the

dimensions, proceed with the normal jointing. SCM Busduct System

allows dimensional adjustment of approximately ±3.5mm, at each joint.

- If a megger value is found to be abnormal after jointing the whole route, it

means that much time is needed to detect faulty parts. It is therefore

recommended that the megger checking to be partially conducted even

during the joint work.

- If the work is temporary halt during construction, then the ends of the

connecting section should be protected against water and dust.

- Do not use the installed busduct as a scaffold or material yard.

12.2.2 Jointing Procedure :

General

- The following procedures are for the assembly for SCM Busduct System

jointing section. Check the directions of the load and supply side of the

busduct jointing part as shown in the diagram below.

Able

to

insert

from

either

direction

12.2.3 Jointing Method :

- Ensure the jointing direction of load and supply sides are confronting each

other before jointing. Place the inserting tool in order to make sure that

both holes of the busbar conductor are aligned with each orther.

- Make sure the contact surfaces of the bus-bar conductor are smooth and

lean to ensure a good electrical contact.

- Insert the joint bolt completely with the joint support and plate spring

Once through the busduct jointing, the hole will be closed with plate

spring and maintenance free nut.

Busduct 11/20 Version:00-Effective date: 10-02-2023

DHG PHARMACEUTICAL PLANT (PHASE 1)

E&I PACKAGE

- Make sure that the bolt has a complete and proper fastening in order to get

enough tightening. Revolve the outer nut clockwise until the neck part of

the bolt breaks.

- Fix the joint covers at the front and the back of the jointing part with bolt

and nut. The joint covers have four housing mounting holes than contain

twist-outs that would permit the expansion or contraction of the joint.

Maintenance free nuts.

- SCM Busduct System provides a reliable and complete fastening of joint

bolts, with a maintenance-free nut system. The maintenance-free nut

system, as shown in the below diagram, consists of an inner Thread and

Torque Limited Neck. When a MF Nut is fastened by the torque wrench

with the requirement torque of 1500kg/cm and simultaneously. Later, the

outer Nut head, which can be tightened with any long-handle wrench until

the neck is twisted off and reaches the locked nut prerequisite

Safety Point:

- Upon fastening and locking of joint bolts, Nut (I) will either be taken off

or dropped. This indicates a proper safety of af fastened locked Nut.

- Lock with twisted force will remain even through Neck (II) is broken in

the process

Busduct 12/20 Version:00-Effective date: 10-02-2023

DHG PHARMACEUTICAL PLANT (PHASE 1)

E&I PACKAGE

12.2.4 Actual Measurement:

- If there is any remaining portion from the actual measurement, then the

measurement shall be taken from point A to point B as shown in the

diagram below.

12.2.5 Connection with equipment :

- Note followings when jointing the busduct with the transformer and

switchboard.

- Apply the under mentioned values as a yardstick for the clamping torque

of the conductor clamping bolt

Bolt Size Clamping Torque (kg/cm)

M8 90-110

M10 180-230

12.2.6 Horizontal Hanger Installation

- Fix horizontal hanger to the hanger rod and adjust it for correct elevation

of the busduct as per site condition.

- Lay the busduct on the horizontal hanger.

- Install the hanger clamp on both side of the busduct for fixture.

- Ensure the busduct is aligned in straight line.

- Additional horizontal hangers shall be placed on elbows, such as vertical /

Horizontal elbow, offset elbow, combination elbow and etc.

- Supporting interval of horizontal hanger shall not exceed 1.5 metres.

Busduct 13/20 Version:00-Effective date: 10-02-2023

DHG PHARMACEUTICAL PLANT (PHASE 1)

E&I PACKAGE

12.2.7 Vertical spring hanger installation

12.2.7.1 Temporarily support the busduct section in place. Fit the C-chanel

(customer supply) onto the floor flange. Fix on the bolts (customer supply)

onto the slab in order to hold the C-chanel firmly to the slab.

12.2.7.2 Drill the C-chanel with opening hole of Ø14mm to accommodate the fixed

support rod. Locate the hole in line with the centerline of the side of the

busduct housing. The distance in between these two holes from center to

center is 65mm [E]. ( Figure 1)

-Then, drill the busduct housing with opening hole of Ø12mm with the

height around 190mm

-[F] from the top of the C-chanel for installing the L-chanel bracket by

using M10 bolts supplied. The distance in between these two holes

from center to center is 60mm [G]. (Figure 1)

12.2.7.3 Fix the rod to the top of the C-chanel together with the nuts as shown in

[1].

-Try to adjust the top nut on both sides until the height from bottom of the

L-chanel to the top or the C-chanel is around 155mm as shown in [H]

while the height from the bottom of L-chanel to the bracket of the

Vertical Spring Hanger is 100mm as shown in [J].

-Then, fix the L-chanel together with the nuts as shown in [2]. (Figure 2).

12.2.7.4 Remove the top nut after installation. The process of installing Vertical

Spring Hanger is completed.

Busduct 14/20 Version:00-Effective date: 10-02-2023

DHG PHARMACEUTICAL PLANT (PHASE 1)

E&I PACKAGE

Busduct 15/20 Version:00-Effective date: 10-02-2023

DHG PHARMACEUTICAL PLANT (PHASE 1)

E&I PACKAGE

Detail 1: Busduct through the wall installation

Busduct 16/20 Version:00-Effective date: 10-02-2023

DHG PHARMACEUTICAL PLANT (PHASE 1)

E&I PACKAGE

Detail A: Busduct through the wall installation

Detail B: Busduct through the wall installation

Busduct 17/20 Version:00-Effective date: 10-02-2023

DHG PHARMACEUTICAL PLANT (PHASE 1)

E&I PACKAGE

12.2.8 Test and checking after installation:

- Check the whole route, mainly the points below at the same time with the

measurement of insulation resistance of the whole structure being carried

out once the laying of the busduct is completed.

- When carrying out the measurement of the insulation resistance,

disconnect the equipment after the plug-in box is installed Once breaker

has set to 'OFF' position (conduct the measurement).

- The Insulation resistance value cannot be specified due to the differences

os the length of the route and the environmental factors. In a dried

atmosphere, it would give a value of approximately 100MΩ (1000V

Megger). If it is below 10MΩ, it has to be checked due to some factors

that can reduce the insulation and the other factors can be as follow;

a. Whether the busduct is damaged,

b. Whether the connecting parts are fixed precisely,

c. Whether the bolts for connecting the equipment are securely fastened,

d. Whether the hangers are supporting the busduct securely,

e. Whether the vertical spring hanger is fixed properly

12.2.9 Maintenance and Checking:

12.2.9.1 Check the external appearance

Check whether there are any deformation, damage, dirt and etc.,

throughout the whole run of the busduct and whether there is

dislocation, bending and other abnormality of connecting cover,

hanger and plug-in appliances.

12.2.9.2 Environmental check.

The environment, where the busduct is used, may change after the

installation. Check whether the environment has become hazardous

even partially due to water, moisture, high temperature, corrosive gas,

immoderate vibration, dust and etc.

12.2.9.3 Check the joint connection section.

There will be no problem of loosening at the joint connection of SCM

Busduct by 'concordance' as maintenance free nut system. Therefore, a

periodical increased clamping is unnecessary. However, when the

contact surface is soiled or deteriorated during the construction or

during storage, a simple check by touching the external portion during

the current sending is recommended as the above effects would

gradually arise. If the temperature of the connecting section and the

main body is about the same, then there will be no problem.

12.2.9.4 Check the load condition

Increase of load is expected at the early stage after the installation of

the busduct. Check the total load is not exceeding the capacity of the

busduct at the increased in load. Closely monitor especially when the

mainline is branched by T-branch or cross.

Busduct 18/20 Version:00-Effective date: 10-02-2023

DHG PHARMACEUTICAL PLANT (PHASE 1)

E&I PACKAGE

12.3 Inspection & Testing

o Material delivered shall be checked of quality, quantity, size Kajima’s Engineer.

o Check technical installation after setting.

o Check Busducts:

Shop drawing approved.

Material approved.

Test method by visual/Inspection check list :

- Check quality of Busducts on site.

- Check installation according to approved shop drawings.

- Check dimension, level and finishing of Busducts.

12.4 Reference Document

o Approved shop drawing.

o Approved material

o Approved inspection and test plan

o Approved method of statement

13. Responsibility

The Project Manager is the overall responsible person for the process implementation of the

works. The Construction Managers will be responsible for all construction activities at the

site and will directly supervise through erection supervisor/ skilled workmen the work at site.

The Construction Manager will also be responsible for arranging and controlling the

inspection and testing activities. Notwithstanding the above, it is the responsibility of each

individual employed in the project to take due care to ensure their own personal safety and

that of their work colleagues.

14. Design & Drawings

Construction shop drawings will be prepared based on approved design to be prepared and

will be submitted separately for approval before commencement of works.

15. Statutory Consents

There is no requirement in respect. However we will follow the local Regulations for

Electrical Installation

16. Work Program

Latest coordinated installation program will be strictly followed and strictly complied,

17. Quality Assurance

All applicable procedures described in the approved quality plan for the Project contract will

be followed.

18. Health & Safety

The execution of works will strictly follow the Project Safety Plan, Manual and Procedures.

19. Environmental Policy

The Execution of works will strictly follow the Project Environmental Plan.

Busduct 19/20 Version:00-Effective date: 10-02-2023

DHG PHARMACEUTICAL PLANT (PHASE 1)

E&I PACKAGE

20. Relevant documentation

20.1 Approved Design Drawings,

20.2 Approved Shop Drawings (To be submitted later)

20.3 Relevant codes as in approved design documents to be issued

20.4 Approved Materials submissions.

20.5 ITP

20.6 Method statement

20.7 Packing list

20.8 Testing Certificate from manufacture

20.9 Certificate of Origin

20.10 Quality Certificate from manufacture

20.11 Guaranty Certificate from manufacture

21. Subcontractor

VIETPHAT has been appointed as Electrical subcontractor for the LixilProject. It is

envisaged that the Busduct installation works will be undertaken by VIETPHAT direct

workforce.

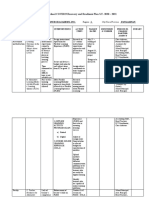

22. Risk& Hazard Assessment

As per attached risk assessment form

23. Organization Chart

As per Organization Chart of the project

24. Inspection

As per Attached ITP

Busduct 20/20 Version:00-Effective date: 10-02-2023

You might also like

- WMS Installation of Street Lighting SystemDocument8 pagesWMS Installation of Street Lighting SystemLeoj Saliw-an Palaoag100% (1)

- Epic For Upgrade of Port Control Tower and Systems at RlicDocument8 pagesEpic For Upgrade of Port Control Tower and Systems at RlicsreeNo ratings yet

- SUDAIR-HSE-PR-019-00-Management of P&MDocument20 pagesSUDAIR-HSE-PR-019-00-Management of P&MGerardoNo ratings yet

- Bus Duct Installation - Method of StatementDocument13 pagesBus Duct Installation - Method of StatementTalha Altaf100% (1)

- Removal of Equipment (SAMPLE)Document9 pagesRemoval of Equipment (SAMPLE)Hasann MaawiaNo ratings yet

- Lps 01 Hti MST Me 007 GRP Water TankDocument12 pagesLps 01 Hti MST Me 007 GRP Water TankJomy JohnyNo ratings yet

- Method Statement For Installation of Gate Valves & Check Valves (Ps-17, Ps40 &Psw1)Document18 pagesMethod Statement For Installation of Gate Valves & Check Valves (Ps-17, Ps40 &Psw1)shujad77100% (1)

- Underground UPVC Drainage Method StatementDocument50 pagesUnderground UPVC Drainage Method StatementDiaa GobranNo ratings yet

- 1.MS Fcu (07.7.2011)Document9 pages1.MS Fcu (07.7.2011)721917114 47No ratings yet

- T41. GIS - Refractory Inspection - GIS 72-004Document8 pagesT41. GIS - Refractory Inspection - GIS 72-004Hung LuongNo ratings yet

- Method Statement For Earthing PDFDocument12 pagesMethod Statement For Earthing PDFPraveen Kumar50% (2)

- 5 - Sample Invitation Letter-J-1Scholar141218Document2 pages5 - Sample Invitation Letter-J-1Scholar141218saimaNo ratings yet

- Manufacturer Prequalification Procedure For Optical Fiber Network Sdmpfn-00Document43 pagesManufacturer Prequalification Procedure For Optical Fiber Network Sdmpfn-00ashrafNo ratings yet

- LPS-01-HTI-MST-EL-009 - Light FixturesDocument18 pagesLPS-01-HTI-MST-EL-009 - Light FixturesJomy JohnyNo ratings yet

- Preservation Proceedure (SAMPLE)Document29 pagesPreservation Proceedure (SAMPLE)Hasann Maawia100% (1)

- Method of Statements Ventilation FansDocument13 pagesMethod of Statements Ventilation FansJomy Johny100% (1)

- MS For Lead LiningDocument19 pagesMS For Lead LiningJervino RuahNo ratings yet

- Testing and Commissioning Procedure For Broadcast Reception InstallationDocument45 pagesTesting and Commissioning Procedure For Broadcast Reception Installationriyan hidayatullahNo ratings yet

- Method Statement For PFC BoardDocument13 pagesMethod Statement For PFC BoardSARAVANAN ANo ratings yet

- Metallic Raceways & Boxes Method StatementDocument15 pagesMetallic Raceways & Boxes Method StatementRahil Tasawar67% (3)

- Catering Equipment InstallationDocument27 pagesCatering Equipment InstallationTrần ChâuNo ratings yet

- Lps 01 Hti MST El 005 Point WiringDocument22 pagesLps 01 Hti MST El 005 Point WiringJomy JohnyNo ratings yet

- Testing and Commissioning Procedure For Plumbing and Drainage InstallationDocument76 pagesTesting and Commissioning Procedure For Plumbing and Drainage InstallationSean Chan100% (19)

- Jan 2016-Approved Vendor List JuneDocument49 pagesJan 2016-Approved Vendor List JuneRemi Raji100% (1)

- Installation of Air Ducting: Standard Method StatementDocument18 pagesInstallation of Air Ducting: Standard Method StatementPhuNguyenHoangNo ratings yet

- Method Statement For Installation & Testing of Underground Drainage PipingDocument18 pagesMethod Statement For Installation & Testing of Underground Drainage PipingMohammed Mostafa El HaddadNo ratings yet

- DRP001 Ouf Pro Q 000 515 O1Document15 pagesDRP001 Ouf Pro Q 000 515 O1Daniel MartinezNo ratings yet

- Lean Concrete MOSDocument9 pagesLean Concrete MOSebrahimlinda25619No ratings yet

- Health and SafetyDocument15 pagesHealth and Safetygroup2sd1314No ratings yet

- Di Tcp2017 DrainageDocument41 pagesDi Tcp2017 Drainagevin ss100% (1)

- Testing and Commissioning Procedure: 2012 EDITIONDocument76 pagesTesting and Commissioning Procedure: 2012 EDITIONQuerubin R Yolando Jr.No ratings yet

- Testing and Commissioning Procedure: 2017 EDITIONDocument36 pagesTesting and Commissioning Procedure: 2017 EDITIONvin ssNo ratings yet

- Vol-Ii - Section-I - PMS, Qam & PmaDocument25 pagesVol-Ii - Section-I - PMS, Qam & PmaAmit Kumar SinghNo ratings yet

- Qualtrics 2021 Employee Experience TrendsDocument32 pagesQualtrics 2021 Employee Experience Trendskelly vasquezNo ratings yet

- Group Assignment RAP SWOT&TOWS HongeditDocument10 pagesGroup Assignment RAP SWOT&TOWS HongeditBùi Thị Thu HồngNo ratings yet

- Testing and Commissioning Procedure: 2017 EDITIONDocument52 pagesTesting and Commissioning Procedure: 2017 EDITIONvin ssNo ratings yet

- Firefighting Network Method StatementDocument60 pagesFirefighting Network Method StatementDiaa GobranNo ratings yet

- PDF文件Document35 pagesPDF文件Oscar WanNo ratings yet

- SMS 05. Distribution Board - Rev.00 Y2023.02.10Document21 pagesSMS 05. Distribution Board - Rev.00 Y2023.02.10thancvNo ratings yet

- ESC-GASTPE School COVID19 Recovery and Readiness Plan S.Y. 2020 - 2021Document5 pagesESC-GASTPE School COVID19 Recovery and Readiness Plan S.Y. 2020 - 2021Jubylyn Aficial100% (3)

- SMS 03. Cable Tray, Ladder and Trunking - Rev.00 Y2023.02.10Document21 pagesSMS 03. Cable Tray, Ladder and Trunking - Rev.00 Y2023.02.10thancvNo ratings yet

- SMS 06. LV Cable & Wire - Rev.00 Y2023.02.10Document24 pagesSMS 06. LV Cable & Wire - Rev.00 Y2023.02.10thancvNo ratings yet

- SMS 07. Earthing System - Rev.00 Y2023.02.10Document21 pagesSMS 07. Earthing System - Rev.00 Y2023.02.10thancvNo ratings yet

- Broadcast Reception InstallationDocument44 pagesBroadcast Reception InstallationTrần ChâuNo ratings yet

- J P Mukherji & Associates Pvt. Ltd. Scope of Supply and ServicesDocument6 pagesJ P Mukherji & Associates Pvt. Ltd. Scope of Supply and ServicesAnonymous 7ZYHilDNo ratings yet

- ENP-00070 Rev04 Design Verification Testing (DVT) Procedure and Regulations140820Document11 pagesENP-00070 Rev04 Design Verification Testing (DVT) Procedure and Regulations140820jing zhangNo ratings yet

- Project Scope Statement: Tetra PakDocument5 pagesProject Scope Statement: Tetra PakDania KiyaniNo ratings yet

- J P Mukherji & Associates Pvt. Ltd. Scope of Supply and ServicesDocument4 pagesJ P Mukherji & Associates Pvt. Ltd. Scope of Supply and ServicesAnonymous 7ZYHilDNo ratings yet

- Annex A PHC Jet A1 Rev2Document30 pagesAnnex A PHC Jet A1 Rev2Chisom IkengwuNo ratings yet

- Vuqla/Kku Vfhkdyi, Oa Ekud Laxbu Jsy Ea Ky Research Designs and Standards OrganisationDocument22 pagesVuqla/Kku Vfhkdyi, Oa Ekud Laxbu Jsy Ea Ky Research Designs and Standards OrganisationDinesh MehtaNo ratings yet

- Tvd-Rc-Arg-Mep-Ms-00022 - T&C Ventilation FansDocument13 pagesTvd-Rc-Arg-Mep-Ms-00022 - T&C Ventilation Fansalisheeraz0302No ratings yet

- J P Mukherji & Associates Pvt. Ltd. Scope of Supply and ServicesDocument5 pagesJ P Mukherji & Associates Pvt. Ltd. Scope of Supply and ServicesAnonymous 7ZYHilDNo ratings yet

- Qcs 2010 Section 11 Part 2.2 SAFETY, HEALTH AND ENVIRONMENT PROCEDURA PDFDocument24 pagesQcs 2010 Section 11 Part 2.2 SAFETY, HEALTH AND ENVIRONMENT PROCEDURA PDFbryanpastor106No ratings yet

- LPS-01-HTI-MST-EL-005 - Point WiringDocument11 pagesLPS-01-HTI-MST-EL-005 - Point WiringJomy JohnyNo ratings yet

- DOD-QCP-INS-002, Rev-0Document7 pagesDOD-QCP-INS-002, Rev-0BharathiNo ratings yet

- Sanitary Fixtures Method StatementDocument14 pagesSanitary Fixtures Method StatementSwapnil ChavanNo ratings yet

- Tab Bah-6656-Ms-Se-00053-R00 Method Statement For Steel Structure Fabrication For Bldg. 6656 Aircraft ShadesDocument107 pagesTab Bah-6656-Ms-Se-00053-R00 Method Statement For Steel Structure Fabrication For Bldg. 6656 Aircraft ShadesmustafaansmeNo ratings yet

- MS-0009 Shade StructureDocument11 pagesMS-0009 Shade StructureAbdul LatheefNo ratings yet

- O&m Manual For Access Control SystemDocument81 pagesO&m Manual For Access Control SystemyoutechriveNo ratings yet

- MS For AIR CURTIANDocument12 pagesMS For AIR CURTIANlike saddamNo ratings yet

- LPS-01-HTI-MST-EL-009 - Light FixturesDocument25 pagesLPS-01-HTI-MST-EL-009 - Light FixturesJomy JohnyNo ratings yet

- Drainage Approved Vendors List - June 2016Document49 pagesDrainage Approved Vendors List - June 2016shujad77No ratings yet

- Regulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsFrom EverandRegulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsNo ratings yet

- Methodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsFrom EverandMethodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsNo ratings yet

- Jamasurgery Di Martino 2023 Oi 230054 1692713713.90734Document10 pagesJamasurgery Di Martino 2023 Oi 230054 1692713713.90734Sergio MozoNo ratings yet

- Benjamin P. Solder: EducationDocument3 pagesBenjamin P. Solder: Educationapi-519801593No ratings yet

- INTERSALT Study Findings Public Health and Medical Care ImplicationsDocument9 pagesINTERSALT Study Findings Public Health and Medical Care ImplicationsMore Force CompanyNo ratings yet

- Human Development 11Document5 pagesHuman Development 11steven msusaNo ratings yet

- Accuracy of Focused Assessment With Sonography For Trauma (FAST) in Blunt Trauma Abdomen - A Prospective StudyDocument5 pagesAccuracy of Focused Assessment With Sonography For Trauma (FAST) in Blunt Trauma Abdomen - A Prospective StudyEdison HernandezNo ratings yet

- Gordons Caminade - DoxDocument4 pagesGordons Caminade - DoxZachary CaminadeNo ratings yet

- The Diagnosis and Management of Soft Tissue Knee Injuries - Internal Derangements, New Zeeland Guideline Group, 2003Document104 pagesThe Diagnosis and Management of Soft Tissue Knee Injuries - Internal Derangements, New Zeeland Guideline Group, 2003Pedro FonsecaNo ratings yet

- Spiritual CareDocument7 pagesSpiritual CareSyarief NurseNo ratings yet

- Unknown 79 Mycology University of Adelaide PDFDocument1 pageUnknown 79 Mycology University of Adelaide PDFLinda Gonzalez (Maddy)No ratings yet

- Surgical Position Supino DecubbitusDocument4 pagesSurgical Position Supino DecubbitusMariana AmayaNo ratings yet

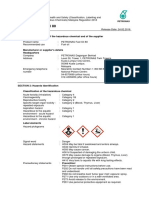

- Material Safety Data Sheet Avades 100Document4 pagesMaterial Safety Data Sheet Avades 100fs1640No ratings yet

- Popular Notions About Discipline of PsychologyDocument5 pagesPopular Notions About Discipline of PsychologyThe noble savageNo ratings yet

- PORT INFO Oiltanking Karimun 4.0Document3 pagesPORT INFO Oiltanking Karimun 4.0Ikhsan Nurpratama100% (1)

- Basic Training: Elementary First Aid: Written AssessmentDocument2 pagesBasic Training: Elementary First Aid: Written AssessmentClark LlameraNo ratings yet

- Patient AttendanceNo-Show PredictionDocument10 pagesPatient AttendanceNo-Show PredictionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Các Thì C A Đ NG TDocument3 pagesCác Thì C A Đ NG TThanh TuyếtNo ratings yet

- 6th Grade BookletDocument6 pages6th Grade BookletYolanda FrutosNo ratings yet

- Jurnal Ckd-EpiDocument6 pagesJurnal Ckd-EpinezaNo ratings yet

- Mandated Reporter FormDocument2 pagesMandated Reporter FormLex TalamoNo ratings yet

- Chapter 22: The Thyroid Gland: by Marissa Grotzke, Dev AbrahamDocument21 pagesChapter 22: The Thyroid Gland: by Marissa Grotzke, Dev AbrahamJanielle FajardoNo ratings yet

- PETRONAS Fuel Oil 80: Safety Data SheetDocument10 pagesPETRONAS Fuel Oil 80: Safety Data SheetJaharudin JuhanNo ratings yet

- SKM 4 - COCU - CU5 - Child - Care - Centre - ParentalDocument11 pagesSKM 4 - COCU - CU5 - Child - Care - Centre - ParentalShireen TahirNo ratings yet

- Lab Design Guide ChecklistDocument9 pagesLab Design Guide ChecklistTanveer AzizNo ratings yet

- T27208AQCDocument1 pageT27208AQCpiagiopersempreNo ratings yet

- Rac Report Khed TeamDocument41 pagesRac Report Khed TeamPurushottam WankhedeNo ratings yet

- Of RRR PDFDocument14 pagesOf RRR PDFMr XYZNo ratings yet