Professional Documents

Culture Documents

August Practice Insight NEW 02 2

Uploaded by

Osama Fadel ahmedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

August Practice Insight NEW 02 2

Uploaded by

Osama Fadel ahmedCopyright:

Available Formats

A Workflow

With No Limits

Dr. August de Oliveira fills us in on how he leverages 3D printed

surgical guides for better planning, a rapid ROI, and a tightly

integrated seamless workflow.

“

A household name in digital dentistry, Dr. August de Oliveira has

been a lecturer of chairside CAD/CAM since 2005 and guided

surgery since 2009. As a pioneering figure in the world of dental

3D printing, Dr. de Oliveira has consistently championed the use of

The process as simple as this technology in dentistry, and his innovative approaches to the

profession have been adopted by dentists internationally. Dr. de

just scanning, sending it Oliveira has written three books on implants and is the co-founder of

the magazine Digital Enamel. Currently, he uses 3D printing as part of

to SprintRay, and allowing his everyday practice for various clinical purposes like the fabrication

them to take care of the of aligners, temporary restorations, and surgical guides.

As for what made him embrace 3D printing in the first place as part

design process. After of his regular workflow? “The tipping point was surgical guides.

that, you just push a That’s what gravitated many people, including myself, to 3D printing,”

says Dr. de Oliveira. “I was probably spending two- to three-thousand

button and go. dollars a month on surgical guides, and there were a lot of guys

making their own guides for under $30 a piece.”

SprintRay Practice Insights A Workflow with No Limit 1 of 4

3D printing drastically reduces the production cost and lead time of

$350

surgical guide fabrication, and this kind of savings made bringing

in a 3D printer a no-brainer for Dr. de Oliveira.“ Usually when we buy

dental equipment we’re worried about the cost. The cost [of a 3D

Per Surgical Guide* printer] is pretty negligible,” he says, “I got in on some of the early 3D

printing systems out there and quickly found MoonRay and SprintRay

Pro, and those have been our workhorses since then.”

3D Printed Surgical Guides – A Better Way to Plan

So what are surgical guides, and how are they helpful to your

practice? Simply put, surgical guides are a template used during

surgery to assist in the proper placement and angulation of dental

implants. They replicate the surfaces of the intraoral environment

and allow the clinician to drill implants with maximum accuracy,

predictability, and precision.

10-day Turnaround

Traditional methods of surgical guide fabrication can be labor-

intensive and time-consuming. Outsourcing surgical guide

fabrication to dental laboratories is costly and the available kits on

the market are often primitive and messy.

This is where SprintRay provides a better solution. 3D printing allows

for the cost-effective and quick fabrication of surgical guides, in-

office. By offering reduced lead times and an efficient method of

surgical guide fabrication, 3D printing provides a much better, faster,

and more accurate pathway to guided surgery. “My turnaround time

for surgical guides was a week and now it’s a day - I can do same-

day guided surgery,” says Dr. de Oliveira.

Additionally, having an in-office 3D printing ecosystem streamlines

$110

the dental workflow and increases flexibility, especially for busier

clinics. “If you have a busy office, you don’t want your mill to be

involved in an hour of milling. You want to keep it open for other

Per Surgical Guide** things. So 3D printing is just a better way to go,” says Dr. de Oliveira.

“When you mill, especially on a 3 or 4 axis mill, you’re limited by the

direction in which these mills can go. But 3D printing doesn’t care

about that.”

Turnaround

“

3-day

My turnaround time for surgical

guides was a week and now it’s a day -

I can do same-day guided surgery.

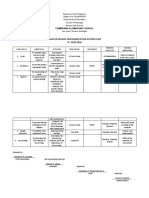

Traditional vs SprintRay

Surgical Guides Surgical Guides

*Average cost for traditionally-fabricated full-arch surgical guide

** Cost including design fee and materials cost

SprintRay Practice Insights A Workflow with No Limit 2 of 4

The SprintRay In-Office Workflow

Having a seamless workflow is a crucial aspect of any successful

dental practice. While 3D printing has been gaining momentum

amongst dental clinicians, some remain hesitant about the potential

complications of switching over to a fully digital workflow.

To address these hesitations, Dr. Oliveira often recommends

SprintRay, who creates a 3D printing ecosystem that is accurate,

Capture Data flexible, and is easy to embed into the existing clinical workflow - all

of which are important deciding factors for choosing an in-office

fabrication system. “What I really like about the SprintRay products

is that they’re very easy to use. The printers are very easy to use, the

resins are reasonably priced,” says Dr. de Oliveira. “It’s just a very

easy system to use. I can use it myself and I can train my team to

use it.”

Today, the biggest complication in a digital workflow is often the

design step of 3D printing. Once the patient’s digital anatomy

has been captured, the raw intraoral scan and CBCT data must

Submit to SprintRay be processed and used to plan a surgical implant guide. Many

Cloud Design outsource this step, while others prefer to handle it themselves by

mastering CAD design software. But CAD software has a steep

learning curve and is time consuming, while traditional outsourcing

can suffer from high costs and slow turnaround times.

SprintRay Cloud Design requires no design software knowledge on

the part of the clinician. It allows the seamless ordering and printing

of the desired dental appliances with just a few clicks and without

ever having to leave the SprintRay ecosystem, providing a truly

3D print Wash Cure frictionless workflow. “The process is as simple as just scanning,

sending it to SprintRay, and allowing them to take care of the design

In-office Fabrication process. After that, you just push a button and go,” Dr. de Oliveira

says.

The Two-printer Advantage

Currently, Dr. de Oliveira owns both a SprintRay Pro 95 and a

SprintRay Pro 55 as part of his practice, using them in conjunction

with each other to create a more efficient workflow. “Whenever

Sterilize you have one printer, you’re going to be quickly forced to either

take longer to do your jobs or buy a second printer,” he says. “Even

though the Pro 95 is a very fast printer, when you’re printing six to

ten models at a time your printer is going to be tied up for some

time. So buying a second printer is usually the way that doctors go.

You could buy another SprintRay Pro 95. However, buying a Pro 55 in

addition to the Pro 95 just opens up that whole new world of implant

restoratives”.

As for the difference between the two printers and the various uses

you can get out of them?

Place Appliance

“The Pro 55 has the same exact workflow that you would expect

for Surgery

from the Pro 95. Super easy software, super easy ways of owning

SprintRay Practice Insights A Workflow with No Limit 3 of 4

and cleaning the printer… We get that high level of detail we need

Available Design Options for restorations. The doctors that would gravitate towards the

Pro 55 would be those that are doing big cases, cases requiring

Fast dentistry done in more than two visits, doctors who are doing full

arch implantology, or doing a lot of implant restorations requiring an

SprintRay

Cloud Design

In-house CAD implant analog model.”

As for who should get involved in 3D printing, Dr. de Oliveira is

bullish. For doctors who have a scanner, he sees investing in

Easy Difficult SprintRay as a no brainer. “Look, if you’re doing any clear aligner

Digital Lab

therapy, any surgical guides, you’ll pay for SprintRay Pro in months,”

he says. “After that it’s all gravy. So I’d say definitely, right now is the

time to get into 3D printing.”

Traditional Lab Thanks to Dr. August de Oliveira and the staff at Sunrise Dental for

Slow

their time in sharing their experience.

SprintRay Ecosystem

About Dr. August de Oliveira

Dr August de Oliveira graduated from dental school in 1997 from Easy and Guided Implantology Made Easy. He has been involved

the University of Washington and completed his General Practice with beta testing Sirona’s Sidexis Program, as well as developing

Residency in Los Angeles in 1998. Dr de Oliveira has been lecturing the Opti and CEREC Milled Surgical Guides. Dr de Oliveira lectures

on 3D technology since 2004, when he started as a CEREC Basic nationwide for Sirona on the Galileos Cone Beam system and

trainer. Since 2008 he has been involved with Implant Direct’s R and Sirona Guided Implant Surgery. He also teaches for Implant Direct

D department developing Guided Surgery Software and Hardware at their Las Vegas Educational Facility and with the Engel Institute

and testing their CAD Milled Bars and Substructure Department. Dr in Charlotte. Dr de Oliveira lives and practices in Los Angeles CA.

de Oliveira has written two books on Implantology: Implants Made

SprintRay Practice Insights A Workflow with No Limit 4 of 4

You might also like

- 1949 Neff TAILORED OCCLUSION WITH THE ANTERIOR COEFFICIDocument5 pages1949 Neff TAILORED OCCLUSION WITH THE ANTERIOR COEFFICIRockey ShrivastavaNo ratings yet

- PolyJet Case Study - Dawood and Tanner EN A4 - 0818aDocument4 pagesPolyJet Case Study - Dawood and Tanner EN A4 - 0818aAlex BurdeNo ratings yet

- Research Written PaperDocument5 pagesResearch Written Paperapi-319495011No ratings yet

- Polymers: Dental 3D-Printing: Transferring Art From The Laboratories To The ClinicsDocument25 pagesPolymers: Dental 3D-Printing: Transferring Art From The Laboratories To The ClinicssmilesindiaNo ratings yet

- 3d Dental ImplantsDocument9 pages3d Dental Implantsapi-663988238No ratings yet

- Current TrendsDocument4 pagesCurrent Trendsyoursie accountNo ratings yet

- 1 s2.0 S2214031X22000213 MainDocument20 pages1 s2.0 S2214031X22000213 MainThanh Tùng NguyễnNo ratings yet

- Implementingdigital Dentistryintoyouresthetic DentalpracticeDocument13 pagesImplementingdigital Dentistryintoyouresthetic DentalpracticeAde Dian KaruniaNo ratings yet

- 3D Printing in OrthodonticsDocument117 pages3D Printing in OrthodonticsAnjali Shewale100% (1)

- Anatomical-Models ENDocument14 pagesAnatomical-Models ENfabian hernandez medinaNo ratings yet

- Digital Workflows in Contemporary OrthodonticsDocument7 pagesDigital Workflows in Contemporary OrthodonticsAndreaVanoyMartinNo ratings yet

- Digital Impressions - Paving Path Towards Green Dentistry: A ReviewDocument8 pagesDigital Impressions - Paving Path Towards Green Dentistry: A ReviewIJAR JOURNALNo ratings yet

- Form 2 FormlabsDocument8 pagesForm 2 FormlabsLaura GheorgheNo ratings yet

- Current TrendsDocument14 pagesCurrent TrendsEsper SorianoNo ratings yet

- 3D Printed CastDocument3 pages3D Printed CastSidraNo ratings yet

- 3D Printing Helps in Cranioplasty Reconstruction: Case Study - HealthcareDocument4 pages3D Printing Helps in Cranioplasty Reconstruction: Case Study - HealthcareAyyappa ChinnuNo ratings yet

- 3D Printing ScriptDocument2 pages3D Printing Scriptahmet çelikNo ratings yet

- Redefining Prosthodontics With 3D PrintingDocument8 pagesRedefining Prosthodontics With 3D PrintingIJAR JOURNALNo ratings yet

- Guided EndodonticsFrom EverandGuided EndodonticsNiraj KinariwalaNo ratings yet

- 3d News ReportDocument2 pages3d News Reportstream accountNo ratings yet

- Digital Orthodontics - A Contemporary View of Futuristic PracticeDocument10 pagesDigital Orthodontics - A Contemporary View of Futuristic PracticeIJAR JOURNALNo ratings yet

- Digital Implantology With Desktop 3D Printing: Formlabswhite PaperDocument15 pagesDigital Implantology With Desktop 3D Printing: Formlabswhite PaperEver SavedraNo ratings yet

- 3D Printing and Digital Processing Techniques IndentistryDocument29 pages3D Printing and Digital Processing Techniques IndentistryBalavigneshwaran bt18ipf04No ratings yet

- Whitley Bencharit Formlabs Whitepaper2016Document15 pagesWhitley Bencharit Formlabs Whitepaper2016SadishNo ratings yet

- 3D PrintingDocument7 pages3D PrintingMiru BorcanNo ratings yet

- Dental Industry Trends in 2020Document14 pagesDental Industry Trends in 2020David LeongNo ratings yet

- 3D Printing, A Maturing Technology: Karel BransDocument5 pages3D Printing, A Maturing Technology: Karel BransEsteban Jurko ENo ratings yet

- Introducing 3D Printing in Your Orthodontic Practice: Richard RJ CousleyDocument8 pagesIntroducing 3D Printing in Your Orthodontic Practice: Richard RJ CousleyHenrique de PársiaNo ratings yet

- 3D Printing and Digital Processing Techniques in Dentistry: A Review of LiteratureDocument28 pages3D Printing and Digital Processing Techniques in Dentistry: A Review of LiteratureMishal AliNo ratings yet

- DigitalDocument9 pagesDigitalTanhaz KareemNo ratings yet

- Three Dimensional ImagingDocument2 pagesThree Dimensional ImagingEdgar PadillaNo ratings yet

- Industry 1Document20 pagesIndustry 1IshwarNo ratings yet

- 2018 3D Family BrochureDocument27 pages2018 3D Family BrochureSam Al AbabNo ratings yet

- Intraoral ScannerDocument6 pagesIntraoral ScannerBelanwahidNo ratings yet

- PDF EN DentitudeDocument13 pagesPDF EN DentitudeChristian NguyễnNo ratings yet

- Dentistry 10 00181Document8 pagesDentistry 10 00181Mircavid HeydəroğluNo ratings yet

- 2016 JOO Camardella PDFDocument11 pages2016 JOO Camardella PDFSelvaNo ratings yet

- 3D Printing in Dentistry - 2019/2020: November 2018Document4 pages3D Printing in Dentistry - 2019/2020: November 2018smilesindiaNo ratings yet

- 3D Printing in DentistryDocument9 pages3D Printing in DentistryIJAR JOURNAL100% (1)

- Intraoral Scanner: An Innovative Precision Digital Impression TechnologyDocument12 pagesIntraoral Scanner: An Innovative Precision Digital Impression TechnologySushmaNo ratings yet

- 3D Workflows in Orthodontics Maxillofacial Surgery and ProsthodonticsDocument182 pages3D Workflows in Orthodontics Maxillofacial Surgery and ProsthodonticsA ANo ratings yet

- Create Custom 3D-Printed Tools: StudiesDocument2 pagesCreate Custom 3D-Printed Tools: StudiesrodolfoNo ratings yet

- Poster Strisca StanislavDocument1 pagePoster Strisca StanislavStanislav StrîșcaNo ratings yet

- Digital Dentistry - 3D Printing ApplicationsDocument4 pagesDigital Dentistry - 3D Printing ApplicationsDesi YuliNo ratings yet

- There Are Many Ways Dentists Can Use 3D PrintingDocument2 pagesThere Are Many Ways Dentists Can Use 3D PrintingMuhammad RizQi Aksanu AziziNo ratings yet

- Digitalized ProsthodonticsDocument3 pagesDigitalized ProsthodonticsSg100% (1)

- Guided Surgery in Dental ImplantologyDocument5 pagesGuided Surgery in Dental Implantologynarendra singhNo ratings yet

- Hablamos - Smylife - Magazine - Maxillaris - 160 CoachmanDocument5 pagesHablamos - Smylife - Magazine - Maxillaris - 160 CoachmanZayra SucariNo ratings yet

- 2021 Digital - GenericDocument4 pages2021 Digital - GenericHarsh ShahNo ratings yet

- 3D Technology ChapterDocument42 pages3D Technology ChapterKrupal MehtaNo ratings yet

- 3 DPrinted Copingfor Intraoral EvaluationDocument5 pages3 DPrinted Copingfor Intraoral EvaluationAriz Habiiballah AstsaqiifNo ratings yet

- 3D Printing AdvantagesDocument7 pages3D Printing AdvantagesionutmbNo ratings yet

- 3D Printing in MedicalDocument4 pages3D Printing in MedicalAadil KakarNo ratings yet

- Flapless Dental Implant Surgery With Surgical GuideDocument3 pagesFlapless Dental Implant Surgery With Surgical GuideImplant Surgical GuidesNo ratings yet

- Current Trends in EducationDocument2 pagesCurrent Trends in EducationTofuraii SophieNo ratings yet

- E3D Brochure ProductDocument10 pagesE3D Brochure ProductSindy GunawanNo ratings yet

- 3D Printing Advancements in Medical Sciences: Department of Mechanical Engineering Wright State UniversityDocument12 pages3D Printing Advancements in Medical Sciences: Department of Mechanical Engineering Wright State UniversityAbhishek UdataneniNo ratings yet

- Design and Development of Wireless Operated Low Cost Prosthetic Hand by Fused Deposition ModelingDocument6 pagesDesign and Development of Wireless Operated Low Cost Prosthetic Hand by Fused Deposition ModelingTJPRC PublicationsNo ratings yet

- Final Draft - Research Paper - Eng 1201Document12 pagesFinal Draft - Research Paper - Eng 1201api-609432315No ratings yet

- 3D Printing ProthesticsDocument3 pages3D Printing ProthesticsKamugisha MosesNo ratings yet

- Recent Advances in Dental Optics - Part I: 3D Intraoral Scanners For Restorative DentistryDocument20 pagesRecent Advances in Dental Optics - Part I: 3D Intraoral Scanners For Restorative DentistryCristobalVeraNo ratings yet

- CTS Dental Laboratory Equipment Technician - CTS - NSQF-5Document42 pagesCTS Dental Laboratory Equipment Technician - CTS - NSQF-5Osama Fadel ahmedNo ratings yet

- 7 Dental Laboratory TechnicianDocument14 pages7 Dental Laboratory TechnicianOsama Fadel ahmedNo ratings yet

- 4-Defense Mechanisms of The Gingiva2Document58 pages4-Defense Mechanisms of The Gingiva2Osama Fadel ahmedNo ratings yet

- 12 2020 DentalCAD Galway Release Presentation EN FinalDocument33 pages12 2020 DentalCAD Galway Release Presentation EN FinalOsama Fadel ahmedNo ratings yet

- Troubles of Heating CD: Processing ErrorsDocument14 pagesTroubles of Heating CD: Processing ErrorsOsama Fadel ahmedNo ratings yet

- Trauma From Occlution: Presented By: Dr. Zihoor Eltayeb Ali Assist Prof. of PeriodontologyDocument21 pagesTrauma From Occlution: Presented By: Dr. Zihoor Eltayeb Ali Assist Prof. of PeriodontologyOsama Fadel ahmedNo ratings yet

- Wound Healing: Dr. Shaimaa Alaraby Specialist of General SurgeryDocument21 pagesWound Healing: Dr. Shaimaa Alaraby Specialist of General SurgeryOsama Fadel ahmedNo ratings yet

- Blood TransusionDocument21 pagesBlood TransusionOsama Fadel ahmedNo ratings yet

- Mandibular Major Connectors: 3Rd Grade LEC. 6Document14 pagesMandibular Major Connectors: 3Rd Grade LEC. 6Osama Fadel ahmed100% (1)

- Four Handed Dentistry and AssistantsDocument1 pageFour Handed Dentistry and AssistantsjohanNo ratings yet

- Wash in School Implementation Action Plan SY. 2019-2020Document2 pagesWash in School Implementation Action Plan SY. 2019-2020RONALYN ALVAREZNo ratings yet

- Cracked Tooth Syndrome-Overview of Literature PDFDocument6 pagesCracked Tooth Syndrome-Overview of Literature PDFpopowiii 01No ratings yet

- Occlusal Schemes in FPDDocument6 pagesOcclusal Schemes in FPDPadmini ReddyNo ratings yet

- The Biological Basis of The Orthodontic Therapy: Fengshan Chen Tongji UniversityDocument60 pagesThe Biological Basis of The Orthodontic Therapy: Fengshan Chen Tongji UniversityNaeem MoollaNo ratings yet

- Sri Aurobindo College of Dentistry & PG Institute, Indore Dept. of Prosthodontics Roaster For Seminar PresentationDocument5 pagesSri Aurobindo College of Dentistry & PG Institute, Indore Dept. of Prosthodontics Roaster For Seminar PresentationHamzah AsifNo ratings yet

- A Comparison of Pulpectomies Using ZOE and KRI Paste in PrimaryDocument5 pagesA Comparison of Pulpectomies Using ZOE and KRI Paste in PrimarymahmoudNo ratings yet

- Calcium and Phosphorus Metabolism and Its Importance in OrthodonticsDocument56 pagesCalcium and Phosphorus Metabolism and Its Importance in OrthodonticsVijay ChinthaNo ratings yet

- Final Exam Assignment PERIODocument4 pagesFinal Exam Assignment PERIOيارا حسينNo ratings yet

- Test Bank For Dental Instruments A Pocket Guide 4th Edition Boyd DownloadDocument5 pagesTest Bank For Dental Instruments A Pocket Guide 4th Edition Boyd Downloadstevenjohnsondcnpxgskyi100% (24)

- Professional Care: OXYJET + 1000 3000Document75 pagesProfessional Care: OXYJET + 1000 3000Murat ZemereNo ratings yet

- (PDF) Piperacillin-Tazobactam As An Adjuvant in The Mechanical Treatment of Patients With Periodontitis - A Randomized Clinical StudyDocument12 pages(PDF) Piperacillin-Tazobactam As An Adjuvant in The Mechanical Treatment of Patients With Periodontitis - A Randomized Clinical StudyAmruta MahajanNo ratings yet

- Original Report Dependence of Canine Guided....Document4 pagesOriginal Report Dependence of Canine Guided....habeebNo ratings yet

- Signs and Symptoms of Pulpal DiseasesDocument37 pagesSigns and Symptoms of Pulpal DiseasesDR.AMITHBABU.C.BNo ratings yet

- s140018 ElectiveDocument12 pagess140018 ElectiveSonishNo ratings yet

- No Prep VeneersDocument7 pagesNo Prep VeneersPablo GodinezNo ratings yet

- Functional Crown Lengthening Surgical PlanningDocument5 pagesFunctional Crown Lengthening Surgical PlanningNajeeb UllahNo ratings yet

- Fractura Condilar y Nervio FacialDocument4 pagesFractura Condilar y Nervio FacialJuly CabariqueNo ratings yet

- 563421.v1 PerioDocument15 pages563421.v1 Perioikeuchi_ogawaNo ratings yet

- Full Teks Drg. FuadDocument15 pagesFull Teks Drg. FuadYuvitri AyuNo ratings yet

- Comparative Evaluation of Serum High Sensitivity CDocument9 pagesComparative Evaluation of Serum High Sensitivity Catif nawazNo ratings yet

- An Evaluation of Mandibular Canal Variations: A Systematic Review and Meta AnalysisDocument9 pagesAn Evaluation of Mandibular Canal Variations: A Systematic Review and Meta AnalysisDANTE DELEGUERYNo ratings yet

- Current Concepts About Principles of Cavity DesignsDocument45 pagesCurrent Concepts About Principles of Cavity DesignsAlan NasirNo ratings yet

- Stage-Two Surgery For Dental Implants: Overview and Relevance of Advanced ProceduresDocument5 pagesStage-Two Surgery For Dental Implants: Overview and Relevance of Advanced ProceduresasclepiuspdfsNo ratings yet

- Literature Review On Dental ImplantsDocument8 pagesLiterature Review On Dental Implantsafdtbluwq100% (1)

- Effective 1 Visit Therapy For The Acute Periapical Abscess Southard 1984Document4 pagesEffective 1 Visit Therapy For The Acute Periapical Abscess Southard 1984abcder1234No ratings yet

- Kolkata Dental - 276Document7 pagesKolkata Dental - 276deva nesanNo ratings yet

- Pediatric Bruxism: From Etiology To Treatment: A ReviewDocument4 pagesPediatric Bruxism: From Etiology To Treatment: A ReviewApurava SinghNo ratings yet

- Unit Iv. Prosthetics. Effects of Loss of Teeth. Stages of Denture ConstructionDocument8 pagesUnit Iv. Prosthetics. Effects of Loss of Teeth. Stages of Denture ConstructionStanislavNemtanuNo ratings yet