Professional Documents

Culture Documents

Notatka 1

Uploaded by

Agnieszka CichaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Notatka 1

Uploaded by

Agnieszka CichaCopyright:

Available Formats

TECH SHEET - DO NOT DISCARD PAGE 1

■ A potential cause of a control not DIAGNOSTIC: Saved Fault Codes

WARNING functioning is corrosion on

If there are saved fault codes, the most

connections. Observe connections and

Electrical Shock Hazard check for continuity with an ohmmeter. recent fault code will show “F:” and flash

Disconnect power before “XX” where XX is the fault code.

■ Connectors: Look at top of connector.

servicing.

Check for broken or loose wires. Check Press and

Replace all parts and for wires not pressed into connector far release the

panels before operating. beep Second most recent

enough to engage metal barbs. same button ➔ ➔

tone fault code is displayed.

Failure to do so can used to activate

■ Resistance checks must be made with

result in death or Diagnostics

dryer unplugged or power

electrical shock. disconnected. beep Third most recent fault

Repeat ➔ ➔

tone code is displayed.

DIAGNOSTIC TESTS beep Fourth most recent

Repeat ➔ ➔

tone fault code is displayed.

These tests allow service personnel to test

IMPORTANT All indicators momentarily turn

and verify all inputs to the machine control Repeat ➔

off, then stay on.

electronics. You may want to do a quick

Electrostatic Discharge (ESD)

and overall checkup of the dryer with

Sensitive Electronics these tests before going to specific DIAGNOSTIC: Console Buttons

ESD problems are present everywhere. troubleshooting tests. and Indicators

ESD may damage or weaken the

machine control electronics. The new ACTIVATING THE SERVICE Pressing buttons and rotating the cycle

control assembly may appear to work selector will turn off the corresponding

DIAGNOSTIC TEST MODE indicator and sound a beep as shown in

well after repair is finished, but failure

may occur at a later date due to ESD 1. Be sure the dryer is in standby mode figure 1, page 2. Pressing (more time)

stress. (plugged in with all indicators off, or will toggle the left digit and colon on the

with only the Done indicator on). display while sounding a beep. Pressing

■ Use an anti-static wrist strap. (less time) will toggle the right two

2. Select any one button (except

Connect wrist strap to green ground digits on the display while sounding a

Pause/Cancel) and follow the steps

connection point or unpainted metal beep.

below, using the same button

in the appliance -OR- Touch your

(remember the button): ➔ If indicators fail to come on and beep

finger repeatedly to a green ground

a. Press/hold 2 seconds after pressing buttons and rotating the

connection point or unpainted metal

b. Release for 2 seconds cycle selector, go to TEST #7, page 9.

in the appliance.

c. Press/hold 2 seconds

■ Before removing the part from its d. Release for 2 seconds DIAGNOSTIC: Door Switch

package, touch the anti-static bag to e. Press/hold 2 seconds Opening the door should cause a beep

a green ground connection point or

3. If this test mode has been entered and an alphanumeric number to be

unpainted metal in the appliance.

successfully, all indicators on the displayed. Closing the door should cause

■ Avoid touching electronic parts or

console are illuminated for 5 seconds a beep and 8:88 to be displayed.

terminal contacts; handle machine

with 8:88 showing in the Estimated ➔ If opening the door fails to cause a beep

control electronics by edges only.

Time Remaining three-digit display. If and a number and letter to be

■ When repackaging failed machine there are no saved fault codes or active displayed, go to TEST #8, page 9.

control electronics in anti-static bag, fault codes, all indicators on the

observe above instructions. console will momentarily turn off, then DIAGNOSTIC: Moisture Sensor

stay on with 8:88 displayed. Continue Open the door and locate two metal strips

with Diagnostics. on the inside of the dryer. Bridge these

DIAGNOSTIC GUIDE 4. If entry into diagnostic mode is strips with a wet cloth or a finger.

unsuccessful, choose a different button ➔ If a continuous beep tone is heard and

Before servicing, check the following: (except Pause/Cancel) and repeat an alphanumeric number is displayed

■ Make sure there is power at the wall step 2. on the console, the sensor is OK.

outlet. ➔ If no indicators come on after ➔ If not, or if a continuous beep tone is

■ Has a household fuse blown or circuit repeating step 2 using a different heard before bridging the moisture

breaker tripped? Time delay fuse? button, go to TEST #1, page 4. strips, go to TEST #5, page 8.

■ Is dryer vent properly installed and

DIAGNOSTIC: Active Fault Codes DIAGNOSTIC: Motor, Heater, and

clear of lint or obstructions?

■ All tests/checks should be made with a

If there is an active fault code, it will be Console ID

VOM (volt-ohm-milliammeter) or DVM flashing in the display. Review the Display

Close the door. Press the Start button. The

(digital-voltmeter) having a sensitivity of Fault/Error Codes table, page 3, for the

motor and heater will turn on. Continuing

20,000 Ω per volt DC or greater. recommended procedure.

to press the Start button will display the

■ Check all connections before replacing If there is no active fault code, 8:88 will be project codes and software revisions.

components. Look for broken or loose displayed.

➔ If the motor does not turn on, go to

wires, failed terminals, or wires not TEST #3, page 5.

pressed into connectors far enough.

➔ If no heat is detected, go to TEST #4,

page 6.

FOR SERVICE TECHNICIAN’S USE ONLY PART NO. W10110638

TECH SHEET - DO NOT DISCARD PAGE 2

Figure 1. Console Diagnostics.

DIAGNOSTIC: Displaying Inlet Air Flow ➔ If the line voltage is not seen on L2, the display will flash L2. Go to

TEST #1, page 4.

Used to display the airflow value at the inlet of the heater

box being measured by the machine control.

DEACTIVATING THE DIAGNOSTIC TEST MODE

After all saved fault codes have been displayed, press the

Wrinkle Shield button to activate airflow detection. A 30 or Press the Pause/Cancel button to exit diagnostics.

50 second countdown timer will start and the dryer will turn on.

ACTIVATING THE MANUAL LOAD TEST

➔ If the dryer is cold, the countdown will start at 50 seconds.

1. Be sure the dryer is in standby mode (plugged in with all indicators

NOTE: If the dryer is extremely cold (less than 40°F off, or with only the Done indicator on).

[4.4°C]) the airflow may not be detected properly, and “--”

will be displayed. 2. Select any one button (except Pause/Cancel) and follow the steps

below, using the same button (remember the button):

➔ If the dryer is hot, the countdown timer will start at

30 seconds (cool down period) followed by an additional Press/ Release Press/ Release Press/ Release Press/

50 second countdown. hold 2 ➔ for 2 ➔ hold 2 ➔ for 2 ➔ hold 2 ➔ for 2 ➔ hold 2

seconds seconds seconds seconds seconds seconds seconds

A Dryness Level modifier LED will also be illuminated to

indicate the airflow range corresponding to the number The motor starts right away, the “Sensing” Status LED comes on,

displayed. and “0” (zero) is displayed (this step starts the Manual Load

■ The More LED will be illuminated for airflow readings sequence):

above 40 cfm. 1. Motor turns on. ➔ “Sensing” Status LED turns on. ➔ 0:00 is displayed.

■ The Normal LED will be illuminated for airflow readings

between 29 and 40 cfm. Now press any key (except Pause/Cancel) and the control will

advance through each step of the following sequence:

■ The Less LED will be illuminated for airflow readings less

than 29 cfm. 2. Motor + full heater. ➔ “Damp” Status LED turns on. ➔ 0:02 is displayed.

➔ If airflow value is low (Less LED is lit), check to make Motor + full heater “Cool Down” Status LED

3. ➔ ➔ 0:03 is displayed.

sure the lint screen is clean, the door seal is in place + drum light. turns on.

and the vent is not obstructed. 4. All loads turn off. ➔ “Done” Status LED turns on. ➔ 0:04 is displayed.

DIAGNOSTIC: Displaying Line Voltage

Used to display the line voltage currently being measured by DEACTIVATING THE MANUAL LOAD TEST

the machine control. Press the Pause/Cancel button to exit this mode.

After all saved fault codes have been displayed, press the

Cycle Signal button. The voltage value will be displayed.

FOR SERVICE TECHNICIAN’S USE ONLY PART NO. W10110638

TECH SHEET - DO NOT DISCARD PAGE 3

DISPLAY FAULT/ERROR CODES See Accessing & Removing the Electronic

The fault codes below would be indicated when Assemblies, page 9, to access:

attempting to start a drying cycle, or after activating the ■ Machine Control Electronics

diagnostic test mode. ■ UI Power Cube

■ Console Electronics and Housing

Display Description Explanation / Recommended Procedure

PF flashes to indicate that a power failure

Power occurred while the dryer was running.

PF Failure ■ Press Start to continue the cycle, or See Removing the Back

press Pause/Cancel to clear the display. Panel, page 11, to access:

F:01 flashes when there is a primary ■ Drum Light Assembly

control failure. ■ Blower Motor Assembly

Primary Control

F:01 Failure

■ Replace the machine control electronics.

See Accessing & Removing the

Electronic Assemblies, page 9.

Door

F:02 flashes when there is a stuck button Switch

Keypad/ or user interface mismatch. This fault code

F:02 User Interface will ONLY appear when in the diagnostic

Failure test mode.

■ See TEST #7, page 9.

Outlet F:22 flashes if the outlet thermistor is open.

F:22 Thermistor

■ See TEST #4a, page 6.

Open See Removing

the Toe Panel,

Outlet F:23 flashes if the outlet thermistor has page 9, to access:

F:23 Thermistor shorted.

■ Moisture Sensors

Shorted ■ See TEST #4a, page 6. Heater

■ Outlet Thermistor

Assembly

F:24 flashes if the inlet thermistor is open. ■ Thermal Cut-off

Inlet This fault code will ONLY appear when in ■ Inlet Thermistor/High Limit

F:24 Thermistor the diagnostic test mode. Thermostat Assembly (Electric Models)

Open Moisture Sensor

■ See TEST #4a, page 6. ■ High Limit Thermostat (Gas Models) Strips

F:25 flashes if the inlet thermistor is ■ Heater Assembly (Electric or Gas)

Inlet shorted. This fault code will ONLY appear ■ Thermal Fuse

F:25 Thermistor when in the diagnostic test mode.

Shorted Figure 2. Component locations.

■ See TEST #4a, page 6.

F:26 flashes if there is a motor drive

Motor Drive

F:26 System Failure system failure. TROUBLESHOOTING GUIDE

■ See TEST #3, page 5. Some tests will require accessing components.

F:28 flashes if the moisture sensor strip is

Moisture open. This fault code will ONLY appear Problem Possible Cause / Test Problem Possible Cause / Test

F:28 Sensor Open when in the diagnostic test mode. NOTE: Possible Cause/Tests MUST be Won’t heat.

■ See TEST #5, page 8. performed in the sequence shown for 1. Heater. See TEST #4, page 6.

F:29 flashes if the moisture sensor strip each problem.

Moisture 2. Check harness connections.

has shorted. This fault code will ONLY Won’t power up.

F:29 Sensor appear when in the diagnostic test mode. (No response when buttons are pressed.) 3. See DIAGNOSTIC: Displaying Line

Shorted Voltage, page 2.

■ See TEST #5, page 8. 1. Supply connections. See TEST #1,

4. Check installation.

F:30 flashes if a restricted airflow condition page 4.

exists. This fault code will ONLY appear Heats in air cycle.

2. Check harness connections.

when in the diagnostic test mode. 3. Console electronics and housing Heater. See TEST #4, page 6.

Restricted ■ Check to make sure the lint screen is

F:30 Airflow assembly. See TEST #7, page 9. Shuts off before clothes are dry.

clean, the door seal is in place and the

Condition Won’t start cycle when Start button is 1. Check the dryness setting for auto

vent is not obstructed.

pressed. cycles.

■ See DIAGNOSTIC: Displaying Inlet Air

Flow, page 2. 1. If number display flashes, check to be 2. Check for full lint screen.

sure the door is completely shut, and 3. See DIAGNOSTIC: Displaying Inlet Air

F:70 / F:71 flashes when there is no

press and hold down Start for about Flow, page 2.

communication between the machine

No control and the console electronics. 1 second. 4. Check for clogged vent.

F:70 Communication ■ 2. See TEST #3, page 5.

Check console electronics harness 5. Moisture sensor. See TEST #5, page 8.

Between 3. See TEST #8, page 9.

F:71 connections to the machine control. 6. Dryness level adjust. See TEST #5a,

Electronic

■ Replace the machine control electronics. Won’t shut off when expected. page 8.

Assemblies

See Accessing & Removing the

1. Check Pause/Cancel button. Pushing Power button causes dryer to

Electronic Assemblies, page 9.

2. Console electronics and housing beep, but no indicators light.

F:72 through F:78 flashes when there is a assembly. See TEST #7, page 9.

F:72 Console console electronics failure. 1. Check console electronics harness

3. Moisture sensor. See TEST #5, page 8. connections to the machine control.

through Electronics ■ Replace the console electronics. See

Failure Accessing & Removing the Electronic Control won’t accept selections. 2. Replace machine control electronics.

F:78 Assemblies, page 9. See Accessing & Removing the

Console electronics and housing

Electronic Assemblies, page 9.

assembly. See TEST #7, page 9.

FOR SERVICE TECHNICIAN’S USE ONLY PART NO. W10110638

TECH SHEET - DO NOT DISCARD PAGE 4

TROUBLESHOOTING TESTS 5. Access the machine control electronics 4. Access the machine control electronics

without disconnecting any wiring to the without disconnecting any wiring to the

NOTE: These checks are done with the control board. See Accessing & control board. See figure 16, page 10.

dryer unplugged or disconnected from Removing the Electronic Assemblies,

power. 5. With an ohmmeter, check for continuity

page 9. between the neutral (N) terminal of the

6. With an ohmmeter, check for continuity plug and P8-3 (white wire) on the

TEST #1 Supply Connections between the L1 terminal of the plug machine control board. The left-hand

(found in step 4) and P9-2 (black wire) side of figure 6 shows the position of the

This test assumes that proper voltage is

on the machine control board. See neutral terminal (N) on the power cord

present at the outlet, and visual inspection

figure 17, page 10. plug. Also see figure 17, page 10.

indicates that the power cord is securely

fastened to the terminal block (electric ➔ If there is continuity, go to step 7. ➔ If there is continuity, go to step 6.

dryer) or wire harness connection (gas ➔ If there is no continuity, check that ➔ If there is no continuity, disconnect

dryer). wires to the terminal block are the white wire of the harness from

mechanically secure. If so, replace the power cord at the location

the main wire harness and test the illustrated in figure 5. Test the

dryer. continuity of the power cord neutral

Remove

Screw 7. Check for continuity between the wire as illustrated in figure 6. If an

neutral (N) terminal of the plug and open circuit is found, replace the

P8-3 (white wire) on the machine power cord. Otherwise, go to step 6.

Cover Plate control board.

➔ If there is continuity, go to step 8. Power Cord

Plug

➔ If there is no continuity and the L1 N COM

mechanical connections of the wire

Figure 3. Remove the cover plate. are secure, replace the main wire L1

N

harness. G

ELECTRIC DRYER: 8. Visually check that the P5 connector is

inserted all the way into the machine G

1. Unplug dryer or disconnect power.

control electronics.

2. Remove the cover plate from the top Figure 6. Power cord terminals, gas

right corner of the back of the dryer. 9. Visually check that the console dryer.

See figure 3. electronics and housing assembly is

properly inserted into the front console. 6. In a similar way, check the continuity

3. With an ohmmeter, check for continuity

between the neutral (N) terminal of the 10. If both visual checks pass, replace the between the L1 terminal of the plug

plug and the center contact on the console electronics and housing and P9-2 (black wire) on the control

terminal block. See figure 4. assembly. board.

➔ If there is no continuity, replace the 11. Plug in dryer or reconnect power. ➔ If there is continuity, go to step 8.

power cord and test the dryer. 12. Perform the Console Buttons and ➔ If there is no continuity, check the

➔ If there is continuity, go to step 4. Indicators Diagnostic test, page 1 to continuity of the power cord in a

verify repair. similar way to that illustrated in

4. In a similar way, check which terminal figure 6, but for power cord’s L1

of the plug is connected to the 13. If indicators still do not light, perform wire.

left-most contact on the terminal block TEST #2, page 5.

and make a note of it. This will be L1 ➔ If an open circuit is found, replace the

GAS DRYER: power cord. Otherwise, replace the

(black wire) in the wiring diagram. See

figure 4. 1. Unplug dryer or disconnect power. main harness.

2. Remove the cover plate from the top 7. Visually check that the P5 connector is

Power Cord Terminal Block

right corner of the back of the dryer. inserted all the way into the machine

Plug L1 See figure 3. control electronics.

N

3. Check that the power cord is firmly 8. Visually check that the console

connected to the dryer’s wire harness. electronics and housing assembly is

See figure 5. properly inserted into the front console.

9. If both visual checks pass, replace the

COM console electronics and housing

assembly.

Figure 4. Plug-to-terminal connections Wire

10. Plug in dryer or reconnect power.

for electric dryer. Harness 11. Perform the Console Buttons and

Indicators Diagnostic test, page 1 to

➔ When this is found, go to step 5. verify repair.

➔ If neither of the plug terminals have 12. If indicators still do not light, perform

continuity with the left-most contact Power Cord TEST #2, page 5.

of the terminal block, replace the

power cord and test the dryer.

Figure 5. Power cord-to-wire harness

connection for gas dryer.

FOR SERVICE TECHNICIAN’S USE ONLY PART NO. W10110638

TECH SHEET - DO NOT DISCARD PAGE 5

ALL DRYERS: Continue with step 4 6. Using figure 9, check for the resistance

TEST #2 Machine Control below to test the remaining values of the motor’s Main and Start

Power Check components in the motor circuit. winding coils as shown in the following

This test is used to determine if power is 4. Check the belt switch and drive motor. table.

present at the machine control electronics. Access the belt switch and drive motor NOTE: Main and Start winding coils

This test assumes that TEST #1 has been by removing the back panel. See must be checked at the motor.

completed. Removing the Back Panel, page 11.

NOTE: The drum light is controlled by the Slowly remove the drum belt from the Winding Resistance Contact Points

of Measurement

machine control on all models. spring-loaded belt switch pulley, gently

letting the belt switch pulley down. See Lt. blue wire in back at

1. Plug in dryer or reconnect power. figure 7. pin 4 and bare copper wire

MAIN 3.3–3.6

2. Open the door. on pin 5 of black drive

Belt Switch Pulley motor switch

➔ If the drum light illuminates, then

power is present at the machine Lt. blue wire in back at

control. Go to TEST #6, page 8. pin 4 and bare copper wire

START 2.7–3.0

on pin 3 of black drive

➔ If the drum light fails to illuminate, motor switch

the problem may be as simple as a

bad bulb. Replace bulb with a ➔ If the resistance at the motor is

working bulb. If drum light still fails to correct, there is an open circuit

illuminate, continue with step 3. between the motor and machine

3. Unplug dryer or disconnect power. Drum control electronics. Check for failed

4. Replace the machine control Belt belt switch.

electronics. ➔ If the Start winding resistance is

Figure 7. Slowly remove drum belt. much greater than 3 Ω, replace the

5. Plug in dryer or reconnect power.

motor.

6. Perform the Console Buttons and 5. Remove the white connector from the

Indicators Diagnostic test, page 1 to 7. Check the belt switch by measuring

drive motor switch. See figure 8. resistance between the two light blue

verify repair.

wires, as shown in figure 10, while

Drive Motor pushing up the belt switch pulley.

TEST #3 Motor Circuit Switch

➔ If the resistance reading goes from

This test will check the wiring to the motor White infinity to a few ohms as pulley arm

and the motor itself. The following items Connector closes the switch, belt switch is OK.

are part of this motor system: If not, replace the belt switch.

➔ If belt switch is OK and there is still

1

Part of Motor System Electric Gas

an open circuit, check and repair the

5

Dryer Dryer

wiring harness.

26 4 3

Harness/connection ✔ ✔

Thermal fuse ✔ no

Belt/belt switch ✔ ✔

Drive Motor ✔ ✔

Centrifugal switch ✔ ✔

Figure 8. Remove white connector.

1

Door switch ✔ ✔ Lt. Blue

Wires

5

Machine control electronics. ✔ ✔

See ESD information, page 1.

26 4 3

Main Winding:

Lt. Blue Wire in Back

1. Unplug dryer or disconnect power. and Bare Copper Wire

2. Access the machine control electronics

and measure the resistance across

P8-4 and P9-1. See Accessing &

Belt Switch

Removing the Electronic Assemblies, Start Winding: Pulley Belt Switch

page 9. Lt. Blue Wire

1

in Back and

➔ If resistance across P8-4 and P9-1 is Figure 10. Checking the belt switch.

5

Bare Copper

in the range of 1 to 6 ohms, replace Wire

26 4 3

the machine control electronics. 8. Door Switch problems can be

➔ Otherwise, go to step 3. uncovered in the Door Switch

Diagnostic Test, page 1; however, if this

3. Check the wiring and components in

was not done, the following can be

the path between these measurement

done without applying power to the

points by referring to the appropriate

Figure 9. Main and start winding dryer. Connect an ohmmeter across

wiring diagram (gas or electric) on

measure points. P8-3 (neutral, white wire) and P8-4

page 12.

(door, tan wire).

ELECTRIC DRYER ONLY: Check the

thermal fuse. See TEST #4b, page 7.

FOR SERVICE TECHNICIAN’S USE ONLY PART NO. W10110638

TECH SHEET - DO NOT DISCARD PAGE 6

➔ With the door properly closed, the GAS DRYER:

ohmmeter should indicate a closed 1. Unplug dryer or disconnect power.

circuit (0–2 Ω).

2. Remove the toe panel to access the

➔ If not, replace the door switch thermal components. See Removing the

assembly. Toe Panel, page 9.

3. Perform TEST #4b, page 7. If the

TEST #4 Heater thermal fuse is OK, go to step 4.

This test is performed when either of the 4. Perform TEST #4c, page 7. If the

following situations occur: thermal cut-off is OK, go to step 5.

✔ Dryer does not heat 5. Locate the high limit thermostat. See

✔ Heat will not shut off figure 11. Measure the continuity

through it by connecting the meter

This test checks the components making probes on the red wire and black wire

up the heating circuit. The following items terminals.

are part of this system:

➔ If there is an open circuit, replace the

Part of Heating System Electric Gas high limit thermostat and the thermal

Dryer Dryer

cut-off.

Harness/connection ✔ ✔

➔ Otherwise, go to step 6.

Heater relay ✔ ✔

6. Perform TEST #4d, page 8. If this is OK,

Thermal cut-off ✔ ✔ replace the machine control electronics.

Thermal fuse no ✔

Heat will not shut off:

Inlet thermistor/high limit ✔ no

thermostat assembly 1. Unplug dryer or disconnect power.

high limit thermostat no ✔ 2. Access the machine control electron-

Heat element assembly ✔ no ics. See figure 17, page 10 for connec-

tor location; and Accessing & Remov-

Gas burner assembly no ✔

ing the Electronic Assemblies, page 9.

Centrifugal switch ✔ ✔

ELECTRIC DRYER: Remove the P4

Outlet thermistor ✔ ✔ connector, then measure the resistance

Machine control electronics. ✔ ✔ between P4-3 (red wire) and P4-6 (red

See ESD information, page 1. wire) at the connector.

Console electronics and ✔ ✔

housing assembly GAS DRYER: Remove the P14

connector, then measure the resistance

Gas supply no ✔

between P14-3 (red-white wire) and

P14-6 (red-white wire) at the connector.

Dryer does not heat:

ALL DRYERS:

Locate the components using figure 11.

➔ If 5–15 kΩ are measured, replace the

ELECTRIC DRYER: machine control electronics.

1. Unplug dryer or disconnect power. ➔ If the resistance is greater than

2. Remove the toe panel to access the 20 kΩ, replace the outlet thermistor.

thermal components. See Removing

the Toe Panel, page 9.

TEST #4a Thermistors

3. Using an ohmmeter and referring to the

wiring diagram, measure the resistance Figure 11. Thermal Components, Outlet Thermistor

from the red wire terminal at the viewed from front. The machine control electronics monitors

thermal cut-off to the red wire terminal the exhaust temperature using the outlet

at the heater. thermistor, and cycles the heater relay on

assembly if either the thermal cut-off

➔ If the resistance is about 10 Ω, go to and off to maintain the desired temperature.

or the high limit thermostat is

step 5. electrically open. Begin with an empty dryer and a clean lint

➔ If an open circuit is detected, go to screen.

5. If no open circuit is detected, remove

step 4. the P4 connector, then measure the 1. Plug in dryer or reconnect power.

4. Visually check the wire connections to resistance between P4-3 (red wire) and 2. Start the Timed Dry cycle.

the thermal cut-off, high limit P4-6 (red wire) at the connector. See

thermostat, and heater. If connections figure 17, page 10 for connector 3. If after 60 seconds, F:22 or F:23

look good, check for continuity across location; and Accessing & Removing flashes in the display and the dryer

each of these components. the Electronic Assemblies, page 9. shuts off, the thermistor or wire harness

is either open or shorted.

➔ Replace the heater if it is electrically ➔ If 5–15 kΩ are measured, replace the

open. machine control electronics. ➔ Unplug dryer or disconnect power.

➔ Replace both the thermal cut-off and ➔ If the resistance is less than 1 kΩ, ➔ Check wire connections at the

inlet thermistor/high limit thermostat replace the outlet thermistor. machine control electronics and

thermistor. See Accessing &

FOR SERVICE TECHNICIAN’S USE ONLY PART NO. W10110638

TECH SHEET - DO NOT DISCARD PAGE 7

Removing the Electronic Assemblies OUTLET THERMISTOR RESISTANCE INLET THERMISTOR RESISTANCE

on page 9, and for thermistor

RES. RES. RES. RES.

location see figure 11, page 6. TEMP. RANGE TEMP. RANGE

TEMP. RANGE TEMP. RANGE

°F (°C) °F (°C) °F (°C) kΩ °F (°C) kΩ

➔ If wire connections are OK, check kΩ kΩ

the outlet thermistor resistance per 50° (10°) 19.0–22.0 80° (27°) 8.5–10.5 68° (20°) 61.2–63.7 131° (55°) 14.6–15.3

step 5, page 7. 60° (16°) 14.8–16.8 90° (32°) 6.8–8.8 77° (25°) 49.0–51.0 140° (60°) 12.1–12.8

4. If F:22 or F:23 does not flash in the 70° (21°) 11.5–13.5 100° (38°) 5.0–7.0 86° (30°) 39.5–41.1 149° (65°) 10.2–10.7

display, the connections to the

thermistor are good. Therefore, check 95° (35°) 32.0–33.3 158° (70°) 8.5–9.0

➔ If the thermistor resistance does not

the exhaust temperature value at any or agree with table, replace the outlet 104° (40°) 26.1–27.2 167° (75°) 7.2–7.6

all of the temperature levels in thermistor. 113° (45°) 21.4–22.3 176° (80°) 6.1–6.5

question, using the Timed Dry cycle,

and the following process: ➔ If the thermistor resistance checks 122° (50°) 17.6–18.5

agree with the measurements in the

Hold a glass bulb thermometer capable table, replace the machine control The table above shows the resistance

of reading from 90° to 180°F (32° to electronics. values that should be observed for the

82°C) in the center of the exhaust various temperatures at the heater

outlet. The correct exhaust Inlet Thermistor, Electric Dryer assembly.

temperatures are as follows: The machine control electronics monitors ➔ If the thermistor resistance does not

the inlet temperature using an inlet agree with the measurements in the

EXHAUST TEMPERATURES thermistor that is part of the high limit table, replace the inlet thermistor/

TEMPERATURE HEAT TURNS HEAT TURNS ON

thermostat assembly. high limit thermostat assembly.

SETTING OFF* °F (°C)

°F (°C) 1. Activate the diagnostic test mode. See ➔ If the thermistor resistance agrees

procedure on page 1. with the measurements in the table,

155°±5°

High

(68°±3°) 2. If F:24 or F:25 is a displayed error in the replace the machine control

140°±5° diagnostic test mode, the inlet electronics.

Medium 10–15° (6–8°)

(60°±3°) thermistor or wire harness is either

below the

open or shorted.

125°±5° heat turn off TEST #4b Thermal Fuse

Low temperature ➔ Unplug dryer or disconnect power.

(52°±3°)

ELECTRIC DRYER: The thermal fuse is

105°±5° ➔ Check wire connections at the wired in series with the dryer drive motor.

Extra Low machine control electronics and inlet

(41°±3°)

thermistor. See Accessing & GAS DRYER: The thermal fuse is wired in

* The measured overshoot using the Removing the Electronic series with the dryer gas valve.

glass bulb thermometer in the exhaust Assemblies, page 9, and for inlet ALL DRYERS:

outlet can be 30°F (17°C) higher. thermistor location see figure 11, 1. Unplug dryer or disconnect power.

5. If the exhaust temperature is not within page 6.

2. Access the thermal fuse by first

specified limits, or you have come here ➔ If wire connections are good,

removing the toe panel. See Removing

from step 3, perform the following: remove the wires from the inlet the Toe Panel, page 9; and for thermal

NOTE: All thermistor resistance thermistor/high limit thermostat fuse location see figure 11, page 6.

measurements must be made while assembly and replace the assembly.

3. Using an ohmmeter, check the

dryer is unplugged or disconnected ➔ Plug in dryer or reconnect power.

continuity across the thermal fuse.

from power. 3. If F:24 or F:25 is not an error that is ➔ If the ohmmeter indicates an open

ELECTRIC DRYER: Remove the P4 displayed in the diagnostic test mode, circuit, replace the failed thermal

connector, then measure the resistance the connections to the thermistor are fuse.

between P4-3 (red wire) and P4-6 (red good. Therefore, check the thermistor’s

wire) at the connector. resistance value, using the following

➔ If the resistance is OK, check P4-3 process: TEST #4c Thermal Cut-Off

and P4-6 to machine ground. ➔ Unplug dryer or disconnect power. If the dryer does not produce heat, check

➔ If resistance is greater than 0 (zero), ➔ Access the heater assembly. See the status of the thermal cut-off.

replace wiring harness. figure 2, page 3; and Removing the 1. Unplug dryer or disconnect power.

GAS DRYER: Remove the P14 Toe Panel, page 9.

2. Access the thermal cut-off by first

connector, then measure the resistance ➔ Hold a glass bulb thermometer removing the toe panel. See Removing

between P14-3 (red-white wire) and capable of reading from 68° to 176°F the Toe Panel, page 9.

P14-6 (red-white wire) at the connector. (20° to 80°C) in the heater assembly.

3. Using an ohmmeter, check the

➔ If the resistance is OK, check P14-3 ➔ Check the resistance of the inlet continuity across the thermal cut-off.

and P14-6 to machine ground. thermistor. See figure 11, page 6 for See figure 11, page 6 for location.

➔ If resistance is greater than 0 (zero), location.

4. If the ohmmeter indicates an open

replace wiring harness. circuit, perform the following:

ALL DRYERS: ELECTRIC DRYER: Replace the failed

The following table gives temperatures thermal cut-off and inlet thermistor/high

and their associated resistance values. limit thermostat assembly. In addition,

check for blocked or improper exhaust

system, or failed heat element.

FOR SERVICE TECHNICIAN’S USE ONLY PART NO. W10110638

TECH SHEET - DO NOT DISCARD PAGE 8

GAS DRYER: Replace the failed NOTE: Over drying may be caused by 8. If moisture sensor diagnostic test

thermal cut-off and high limit a short circuit in the sensor system. passes, check the thermistor: Perform

thermostat. In addition, check for 4. Access the moisture sensor wires by TEST #4a, page 6.

blocked or improper exhaust system. removing the toe panel. See Removing ➔ If the problem persists after

the Toe Panel, page 9. Disconnect the replacing the moisture sensor and

TEST #4d Gas Valve, Gas sensor wires from the harness. See thermistor, replace the machine

Dryer figure 12. control electronics.

1. Unplug dryer or disconnect power.

TEST #5a Adjusting

2. Access the gas valve by removing the Drum Customer-Focused Drying

toe panel. See Removing the Toe

Panel, page 9. Modes

3. Use an ohmmeter to determine if a NOTE: If the customer is complaining

gas valve coil has failed. Remove about the clothes being damp and the

FRONT

harness plugs. Measure resistance moisture sensor passes TEST #5, step 3,

across terminals. Readings should the total dry time can be lengthened by

match those shown in the following changing from a “CF1” (standard auto cy-

chart. If not, replace coil. cle) to a “CF2” (15% more drying time) or

“CF3” (30% more drying time) auto cycle.

Terminals Resistance

1. Activate the diagnostic test mode, and

1 to 2 1365 ± 60 MOVs advance past saved fault codes. See

(Metal Oxide Harness Activating the Diagnostic Test Mode,

1 to 3 560 ± 25 Varistors) Connection page 1.

4 to 5 1325 ± 55

Blower 2. In diagnostic test mode, press and hold

IMPORTANT: Housing the Dryness Level button for 5

Be sure all harness seconds. The dryer will beep and the

wires are looped back current drying mode will be seen on

through the strain relief the display. The factory default value

after checking or replacing coils. is “CF1”.

Figure 12. Disconnect sensor from wire

harness. 3. To select a different drying mode, press

TEST #5 Moisture Sensor the Dryness Level button again. The

NOTE: This test is started with the dryer display will flash and show CF2,

5. Access the machine control CF3, or CF1.

machine completely assembled.

electronics. See Accessing &

This test is performed when an automatic Removing the Electronic Assemblies, 4. With the display flashing the selected

cycle stops too soon, or runs much longer page 9. Remove connector P13 from auto cycle mode, press the Start button

than expected. the circuit board. Check the main to save the drying mode and exit

NOTE: Dryer will shut down automatically harness connections between the diagnostics (the Start button in this

after 2½ hours. sensor harness and machine control mode does not start a drying cycle).

for a short or open circuit. The result will be stored in EEPROM of

The following items are part of this system: the control board, and will be retained

➔ Replace the main harness if

Harness/connection after a power loss.

necessary.

Metal sensor strips 5. Press the Pause/Cancel button at any

➔ If harness is OK, continue with step 6.

Machine control electronics. See ESD time to cancel changes and exit from

information, page 1. 6. Measure the resistance this mode.

across the outermost

1. Activate the diagnostic test mode and contacts of the cable that

advance past saved fault codes. See includes the two red MOVs. TEST #6 Power Cube

procedure on page 1. ➔ If a small resistance is measured, This test is performed when:

2. Open the dryer door. The dryer will check for debris across moisture ✔ None of the indicators light up

beep and an alphanumeric number strips inside of the drum; clean if

✔ No beep sound is heard

will be displayed. debris is present. If debris is not

present, replace sensor harness. 1. Unplug dryer or disconnect power.

3. Locate the two metal sensor strips on

the face of the lint screen housing. ➔ If a small resistance is not measured, 2. Check to make sure the connector is

Bridge these strips with a wet cloth or continue with step 7. fully inserted in the power cube board

finger. at P1.

7. Measure the resistance across

➔ If a beep tone is heard and an each of the outermost 3. Using an ohmmeter and referring to the

alphanumeric number is displayed contacts and the center appropriate wiring diagram on page 11,

on the console, the sensor passes terminal (ground connection). and figure 17 on page 10, check to be

the test. Go to step 9. sure there is continuity between P2-1

➔ If a resistance less than infinity is

on the power cube board and P003-3

➔ If a beep tone is not heard, or a measured, replace the sensor

on the console electronics user

continuous beep tone is heard harness.

interface board.

before bridging the moisture strips,

continue with step 4. ➔ If all connections are good, go to

TEST #7, page 9.

FOR SERVICE TECHNICIAN’S USE ONLY PART NO. W10110638

TECH SHEET - DO NOT DISCARD PAGE 9

➔ If TEST #7 fails also, replace the 4. If replacing the console electronics and

UI power cube and the console housing assembly failed:

REMOVING THE TOE PANEL

electronics and housing assembly. ➔ Unplug dryer or disconnect power. 1. Unplug dryer or disconnect power.

See Accessing & Removing the

➔ Replace the machine control 2. Remove two screws below the toe

Electronic Assemblies, at right.

electronics. panel.

➔ Plug in dryer or reconnect power. 3. Slide the toe panel down, then pull it

TEST #7 Buttons and out from the bottom. See figure 14.

Indicators ➔ Perform the Console Buttons and

Indicators Diagnostic test, page 1

This test is performed when any of the to verify repair.

following situations occurs during the Flange

Console Buttons and Indicators Diagnostic Some buttons do not light

Test, page 1: indicators:

✔ None of the indicators light up 1. Perform steps in Accessing and

✔ No beep sound is heard Removing the Electronic Assemblies, at

right, and visually check that the

✔ Some buttons do not light console electronics and housing

indicators assembly is properly inserted into the

None of the indicators light up: front console.

1. See Diagnostic Guide/Before ➔ If visual check passes, replace the

Servicing... on page 1. console electronics and housing Figure 14. Pull the toe panel down to

assembly. clear flange, then pull panel out.

2. Perform Test #1, page 4 to verify

supply connections. 2. Plug in dryer or reconnect power.

3. Perform steps in Accessing and 3. Perform the Console Buttons and ACCESSING & REMOVING

Removing the Electronic Assemblies, at Indicators Diagnostics test, page 1 to

right, and visually check that the P5 verify repair. THE ELECTRONIC

connector is inserted all the way into ASSEMBLIES

the machine control electronics.

TEST #8 Door Switch There are three electronic assemblies: the

4. Visually check that the console Machine Control Electronics, the UI Power

electronics and housing assembly is Activate the diagnostic test mode as Cube, and the Console Electronics and

properly inserted into the front console. shown on page 1, and perform the Door Housing. See figure 15.

Switch Diagnostic test, page 1. Functional-

5. If both visual checks pass, replace the ity is verified with a beep each time the 1. Unplug dryer or disconnect power.

console electronics and housing door is closed and opened, and an alpha- 2. Remove the three rear screws from the

assembly. numeric number appears in the display. top panel, and slide the top panel to

6. Plug in dryer or reconnect power. If any of the above conditions are not met: the rear to remove.

7. Perform the Console Buttons and ➔ Unplug dryer or disconnect power.

Indicators Diagnostic test, page 1 to

verify repair. ➔ Check that the wires between the door

switch and machine control electronics

8. If indicators still do not light, the are connected. See figure 13 for switch

machine control electronics has failed: location, and see Accessing and

➔ Unplug dryer or disconnect power. Removing the Electronic Assemblies, at

right.

➔ Replace the machine control

electronics.

➔ Plug in dryer or reconnect power.

➔ Perform the Console Buttons and

Indicators Diagnostic test, page 1 to

verify repair.

1. Perform steps in Accessing and

Figure 15. Locate the electronic

Removing the Electronic Assemblies, at

assemblies.

right, and visually check that the P5

connector is inserted all the way into

the machine control electronics. Figure 13. Door switch location. Machine Control Electronics

➔ If visual check passes, replace the 1. Perform preceding steps 1 and 2, then

console electronics and housing remove the two screws that hold the

➔ If the connections are OK, replace the

assembly. machine control electronics bracket in

wire and door switch assembly and

2. Plug in dryer or reconnect power. retest. place.

3. Perform the Console Buttons and ➔ If wire and door switch assembly have 2. Slide the bracket over the top of the

Indicators Diagnostic test, page 1 to been replaced and dryer still does not drum to access the machine control

verify repair. start, replace the machine control electronics connectors and mounting

electronics. screw. See figure 16.

FOR SERVICE TECHNICIAN’S USE ONLY PART NO. W10110638

TECH SHEET - DO NOT DISCARD PAGE 10

UI Power Cube

1. Perform steps 1 and 2 under Accessing

and Removing the Electronic

Assemblies, page 9.

2. Remove all wire connections to the UI

power cube. See figure 17.

3. Remove the screw holding the UI

power cube to the mounting bracket.

See figure 16.

4. There are two plastic legs on the front

of the UI power cube that slide under

the mounting bracket. Slide cube out

and remove.

Console Electronics and Housing

Figure 16. Remove machine control

electronics from mounting bracket.

Assembly

The console panel must be removed to

3. Remove all the wire connections to the access the console electronics and

machine control electronics. See housing assembly.

Figure 18. Remove the console panel

figure 17. 1. Perform steps 1 and 2 under Accessing to access the console electronics and

4. Remove the screw holding the machine & Removing the Electronics housing assembly.

control electronics assembly to the Assemblies, page 9, and disconnect the

mounting bracket. See figure 16. P2 harness from the machine control,

3. Gently remove the decorative trim that

and the P2 connector from the UI power

5. There are two plastic legs on the front surrounds the door and upper console

cube.

of the machine control electronics that by unsnapping it from the machine.

slide under the mounting bracket. 2. Remove the screw that fastens the See figure 19.

assembly to the machine control

✔ There is one plastic leg on the rear of mounting bracket (figure 16), and the

the machine control electronics that two screws that fasten the console

slides under the mounting bracket. assembly to the machine (figure 18).

✔ There is a locking tab on the bottom

of the machine control electronics

that snaps into the mounting bracket.

Press the locking tab on the bottom of

the machine control electronics and

slide the assembly to the front, then lift.

Figure 19. Remove the decorative trim.

Figure 17. UI Power Cube and Machine control electronics.

FOR SERVICE TECHNICIAN’S USE ONLY PART NO. W10110638

TECH SHEET - DO NOT DISCARD PAGE 11

4. Slide the console up and off of the

machine. See figure 18, page 10.

REMOVING THE BACK

PANEL

5. The console mounting bracket is

fastened to the console front panel with 1. Unplug dryer or disconnect power.

two latches at both sides of the console 2. Remove the three rear screws from the Contacts

assembly. Unlatch the bracket gently top panel, and slide the top panel to

with a screwdriver while pulling the Function 1M 2M 3M 5M 6M

the rear to remove.

mounting bracket assembly out. See Start

figure 18, page 10. 3. Remove the cover plate, disconnect the

power cord, and remove ground screw. Run

6. The console electronics is split into two

assemblies connected by two cables. 4. Remove the metal spring clip between = Contacts closed

Each assembly is fastened to the the back panel and the exhaust outlet.

decorative piece by four plastic latches. See figure 21. Centrifugal Switch

To remove these assemblies, gently (Motor)

compress the plastic latches while

pulling up on the assembly. For the

cycle selector assembly, the cycle

selector knob must first be removed by

firmly pulling on it or gently prying it Lt. Blue

straight upward. See figure 20. Black-White Green-Yellow

Red Red

Pluggable Drive Motor Switch

Figure 20. Locate 8 plastic latches.

Figure 21. Remove 12 screws.

5. Remove the ten screws on the rear,

and two screws on the top of the back Black

panel. Pull the back panel off the White

Blue

machine.

WHITE

White Blue

ELECTRIC DRYER: In addition to the

above, remove the terminal block from the

back panel. Gas Valve, Gas Dryer

SOFTWARE COPYRIGHTED.

MANUFACTURED UNDER ONE OR MORE

OF THE FOLLOWING U.S. PATENTS:

4669200 4989347 6446357 D314261

4700495 5066050 6597144 D314262

4754556 5560120 6604298 D457991

4840285 5809828 6685241 D457992

4865366 6020698 6732447 D495453

4899464 6047486 6784673

4908959 6199300 6819255

FOR SERVICE TECHNICIAN’S USE ONLY PART NO. W10110638

TECH SHEET - DO NOT DISCARD PAGE 12

ELECTRIC DRYER WIRING DIAGRAM IMPORTANT: Electrostatic (static

electricity) discharge may cause damage

to machine control electronics. See page 1

L1 LINE – BK R – LINE L2

240 VOLTS

W – NEUTRAL N

120 VOLTS NEUTRAL

BK BR TERMINAL

W W LINKED TO

CABINET R

DRUM LAMP NC

P8-3 NEUTRAL W

P8-1 NEUTRAL W

LAMP LOAD W

BK P9-2 P8-4 T BU-W BU

L1 DOOR DOOR

P8-2 G-Y NO SWITCH

BK P1-1 GND LBU

L1 POWER CUBE

W P1-2 P9-1 LBU LBU

N +5 V Gnd MOTOR CENTRIFUGAL SWITCH

5M 2M

P8-5 BK-W THERMAL FUSE

P2-2 P2-1 MTR CS MAIN

196°F (91°C) 4M 3.3–3.6 Ω

P003-1 P003-2 P003-3 G-Y

P13-1 Y-R START

MOIST. Y-R

N.C. +5 V Gnd BELT 2.7–3.0 Ω

SENSOR MOVS SWITCH

3M 6M 1M

P005-3 VDD P2-1 VDD SERIAL SENSOR

P005-2 DATA P2-2 DATA P13-2 DRIVE MOTOR

CONSOLE P005-1 VSS P2-3 VSS

COM MOIST RTN 1/3 H.P.

ELECTRONICS G-Y

MODEL P4-4 Y-R

BK

HEATER RELAY 1 MODEL RTN P4-5

OUTLET THERMISTOR

BK N.O. P4-3 R

HEATER +V OUTLET TEMP.

(0.25 TERMINAL) 10 kΩ

OUTLET P4-6 R

R COM TEMP. RTN

HEATER RTN INLET THERMISTOR

(0.25 TERMINAL) P4-2 R

INLET TEMP.

MACHINE 50 kΩ

P4-1 R

CONTROL INLET

ELECTRONICS TEMP. RTN

NC

HEATER

R R-W R-W R

HIGH LIMIT

THERMAL

THERMOSTAT 7.8–11.8 Ω

295°F (146°C)

CUT-OFF

352°F (178°C) COMBINED PART

GAS DRYER WIRING DIAGRAM

L1 LINE – BK W – NEUTRAL N

BK

120 VOLTS

BK BR

W W

DRUM LAMP NC

P8-3 NEUTRAL W

P8-1 NEUTRAL W

LAMP LOAD

BK P9-2 P8-4 T LBU BU

L1 DOOR DOOR

BK P1-1 P8-2 G-Y NO SWITCH

L1 POWER CUBE GND

W P1-2 P9-1 LBU

N MOTOR

+5 V Gnd LBU R

P8-5 BK-W

P2-2 P2-1 MTR CS

P13-1 Y-R

MOIST. Y-R

P003-1 P003-2 P003-3 5M CENTRIFUGAL SWITCH 2M

SENSOR MOVS MAIN

N.C. +5 V Gnd 4M

SENSOR 3.3–3.6 Ω

G-Y

P13-2

P005-3 VDD P2-1 VDD SERIAL MOIST RTN START

G-Y BELT 2.7–3.0 Ω

CONSOLE P005-2 DATA P2-2 DATA COM

P005-1 VSS P2-3 VSS SWITCH

ELECTRONICS Y-R 3M 6M

1M

BK DRIVE MOTOR

P14-4 1/3 H.P.

MODEL

HEATER RELAY 1 P14-5 BK

MODEL RTN

N.O. OUTLET THERMISTOR R

BK P14-3 R-W

HEATER +V TEMP.

(0.25 TERMINAL)

10 kΩ IG IGR

R P14-6 R-W

COM TEMP RTN 1V

HEATER RTN IGNITOR

(0.25 TERMINAL) 50–500 Ω

N.C. P14-2

VALVE 3

MACHINE MOV 2 1

CONTROL N.C. VALVE

P14-1 HOLD ASSIST NO. 1

ELECTRONICS 4 5

NC BU

VALVE

BK TF1 TF2 MAIN NO. 2

R R-W

HIGH LIMIT FS1 FS2

THERMAL THERMAL FUSE

THERMOSTAT CUT-OFF 196°F (91°C)

245°F (118°C) 352°F (178°C) FLAME SENSOR

11/06 FOR SERVICE TECHNICIAN’S USE ONLY PART NO. W10110638

You might also like

- Dryer Tech SheetDocument12 pagesDryer Tech SheetalanbrannNo ratings yet

- Maytag Dryer Medx700xw0 Service ManualDocument64 pagesMaytag Dryer Medx700xw0 Service Manualdan theman100% (1)

- 2009-10-17 160959 Tech Sheet - 110.62042100Document6 pages2009-10-17 160959 Tech Sheet - 110.62042100Ramesh SarvaryNo ratings yet

- Whirlpool Calypso Dryer Tech - Sheet / Service Manual 8541836Document8 pagesWhirlpool Calypso Dryer Tech - Sheet / Service Manual 8541836Dude manNo ratings yet

- Tech Sheet - 4453233 - Rev EDocument8 pagesTech Sheet - 4453233 - Rev Ekyubok chongNo ratings yet

- For Service Technician'S Use Only: Voltage Measurement Safety InformationDocument48 pagesFor Service Technician'S Use Only: Voltage Measurement Safety Informationjorge castilloNo ratings yet

- Tech Sheet - W10607408 - Rev F PDFDocument48 pagesTech Sheet - W10607408 - Rev F PDFNolan HicksNo ratings yet

- Whirlpool Kitchen 8302067Document8 pagesWhirlpool Kitchen 8302067Alejandro MarquezNo ratings yet

- For Service Technician'S Use Only: Voltage Measurement Safety InformationDocument48 pagesFor Service Technician'S Use Only: Voltage Measurement Safety Informationdan themanNo ratings yet

- Model#MVWX655DW0 Washer W10677676 - Tech SheetDocument22 pagesModel#MVWX655DW0 Washer W10677676 - Tech SheetbiggbioNo ratings yet

- W10240504 Maytag Bravos MVWX600XW0 MCT Washer Tech SheetDocument44 pagesW10240504 Maytag Bravos MVWX600XW0 MCT Washer Tech SheetJason ArnoldNo ratings yet

- Whirlpool Refrigerator GB2FHDXWS03 Tech Sheet W10308623Document2 pagesWhirlpool Refrigerator GB2FHDXWS03 Tech Sheet W10308623xsupportaccountNo ratings yet

- Washing Machine Model # 110.26002012 Tech Sheet - W10468342 - Rev CDocument44 pagesWashing Machine Model # 110.26002012 Tech Sheet - W10468342 - Rev CMelissa MorganNo ratings yet

- Warning Danger: No-Load Performance, Controls in Normal PositionDocument2 pagesWarning Danger: No-Load Performance, Controls in Normal Positionhenry ramirezNo ratings yet

- Service Manual: Job AidDocument30 pagesService Manual: Job AidJim HarmkeNo ratings yet

- For Service Technician'S Use Only: Voltage Measurement Safety InformationDocument56 pagesFor Service Technician'S Use Only: Voltage Measurement Safety InformationFrancis Ross NuevaNo ratings yet

- For Service Technician'S Use Only: Voltage Measurement Safety InformationDocument60 pagesFor Service Technician'S Use Only: Voltage Measurement Safety Informationcris melosNo ratings yet

- CAE2743BQ0 Technical Info SheetDocument40 pagesCAE2743BQ0 Technical Info SheetNicholas KaminskiNo ratings yet

- Dryer Service ManualDocument35 pagesDryer Service ManualReggie Byrum50% (2)

- Voltage Measurement Safety Information: For Service Technician'S Use OnlyDocument20 pagesVoltage Measurement Safety Information: For Service Technician'S Use Onlyjrem.ypNo ratings yet

- Maytag Maxima Washer MHW6000XW Service PDFDocument52 pagesMaytag Maxima Washer MHW6000XW Service PDFCarlos RuizNo ratings yet

- Methods To Get Blink Code v.01 Iveco Dily S2000Document33 pagesMethods To Get Blink Code v.01 Iveco Dily S2000BobNo ratings yet

- Wireless Door Lock Control System Registration ProcedureDocument5 pagesWireless Door Lock Control System Registration Procedureawan wijayantoNo ratings yet

- Fire Alarm Testing Procedure - Astra - Rev1Document5 pagesFire Alarm Testing Procedure - Astra - Rev1Mariano obilleNo ratings yet

- Wfw96heaw0 Tech Sheet-w10441104-Rev BDocument56 pagesWfw96heaw0 Tech Sheet-w10441104-Rev BmoiNo ratings yet

- Manual Tecnico Whirlpool RevCDocument56 pagesManual Tecnico Whirlpool RevCGustavo RangelNo ratings yet

- Tech Sheet - W10450076 - Rev A PDFDocument2 pagesTech Sheet - W10450076 - Rev A PDFEdison EspinalNo ratings yet

- Techsheet w10740624 RevbDocument44 pagesTechsheet w10740624 RevbPaulStaplesNo ratings yet

- Antilock Brake System: T DiagnosticsDocument42 pagesAntilock Brake System: T Diagnosticsvadim vadimNo ratings yet

- 9IS44317.07 IS ICPlus 915 EN-IT-ES-DE-FR 1021Document33 pages9IS44317.07 IS ICPlus 915 EN-IT-ES-DE-FR 1021cipx2No ratings yet

- 9IS44317.07 IS ICPlus 915 EN-IT-ES-DE-FR 1021Document156 pages9IS44317.07 IS ICPlus 915 EN-IT-ES-DE-FR 1021Mario PitaNo ratings yet

- 0.1.013 Sofware Update - ENDocument7 pages0.1.013 Sofware Update - ENAbdalazeez AlsayedNo ratings yet

- Calibración de Carga TLTDocument6 pagesCalibración de Carga TLTAbnerAnonaNo ratings yet

- rp120 PDFDocument12 pagesrp120 PDFCris100% (1)

- DM-200A - DM-210A DM-510A Digital Multimeters Multímetros DigitalesDocument168 pagesDM-200A - DM-210A DM-510A Digital Multimeters Multímetros DigitalesSaša MinićNo ratings yet

- SFP 5 UdceDocument1 pageSFP 5 UdcefaisalhidayatmdeNo ratings yet

- Bs 636Document10 pagesBs 636ali kuşçuNo ratings yet

- Multifunction Digital: Clamp MeterDocument9 pagesMultifunction Digital: Clamp MeterAgung DuemilanoveNo ratings yet

- Lem 2.4 Power AmplifierDocument5 pagesLem 2.4 Power Amplifiernadeemsound9467No ratings yet

- DCL-33A Short Manual (ENG) 1546677984556Document2 pagesDCL-33A Short Manual (ENG) 1546677984556kiepluhanh2014No ratings yet

- ST Lathe Installation - NGCDocument28 pagesST Lathe Installation - NGCdurmotzNo ratings yet

- Product Manual 126Document6 pagesProduct Manual 126ELECTROREFRICAP Santa martaNo ratings yet

- cp9660 Users ManualDocument13 pagescp9660 Users ManualJohn Jeshurun SamonteNo ratings yet

- Rm e82八国语说明书未简化的Document26 pagesRm e82八国语说明书未简化的Tatfung AuNo ratings yet

- NV11 Q R G: Configuration ButtonDocument2 pagesNV11 Q R G: Configuration ButtonГеннадий ЧашницкийNo ratings yet

- Secadora Electrolux Manual de ServicioDocument8 pagesSecadora Electrolux Manual de Servicioorkys TenorioNo ratings yet

- Faqe7073ka0 Secadora FrigidaireDocument8 pagesFaqe7073ka0 Secadora FrigidaireVasti Diaz AguilarNo ratings yet

- Cummins: Fault Code: 298 PID: P223 SPN: 1084 FMI: 4Document4 pagesCummins: Fault Code: 298 PID: P223 SPN: 1084 FMI: 4Enrrique LaraNo ratings yet

- Installation Manual enUS 165636133387 PDFDocument16 pagesInstallation Manual enUS 165636133387 PDFRicardo MercadoNo ratings yet

- English User Guide - 0044-033-05 - enDocument16 pagesEnglish User Guide - 0044-033-05 - enZemouraMohamedNo ratings yet

- NV9USB Quick Ref GuideDocument2 pagesNV9USB Quick Ref GuidezhekasxgNo ratings yet

- DM-200A, DM-210A, DM-510A Multimeters (Europe) Instruction ManualDocument168 pagesDM-200A, DM-210A, DM-510A Multimeters (Europe) Instruction ManualGonsalez JuanNo ratings yet

- 5100 Series S.M.a.R.T. Panel Display Owners ManualDocument1 page5100 Series S.M.a.R.T. Panel Display Owners ManualGreg MartinNo ratings yet

- TSC Bomba SPDocument3 pagesTSC Bomba SPdarwin jumboNo ratings yet

- Reading And, Resetting of Various Numerical RelaysDocument6 pagesReading And, Resetting of Various Numerical RelaysAnand SundaramNo ratings yet

- 2006101921011453187392Document6 pages2006101921011453187392Roman RufoNo ratings yet

- DBC CounterDocument4 pagesDBC CounterRonald Rubina JustoNo ratings yet

- Operation Manual Jenco Model 3250 Microcomputer Based Conductivity/Salinity/Temperature Portable MeterDocument21 pagesOperation Manual Jenco Model 3250 Microcomputer Based Conductivity/Salinity/Temperature Portable MeterMario Alfonso MartinezNo ratings yet

- An ISO 9001: 2000 COMPANYDocument24 pagesAn ISO 9001: 2000 COMPANYOo Pen DraNo ratings yet

- Wiper WasherDocument25 pagesWiper Washers.e. e.p.No ratings yet

- 014 Timer ConversionDocument7 pages014 Timer Conversionsghane5674No ratings yet

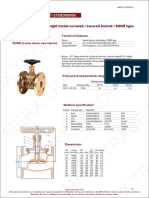

- Globe Valve Bronze SDNR 275Document1 pageGlobe Valve Bronze SDNR 275Przemek SankowskiNo ratings yet

- Appendix 1 93M-0501-B13-NC000-DGM-00003 NCC Mainline Power Sectioning Diagram (FDR)Document15 pagesAppendix 1 93M-0501-B13-NC000-DGM-00003 NCC Mainline Power Sectioning Diagram (FDR)AHMED ATIFNo ratings yet

- Maintenance Manual Rev2 - ENDocument30 pagesMaintenance Manual Rev2 - ENMartha BenavidesNo ratings yet

- Oxymixer High Flow Without Monitor - BrochureDocument6 pagesOxymixer High Flow Without Monitor - BrochureochaNo ratings yet

- Katalog BarangDocument29 pagesKatalog BarangNovi DamayantiNo ratings yet

- Prooduct Datasheet - PrevaLED COIN 50 COB G2 (2021-2-1 Update)Document5 pagesProoduct Datasheet - PrevaLED COIN 50 COB G2 (2021-2-1 Update)ovanNo ratings yet

- Proposed Scope of Work For Ogbotobo v3Document6 pagesProposed Scope of Work For Ogbotobo v3martins73No ratings yet

- 60 4690e PDFDocument3 pages60 4690e PDFMarudhasalamMarudhaNo ratings yet

- Fabrication of Stainless Fish Washer (PB)Document1 pageFabrication of Stainless Fish Washer (PB)Draftsman EngineeringNo ratings yet

- Kelani Cables Technical Guide21516810912 PDFDocument21 pagesKelani Cables Technical Guide21516810912 PDFajith100% (2)

- Mini 500 - BBP/BCP/BGP500 LED Under Canopy Luminaires: BenefitsDocument4 pagesMini 500 - BBP/BCP/BGP500 LED Under Canopy Luminaires: Benefitsamin tariqNo ratings yet

- PGHU-CV-LDSTS-000001 R2 Piping Standards DrawingDocument46 pagesPGHU-CV-LDSTS-000001 R2 Piping Standards DrawingRiyan EsapermanaNo ratings yet

- Diagrams 621iDocument149 pagesDiagrams 621iJohnatan MezaNo ratings yet

- Dremel 200 ManualDocument68 pagesDremel 200 ManualAmber WhitsonNo ratings yet

- 16 Screw Hoist For Sluice Gate PDFDocument10 pages16 Screw Hoist For Sluice Gate PDFsamNo ratings yet

- Buy AmazonBasics 21 Ltrs Classic Fabric Backpack - Navy at Amazon - inDocument1 pageBuy AmazonBasics 21 Ltrs Classic Fabric Backpack - Navy at Amazon - inAnjali PatelNo ratings yet

- AV-SWP-44 HV Electricity Iss 1Document8 pagesAV-SWP-44 HV Electricity Iss 1Kevin DeLimaNo ratings yet

- Guide To Overvoltage Categories and Measurement Categories 1Document11 pagesGuide To Overvoltage Categories and Measurement Categories 1Ahmed IsmailNo ratings yet

- Small Power Distribution BoardsDocument6 pagesSmall Power Distribution BoardsSARAVANANo ratings yet

- Bridge Engineeing Drawings 10.2 - A4 - 3Document1 pageBridge Engineeing Drawings 10.2 - A4 - 3Adnan NajemNo ratings yet

- Faz Bindlestick's Guide To Firearms - GM BinderDocument14 pagesFaz Bindlestick's Guide To Firearms - GM Binder2ooneyNo ratings yet

- Upah Machine Operator Jan14 - Semenanjungupload 1 PDFDocument8 pagesUpah Machine Operator Jan14 - Semenanjungupload 1 PDFSiti Nurhani Datul AsikienNo ratings yet

- ESP Price List 06.08.2012Document76 pagesESP Price List 06.08.2012Manisankar DhabalNo ratings yet

- Aurora MEA Price List 2009Document5 pagesAurora MEA Price List 2009راكان خالدNo ratings yet

- Schischek Explosionproof.: Protection of Life. Health. AssetsDocument44 pagesSchischek Explosionproof.: Protection of Life. Health. Assetssooriya_82No ratings yet

- FCHIRISE - FCH-2 - Consolidated Customer Package PDFDocument11 pagesFCHIRISE - FCH-2 - Consolidated Customer Package PDFWilvir MurilloNo ratings yet

- Manual de Usuario Htw-Yan1f1-EngDocument10 pagesManual de Usuario Htw-Yan1f1-EngJonathan Hernán Valderrama RamírezNo ratings yet

- Thetford Repair ManualDocument43 pagesThetford Repair ManualZoran Prokic50% (4)