Professional Documents

Culture Documents

Comparative Study of Ultimate Moment and Cost by Using ACI 318-08, BS 8110-1:1997 and IS 456:2000

Uploaded by

Amadeus MozartOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comparative Study of Ultimate Moment and Cost by Using ACI 318-08, BS 8110-1:1997 and IS 456:2000

Uploaded by

Amadeus MozartCopyright:

Available Formats

Asian Journal of Applied Sciences (ISSN: 2321 – 089)

Volume 04 – Issue 03, June 2016

Comparative Study of Ultimate Moment and Cost by using

ACI 318-08, BS 8110-1:1997 and IS 456:2000

R. R. Adkins1* and Dr. S. Thirumalini2

1

Student

S. A. Engineering College

Poonamallee-Avadi Road, India

2

Associate Professor

Vellore Institute of Technology

Vellore, India

*

Corresponding author’s email: vcsrobi [AT] gmail.com

_____________________________________________________________________________________________

ABSTRACT— When designing a safe and economical structure, the ultimate moment a rectangular beam defines

the strength of the structure. By considering the above needs, this study gives the comparative design of ultimate

moment of a rectangular beam by using three different international design codes. The reduction factor used differs

for different codes which affects the strength of the flexural member. The design data obtained from a particular

design is used in other standards to bring out similar results. The design methodology is quite similar, but there are

some differences in the parameters and constants mentioned in the three code provisions. The cost is estimated to

ensure an economical design.

Keywords— Ultimate moment, ACI 318-08, BS 8110-1:1997 and IS 456:2000

_____________________________________________________________________________________________________________

1. INTRODUCTION

The study of ultimate moment in a rectangular section by ACI 318-08 and BS 8110-1:1997 are comparatively studied

with IS 456:2000. This study is about the economical design and cost of the flexural element. The objective of the study,

the constants and parameters used in this paper are discussed in the best way as possible. The design procedure includes

brief explanation for the procedure used, parameters and constants that vary according to different standards and

elimination of few calculations in various codes of practice. Tables are included briefly to discuss the cost of the element

and ultimate moment separately. The cost includes labor cost and material cost which defines the cost efficiency of a

section by using the three codes of practice. Eventually the results are evaluated and compared in tabular format.

The paper can be of great value to budding engineers to comparatively learn the design aspects of the international

codes - ACI 318-08, BS 8110-1:1997 and IS 456:2000 as it carries an example for each code of practice to explain the

research in detail.

2. OBJECTIVE OF STUDY

i. To compare the design strength of the beam for the following three code provisions: ACI 318-08, BS 8110-1:1997

and IS 456:2000.

ii. To comparatively study the design procedure for beams of the following codes of practice— ACI 318-08, BS 8110-

1:1997 and IS 456:2000.

Asian Online Journals (www.ajouronline.com) 600

Asian Journal of Applied Sciences (ISSN: 2321 – 089)

Volume 04 – Issue 03, June 2016

3. DESIGN PROCEDURE FOR ACI 318-08, BS 8110-1:1997 AND IS 456:2000

Table 1: Comparison of design procedures

S.NO DESCRIPTION ACI 318-08 BS 8110-1:1997 IS 456:2000

1. Factored load: Find the factored loads, W= 1.4 gk + 1.6 qk Area of reinforcement

Bars in compression are Wu = 1.2WD + 1.6WL is taken from

near the neutral axis, previous method;

hence a factor is hence load calculation

assumed to be greater is not needed.

than 3%.

2. Compression and Check for minimum steel Equilibrium of the Forces of

tension forces: compromises with this compressive and compression = Forces

Axial tension and calculation. tensile forces. of tension

flexure is taken as 0.95. 0.95fyAs = C=T

In IS 456 steel yield is 0.45fcub(0.9x) 0.36fckbd = 0.87fyAst

assumed to be 80%. Where, x = 2.346

Asfy/fcub

3. Lever arm: The lever arm between Lever arm, z = d- Lever arm, z = d-

Lever arm is the tensile and compressive 0.45x 0.42x

distance between force resultants in a concrete z = d(1- 1.056 z = d- (fyAst/fckb)

of compression and beam is equal to 90% of Asfy/fcub)

tension in a beam. the effective depth (d),

then the (d-a/2)

component of the ―exact‖

equation above simply

becomes 0.9d.

4. Percentage steel Mu dist = WuL2/8 Mu = 0.95fyAsz Mu (concrete) =

Pu = 1.6P Mu =0.95fyAs 0.36fckbz

Mu point = PuL/4 d(1- 1.056 Asfy/fcub) Mu (steel) =

Mu = Mu dist + Mu point 0.87fyAstz

Check for minimum

steel-

= As/bd

As min= 3fcbwd/fy < As

Assume steel has yielded.

C=T

T = fyAs ; C = 0.85fcab

Check for minimum steel

strain-

Mn = T(d- a/2)

5. Factor of depth Factor of depth, k Maximum depth of

k =Mu/fubd2; neutral axis

=100As/bd ; Xm/d=0.0035/(0.87fy/

m = fy/fcu Es)+0.0055

k= 0.0095m-

0.0001(m)2

6. Ultimate moment Check: Mn ≥Mu M = 100Asfy/bdfcu Mu=0.87fyAstd (1-Astfy

/ bd2fcu)

7. Design stage Designed at the stage of Analysis and fatigue Designed at the point

collapse. load calculation. of ultimate strength.

4. METHODOLOGY

4.1 American Code of Practice— ACI 318-08

In this paper we find the ultimate load by determining the self-weight and live load of the beam. Maximum moment is

calculated at a distance from the midspan where it occurs. Maximum factored load is assumed as per ACI 318-08 and

maximum factored moment is obtained. A method called weighted average is used to determine the depth of the section,

d. Area of reinforcement, AS and minimum area of reinforcement, AS min are determined to calculate the tension and

Asian Online Journals (www.ajouronline.com) 601

Asian Journal of Applied Sciences (ISSN: 2321 – 089)

Volume 04 – Issue 03, June 2016

compression by assuming that the steel as yielded, in order to check the section for minimum steel and tension control.

The beam is checked for adequacy and strength.

4.2 British Code of Practice— BS 8110-1:1997

The ultimate load of the simply supported rectangular beam is calculated by adding the characteristic dead loads and

live loads to the constants. The beam is checked for the condition of singly reinforced design by determining the design

moment and ultimate moment of resistance. The factor of depth and lever arm is calculated to check the beam for safety.

The area of reinforcement is also obtained.

4.3 Indian Code of Practice— IS 456:2000

The rectangular beam section is assumed to be a balanced section to initiate the design; the depth of neutral axis for

balanced failure is calculated. The balanced percentage of steel is obtained by equating the compression and tension. It is

clear that steel failure controls the design and hence the beam is an under-reinforced section. According to IS 456:2000,

Annex G the ultimate moment of resistance for steel is evaluated.

5. DESIGN EXAMPLE

5.1 American Method (ACI 318-08)

In an office building, the point load is a live load with P = 15 kip. The distributed loads are W d = 0.6638 kip/ft and

Wl = 1.45 kip/ft. The span length is L = 26.246 ft. Material strength are fc’ = 4 kip/in2, fy = 60 kip/in2. Is the beam

adequate?

Solution:

By equation 9.2. in clause 9.2.1. of ACI 318-08

Wu = 1.2WD + 1.6WL

= 1.2(0.6638) + 1.6(1.45)

Wu = 3.116 kip/ft

For a constantly distributed load, the maximum moment occurs at midspan, Mu dist

Mu dist = WuL2/8

= 3.116 (26.246)2 = 268.3 kip. ft

To get the maximum factored load, use Pu = 1.6P in place of Pu.

Mu point = PuL/4

= (1.6P)L/4 = ((1.6)(15)(26.246)) / 4

= 157.476 kip. ft

The total factored moment is Mu = Mu dist + Mu point

= 268.3 + 157.47

= 425 kip. ft

Weighted average is used to determine d.

d = (((4)(27‖)) + ((2)(25‖))) / 6 = 26.3‖

Now As is calculated, = As/bd

Where = 0.0239 (Table from ACI 318)

0.0239 = As / ((26.3‖)(20‖))

As = 1.25 in2

As = 6(1.25) = 7.54 in2

As min = 3fcbwd/fy

= 34000 (20‖)(26.3‖) / 60000

= 1.66 in2 < As

200bwd / fy = ((200)(20‖)(26.3‖)) / 60000 = 1.75 in2 < As

The steel area As which is provided is greater than the above required minimum areas of reinforcement from ACI

318-08.

Assume the steel as yielded.

Asian Online Journals (www.ajouronline.com) 602

Asian Journal of Applied Sciences (ISSN: 2321 – 089)

Volume 04 – Issue 03, June 2016

T = fyAs = (60)(7.54) = 452.4 kip

By equilibrium, C = T

C = 0.85fcab

a = C /0.85fc b = T /0.85fcb

= 452.4/ (0.85)(4)(20‖)

a = 6.65‖

For 4000psi =fc , 1 = 0.85

c = a / 1 = 6.65‖ / 0.85 = 7.82‖

Check for minimum steel, c / dt = 7.82‖ / 27‖ = 0.289‖ 0.375‖

The section is tension controlled. Thus the steel has yielded as assumed and the section meets minimum steel strain

requirements of the code.

= 0.9 for a tension controlled section.

Mn = T (d- a/2)

= 452.4 (26.3‖- 6.65‖/2)(1 ft/12 in)

= 866.15kip.ft

Mn = 0.9(866.15‖) = 780 kip.ft ≥ Mu

The beam is adequate in strength and okay.

5.2 British Method (BS 8110-1:1997)

A simply supported rectangular beam 8m span carries a characteristic dead load g k and imposed loads qk of 10kN/m

and 20kN/m respectively. The beam dimensions are breadth, b = 500mm and effective depth, d = 780mm.

Assuming the following material strength: f cu = 25 N/mm2; fy = 415 N/mm2.

Solution:

Ultimate Load (W) = 1.4 gk + 1.6 qk

= (1.4*10) + (1.6*20)

= 46 kN/m

Design method, M = Wl2/8

= ((46)(82)) /8

= 368 kNm

Ultimate moment of resistance, Mu = 0.156fcu bd2

= 0.156*25*500*7802*10-6 = 1186.38 kNm

Hence Mu > M, design as singly-reinforced beam.

k =M /fubd2

= 368*106 / 25*500*7802

= 0.0483

Lever arm, z = d (0.5 + (0.25 – k/0.9))

= 780 (0.5 + (0.25 – 0.0483/0.9))

= 780 (0.942) = 735.52mm

735.52mm 0.95d = 741mm

Hence okay.

Area of steel reinforcement, As = M/0.87fy z

= 368*106 / 0.87*415*735.52 = 1385.75mm2

Provide 5 numbers of 20mm diameter bars as longitudinal reinforcement.

5.3 Indian Method (IS 456:2000)

Calculate the Ultimate Moment, in a office building. A rectangular beam is designed for b = 500mm and d =

780mm. The area of steel reinforcement is Ast = 4865mm2. Assume grade 25 concrete and Fe 415 steel.

Solution:

Depth of neutral axis for balanced failure x/d = 0.0035/0.0035+ (0.87(f y / Es) + 0.002)

Es = 2*105 N/mm2

x / d = 0.0035/ 0.0035+0.00038

x / d = 0.5

Asian Online Journals (www.ajouronline.com) 603

Asian Journal of Applied Sciences (ISSN: 2321 – 089)

Volume 04 – Issue 03, June 2016

Balanced percentage of steel,

0.87 fy As = 0.36 fck bx

(P/100 bd) (0.87 fy) = 0.36 fck bx

Substituting for x/d, we get

Pfy / fck = 0.36*0.50*100/0.87 = 20.68

For fy = 415N/mm2 ; fck = 25 N/mm2

P = 20.68*25/415 = 1.25%

Actual percentage of steel in beam = 4865*100 /500*780 = 1.2%

Steel failure controls.

Hence, beam is under-reinforced.

Mu steel failure,

Mu = 0.87fy (p/100) (1-(p/100) (fy /fck) ) bd2

= 0.87*415*1.2 /100 (1- 1.2*415 / 100*25) *500*7802

Mus = 1055 kNm

Mu concrete (for conformation only)

Mu = 0.138 fck bd2

= 0.138*25*500*7802

Muc = 17.42 MNm

Steel failure controls strength, therefore ultimate moment capacity is Mus = 1055 kNm

6. RESULT AND DISCUSSION

The Ultimate Moment of a singly reinforced beam of dimension 500mm * 780 mm is calculated by ACI 318-08, BS

8110-1:1997 and IS 456:2000. The cost for the section 500mm * 780mm is also determined in the table 2 shown below.

Table 2: Results by ACI 318-08, BS 8110-1:1997 and IS 456:2000

Code of Practice Ultimate Moment Cost of a section

ACI 318-08 1057.5 kNm 174550.73 INR

BS 8110-1:1997 1187 kNm 3838.27 INR

IS 456:2000 1055 kNm 717.6 INR

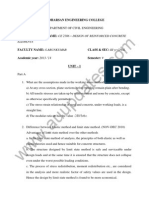

Chart 1: Cost Analysis of a section 500mm*780mm by ACI 318-08, BS 8110-1:1997 and IS 456:2000.

180000

162000 Cost Analysis of a Beam

144000 500mm*780mm

126000

108000

90000

72000

Cost of a Beam in INR

54000

36000

18000

Asian Online Journals (www.ajouronline.com) 604

Asian Journal of Applied Sciences (ISSN: 2321 – 089)

Volume 04 – Issue 03, June 2016

Chart 2: Ultimate Moment of a section 500mm*780mm by ACI 318-08, BS 8110-1:1997 and IS 456:2000

Ultimate Moment capacity in kNm

1200

1080

960

840

720

600 Ultimate Moment

480 capacity in kNm

360

240

120

0

ACI 318-08 BS 8110-1:1997 IS 456:2000

The ACI 318-08 use the nominal yield stresses to calculate the section moment and axial load capacity , then reduce

these values by a global capacity reduction factor, whereas British code apply different reduction factors to the concrete

and steel yield stress, and use these values to calculate the design ultimate capacities.

All the codes have a greater reduction factor in capacity for sections where concrete crushing controls the design,

compared with sections where steel yield in tension controls.

The moment acting or the given section of beam is designed for large moment as the factor for British design is 0.95

whereas for American design and Indian design it is 0.85 and 0.87 respectively.

7. CONCLUSION

This comparative study on the design procedures and cost on all three international codes of practice is brought out to

learn about the best design practice that can be economical and serviceable.

The BS 8110-1:1997 stands to the above paragraph as it has a good design practice as well as economical. The

ultimate moment capacity of ACI 318-08 is okay but uneconomical when compared to other standards. The IS 456:2000

proves okay.

8. ACKNOWLEDGMENT

This report is completed by the support of S.A. Engineering College, Avadi, India. We thank the faculties and

colleagues from department of Civil Engineering for providing insight and expertise in the research. The discussions

were greatly helpful though all the points are not agreed.

9. REFERENCES

[1] Chanakya Arya, Design of structural elements: Concrete, Steelwork, Masonry and Timber Designs to British

Standards and Euro codes, Third edition, CRC Press, 2009.

[2] Matthew W. Roberts, CEE 3150 – Reinforced Concrete Design Course wares, University of Wisconsin - Platteville

and The Board of Regents Wisconsin system, 2009.

[3] American Concrete Institute (2008). Building Code Requirements for Structural Concrete, ACI 318M-08, USA.

[4] BS 8110 – 1:1997, Structural use of concrete — Part 1: Design charts for singly reinforced beams, doubly reinforced

beams and rectangular columns.

[5] IS 456:2000, Indian Standard Plain and Reinforced Concrete — Code of Practice.

[6] P.C. Varghese, Limit State Design of Reinforced Concrete, Second edition, PHI learning private limited,

September 2013.

[7] Anupam Sharma and Dr. Suresh Singh Kushwah, ―Comparative Analysis of Reinforcement and Prestressed Concrete

Beams‖, International Journal of Current Engineering and Technology, vol. 5, no. 4, pp.2564-2566, August 2015.

Asian Online Journals (www.ajouronline.com) 605

Asian Journal of Applied Sciences (ISSN: 2321 – 089)

Volume 04 – Issue 03, June 2016

[8] Bhavin H. Zaveri, Jasmin A. Gadhiya, Hitesh K. Dhameliya, ―A Review on the Comparative Study of Steel, RCC and

Composite Building‖, International Journal of Innovative Research in Science, Engineering and Technology, Vol. 5,

Issue 1, pp 354-365, January 2016.

[9] K. H. Bayagoob, Yavuz Yardim, S. A. Ramoda, ―Design Chart for Reinforced Concrete Rectangular Section‖, 2 nd

International Balkans Conference on Challenges of Civil Engineering, BCCCE, 23-25 May 2013, Epoka University,

Tirana, Albania.

[10] Morteza Fadaee, Atefeh Iranmanesh, and Mohammad J. Fadaee, ―A Simplified Method for Designing RC Slabs

under Concentrated Loading‖, IACSIT International Journal of Engineering and Technology, Vol. 5, No. 6, pp 675-679,

December 2013.

Asian Online Journals (www.ajouronline.com) 606

You might also like

- Reinforced Concrete Beam DesignDocument11 pagesReinforced Concrete Beam DesignMark Ruby OpawonNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- CE 437 - PDF 04 - Intro 04 - Steel - (Design of Steel Structure)Document6 pagesCE 437 - PDF 04 - Intro 04 - Steel - (Design of Steel Structure)Md Mufazzel Hossain ChowdhuryNo ratings yet

- CAUSON Assignment 1MDocument5 pagesCAUSON Assignment 1MEmmanuel CausonNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Preliminary Structural DesignDocument8 pagesPreliminary Structural Designaikaless100% (1)

- Design of Beam-Aci-11-01-05Document23 pagesDesign of Beam-Aci-11-01-05pareen9No ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Nottingham Concrete Beam TestingDocument8 pagesNottingham Concrete Beam TestingYaasiin OozeerNo ratings yet

- Limit State Design FinalDocument53 pagesLimit State Design FinalHariom KhungarNo ratings yet

- Afghan University "Engineering Faculty": Subject: Design of Steel StructuresDocument18 pagesAfghan University "Engineering Faculty": Subject: Design of Steel StructuresHamid ElmyNo ratings yet

- Stress AnalysisDocument8 pagesStress Analysisram vomNo ratings yet

- Blade Design Calvin John PDFDocument35 pagesBlade Design Calvin John PDFElijah NormanNo ratings yet

- Moment Distribution MethodDocument14 pagesMoment Distribution MethodAyad SlabyNo ratings yet

- 012 Working Stress, Ultimate Load, Limit State MethodDocument7 pages012 Working Stress, Ultimate Load, Limit State MethodArchita KajaleNo ratings yet

- Optimization of Prestressed Concrete Bridge DecksDocument7 pagesOptimization of Prestressed Concrete Bridge DecksParth TrivediNo ratings yet

- Experiment 1 Tensile and Torsion TestDocument27 pagesExperiment 1 Tensile and Torsion TestMuhd Fauzan Ibrahim100% (1)

- Comparing Conventional and Tubular Steel StructuresDocument5 pagesComparing Conventional and Tubular Steel Structuresa duttaNo ratings yet

- 0250 PDFDocument8 pages0250 PDFGREATANo ratings yet

- EDA3 Fatigue2 TutQ4 V1Document7 pagesEDA3 Fatigue2 TutQ4 V1celticglasgow99No ratings yet

- Design and dynamic analysis of 70T overhead crane girderDocument8 pagesDesign and dynamic analysis of 70T overhead crane girderGogyNo ratings yet

- Vibration and Flow Simulation AnaylsisDocument17 pagesVibration and Flow Simulation AnaylsisAdeel AltafNo ratings yet

- Chapter 3 USD P1Document26 pagesChapter 3 USD P1Angelo RosNo ratings yet

- Lecture 3Document17 pagesLecture 3Minakshi KalraNo ratings yet

- Lab Report # 1Document8 pagesLab Report # 1Awais26No ratings yet

- Design of Steel StructuresDocument179 pagesDesign of Steel StructuresneophymenNo ratings yet

- Asd VS LRFDDocument179 pagesAsd VS LRFDALONSO GOMEZNo ratings yet

- 4 - ME3263 SupplementsDocument102 pages4 - ME3263 SupplementsSam MottahediNo ratings yet

- Lug Analysis Calculator - ResultsDocument13 pagesLug Analysis Calculator - ResultsShreya GiriNo ratings yet

- CIE3150 2017 Case Study Beam V 03-2Document19 pagesCIE3150 2017 Case Study Beam V 03-2FerdiVKNo ratings yet

- 22 Shaft and Its Design Based On StrengthDocument11 pages22 Shaft and Its Design Based On StrengthPRASAD326100% (4)

- Fatigue of ShaftDocument8 pagesFatigue of ShaftSathish KumarNo ratings yet

- Design MethodsDocument20 pagesDesign Methodslenah_22No ratings yet

- 6.3 Design Values of Combined ActionsDocument7 pages6.3 Design Values of Combined Actionsmn4webNo ratings yet

- Learning Packet 3 Partial01Document10 pagesLearning Packet 3 Partial01ronnie oraleNo ratings yet

- TALAT Lecture 2711: Design of A Helicopter DeckDocument11 pagesTALAT Lecture 2711: Design of A Helicopter DeckCORE MaterialsNo ratings yet

- Calculation Sheet 0Document10 pagesCalculation Sheet 0Bahiya Al-rifaiiNo ratings yet

- CE2306 - Design of RC ElementsDocument22 pagesCE2306 - Design of RC ElementsViswanathan NatesanNo ratings yet

- Preliminary Structural Design PDFDocument8 pagesPreliminary Structural Design PDFKenny Manuel VettoorNo ratings yet

- Doubly Reinforced Concrete Beam Design (ACI 318-14)Document17 pagesDoubly Reinforced Concrete Beam Design (ACI 318-14)John Amir A AguilarNo ratings yet

- 5 - RCE-design-of-Tbeam-and-double-reinforcedDocument33 pages5 - RCE-design-of-Tbeam-and-double-reinforced'Riky Dwi Prasetyo'No ratings yet

- ACI 318-08 RC-SL Example 001Document3 pagesACI 318-08 RC-SL Example 001Novin KamyabNo ratings yet

- Engineers: My Notes StructuralDocument14 pagesEngineers: My Notes StructuralGladies Mhay Binay SandovalNo ratings yet

- Simply Supported Reinforced Concrete Beam Analysis and Design (ACI 318-14)Document33 pagesSimply Supported Reinforced Concrete Beam Analysis and Design (ACI 318-14)Anonymous ARMtmNKLNo ratings yet

- C ClampDocument26 pagesC Clamparulmurugu100% (4)

- Formulário Técnico CableApp enDocument12 pagesFormulário Técnico CableApp enPvd CoatingNo ratings yet

- Study of Forming Parameters in HydroformDocument10 pagesStudy of Forming Parameters in HydroformĐặng Quốc ĐạiNo ratings yet

- Fluctuating Stresses and Fatigue FailureDocument9 pagesFluctuating Stresses and Fatigue FailureMelese AschalewNo ratings yet

- CVX7640 32Document14 pagesCVX7640 32malingauomNo ratings yet

- Blade Design Calvin John PDFDocument35 pagesBlade Design Calvin John PDFADKMARNo ratings yet

- Machine design review: gears, shafts, fatigueDocument80 pagesMachine design review: gears, shafts, fatiguevenkatNo ratings yet

- Aci 318-11 RC-SL Example 001Document3 pagesAci 318-11 RC-SL Example 001Novin KamyabNo ratings yet

- Learning Packet-3 CE 14 Singly Reinforced BeamDocument17 pagesLearning Packet-3 CE 14 Singly Reinforced BeamWalwal WalwalNo ratings yet

- Time-Dependent Prestress Loss and Deflection in Prestressed Concrete Members - PCI PDFDocument13 pagesTime-Dependent Prestress Loss and Deflection in Prestressed Concrete Members - PCI PDFKatherine StuartNo ratings yet

- Design of 26m Precast Piles for Bangladesh Power PlantDocument6 pagesDesign of 26m Precast Piles for Bangladesh Power PlantcivixxNo ratings yet

- Module 4Document34 pagesModule 4holeeshet holeeshetNo ratings yet

- Experimental and Analytical Study On Behaviour ofDocument9 pagesExperimental and Analytical Study On Behaviour ofrudynyambiNo ratings yet

- Abellera Fenelachristina Ce Geol131aDocument1 pageAbellera Fenelachristina Ce Geol131aAmadeus MozartNo ratings yet

- Afable - Crystal Rose - B. - Ce - Geol131aDocument1 pageAfable - Crystal Rose - B. - Ce - Geol131aAmadeus MozartNo ratings yet

- Structural Design Concepts and Load CombinationsDocument2 pagesStructural Design Concepts and Load CombinationsAmadeus MozartNo ratings yet

- Late Payment Explanation LetterDocument2 pagesLate Payment Explanation LetterAmadeus MozartNo ratings yet

- Layers of The Earth InfographicDocument2 pagesLayers of The Earth Infographicxyron huangNo ratings yet

- A Molecular Imprinted Polymer With Recognition Properties Towards The Carcinogenic Mycotoxin Ochratoxin ADocument6 pagesA Molecular Imprinted Polymer With Recognition Properties Towards The Carcinogenic Mycotoxin Ochratoxin AOditio ArizalNo ratings yet

- Introduction and Basic Concepts Study Guide in Powerpoint: To AccompanyDocument34 pagesIntroduction and Basic Concepts Study Guide in Powerpoint: To AccompanyDuy NguyenNo ratings yet

- Photoelastic stress analysisDocument50 pagesPhotoelastic stress analysisSunder Veera KarthikeyanNo ratings yet

- MATLS 4I03 Assignment 2Document3 pagesMATLS 4I03 Assignment 2RoyNo ratings yet

- Triangulo de DuvalDocument8 pagesTriangulo de Duvalcarlos patrickNo ratings yet

- 2.2 WaterDocument32 pages2.2 WaterHelena GlanvilleNo ratings yet

- Entrance Exam - 2020: Test No. 2Document24 pagesEntrance Exam - 2020: Test No. 2Shaestah Fatima100% (2)

- W.G. Szymczak and A.B. Wardlaw - Numerical Methods For Explosion Plume PredictionsDocument47 pagesW.G. Szymczak and A.B. Wardlaw - Numerical Methods For Explosion Plume PredictionsMallamaxNo ratings yet

- KineticsDocument26 pagesKineticsMelissa M. Abansi-BautistaNo ratings yet

- Colligative Properties NotesDocument5 pagesColligative Properties Notesjehov cantera100% (1)

- Dokumen - Tips - Pressure Loss of Orifice Plates According To Iso 5167 1Document3 pagesDokumen - Tips - Pressure Loss of Orifice Plates According To Iso 5167 1Tomi GánnNo ratings yet

- Mechanical IOCL Technical PYQsDocument19 pagesMechanical IOCL Technical PYQsSANDIP PATELNo ratings yet

- The Bouma Sequence and the Turbidite Mind SetDocument29 pagesThe Bouma Sequence and the Turbidite Mind SetEric EspirituNo ratings yet

- Lect 17Document26 pagesLect 17vatsalp3No ratings yet

- Introduction To Magneto OpticsDocument37 pagesIntroduction To Magneto OpticsPooja GittyNo ratings yet

- Allen Practice Test Series - (2021-22)Document1 pageAllen Practice Test Series - (2021-22)Raghav KaranNo ratings yet

- Vibration Analysis and Control Exam QuestionsDocument4 pagesVibration Analysis and Control Exam QuestionsAshokNo ratings yet

- 2306 9MA0-32 A Level Mechanics - June 2023 PDFDocument20 pages2306 9MA0-32 A Level Mechanics - June 2023 PDFkong99999seifalikong99999100% (3)

- Chemistry-SQP Term2Document6 pagesChemistry-SQP Term2Divya SharmaNo ratings yet

- Water Potential LabreportDocument3 pagesWater Potential LabreportmichyyyyyNo ratings yet

- Gel Coat 340028ADocument8 pagesGel Coat 340028Agustavo gonzalezNo ratings yet

- Polimeri Uropa StyreneDocument8 pagesPolimeri Uropa StyreneSubrata BanerjeeNo ratings yet

- HKDSE Physics Part - 2 MechanicsDocument17 pagesHKDSE Physics Part - 2 MechanicsdexterNo ratings yet

- Aieee-2010 Model Paper/SAMPLE PAPER BY ANURAG TYAGI CLASSESDocument7 pagesAieee-2010 Model Paper/SAMPLE PAPER BY ANURAG TYAGI CLASSESANURAG TYAGINo ratings yet

- ThesisDocument214 pagesThesisWill BlackNo ratings yet

- Sodium To Phosphate RatioDocument16 pagesSodium To Phosphate RatioKanchan100% (4)

- Exp. 5 (Carey Foster's Bridge)Document6 pagesExp. 5 (Carey Foster's Bridge)Saniya WalavalkarNo ratings yet

- Lab Report Chm510 Final (All Reports)Document54 pagesLab Report Chm510 Final (All Reports)Dang HumairahNo ratings yet

- PhysicscaDocument19 pagesPhysicscabishal2632No ratings yet

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeFrom EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeRating: 4.5 out of 5 stars4.5/5 (59)

- Summary of Neil Postman's Amusing Ourselves to DeathFrom EverandSummary of Neil Postman's Amusing Ourselves to DeathRating: 4 out of 5 stars4/5 (2)

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetFrom EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetRating: 4.5 out of 5 stars4.5/5 (10)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansRating: 4.5 out of 5 stars4.5/5 (21)

- Structural Cross Sections: Analysis and DesignFrom EverandStructural Cross Sections: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (19)

- The Finite Element Method: Linear Static and Dynamic Finite Element AnalysisFrom EverandThe Finite Element Method: Linear Static and Dynamic Finite Element AnalysisRating: 5 out of 5 stars5/5 (3)

- Principles of Forensic Engineering Applied to Industrial AccidentsFrom EverandPrinciples of Forensic Engineering Applied to Industrial AccidentsNo ratings yet

- Pile Design and Construction Rules of ThumbFrom EverandPile Design and Construction Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (15)

- Professional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionFrom EverandProfessional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionNo ratings yet

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsFrom EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsRating: 4 out of 5 stars4/5 (16)