Professional Documents

Culture Documents

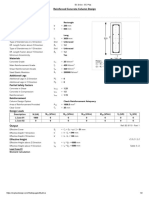

150x100x10UA STANDARD LINTEL 3.6m

Uploaded by

Terry CheukOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

150x100x10UA STANDARD LINTEL 3.6m

Uploaded by

Terry CheukCopyright:

Available Formats

L1 Lintel Angle Supporting Brick Work Only

Wall type Single Leaf: 2.2 kN/m2

Opening Span: 3.6 m (maximum span)

Height of wall above: 0.6 m

Lintel self-weight: 0.18 kN/m (150x100x10 UA)

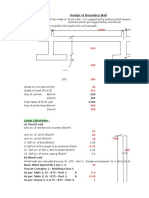

Dead load G = w wall + w Roof + w lintel

= 1.50 (kN/m)

STRENGTH DESIGN LOAD

w* = 1.25G

= 1.88 (kN/m)

SERVICEABILITY

w= G

= 1.50 (kN/m)

FROM AISC CAPACITY TABLES

ALLOWABLE MAXIMUM DESIGN kN/m FOR STRENGTH 26.16kN 7.27 (kN/m)

=

3.6m

ALLOWABLE kN/m SERVICEABILITY DEFLECTION (SPAN/500) 9.42kN 2.62 (kN/m)

=

3.6m

THEREFORE 7.27 kN/m > 1.88 kN/m O.K FOR STRENGTH LOADING

THEREFORE 2.62 kN/m > 1.50 kN/m O.K FOR SERVICEABILITY LOADING

ADOPT 150x100x10 UA AS SUPPORTING LINTEL L1

WITH 200mm (MIN) END BEARING LONG LEG UP

TO SUPPORT BRICK WORK ONLY

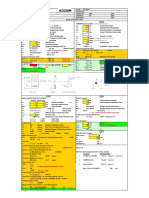

T-LINTEL DESIGN AS PER AS 4100 STRUCTURAL SYSTEMS PTY LTD

SECTION TYPE : 0 ( 0 ="Tee", 1= COMPOSITE)

DESCRIPTION : 250 X 10PL + 300 X 10PL Designed : RR

MATERIAL PROPERTIES GEOMETRY

Capacity factor phi 0.9

Steel grade G 500 Gross section area A (mm2) 5500

Top flange t1 (mm) 0 Overall depth do (mm) 260

b1 (mm) 0 Centroid coordinates y (mm) 195.90909091

fy (MPa) 320 x (mm)

fu (MPa) 430 Moment of inertia Ix (mm4) 3.61E+07

Web t w(mm) 10 Iy (mm4) 2.25E+07

dw (mm) 250 Elastic section modulus Zx,top (mm3) 1.84E+05

fy (MPa) 310 Zx,bott (mm3) 5.63E+05

fu (MPa) 430 Warping moment of inertia Iw (mm4) 0

Bottom flange t2 (mm) 10 Torsion constant J (mm4) 1.83E+05

b2 (mm) 300 Position of the neutral axis yn (mm) 9.17

fy (MPa) 310 Plastic modulus S (mm3) 3.27E+05

fu (MPa) 430 Distance between flange centroids df (mm) 255

Modulus of elasticity E (MPa) 200000 Coeficient alpha 1 Ref. H6.11

Shear modulus G (MPa) 80000 Coordinate of the shear centre yo (mm) 59.090909091

Density (kN/mc) 78.5 Monosymmetry constant - beta x -165.64 5.6.1.2 (ii)

DESIGN LOADS CHECKS

SERVICEABILITY SERVICEABILITY OK

Span L (m) 3.6

Udl w* (kN/m) 1.50 Deflection Dmax (mm) 0.45

Point load P1 P1 (kN) 0

P1 location from left (m) 0 STRENGTH Section bending capacity OK

Point load P2 P2 (kN) 0 Member bending capacity OK

P2 location from left (m) 0

Deflection-ratio of span 500 Element slendernes - top plate lambda e_tp 0 5.2.2

Plasticity limit - top plate lambda ep_tp 9 T.5.2 & yn

STRENGTH Yield limit - top plate lambda ey_tp 16 T.5.2 & yn

Span L (m) 3.6 lambda e_tp/lambda ey_tp 0.00

Udl w* (kN/m) 1.88

Point load P1 P1 (kN) 0 Element slenderness - web lambda e_w 28 5.2.2

P1 location from left (m) 0 Plasticity limit - web lambda ep_w 8 T.5.2 & yn

Point load P2 P2 (kN) 0 Yield limit - web lambda ey_w 22 T.5.2 & yn

P2 location from left (m) 0 lambda e_w/lambda ey_wp 1.27

Design bending moment M* (kN m) 3.04

Section slenderness lambda s 28

Plasticity limit - section lambda sp 8

Yield limit -section lambda sy 22

Type of section SLENDER 5 5.2.4

Eff. sec. modulus for compact section Zc (mm3) 2.76E+05

Effective section modulus Ze (mm3) 1.15E+05

Section moment capacity phi Ms (kNm) 32.10 5.1

Twist restrain factor kt 1 (T 5.6.3(1))

Load height factor kl 1 (T 5.6.3(2))

Lateral rotation restrain factor kr 1 (T 5.6.3(3))

Effective length Le (mm) 3600

Reference buckling moment Mo (kNm) 77.87 (5.6.1.2. (a))

Moment reduction factor alpha m 1 (T.5.6.1)

Slenderness reduction factor alpha s 0.80 (5.6.1.1. (a))

Member moment capacity phi Mb (kNm) 25.68 5.1

Flange web thickness Root Radius

Size MASS/m depth width thinkness

d bf tf tw r1

kg/m mm mm mm mm mm

380PFC 55.2 380 100 17.5 10 14

300PFC 40.1 300 90 16 8 14

250PFC 35.5 250 90 15 8 12

230PFC 25.1 230 75 12 6.5 12

200PFC 22.9 200 75 12 6 12

180PFC 20.9 180 75 11 6 12

150PFC 17.7 150 75 9.5 6 10

610UB125 125 612 229 19.6 11.9 14

610UB113 113 607 228 17.3 11.2 14

610UB101 101 602 228 14.8 10.6 14

530UB92.4 92.4 533 209 15.6 10.2 14

530UB82 82 528 209 13.2 9.6 14

460UB82.1 82.1 460 191 16 9.9 11.4

460UB74.6 74.6 457 190 14.5 9.1 11.4

460UB67.1 67.1 454 190 12.7 8.5 11.4

410UB59.7 59.7 406 178 12.8 7.8 11.4

410UB53.7 53.7 403 178 10.9 7.6 11.4

360UB56.7 56.7 359 172 13 8 11.4

360UB50.7 50.7 356 171 11.5 7.3 11.4

360UB44.7 44.7 352 171 9.7 6.9 11.4

310UB46.2 46.2 307 166 11.8 6.7 11.4

310UB40.4 40.4 304 165 10.2 6.1 11.4

310UB32 32 298 149 8 5.5 13

250UB37.3 37.3 256 146 10.9 6.4 8.9

250UB31.4 31.4 252 146 8.6 6.1 8.9

250UB25.7 25.7 248 124 8 5 12

200UB29.8 29.8 207 134 9.6 6.3 8.9

200UB25.4 25.4 203 133 7.8 5.8 8.9

200UB22.3 22.3 202 133 7 5 8.9

200UB18.2 18.2 198 99 7 4.5 11

180UB22.2 22.2 179 90 10 6 8.9

180UB18.1 18.1 175 90 8 5 8.9

180UB16.1 16.1 173 90 7 4.5 8.9

150UB18 18 155 75 9.5 6 8

150UB14 14 150 75 7 5 8

NOMINATION OVERALL FLANGE FLANGE WEB DEPTH BTW.

DEPTH WIDTH THICKNESS THICKNESS FLANGES

d (mm) bf (mm) tf (mm) tw (mm) d1 (mm)

150UB14 150 75 7 5 136

THICKNESS WIDTH AREA Ix Iy

(mm) (mm) (mm) (mm 4) (mm 4)

PLATE 10 300 3000 25000 22500000

TOTAL DEPTH 160

TOTAL AREA 4780

Y CENTROID 125.209205

Ix 1.38E+07

Iy 22995000

Zx,top 110493.4002

Zx,bottom 397656.6446

Depth d1/tw (bf-tw) Gross Coordinat coordinat About x-axis

between Area of e of e of shear

Flange Cross centroid centre

Section

d1 Ag XL Xo Ix Zx Sx

mm mm2 mm mm 10 mm4

6

10 mm3

3

10 mm3

3

345 34.5 5.14 7030 27.5 56.7 152 798 946

268 33.5 5.13 5110 27.2 56.1 72.4 483 564

220 27.5 5.47 4520 28.6 58.5 45.1 361 421

206 31.7 5.71 3200 22.6 46.7 26.8 233 271

176 29.3 5.75 2920 24.4 50.5 19.1 191 221

158 26.3 6.27 2660 24.5 50.3 14.1 157 182

131 21.8 7.26 2250 24.9 51 8.34 111 129

572 48.1 5.54 16000 986 3230 3680

572 51.1 6.27 14500 875 2880 3290

572 54 7.34 13000 761 2530 2900

502 49.2 6.37 11800 554 2080 2370

502 52.3 7.55 10500 477 1810 2070

428 43.3 5.66 10500 372 1610 1840

428 47.1 6.24 9520 335 1460 1660

428 50.4 7.15 8580 296 1300 1480

381 48.8 6.65 7640 216 1060 1200

381 50.1 7.82 6890 188 933 1060

333 41.6 6.31 7240 161 899 1010

333 45.6 7.12 6470 142 798 897

333 48.2 8.46 5720 121 689 777

284 42.3 6.75 5930 100 654 729

284 46.5 7.79 5410 86.4 569 633

282 51.3 8.97 4080 63.2 424 475

234 36.6 6.4 4750 55.7 435 486

234 38.4 8.13 4010 44.5 354 397

232 46.4 7.44 3270 35.4 285 319

188 29.8 6.65 3820 29.1 281 316

188 32.3 8.15 3230 23.6 232 260

188 37.5 9.14 2870 21 208 231

184 40.9 6.75 2320 15.8 160 180

159 26.5 4.2 2820 15.3 171 195

159 31.8 5.31 2300 12.1 139 157

159 35.3 6.11 2040 10.6 123 138

136 22.7 3.63 2300 9.05 117 135

136 27.2 5 1780 6.66 88.8 102

GROSS Ix Iy

SEC. AREA

Ag (mm 4) (mm 4)

1780 6660000 495000

t x-axis About y-axis Torsion Warping

constant Constant

rx Iy Zyr Zyl Sy ry J Iw

mm 10 mm4

6

103mm3 103mm3 10 mm3

3

mm 10 mm4

3

10 mm6

9

147 6.48 89.4 236 161 30.4 472 151

119 4.04 64.4 148 117 28.1 290 58.2

99.9 3.64 59.3 127 107 28.4 238 35.9

91.4 1.76 33.6 77.8 61 23.5 108 15

80.9 1.65 32.7 67.8 58.9 23.8 101 10.6

72.9 1.51 29.9 61.5 53.8 23.8 81.4 7.82

60.8 1.29 25.7 51.6 46 23.9 54.9 4.59

249 39.3 343 343 536 49.6 1560 3450

246 34.3 300 300 469 48.7 1140 2980

242 29.3 257 257 402 47.5 790 2530

217 23.8 228 228 355 44.9 775 1590

213 20.1 193 193 301 43.8 526 1330

188 18.6 195 195 303 42.2 701 919

188 16.6 175 175 271 41.8 530 815

186 14.5 153 153 238 41.2 378 708

168 12.1 135 135 209 39.7 337 467

165 10.3 115 115 179 38.6 234 394

149 11 128 128 198 39 338 330

148 9.6 112 112 173 38.5 241 284

146 8.1 94.7 94.7 146 37.6 161 237

130 9.01 109 109 166 39 233 197

129 7.65 92.7 92.7 142 38.3 157 165

124 4.42 59.3 59.3 91.8 32.9 86.5 92.9

108 5.66 77.5 77.5 119 34.5 158 85.2

105 4.47 61.2 61.2 94.2 33.4 89.3 65.9

104 2.55 41.1 41.1 63.6 27.9 67.4 36.7

87.3 3.86 57.5 57.5 88.4 31.8 105 37.6

85.4 3.06 46.1 46.1 70.9 30.8 62.7 29.2

85.5 2.75 41.3 41.3 63.4 31 45 26

82.6 1.14 23 23 35.7 22.1 38.6 10.4

73.6 1.22 27.1 27.1 42.3 20.8 81.6 8.71

72.6 0.975 21.7 21.7 33.7 20.6 44.8 6.8

72 0.853 19 19 29.4 20.4 31.5 5.88

62.8 0.672 17.9 17.9 28.2 17.1 60.5 3.56

61.1 0.495 13.2 13.2 20.8 16.6 28.1 2.53

Calculating Design Bending Moment

span 3.6 m

UDL 1.875 kN/m

POINT LOAD

1, 0 kN, at 0 m M*= 0 kN-m

2, 0 kN, at 0 m M*= 0 kN-m

Span locat UDL (kN-mP1 (kN-m) P2 (kN-m) Total Moment

0 0 0 0 0

0.18 0.577125 0 0 0.577125

0.36 1.0935 0 0 1.0935

0.54 1.549125 0 0 1.549125

0.72 1.944 0 0 1.944

0.9 2.278125 0 0 2.278125

1.08 2.5515 0 0 2.5515

1.26 2.764125 0 0 2.764125

1.44 2.916 0 0 2.916

1.62 3.007125 0 0 3.007125

1.8 3.0375 0 0 3.0375

1.98 3.007125 0 0 3.007125

2.16 2.916 0 0 2.916

2.34 2.764125 0 0 2.764125

2.52 2.5515 0 0 2.5515

2.7 2.278125 0 0 2.278125

2.88 1.944 0 0 1.944

3.06 1.549125 0 0 1.549125

3.24 1.0935 0 0 1.0935

3.42 0.577125 0 0 0.577125

3.6 0 0 0 0

Total Applied Moment= 3.0375 kN-m

Calculate Deflection

Calculating Design Bending Moment

span 3.6 m

UDL 1.5 kN/m

POINT LOAD

1, 0 kN, at 0 mm b= 3600

2, 0 kN, at 0 mm b= 3600

Span locat UDL P1 P2 Total Deflection (mm)

0 0.00 0.00 0.00 0.00

0.18 0.07 0.00 0.00 0.07

0.36 0.14 0.00 0.00 0.14

0.54 0.21 0.00 0.00 0.21

0.72 0.27 0.00 0.00 0.27

0.9 0.32 0.00 0.00 0.32

1.08 0.37 0.00 0.00 0.37

1.26 0.41 0.00 0.00 0.41

1.44 0.43 0.00 0.00 0.43

1.62 0.45 0.00 0.00 0.45

1.8 0.45 0.00 0.00 0.45

1.98 0.45 0.00 0.00 0.45

2.16 0.43 0.00 0.00 0.43

2.34 0.41 0.00 0.00 0.41

2.52 0.37 0.00 0.00 0.37

2.7 0.32 0.00 0.00 0.32

2.88 0.27 0.00 0.00 0.27

3.06 0.21 0.00 0.00 0.21

3.24 0.14 0.00 0.00 0.14

3.42 0.07 0.00 0.00 0.07

3.6 0.00 0.00 0.00 0.00

Total Deflection = 0.45 mm

You might also like

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- FLAT BAR DesignDocument8 pagesFLAT BAR DesignTerry CheukNo ratings yet

- Slab DesignDocument9 pagesSlab Designsuleiman.ahNo ratings yet

- Etabs Column Design MT CalculationDocument2 pagesEtabs Column Design MT CalculationAung SoneNo ratings yet

- Column DesignDocument2 pagesColumn Designjohnstruct archNo ratings yet

- Aci 95Document14 pagesAci 95Joseph AsfourNo ratings yet

- Design of RCC Deck Slab:: 1. Material DetailsDocument5 pagesDesign of RCC Deck Slab:: 1. Material DetailsAnonymous wosn1lyNo ratings yet

- Column Design With P-DeltaDocument2 pagesColumn Design With P-DeltaAKSNo ratings yet

- Design of Slab: Slab Unit S1 S2 S3Document3 pagesDesign of Slab: Slab Unit S1 S2 S3jyoti bhilaweNo ratings yet

- My 2 Way Slab ExcelDocument18 pagesMy 2 Way Slab ExcelURVESHKUMAR PATELNo ratings yet

- Compression Member LSMDocument1 pageCompression Member LSMSuman NakarmiNo ratings yet

- Anchor Bolt Size Check For Legged Supported Vessels: Item No.: Active CarbonDocument2 pagesAnchor Bolt Size Check For Legged Supported Vessels: Item No.: Active Carbonmih150% (2)

- ETABS 20.0 Column ReportDocument4 pagesETABS 20.0 Column Reportkheang amgNo ratings yet

- Strut Analysis and Design at - 0.5Document4 pagesStrut Analysis and Design at - 0.5SGOCTNo ratings yet

- Etabs 18.1 PDFDocument2 pagesEtabs 18.1 PDFBißék ŚílwàlNo ratings yet

- Core Wall DesignDocument10 pagesCore Wall Designhala_azhari50% (2)

- BS5400 R.C Design With Crack WidthDocument9 pagesBS5400 R.C Design With Crack WidthWangTF100% (4)

- ETABS Concrete Frame Design: IS 456:2000 Column Section DesignDocument2 pagesETABS Concrete Frame Design: IS 456:2000 Column Section DesignSubhekshya ShresthaNo ratings yet

- Design of Slender Column @ (Column A-1) : Summary ResultsDocument6 pagesDesign of Slender Column @ (Column A-1) : Summary ResultsGAYSON BULFANo ratings yet

- Shear Wall DesignDocument6 pagesShear Wall DesignSreehari Ashok100% (1)

- S1, S2 - S3 - S4 - MergedDocument4 pagesS1, S2 - S3 - S4 - Mergedselvakumar sNo ratings yet

- Channel Steel Beam Torsion Design (EN1993)Document5 pagesChannel Steel Beam Torsion Design (EN1993)Anupam AjayanNo ratings yet

- ETABS Concrete Frame Design: ETABS 20.1.0 License # 1PWEY5GKVXGJ5BPDocument1 pageETABS Concrete Frame Design: ETABS 20.1.0 License # 1PWEY5GKVXGJ5BPTamilselvi MNo ratings yet

- Design One Way SlabDocument22 pagesDesign One Way Slabjohn rey toledoNo ratings yet

- Civil Structural CalculationsDocument2 pagesCivil Structural Calculations3d arch viewsNo ratings yet

- Sheet Pile Design: Fspiii S275 Hot RolledDocument1 pageSheet Pile Design: Fspiii S275 Hot Rolledhessian123No ratings yet

- MiLA Structure Pile Cap Moment Design For One PileDocument3 pagesMiLA Structure Pile Cap Moment Design For One PileLim Wee BengNo ratings yet

- Shear Wall Sample Design CalculationsDocument2 pagesShear Wall Sample Design CalculationsRohan DharmadhikariNo ratings yet

- Appendix A.1: Monorail Beam Design With 3MT SWL, S2 Type (Fy 250 Mpa)Document10 pagesAppendix A.1: Monorail Beam Design With 3MT SWL, S2 Type (Fy 250 Mpa)sundarNo ratings yet

- Design of Pot Ptfe Bearing (Free Bearing) As Per Irc 83:2002 (Part 3)Document7 pagesDesign of Pot Ptfe Bearing (Free Bearing) As Per Irc 83:2002 (Part 3)DPJAIN INFRASTRUCTURENo ratings yet

- Design of ScaffoldingDocument9 pagesDesign of ScaffoldingdfdgggNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 18EMACAKL7JTANKDocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 18EMACAKL7JTANKSanjeev SanjeevNo ratings yet

- Base Plate Design PDFDocument1 pageBase Plate Design PDFmaheshbandhamNo ratings yet

- Appendix B 1 Spread Footing Verification: Pad Footing: Axis A To C (Except Axis 5/C and 8/C) (Section 1.1)Document7 pagesAppendix B 1 Spread Footing Verification: Pad Footing: Axis A To C (Except Axis 5/C and 8/C) (Section 1.1)Civil Mex100% (1)

- TCC63 Core Wall DesignDocument12 pagesTCC63 Core Wall DesignMario Sajulga Dela CuadraNo ratings yet

- Is IsolatedDocument21 pagesIs IsolatedRoshan KejariwalNo ratings yet

- Boundray Wall Design Data Ganj BasodaDocument6 pagesBoundray Wall Design Data Ganj BasodaShubham KhareNo ratings yet

- 8.arch Main MemberDocument3 pages8.arch Main MembervibishnanNo ratings yet

- R.simple Pad FootingDocument4 pagesR.simple Pad FootingRajen Y. DhariaNo ratings yet

- Design of Two-Way Slab: X y y XDocument5 pagesDesign of Two-Way Slab: X y y XNitin BhatiNo ratings yet

- BS5400-R-C-Design-With-Crack-Width SampleDocument1 pageBS5400-R-C-Design-With-Crack-Width SampleAlden CayagaNo ratings yet

- 7tc1 Top FixedDocument2 pages7tc1 Top FixedEmily ShumNo ratings yet

- Lateral Load Carrying CapacityDocument8 pagesLateral Load Carrying Capacityaditya gairNo ratings yet

- 2 Way Slab DesignDocument6 pages2 Way Slab DesignAditya singhNo ratings yet

- Load DistributionsDocument22 pagesLoad DistributionsMuhammad SafdarNo ratings yet

- Villa Assaf ReportDocument37 pagesVilla Assaf ReportReda AtianNo ratings yet

- Slab DesignDocument54 pagesSlab DesignKolen LalongisipNo ratings yet

- Axis: G Storey: 1: Bending (Top Edge) ..Document38 pagesAxis: G Storey: 1: Bending (Top Edge) ..ariesibaraniNo ratings yet

- SB3Document1 pageSB3abhijitkolheNo ratings yet

- Steel Column Design (EN1993)Document8 pagesSteel Column Design (EN1993)Bernard KiruiNo ratings yet

- Analysis & Design By: Er. Bishnu Pandey Civil Engineer NEC Regd. No. 8547 "A"Document5 pagesAnalysis & Design By: Er. Bishnu Pandey Civil Engineer NEC Regd. No. 8547 "A"Santosh BasnetNo ratings yet

- Axis: 1 Storey: 2: Bending (Top Edge) ..Document52 pagesAxis: 1 Storey: 2: Bending (Top Edge) ..Okechukwu BenjaminNo ratings yet

- Steel CalcsDocument3 pagesSteel Calcsloc khaNo ratings yet

- Development of Maa Samleswari at Sambalpur Design of Slab - Pilgrim Facility Two Way SlabDocument2 pagesDevelopment of Maa Samleswari at Sambalpur Design of Slab - Pilgrim Facility Two Way Slabselvakumar sNo ratings yet

- 2.2.1 - DQR EM Capacity Rev BDocument61 pages2.2.1 - DQR EM Capacity Rev BSANDS ENGINEERING DESIGNS & CONSTRUCTION CO. LTD.No ratings yet

- Check Deflection For Beams (R-Section) : InputsDocument1 pageCheck Deflection For Beams (R-Section) : InputsOmar SalahNo ratings yet

- Short Span Coefficient: (Alpha - X: Depth Ok Move OnDocument4 pagesShort Span Coefficient: (Alpha - X: Depth Ok Move OnAmok BajracharyaNo ratings yet

- ETABS 2015 15.1.0-Design DetailsDocument2 pagesETABS 2015 15.1.0-Design DetailsdenyfateNo ratings yet

- The Purpose of This Worksheet Is To Design The Stairway From EL (+) 1500 To EL (+) 6500 From The Boatlanding To The JacketDocument10 pagesThe Purpose of This Worksheet Is To Design The Stairway From EL (+) 1500 To EL (+) 6500 From The Boatlanding To The JacketThomas StephenNo ratings yet

- Design of Two Way Slab: Project Detail: Slab IdDocument6 pagesDesign of Two Way Slab: Project Detail: Slab Idmaheshu78No ratings yet

- Tdu 2023 - All Stages Map - MenDocument1 pageTdu 2023 - All Stages Map - MenTerry CheukNo ratings yet

- BALCONY INSTRUCTIONS Waterproofing Under TilesDocument2 pagesBALCONY INSTRUCTIONS Waterproofing Under TilesTerry CheukNo ratings yet

- Upgrade Online Licence Application ELAF-137872-BLD: CLIENT ID: 726580LDocument7 pagesUpgrade Online Licence Application ELAF-137872-BLD: CLIENT ID: 726580LTerry CheukNo ratings yet

- 0 6mHDocument1 page0 6mHTerry CheukNo ratings yet

- CJ LocationDocument1 pageCJ LocationTerry CheukNo ratings yet

- Stair Stringer DesignDocument2 pagesStair Stringer DesignTerry CheukNo ratings yet

- Structural Design Calculation ChecklistDocument2 pagesStructural Design Calculation ChecklistTerry CheukNo ratings yet

- SHS Column DesignDocument14 pagesSHS Column DesignTerry CheukNo ratings yet

- BalustradeDocument10 pagesBalustradeTerry CheukNo ratings yet

- AS 3798 2007 Guidelines On Earthworks For Commercial and Residential Developments.Document49 pagesAS 3798 2007 Guidelines On Earthworks For Commercial and Residential Developments.Terry CheukNo ratings yet

- Rapt HelpDocument738 pagesRapt HelpTerry CheukNo ratings yet

- Spacegass LectureDocument20 pagesSpacegass LectureTerry CheukNo ratings yet

- Balustrade Cals and DetailDocument5 pagesBalustrade Cals and DetailTerry CheukNo ratings yet

- ColdSteel Manual V120Document87 pagesColdSteel Manual V120Terry CheukNo ratings yet

- Campus Planning: Submitted by Devika S Nath Elvia Raju Nubiya Elsa AniDocument7 pagesCampus Planning: Submitted by Devika S Nath Elvia Raju Nubiya Elsa AniElvia Raju100% (1)

- Result of Inspection: ConclusionDocument5 pagesResult of Inspection: ConclusionBayu Aringga putra100% (1)

- TSA Spec-2Document9 pagesTSA Spec-2Subodh KulkarniNo ratings yet

- A Study of Inbound Logistics Mode Based On JIT Production in Cruise Ship ConstructionDocument18 pagesA Study of Inbound Logistics Mode Based On JIT Production in Cruise Ship ConstructionSandraNo ratings yet

- A Comparison of The Thermal Conductivity of Oil Palm Shell Foamed Concrete With Conventional MaterialsDocument8 pagesA Comparison of The Thermal Conductivity of Oil Palm Shell Foamed Concrete With Conventional Materialsamirdz76No ratings yet

- RA 024 Risk Assessment - Precast Concrete WorksDocument14 pagesRA 024 Risk Assessment - Precast Concrete Worksthomson78% (9)

- Spek Nicosh MOT R. KhususDocument4 pagesSpek Nicosh MOT R. KhususYuni MamaNo ratings yet

- Table DataDocument83 pagesTable DatayaniNo ratings yet

- FIDIC Conditions of Contract Planning, Claims Management & The Resolution of Disputes.Document3 pagesFIDIC Conditions of Contract Planning, Claims Management & The Resolution of Disputes.adamcyzNo ratings yet

- Astm A529 1972Document5 pagesAstm A529 1972dharlanuctcom0% (1)

- Soil-Structure Interaction.Document47 pagesSoil-Structure Interaction.YasirMahmoodNo ratings yet

- Detailed Estimate of Stree Shakti BhavanDocument9 pagesDetailed Estimate of Stree Shakti BhavanObuladas MNo ratings yet

- Fisher 6353 Pilot 3 To 40 PsigDocument8 pagesFisher 6353 Pilot 3 To 40 PsigJoshua Garcia CarrilloNo ratings yet

- Spare Parts Catalogue: SA 841 Separation SystemDocument80 pagesSpare Parts Catalogue: SA 841 Separation SystemMariusBelecciuNo ratings yet

- Louis I KahnDocument27 pagesLouis I KahnGungun TcdNo ratings yet

- Design of The Coatzacoalcos Immersed Tunnel 2Document1 pageDesign of The Coatzacoalcos Immersed Tunnel 2Trong TranNo ratings yet

- Dispute in Construction - ContrDocument8 pagesDispute in Construction - Contrsubhash kumarNo ratings yet

- FMC Flowline Products and Services CatalogDocument74 pagesFMC Flowline Products and Services Catalogisamelgq100% (1)

- TAM Splash Guard BrosurDocument6 pagesTAM Splash Guard Brosurpangalengan zaxNo ratings yet

- LA Ravi Sir NC 2Document10 pagesLA Ravi Sir NC 2mangalamtestingbureaNo ratings yet

- 340-Article Text-771-1-10-20170803 PDFDocument11 pages340-Article Text-771-1-10-20170803 PDFKevin DizonNo ratings yet

- Complete RDSO BS 14 Durability GuideDocument131 pagesComplete RDSO BS 14 Durability Guideqmsudhir100% (1)

- 2acaterpillar Tamir Takimlari 2022 02 PDF - 1655288802Document10 pages2acaterpillar Tamir Takimlari 2022 02 PDF - 1655288802Rakhitha Waragoda0% (1)

- TLE-Grade 12 MELCDocument8 pagesTLE-Grade 12 MELCRex Chambers Ladao91% (11)

- Gedung Sate Teks DeskriptifDocument2 pagesGedung Sate Teks DeskriptifHumaira Adiba100% (1)

- Contested Incrementalism: Elemental's Quinta Monroy Settlement Fifteen Years OnDocument11 pagesContested Incrementalism: Elemental's Quinta Monroy Settlement Fifteen Years OnVanja IvkovicNo ratings yet

- What Is Low Cost HousingDocument19 pagesWhat Is Low Cost Housingsurbhi aggarwalNo ratings yet

- TRITECH COMProfile 09-026-2022Document55 pagesTRITECH COMProfile 09-026-2022Christopher Devi G. DomingoNo ratings yet

- 1 .2 Ultrapure Fittings: Fittings With Either Tri-Weld® For Orbital Welding Connections. Line in Compliance CurrentDocument41 pages1 .2 Ultrapure Fittings: Fittings With Either Tri-Weld® For Orbital Welding Connections. Line in Compliance CurrentAtul SharmaNo ratings yet

- Chapter 5Document59 pagesChapter 5Haile GuebreMariamNo ratings yet