Professional Documents

Culture Documents

Method Statement - Ground Floor Slab

Uploaded by

HannaFouadCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement - Ground Floor Slab

Uploaded by

HannaFouadCopyright:

Available Formats

Method Statement

Project: 66/22 Power Substation – Damac 1,2

Location: 5th Settlement – New Cairo - Egypt

Element: Ground Floor Slab

Index: 1. Purpose.

2. Scope.

3. References.

4. Equipment.

5. Materials.

6. Sequence of works.

7. Sequence of casting.

QA/QC - BIC Page | 1

1. Purpose:

This method statement describes the practices and methods to be used with regards to

placing, curing and repairing of concrete in accordance with the approved construction

drawings, approved mix design, Quality Plan and contract project specification.

2. Scope:

2.1. Formwork for the slab.

2.2. Marking the slab.

2.3. Placing the reinforcement.

3. References:

3.1. Project Specification.

3.2. ACI 318M Building code requirements for reinforcement concrete.

3.3. ACI 305R & 306R Hot & Cold weather concreting.

3.4. ASTM C94 Standard Specifications for Ready-mixed concrete.

3.5. Approved Construction drawings, latest revision.

4. Equipment:

4.1. Concrete pump.

4.2. Concrete transmit mixer truck.

4.3. Vibrators.

4.4. Electric table saw.

4.5. Manual steel cutter.

4.6. Steel cutter machine.

4.7. Steel bender table.

QA/QC - BIC Page | 2

5. Materials:

5.1. Cement:

Cement shall be OPC Ordinary Portland Cement complying with the requirements of ASTM 150 and

complying with the requirements (Project specs); cement shall be used only from approved

manufacturer unless otherwise specified.

5.2. Aggregates:

All types of fine & coarse aggregates shall conform to the requirements of ASTM C 33. All aggregate

materials to be used shall be from approved sources. All properties of aggregates shall comply with the

requirements as required by project specification.

5.3. Water:

Water to be used shall be clean for concrete mixing and curing purposes and carry out test in

accordance with specs.

5.4. Reinforcement:

Reinforcing bar shall conform to ASTM A 615, grade 60, (Project Specifications).

5.5. Admixtures:

All admixtures for concrete works shall comply with any of the ACI C618, ACI 260 and ASTM C 494 and

to contract requirements. And to be added in the batch planet with supervision of the concrete

supplier, after approval of the material data sheet from client.

5.6. Formwork:

All supplied Form work incorporated into any service under this agreement shall be new and of the

most suitable grade. Fair face concrete for all exposed activities including but not limited to

(transformers walls, firefighting walls, outdoor foundation pedestals, internal and external walls for

cable trenches and manholes).

QA/QC - BIC Page | 3

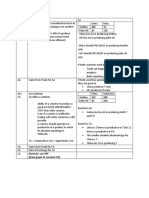

6. Sequence of works:

6.1. Cleaning the columns dowels from the concrete paste.

6.2. Erecting the jack props to support ledgers, which support the formworks for beams after marking

their bottom level according to the levels in the approved drawings.

6.3. Shuttering the beams by horizontal bearers, vertical soldiers and diagonal struts supported by

ledgers; then plywood sides to formwork the beams.

QA/QC - BIC Page | 4

6.4. Erecting the jack props for the slab formwork, then the ledgers and the bearers.

6.5. Decking the plywood on the bearers.

QA/QC - BIC Page | 5

6.6. Placing the reinforcement cages for beams.

6.7. Fixing the bottom reinforcement layer of the slab, then the top layer supported on the steel-chair

spacers as well fixing the concrete spacers.

QA/QC - BIC Page | 6

6.8. Concrete pouring.

6.9. Formwork Removal as per references.

6.10. Repairing using a grouting mortar.

6.11. Curing using a curing chemical.

QA/QC - BIC Page | 7

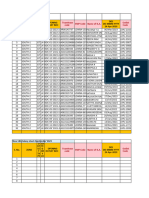

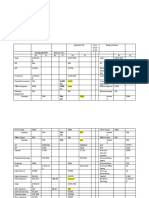

7. Sequence of Casting:

7.1. All shuttering and bracings of the inverted beams to be ready before casting operation.

7.2. Pouring zone [1] level (+5.700).

7.3. Pouring zone [2] the maintenance corridor and the frames. (Took about 6-7 hours)

7.4. Shuttering the inverted beams and bracing works.

7.5. Pouring zone [3] level (+6.400).

7.6. Pouring inverted beams of zone [1].

QA/QC - BIC Page | 8

You might also like

- ModernResidentialConstructionPractices 1Document547 pagesModernResidentialConstructionPractices 1HannaFouad0% (1)

- Confined Masonry Design Guide 82011Document91 pagesConfined Masonry Design Guide 82011Marius IonutNo ratings yet

- Manual For Design and Detailing of RCCDocument340 pagesManual For Design and Detailing of RCCimranmehfoozNo ratings yet

- Proposed Method StatementDocument3 pagesProposed Method StatementkrmchariNo ratings yet

- Method Statement For Aac BlockworkDocument10 pagesMethod Statement For Aac BlockworkobieNo ratings yet

- SEISMIC ISOLATION BEARINGSDocument87 pagesSEISMIC ISOLATION BEARINGSprabhu81100% (2)

- Quality Procedure For ConcreteDocument12 pagesQuality Procedure For ConcreteEdrian DiazNo ratings yet

- Marriot Grand Ballroom Concrete Works: Project Title: Contract Package No. 02Document9 pagesMarriot Grand Ballroom Concrete Works: Project Title: Contract Package No. 02Imho TepNo ratings yet

- Method of Statement-Drain & ShoringDocument3 pagesMethod of Statement-Drain & ShoringMin Min SoeNo ratings yet

- Feasibility Studies Guide for Economic ProjectsDocument60 pagesFeasibility Studies Guide for Economic Projectsice100% (2)

- Solution Manual For Microeconomics 16th Canadian Edition Christopher T S Ragan Christopher RaganDocument13 pagesSolution Manual For Microeconomics 16th Canadian Edition Christopher T S Ragan Christopher RaganChristopherRamosfgzoNo ratings yet

- Method Statement - Crack Control Joint For CCB RC WallDocument7 pagesMethod Statement - Crack Control Joint For CCB RC WallReza RosenoNo ratings yet

- Qatar Building Substructure ProtectionDocument4 pagesQatar Building Substructure ProtectionTATATAHERNo ratings yet

- Method Statement FOR Flooring: 10 M - T A&Bc EV - F & Mep WDocument8 pagesMethod Statement FOR Flooring: 10 M - T A&Bc EV - F & Mep WTariq KhattakNo ratings yet

- Method Statement of HACKING WORKS ON CONCRETE WALL FOR LIFTDocument3 pagesMethod Statement of HACKING WORKS ON CONCRETE WALL FOR LIFTfaizbukhari100% (2)

- T211 Method Statement - RC SlabDocument11 pagesT211 Method Statement - RC SlabStephen David GozunNo ratings yet

- Method Statement Retaining WallDocument3 pagesMethod Statement Retaining Wallibrahim0% (1)

- Method Statement FOR Steel Reinforcement: ProjectDocument5 pagesMethod Statement FOR Steel Reinforcement: ProjectKelvin Lau100% (1)

- Method Statement For Door FrameDocument12 pagesMethod Statement For Door FrameMin Luo100% (2)

- Blinding & Concrete Method StatementDocument5 pagesBlinding & Concrete Method Statementشاز إياسNo ratings yet

- KAPSARC-MRK-Concrete Repair work-METHOD STATEMENTDocument4 pagesKAPSARC-MRK-Concrete Repair work-METHOD STATEMENTsherwin suarezNo ratings yet

- Work Method Statement FOR Reinforced Concrete WorksDocument5 pagesWork Method Statement FOR Reinforced Concrete WorksLynn Mail100% (1)

- MGB-MS-003-ST-003 Formwork InstallationDocument8 pagesMGB-MS-003-ST-003 Formwork InstallationImho Tep100% (1)

- Crack Repair Method StatementDocument10 pagesCrack Repair Method StatementzahangirNo ratings yet

- Tbi 2017Document148 pagesTbi 2017Aie Bantugan100% (1)

- ITP Temporary HoardingDocument1 pageITP Temporary HoardingMohd Azrin100% (1)

- Method of Statement (Open Cut)Document14 pagesMethod of Statement (Open Cut)Syed FaizNo ratings yet

- Earthworks and RoadworksDocument9 pagesEarthworks and RoadworkswagwahkiabatheNo ratings yet

- Concrete Pouring of SHEARWALL and Columns First LiftDocument5 pagesConcrete Pouring of SHEARWALL and Columns First LiftJhundel Factor Pajarillaga100% (2)

- STRUCTURAL MODELING NOTES - rev.3.4 رائـــــــــــــــــــــــــــــــــع PDFDocument67 pagesSTRUCTURAL MODELING NOTES - rev.3.4 رائـــــــــــــــــــــــــــــــــع PDFHannaFouadNo ratings yet

- Sprayed Concrete TechnologyDocument318 pagesSprayed Concrete TechnologyoltaiyrxNo ratings yet

- Method Statement For Casting of Cement Based ScreedDocument8 pagesMethod Statement For Casting of Cement Based Screedmd_rehan_2100% (1)

- Method Statement For Shrinkage CracksDocument2 pagesMethod Statement For Shrinkage Cracksluvvie87No ratings yet

- Method Statement Footing Concrete PourDocument6 pagesMethod Statement Footing Concrete PourNino Celso AstilleroNo ratings yet

- Method Statement and SpecificationDocument17 pagesMethod Statement and SpecificationApai MfarNo ratings yet

- MOS DrainageDocument16 pagesMOS DrainageMohammad Hadoumi Saldan100% (1)

- Inspection Checklist Masonry WallDocument3 pagesInspection Checklist Masonry WallJonatan LopezNo ratings yet

- Seismic ConceptualDocument82 pagesSeismic Conceptualஆனந்த் கிருஷ்ணன்No ratings yet

- Method Statement For Conventional Formwork BlogDocument9 pagesMethod Statement For Conventional Formwork BlogMohasin KhanNo ratings yet

- Method Statement for Slab Ground Floor ConstructionDocument11 pagesMethod Statement for Slab Ground Floor ConstructiondeviesrigatiNo ratings yet

- Method Statement For Retaining Wall Work ExecutionDocument3 pagesMethod Statement For Retaining Wall Work ExecutionSujeet SarukNo ratings yet

- Method Statement For Transfer SlabDocument11 pagesMethod Statement For Transfer Slabray100% (1)

- Method Statement For ScaffoldingDocument3 pagesMethod Statement For ScaffoldingDouglas JambaNo ratings yet

- Casting of RC Slab MosDocument2 pagesCasting of RC Slab MosEngr Badz de DiosNo ratings yet

- Install Horizontal Drainage DrainsDocument3 pagesInstall Horizontal Drainage DrainsTaqiuddin MJNo ratings yet

- Method Statement of Casting SlabDocument4 pagesMethod Statement of Casting SlabShakila Nishani100% (1)

- Method Statement For Anti Termite TreatmentDocument5 pagesMethod Statement For Anti Termite TreatmentrayNo ratings yet

- Survey Setting Out Method StatementDocument4 pagesSurvey Setting Out Method StatementKelvin LauNo ratings yet

- Painting Works Method StatementDocument5 pagesPainting Works Method StatementDavid SeeNo ratings yet

- Reinforcement-Method StatementDocument4 pagesReinforcement-Method StatementTATATAHERNo ratings yet

- Method Statement Excavation BackfillingDocument16 pagesMethod Statement Excavation BackfillingMohsen KeramatiNo ratings yet

- Joseph Kubin - Bim PDFDocument22 pagesJoseph Kubin - Bim PDFMohamad Ridzuan IsmailNo ratings yet

- Method Statement For HoneycombDocument2 pagesMethod Statement For HoneycombCHAR JIN CHEENo ratings yet

- Method Statement FOR Concreting Work: ProjectDocument6 pagesMethod Statement FOR Concreting Work: ProjectKelvin LauNo ratings yet

- MOS - Flexible Pavement RehabilitationDocument6 pagesMOS - Flexible Pavement RehabilitationcdipcinNo ratings yet

- Method Statement Drainage WorksDocument6 pagesMethod Statement Drainage WorksShua Chuah100% (3)

- Etabs Modelling (Jan2015)Document13 pagesEtabs Modelling (Jan2015)HannaFouadNo ratings yet

- Road Construction MethodsDocument150 pagesRoad Construction Methodsblaze14911100% (1)

- Affidavit of Self Adjudication CabudolDocument2 pagesAffidavit of Self Adjudication CabudolMigz SamartinoNo ratings yet

- Bridge Construction MethodologyDocument11 pagesBridge Construction MethodologyMAYMODERN STEELNo ratings yet

- METHOD OF BLINDING CONCRETE WORKSDocument6 pagesMETHOD OF BLINDING CONCRETE WORKSMohd Muksin100% (1)

- Heavy Duty Shoring Installation MethodDocument1 pageHeavy Duty Shoring Installation MethodNizam ShafieNo ratings yet

- Sunken FillingDocument3 pagesSunken FillingASHOKKUMARNo ratings yet

- Proposed Marudi Bridge Over Batang Baram, Miri Division, SarawakDocument8 pagesProposed Marudi Bridge Over Batang Baram, Miri Division, SarawakKelvin LauNo ratings yet

- 23.Checklist-Box Type WaterproofingDocument1 page23.Checklist-Box Type Waterproofingajit karandikarNo ratings yet

- Method Statement: Soil Replacement Under FoundationsDocument1 pageMethod Statement: Soil Replacement Under FoundationsMohamed SalahNo ratings yet

- Work Method Statement For Plain and Reinforced Cement Concrete PCCDocument2 pagesWork Method Statement For Plain and Reinforced Cement Concrete PCCBhargav BbvsNo ratings yet

- GSG Catlog (Full Set)Document24 pagesGSG Catlog (Full Set)naili irfanNo ratings yet

- Diamond Concrete Coring Work Sequence Method StatementDocument1 pageDiamond Concrete Coring Work Sequence Method StatementAnonymous wTTx1L100% (1)

- 2 Finishing Works Method Statement For Building ConstructionDocument15 pages2 Finishing Works Method Statement For Building ConstructionElxao XanNo ratings yet

- Mos For Hacking RectificationDocument1 pageMos For Hacking Rectificationoj_ordeNo ratings yet

- Concrete Works For Foundation (PC-RC) - 1Document7 pagesConcrete Works For Foundation (PC-RC) - 1Mohamed GamalNo ratings yet

- Nrqs-Mos-008 Concrete WorksDocument10 pagesNrqs-Mos-008 Concrete Workscivil.godfatherNo ratings yet

- Installation of Zorin OSDocument9 pagesInstallation of Zorin OSHannaFouadNo ratings yet

- Royal Commission Supplier QuestionnaireDocument9 pagesRoyal Commission Supplier QuestionnaireHannaFouadNo ratings yet

- Anchored Steel Sheet Pile vs. Cross-Lot Bracing for Deep ExcavationDocument4 pagesAnchored Steel Sheet Pile vs. Cross-Lot Bracing for Deep ExcavationHannaFouadNo ratings yet

- Professional Experience: +966 XX XXX XXXX Makkah, Saudi ArabiaDocument1 pageProfessional Experience: +966 XX XXX XXXX Makkah, Saudi ArabiaMADIONo ratings yet

- Step by Step G+4Document61 pagesStep by Step G+4V.m. RajanNo ratings yet

- Artificial Ground Freezing PDFDocument24 pagesArtificial Ground Freezing PDFHannaFouadNo ratings yet

- Performance Artificial Ground Freezing Shield Tunnelling Taipei - V4i12009Document13 pagesPerformance Artificial Ground Freezing Shield Tunnelling Taipei - V4i12009Sen HuNo ratings yet

- Structural Modeling Notes - Rev.3.4 رائـــــــــــــــــــــــــــــــــعDocument8 pagesStructural Modeling Notes - Rev.3.4 رائـــــــــــــــــــــــــــــــــعHannaFouadNo ratings yet

- Step by Step G+4Document61 pagesStep by Step G+4V.m. RajanNo ratings yet

- Column Size Reduction of Size PDFDocument21 pagesColumn Size Reduction of Size PDFHannaFouadNo ratings yet

- Dynamics NotesDocument126 pagesDynamics NotesChitrang BohraNo ratings yet

- Ufc 3 310 04 c1 2007 PDFDocument245 pagesUfc 3 310 04 c1 2007 PDFHannaFouadNo ratings yet

- Dynamics Full VersionDocument278 pagesDynamics Full VersionHannaFouadNo ratings yet

- Base IsolationDocument27 pagesBase IsolationJithin PayyanurNo ratings yet

- This Is My First Document To Upload To ScribdDocument1 pageThis Is My First Document To Upload To ScribdHannaFouadNo ratings yet

- Ufc 3 310 04 c1 2007Document21 pagesUfc 3 310 04 c1 2007HannaFouadNo ratings yet

- Indian EconomyDocument21 pagesIndian Economyprathamginwal22No ratings yet

- Trading checklist and risk management strategiesDocument2 pagesTrading checklist and risk management strategiesDiego RojasNo ratings yet

- 16197967549155457a 01Document3 pages16197967549155457a 01Jaydeep NamdeoNo ratings yet

- Goods and Services To Be Produced and The Quantity To Be Produced of Each Selected CommodityDocument2 pagesGoods and Services To Be Produced and The Quantity To Be Produced of Each Selected CommodityNoelle Lei ReyesNo ratings yet

- Hotel Reservation FormDocument1 pageHotel Reservation FormAdriansyah GokongNo ratings yet

- List of NBFCDocument188 pagesList of NBFCDevansh Sanghvi (QubeHealth)No ratings yet

- Luke Vindasius Resume FinalDocument2 pagesLuke Vindasius Resume FinallukeNo ratings yet

- Moral Economy and Rationalising Islamic Moral EconomyDocument103 pagesMoral Economy and Rationalising Islamic Moral Economyanwaradem225No ratings yet

- Eco Test 1 Prep NotesDocument3 pagesEco Test 1 Prep NotesadzwinjNo ratings yet

- LBA Salary Sheet September'2023 SouthDocument28 pagesLBA Salary Sheet September'2023 SouthManojNo ratings yet

- Personal Finance Canadian Canadian 6th Edition Kapoor Solutions ManualDocument25 pagesPersonal Finance Canadian Canadian 6th Edition Kapoor Solutions ManualStaceyBellewax100% (39)

- Andrew ClarkDocument6 pagesAndrew ClarkhplanettNo ratings yet

- Free E-Book: For RBI Gr. B Economic & Social Issues (ESI) PreparationDocument8 pagesFree E-Book: For RBI Gr. B Economic & Social Issues (ESI) PreparationDhairya ChoudharyNo ratings yet

- Iman Buss ManagementDocument15 pagesIman Buss Managementulzzang looNo ratings yet

- Business Law Chapter 16Document15 pagesBusiness Law Chapter 16Dev TandonNo ratings yet

- Oracle AR Invoicing & Accounting RuleDocument7 pagesOracle AR Invoicing & Accounting Ruleسرفراز احمدNo ratings yet

- Valuation With The Moving Average Price: Problems With Stock CoverageDocument6 pagesValuation With The Moving Average Price: Problems With Stock CoverageUday HawaldarNo ratings yet

- Addiction - 2019 - Rogeberg - The Theory of Rational AddictionDocument4 pagesAddiction - 2019 - Rogeberg - The Theory of Rational Addictionmanuprasadsen1No ratings yet

- J&J Price ListDocument24 pagesJ&J Price ListApotek Hilda AlnairaNo ratings yet

- Calculating product costs using activity-based costing vs traditional methodsDocument4 pagesCalculating product costs using activity-based costing vs traditional methodsKamran ArifNo ratings yet

- CatrionaDocument4 pagesCatrionaShyrine EjemNo ratings yet

- Ground Floor Plan Second Floor Plan: Scale 1: 100 METERS Scale 1: 100 METERSDocument5 pagesGround Floor Plan Second Floor Plan: Scale 1: 100 METERS Scale 1: 100 METERSBon HarperNo ratings yet

- Database Calon PegawaiDocument12 pagesDatabase Calon PegawainadyaNo ratings yet

- Buy Sell Shipment OverviewDocument7 pagesBuy Sell Shipment Overviewvmnyuvaraj rajNo ratings yet

- Development Economics AssignmentDocument5 pagesDevelopment Economics AssignmentAmna ShahzadNo ratings yet

- GBD1006 5033 ASM2 Presentation UniqueTeamDocument49 pagesGBD1006 5033 ASM2 Presentation UniqueTeamPhương DungNo ratings yet

- Chapter 3 In-Class QuestionsDocument8 pagesChapter 3 In-Class Questionsbharath_No ratings yet