Professional Documents

Culture Documents

Valvula Direccional

Uploaded by

leo hernandezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Valvula Direccional

Uploaded by

leo hernandezCopyright:

Available Formats

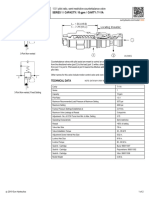

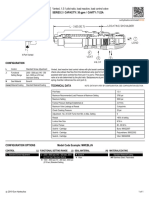

Counterbalance Valves

COUNTERBALANCE

THREE PORT

STANDARD, 4000 PSI MAXIMUM SETTING

Cartridge Dimensions

Typical c Installation

Capacity Cartridge Cavity a b Torque

3 Model Code L C (lb. ft.)

2

15 GPM CBCA – LHN T - 11A 1.38 7/8” 1.97 2.19 30/35

30 GPM CBEA – LHN T - 2A 1.38 1 1/8” 2.38 2.50 45/50

60 GPM CBGA – LHN T - 17A 1.81 1 1/4” 2.75 3.31 150/160

1 120 GPM CBIA – LHN T - 19A 2.50 1 5/8” 3.50 4.09 350/375

OPTION ORDERING INFORMATION

Turn screw clockwise to reduce

setting and release load.

Complete Adjustment 3 Turns

CB ✱ ✱ – ✱ ✱ ✱

+ -

Nominal

Capacity Control** Cracking Pressure Seal

C 15 GPM L Standard Screw 30 psi Check Spring N Buna-N

b E 30 GPM C Tamper Resistant H 1000 - 4000 psi V Viton

c

G 60 GPM I 400 - 1500 psi

Version

I 120 GPM

3 A 3:1 Pilot Ratio 5 psi Check Spring

Pilot Locating

Shoulder B 1.5:1 Pilot Ratio A 1000 - 4000 psi

(with sealed pilot)

B 400 - 1500 psi

a Y 2:1 Pilot Ratio

2 (with bleed through pilot)

Valve Adjustment Range Options:

A and H are standard set at 3000 psi.

** See page 244 for information I and B are standard set at 1000 psi.

Load 1 on Control Options Customer may specify setting.

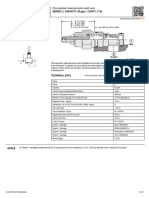

STANDARD, 5000 PSI MAXIMUM SETTING

Cartridge Dimensions

Typical c Installation

Capacity Cartridge Cavity a b Torque

3 Model Code L C (lb. ft.)

2

15 GPM CBCG – LJN T - 11A 1.38 7/8” 1.97 2.19 30/35

30 GPM CBEG – LJN T - 2A 1.38 1 1/8” 2.38 2.50 45/50

60 GPM CBGG – LJN T - 17A 1.81 1 1/4” 2.75 3.31 150/160

1 120 GPM CBIG – LJN T - 19A 2.50 1 5/8” 3.50 4.09 350/375

OPTION ORDERING INFORMATION

Turn screw clockwise to reduce

setting and release load.

CB ✱ ✱ – ✱ ✱ ✱

Complete Adjustment 3 Turns

- + Nominal

Control** Cracking Pressure Seal

Capacity

C 15 GPM L Standard Screw 30 psi Check Spring N Buna-N

E 30 GPM C Tamper Resistant J 2000 - 5000 psi V Viton

b

c

G 60 GPM K 1000 - 2500 psi

Version

I 120 GPM

3 G 4.5:1 Pilot Ratio 5 psi Check Spring

Pilot Locating

Shoulder H 10:1 Pilot Ratio C 2000 - 5000 psi

L 2.3:1 Pilot Ratio D 1000 - 2500 psi

a (with sealed pilot)

2

Valve Adjustment Range Options:

J and C are standard set at 3000 psi.

** See page 244 for information K and D are standard set at 2000 psi.

Load 1 on Control Options Customer may specify setting.

50 US Selected Assemblies Catalogue #999-901-192

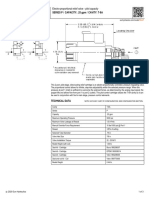

TECHNICAL TIPS / PERFORMANCE CURVES

COUNTERBALANCE

Counterbalance Valves, 3:1, 1.5:1 and 2:1 Pilot Ratio, External Pilot, Non-vented

THREE PORT

Applications Performance Curves

The Sun three port counterbalance cartridges (with Free Flow and Pilot Open Pressure Drop

pilot to open assist) are modulating devices that allow CBC*-L*N CBE*-L*N

400 400

free flow from port 2 (inlet) to port 1 (load) and then

300

block reverse flow until a pilot pressure inversely 300

P = psi

P = psi

proportional to the load pressure is sensed at port 3 200 200

(pilot) or load pressure exceeds relief setting. These 100 100

valves improve the motion control of most control 0 0

0 5 10 15 0 10 20 30

valve systems by ensuring that the actuator always

Q = GPM Q = GPM

sees a positive load pressure, even under overrunning

load situations. CBG*-L*N CBI*-L*N

400 400

Design Concepts and Features

300 300

■

Recommended minimum setting should be 1.3

P = psi

P = psi

times maximum load induced pressure. 200 200

■

3:1, 1.5:1, 2:1 pilot ratio, load holding to 3000 psi 100 100

(with 4000 psi setting). 0 0

■ Load reactive pilot assist for overcenter load 0 20 40 60 0 40 80 120

control applications. Q = GPM Q = GPM

■

5 drops/min. maximum leakage at reseat.

■

Reseat exceeds 85% of set pressure at standard

setting.

■

Back pressure at Port 2 may adversely affect

operation of valve. For circuits with back pressure

Sun recommends vented counterbalance valves

CW** (vented valves).

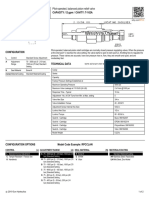

Counterbalance Valves, 4.5:1, 10:1 and 2.3:1 Pilot Ratio, External Pilot, Non-vented

Applications Performance Curves

The Sun three port counterbalance cartridges (with Free Flow and Pilot Open Pressure Drop

pilot to open assist) are modulating devices that allow CBC*-L*N CBE*-L*N

400 400

free flow from port 2 (inlet) to port 1 (load) and then

300 300

block reverse flow until a pilot pressure inversely

P = psi

P = psi

proportional to the load pressure is sensed at port 3 200 200

(pilot) or load pressure exceeds relief setting. These 100 100

valves improve the motion control of most control 0 0

0 5 10 15 0 10 20 30

valve systems by ensuring that the actuator always sees

Q = GPM Q = GPM

a positive load pressure, even under overrunning load

situations. CBG*-L*N CBI*-L*N

400 400

Design Concepts and Features

300 300

■ Recommended minimum setting should be 1.3

P = psi

P = psi

times maximum load induced pressure. 200 200

■

4.5:1 10:1, 2.3:1 pilot ratio, load holding to 3760 100 100

psi (with 5000 psi setting). 0 0

■ 0 20 40 60 0 40 80 120

Load reactive pilot assist for overcenter load

control applications. Q = GPM Q = GPM

■ 5 drops/min. maximum leakage at reseat.

■

Reseat exceeds 85% of set pressure at standard

setting.

■

Back pressure at Port 2 may adversely affect

operation of valve. For circuits with back pressure

Sun recommends vented counterbalance valves

CW** (vented valves).

General Application Requirements

■

Operating Temperature Range: Buna-N seals -50° F to 200° F, Viton seals 0° F to 250° F.

■ Viscosity Range: 60-3000 SUS.

■

Fluid Contamination Level: ISO 4406 18/15 or better; Recommend β10≥75 to achieve ISO 18/15 or better in most systems.

■ Factory Pressure Setting for cartridge is established at cracking flow 35 cc/min.

US Selected Assemblies Catalogue #999-901-192 51

You might also like

- Recip. Comp ECDPDocument51 pagesRecip. Comp ECDPSkydriver Paul100% (1)

- Catalog Pricelist Onda 2023Document40 pagesCatalog Pricelist Onda 2023Tito100% (1)

- Gas Pipe Line DesignDocument31 pagesGas Pipe Line DesignRajnikant DehariaNo ratings yet

- 04 Vertical Roller MillsDocument12 pages04 Vertical Roller MillsaktaserdincNo ratings yet

- TPL-B: Our 2-Stroke Turbocharging Propulsion BoosterDocument8 pagesTPL-B: Our 2-Stroke Turbocharging Propulsion BoosterМаксим АгеевNo ratings yet

- Chargue and Discharger AccomulatorsDocument27 pagesChargue and Discharger Accomulatorsvictor laraNo ratings yet

- Model 20%, Accumulator Sense, Pump Unload Valve With Check - Pilot CapacityDocument2 pagesModel 20%, Accumulator Sense, Pump Unload Valve With Check - Pilot CapacityGamal El Deen KamalNo ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- CBGH Full en Us LetterDocument2 pagesCBGH Full en Us LetterPrakash VasudevanNo ratings yet

- Model 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveErasmo LimaNo ratings yet

- CBCY Full en Us LetterDocument2 pagesCBCY Full en Us LetterVentas Control HidráulicoNo ratings yet

- CACLLGN en Us A4Document1 pageCACLLGN en Us A42fqdw8s8yxNo ratings yet

- 90 R 130 Ka 1 Ab 80 L 3 F1 H 03 Gba 42 42 24 DanfossDocument1 page90 R 130 Ka 1 Ab 80 L 3 F1 H 03 Gba 42 42 24 DanfossJoel PalaciosNo ratings yet

- Model 2.3:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveDocument1 pageModel 2.3:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveCorradoNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveAlaa saidNo ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveANDRESNo ratings yet

- CBEALBN Full en Us LetterDocument2 pagesCBEALBN Full en Us Letterangelo.araza0913No ratings yet

- CBGG Es Metric LetterDocument2 pagesCBGG Es Metric LetterjesusNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValvemateusT850No ratings yet

- Model 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveMuhtadin RizkiNo ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveRobertoNo ratings yet

- Model 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityDocument2 pagesModel 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityleosignareNo ratings yet

- CBGGLJN Es Metric LetterDocument1 pageCBGGLJN Es Metric LetterjesusNo ratings yet

- Model 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveAnurag JainNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- CBIALAN en Metric Letter PDFDocument1 pageCBIALAN en Metric Letter PDFPritesh KoratNo ratings yet

- CBIALAN en Metric Letter PDFDocument1 pageCBIALAN en Metric Letter PDFPritesh KoratNo ratings yet

- CBCALHN-EAC Full en Us LetterDocument5 pagesCBCALHN-EAC Full en Us LetterVentas Control HidráulicoNo ratings yet

- Ac Induction Motor Data Sheet Crown Triton MotorsDocument5 pagesAc Induction Motor Data Sheet Crown Triton Motorschris vilguzNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveRonildo - HydraparNo ratings yet

- Model 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveVignesh PandiyanNo ratings yet

- Modelo Proporción de Pilotaje 2:1, Restrictiva Contrabalance VálvulaDocument1 pageModelo Proporción de Pilotaje 2:1, Restrictiva Contrabalance VálvulaErasmo LimaNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance Valveதமிழன் இராமசாமிNo ratings yet

- Model Vented Pilot-To-Open Check Valve: Series 3 / Capacity: 60 GPM / Cavity: T-23ADocument2 pagesModel Vented Pilot-To-Open Check Valve: Series 3 / Capacity: 60 GPM / Cavity: T-23ANguyễn Thị Ngọc HòaNo ratings yet

- RPGC Full en Us A4Document2 pagesRPGC Full en Us A4zapchasty29No ratings yet

- AM3 3 QF Flow-Regulator-Cetop-3Document1 pageAM3 3 QF Flow-Regulator-Cetop-3PitupyNo ratings yet

- GSL Actuator Sizing Calculation PDFDocument1 pageGSL Actuator Sizing Calculation PDFAnonymous yQ7SQrNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveLennyn Mamani VenturaNo ratings yet

- FREA Full en Us A4Document2 pagesFREA Full en Us A4Rodrigo LisboaNo ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- Model Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveDocument2 pagesModel Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveRonildo - HydraparNo ratings yet

- Model 3:1 Pilot Ratio, Vented Counterbalance Valve - Atmospherically ReferencedDocument2 pagesModel 3:1 Pilot Ratio, Vented Counterbalance Valve - Atmospherically ReferencedVinit ChoudharyNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveJavier AriasNo ratings yet

- Model 4.5:1 Pilot Ratio, Ultra-Restrictive Counterbalance ValveDocument1 pageModel 4.5:1 Pilot Ratio, Ultra-Restrictive Counterbalance ValveRinaldo BompieriNo ratings yet

- Sun Hydraulics-Cbca Lan EccDocument5 pagesSun Hydraulics-Cbca Lan EcchendntdNo ratings yet

- Model Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveDocument1 pageModel Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveRonildo - HydraparNo ratings yet

- SUN RPGC-JCN (Relief Valve)Document3 pagesSUN RPGC-JCN (Relief Valve)ful islamNo ratings yet

- Sun Hydraulics CWEL Technical SpecificationsDocument1 pageSun Hydraulics CWEL Technical SpecificationsJustinNo ratings yet

- CCCALBN Full en Us LetterDocument2 pagesCCCALBN Full en Us Letterisaiahsamsonm_948069No ratings yet

- R18 PDFDocument2 pagesR18 PDFluis ivanNo ratings yet

- SUN RPGC-LAN (Relief Valve)Document3 pagesSUN RPGC-LAN (Relief Valve)ful islamNo ratings yet

- Model 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24ADocument2 pagesModel 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24AАндрей9No ratings yet

- Model Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADocument2 pagesModel Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AErasmo LimaNo ratings yet

- RBAP Full en Us Letter PDFDocument3 pagesRBAP Full en Us Letter PDFfrancis_15inNo ratings yet

- Sun Hydraulics FDBA-LANDocument2 pagesSun Hydraulics FDBA-LANJustinNo ratings yet

- Motion Control: VAA-B-SICN-ST-50 05.71.44 - X - 02 - ZDocument2 pagesMotion Control: VAA-B-SICN-ST-50 05.71.44 - X - 02 - Zvictor bastardoNo ratings yet

- PVDB Full en Us LetterDocument2 pagesPVDB Full en Us LetterIsrael RuizNo ratings yet

- CCCALBN en Us LetterDocument1 pageCCCALBN en Us Letterisaiahsamsonm_948069No ratings yet

- RPCCLAN Full en Us LetterDocument2 pagesRPCCLAN Full en Us Lettera safaieNo ratings yet

- Cbcalin ValveDocument2 pagesCbcalin ValveArun51092No ratings yet

- Sun Hydraulics MWEB-LJN Technical SpecificationsDocument1 pageSun Hydraulics MWEB-LJN Technical SpecificationsJustinNo ratings yet

- Pump Unload Pilot Valve SUN QPABDocument2 pagesPump Unload Pilot Valve SUN QPABankesh_ghoghariNo ratings yet

- 9a01304 Fluid MechanicsDocument4 pages9a01304 Fluid MechanicssivabharathamurthyNo ratings yet

- Model DVS: Horizontal Single Stage API 610 Process PumpDocument2 pagesModel DVS: Horizontal Single Stage API 610 Process PumpadmidakbarNo ratings yet

- Certified Rac Win December2017Document28 pagesCertified Rac Win December2017Jad SantosNo ratings yet

- Ficha Técnica Electrobomba Jockey, Mod. GCR1-19, 2HP, FitFlowDocument4 pagesFicha Técnica Electrobomba Jockey, Mod. GCR1-19, 2HP, FitFlowSUPERVISOR PROYECTOS BCI & RCI (EDUARDO VILLANUEVA)No ratings yet

- Fitting CatalogDocument28 pagesFitting CatalognotreadyNo ratings yet

- Appendix 2-4.ep31422 - g-16Document15 pagesAppendix 2-4.ep31422 - g-16bsnegi111No ratings yet

- Another Innovative Solution From Tronair: Shimmy Damper Fluid Service UnitDocument1 pageAnother Innovative Solution From Tronair: Shimmy Damper Fluid Service UnitProvincial AirwaysNo ratings yet

- Asco 8345 - 4.09R2Document2 pagesAsco 8345 - 4.09R2Aletz AlegríaNo ratings yet

- Best Biosafety Cabinet Manufactures in IndiaDocument2 pagesBest Biosafety Cabinet Manufactures in IndiaJames SmithNo ratings yet

- Eccu 211 Manual T10Document35 pagesEccu 211 Manual T10Kevin MuñozNo ratings yet

- BG Degassing Centrifugal Pump: Applications 50 HZDocument2 pagesBG Degassing Centrifugal Pump: Applications 50 HZJose Luis Vivanco MontenegroNo ratings yet

- Suntec Bomba PDFDocument2 pagesSuntec Bomba PDFPedroNo ratings yet

- Victus ManifoldDocument2 pagesVictus ManifoldMahendran KuppusamyNo ratings yet

- Hydraulic Power Unit (HPU) : EngineeringDocument4 pagesHydraulic Power Unit (HPU) : EngineeringmikafazNo ratings yet

- RM55 160KW Oil Flooded Rotary Screw Compressors - enDocument3 pagesRM55 160KW Oil Flooded Rotary Screw Compressors - enRey HanNo ratings yet

- Amadeus Gas Pipeline - Project Justifications - Item 8 - 18756-5-HAD-001 HAZ Dossier - Katherine Off-Take SS Rev 0 - August 2015Document91 pagesAmadeus Gas Pipeline - Project Justifications - Item 8 - 18756-5-HAD-001 HAZ Dossier - Katherine Off-Take SS Rev 0 - August 2015VivianNo ratings yet

- Global Fire Pump Model Numbers PDFDocument2 pagesGlobal Fire Pump Model Numbers PDFibharNo ratings yet

- Butterfly ValveDocument4 pagesButterfly ValveghjtyuNo ratings yet

- SWP-29 Operation & Maintenance of Air CompressorDocument2 pagesSWP-29 Operation & Maintenance of Air CompressorHassan AbdullahNo ratings yet

- TK - Artificial Lift MethodDocument32 pagesTK - Artificial Lift MethodChisya Ayu PuspitaweniNo ratings yet

- Thermalfluid Lab - MEC 554 / LSRC / SCA Rev. 01-2017: Flow Characteristic Through The Convergent-Divergent DuctDocument27 pagesThermalfluid Lab - MEC 554 / LSRC / SCA Rev. 01-2017: Flow Characteristic Through The Convergent-Divergent DuctAhmad SyamilNo ratings yet

- Carbon, Alloy and Stainless Steel Pipes - ASME/ANSI B36.10/19Document4 pagesCarbon, Alloy and Stainless Steel Pipes - ASME/ANSI B36.10/19stvirtueNo ratings yet

- Ambica Enterprises: Bhagyashree SWR Price List Date:-15-08-2020Document5 pagesAmbica Enterprises: Bhagyashree SWR Price List Date:-15-08-2020Parth DamaNo ratings yet

- Scheda-Tec HN1 SS Rev.2.1 PDFDocument4 pagesScheda-Tec HN1 SS Rev.2.1 PDFRoger HuancaNo ratings yet