Professional Documents

Culture Documents

OMS-720 User's Manual

Uploaded by

paul masakuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OMS-720 User's Manual

Uploaded by

paul masakuCopyright:

Available Formats

ELEVATOR OVERLOAD MEASUREMENT SYSTEM ELEVATOR OVERLOAD MEASUREMENT SYSTEM

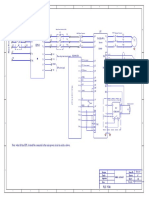

2. Interfaces of the main controller

OMS-720 Elevator overload measurement system

OMS-720 Control unit

User's Manual

① ② ③ ④ ⑤

1. Appearance and installation dimensions of the main controller

COM0 Y01 Y02 Y03 OV+ OV- P1 P2

OMS-720

⑶ ⑴ :Display window

Heavy load contact

heavy and overload contact

Analog voltage output

Overload contact

Light load contact

Analog voltage output

⑵ :Display in percentage

Common terminal for light

⑴

⑵ ⑶ :Display in weight

Power supply

⑻ ⑼ ⑷:Up key;

AC/DC16-45V

negative

Prolonged press to speed up

positive

⑷

⑸:Down key;

⑺ ⑹

Prolonged press to speed up

⑸

⑹ :Confirm NOTES:

⑾ ⑺ :Exit ① :Acts when measured weight≥rated load×(1+P01%) ;

② :Acts when rated load×P08%≤measured weight≤rated load×(1+P01%);

③ :Acts when 0%≤measured weight ≤rated load×P07%;

⑻:No load learning

⑽ ④ :Analog voltage output changes linearly from -10V to +10V or 0V to +10V according to P06 setting when load varies.

⑤:Please make sure the working voltage is AC/DC16V-45V before normal operation;

⑼:Rated load learning

⑽ :Input and output contacts

⑾ : Ф4 screw fitting

45mm

72mm

103mm

45mm

ANT ELECTRONIC CO.,LTD(NINGBO,CHINA)

Version :V1.8

SUMMIT ELECTRONIC CO.,LTD(NINGBO,CHINA)

Tel: +86-0574-87164091/87164092

Fax: +86-0574-87150953

Web: www.summit3e.com www.ant-china.com

Email: sales@summit3e.com

ELEVATOR OVERLOAD MEASUREMENT SYSTEM ELEVATOR OVERLOAD MEASUREMENT SYSTEM

3. The menu structure and parameter setting

Parameter range Default

Parameter Meanings

value

Parameter Parameter range Default

Meanings

value

00– Contact closes, releases on overload ;

Heavy load contact 01– Contact releases, closes on overload ;

00~20 – Indicates 0~20%, 10– Contact closes, no change on overload ; 10

setting;

Overload range over load relay acts when 11– Contact releases, no change on overload ;

measuring load exceeds 10

Setting;

(1+P01%) rated load ;

Spare 01

Bouncing sensitivity 00~10 – The sensitivity decreases

05

setting; with the value of P02 increasing; 0000~9500 – Input correction code

Sensor`s correction

during rate load learning with no load

code or any known or input weight during rated load 0000

weight; learning with known weight in KG ;

Spare 00

0000~9500 – Input rated load in

Rated load value KG; In rated load learning with

setting; full weight, 0000 can be used to 0000

Delay time setting

treat the full weight as rated load;

for overload relay 00~05 – Indicates 0~5 seconds; 02

release;

Spare 01

Mode setting for rated 00 – Learning with full weight load;

03 – Learning with no weight load; 00

load learning;

04 – Learning with any known weight load;

Spare 00

00 – Analog voltage output

Analog voltage output -10V to +10V;

01 – Analog voltage output 00

range setting;

0V to +10V;

Spare 50

05~75 – Indicate 5~75%, light

Light load range load relay acts when measuring

setting; load is in range of 0% to P07% 05

rated load;

Spare 10

90~99 – Indicate 90~99%, heavy

Heavy load range load relay acts when load is in

90

setting; range of P08% to (1+P01%) rated 00 – Contact releases when in

load; Overload contact overload range;

00 – Contact closes when in setting; 01– Contact close when in 00

Light load contact light load range; overload range;

01– Contact releases when in 00

setting;

light load range;

Version

ELEVATOR OVERLOAD MEASUREMENT SYSTEM ELEVATOR OVERLOAD MEASUREMENT SYSTEM

4. The display codes and their meanings 7. Flow chart for device initialization

Codes Explanation States Measuring state.

No key pressed in 5s.

No load learning .

Twinkle for code entrance; Code entrance Move car to

If car is on lowest level.

lowest level? Take load off.

Twinkle for initialization; Initialization state (No)

If the load taken off?

(Yes) (No)

Press [RESET]+[OK]

Parameter setting; Initialization state waiting for

Adjust the distance

(Yes) between magnet

pass code. and the thecontroller.

Value of Pn (n = 01-19) ; Initialization state Press [+] or [-]

If display ?

(No)

Weight: 1080 kilogram; Measuring state Display pass code.

Press [OK] or

(Yes) toggle X06 signal for 5s.

Percentage display of 101%; Measuring state Press [+] or [-] No load learning

done.

If pass code is 11? (No)

Overload; Measuring state (Yes) Press [B]

Waiting for rated

(Yes) Press [OK]

Ready for no load learning; Initialization state load learning.

Ready for

No load learning complete; Initialization state initialization.

Add more weight.

If the weight enough? (No)

Ready for rated load learning ; Initialization state Press [A]

If P1-19 needs to Press [OK] or

be modified? (No) (Yes) toggle X06 signal for 5s.

Rated load learning complete; Initialization state Rated load

(Yes) Press [+] or [-] learning done.

Error code; Initialization state Press [RESET]

Display P1-P19.

Measuring state.

5. Common trouble code and countermeasure to the trouble Press [OK]

Display value of P1-P19.

Codes Phenomena/explanation Countermeasure

Press [+] or [-]

Sensor not installed properly, Check for installation or wiring If the value wanted?

wiring wrong, or used weight error; use heavier weight on rated (No)

too light during initialization; load learning;

(Yes) Press [OK]

No no load learning performed Perform no load learning before rated

Display P1-P19.

during initialization process; load learning process;

Mistake with front and Ajust front and back side, make the If other Press[A]

back side of magnet; front side be directed at the sensor; parameters need to

be modified? (No)

The shift position is too near; The distance between the controller (Yes) Press [+] or [-]

and the magnet is too near;

The distance between the controller

The shift position is too far;

and the magnet is too far; ■Hotkey for prompt tare clearing

(In this case, change 8% to 0% in empty load)

Percentage Percentage

6. Procedures for device initialization

This system provides 2 initialization methods:

Initialization with full weight load : if there is enough weight on site and high

measurement precision required.

Press [A] button for NOTE: before clearing tare, please make sure that the equipment

I nitialization with a ny known weight load: if there is not enough weight 5 seconds and the

on site and high measurement precision required. system clears tare . has no load, good for both percentage and weight displays.

According to on site situation, one of the following procedures can be used ■Fast data modification

for Initialization, and following examples may be referred to accordingly. (This case is for changing display of 380KG to real display of 400KG)

★Initialization with full weight load Weight Weight Weight Weight

★Initialization with any known weight load

Other fast modification:

NOTE: before fast data modification,

■Hotkey for prompt tare clearing please make sure the real load

■Fast data modification weight, good for both percentage

and weight.

■Fast parameter modification press [B] button until

flashing for parameter

Press [+] or [-] to change

weight value (in this case

Press [OK] button

to save values.

■Reset to factory setting modification. change 380KG to400KG)

★Initialization with full weight rated load

(In this case, rated load is 2000KG and weight is 2000KG)

Waiting for code Code display Initialization ready Parameter Value of P05 Value of P05 Parameter No-load learning No-load learning Learning finish Rated load learning Initialization complete

Adjust the distance

between magnet

and the controller.

No action in

5 seconds

Press [OK] and [RESET] Press [OK] to finish noload

simultaneously to enter Press [OK]. Press [A] to start no Press [OK] to finished rated Press [RESET]

Press [+]or[-] to choose press [OK] The lifting load is

load earning process . no learning process,make sure Press [B] to start load learning. (please make

initialization, would go

back to measuring state the code 11. It will return

The code is Press [OK] to Press [+]or[-] to to finish load and Adjust

(Press [A] only when the distance between there is no load and make it rated load learning sure the lifting load is the full to exit

right and the Press [+] to display the change the P05 display two lines before process with full initialization.

if there is no action in to display weight if there system is ready modification the elevator is at the magnet and the weight. In this example the

is no action in 5 seconds. choose P05. value of P05. value to 00. of P05. lowest floor) pressing [OK]) weight load.

5 seconds. for initialization. controller. full weight load is 2000KG.

NOTE: initialization with full weight , P05 should be 00. The equipment should lift rated load. Input rated load value to P13, press [OK] to switch display in percentage or in weight .

★Initialization with known weight load

(In this case, weight is 800KG and rated load is 2000KG)

Waiting for code Code display Initialization ready Parameter Value of P05 Value of P05 Parameter Parameter Value of P12 Value of P12 Parameter Parameter

No action in

5 seconds

Press [OK] and [RESET]

simultaneously to enter press [OK] Press [+]or[-] to change the press [OK]

initialization, would go Press [+]or[-] to choose Press [OK]. The Press [OK] to Press [+]or[-] to to finish Press [OK] to value of P12 . (Enter the known to finish

back to measuring state the code 11. It will return code is right and

the system is ready Press [+] to display P05 change the P05 modification Press [+] to display the weight . In this example enter modification Press [+] to

if there is no action in to display weight if there 800kg.)

is no action in 5 seconds. for initialization. choose P05. value. value to 04. of P05. choose P12. value of P12. of P12. choose P13.

5 seconds.

Initialization complete Rated load learning Learning finish No-load learning No-load learning Parameter Value of P13 Value of P13

Adjust the distance

between magnet

and the controller.

Press [OK] to finish noload Press [+]or [-] to enter

Press [RESET] Press [OK] to finished rated Press [B] to start The lifting load is Press [A] to start no

load learning. (please make learning process,make sure no load and Adjust

press [OK] rated load.(Displayed

to exit rated load learning load learning process . to finish Press [OK] to

sure the lifting load is the process with there is no load and make it the distance between (Press [A] only when rated load is 2000

initialization. modification display the

known weight. In this example known weight load. display two lines before magnet and the the elevator is at the Kilogram, can be set

the weight load is 800KG. pressing [OK]) controller. lowest floor) of P13. based on requirements) value of P13.

NOTE: initialization with any known weight, parameter P05 shoud be 04 and P12 and P13 should also be modified. the equipment should lift known weight during rated load learning period. input

rated load value to P13. Press [OK] to switch display in percentage or in weight .

■Fast parameter modification ■Reset to factory setting

(Following is parameter P13 modification procedures)

Waiting for code Code display Initialization ready Parameter Value of P13 Value of P13 Parameter Waiting for code Code display Initialization ready

No action in No action in

5 seconds 5 seconds

Press [OK] and [RESET] Press [+] and [-]

simultaneously to enter Press [RESET] simultaneously to enter Press [+]or[-] to choose

calibration, would go Press [+]or[-] to choose Press [OK]. The Press [OK] to Press [+]or [-] to enter Press [OK] to initialization, would go

to exit the code 11. It will return

back to measuring state the code 11. It will return code is right and rated load.(Displayed finish the P13 back to measuring state Press [OK] to reset

if there is no action in to display weight if there the system is ready . Press [+] to display P13 . rated load is 1000 KG)

initialization .

if there is no action in to display weight if there

to factory setting.

choose P13. modification. 5 seconds. is no action in 5 seconds.

5 seconds. is no action in 5 seconds.

NOTE: procedure is the same for all parameters . data will be saved after press [RESET]. WARNING: after reset, all previous calibration is gone. please make sure before resetting.

-5-

You might also like

- Manual Yasakawa L1000a 48Document48 pagesManual Yasakawa L1000a 48Yok MulyonoNo ratings yet

- HD-One X: 35A/1000V 4A Kaçak Akim RolesiDocument5 pagesHD-One X: 35A/1000V 4A Kaçak Akim Rolesideribe sisayNo ratings yet

- Mikrolift: CAUTION: These Cables Must Be 2,5mm NYAF !Document19 pagesMikrolift: CAUTION: These Cables Must Be 2,5mm NYAF !Dmitriy ShevchenkoNo ratings yet

- Hidral Maintenance HandbookDocument32 pagesHidral Maintenance HandbookBaltija MechanikasNo ratings yet

- HD BE Easy Installation ManualDocument18 pagesHD BE Easy Installation ManualHedefsan TradeNo ratings yet

- SWORD Elevator Product IntroductionDocument47 pagesSWORD Elevator Product IntroductionMohamad Ikhwan100% (7)

- Gdo-D2 Door Operator: Controller Operation ManualDocument17 pagesGdo-D2 Door Operator: Controller Operation ManualTushar Imran100% (2)

- Ctrl70a V101 2019 3 15Document53 pagesCtrl70a V101 2019 3 15Ali DiabNo ratings yet

- Hamcb SwordDocument101 pagesHamcb SwordNaseh Ya NasehNo ratings yet

- Arem Mobile User Manual.V101.enDocument8 pagesArem Mobile User Manual.V101.enmicrocherietNo ratings yet

- Bg101 User Manual1Document22 pagesBg101 User Manual1MikeNo ratings yet

- Di1 (Si210) Di1 (Si210) Elevator Elevator //: T Trouble Shoo Rouble Shooting TingDocument9 pagesDi1 (Si210) Di1 (Si210) Elevator Elevator //: T Trouble Shoo Rouble Shooting TingNadeem KhanNo ratings yet

- User Manual VF7 07 2019 (V7 01 08 01)Document36 pagesUser Manual VF7 07 2019 (V7 01 08 01)paul masakuNo ratings yet

- Qjwb004 2020 English Ver 1Document66 pagesQjwb004 2020 English Ver 1Fauzi AchmadNo ratings yet

- LEHY-MRL Error CodesDocument8 pagesLEHY-MRL Error CodesMohammad HaiderNo ratings yet

- Slow Down Switch AND ROPINGDocument30 pagesSlow Down Switch AND ROPINGEtienneNo ratings yet

- Happy Version New PDFDocument26 pagesHappy Version New PDFJitheshbabu BabuNo ratings yet

- ML60XS UserGuide A1Document5 pagesML60XS UserGuide A1Bojan DrljachaNo ratings yet

- NBSL - Completed Elevator CatalogueDocument45 pagesNBSL - Completed Elevator CatalogueBurhan NafisNo ratings yet

- Number: SJG 08-007: (Electrical Parts)Document49 pagesNumber: SJG 08-007: (Electrical Parts)Tadeo Benegusenga50% (6)

- NICE3000 User Manual. PrefaceDocument184 pagesNICE3000 User Manual. PrefaceОщттнNo ratings yet

- Electric Drawing-FR2000Document19 pagesElectric Drawing-FR2000MuMoMa100% (1)

- Vector Inverter For Lifts With: Asynchronous/Synchronous MotorsDocument52 pagesVector Inverter For Lifts With: Asynchronous/Synchronous Motorspaul masakuNo ratings yet

- 02 IRIS2 - NV - Controller-ENDocument36 pages02 IRIS2 - NV - Controller-ENAhmedNo ratings yet

- EC100 Operation ManualDocument252 pagesEC100 Operation ManualRamananda Muhammad FirmansyahNo ratings yet

- Fuji AF300 G11 Fault - Codes PDFDocument2 pagesFuji AF300 G11 Fault - Codes PDFAshraful ShohagNo ratings yet

- ME-LIFT-P Microprocessor Control User Manual 20071226 PDFDocument38 pagesME-LIFT-P Microprocessor Control User Manual 20071226 PDFKen LeeNo ratings yet

- DOPPLER Series Cabin Assembly SerialsDocument1 pageDOPPLER Series Cabin Assembly Serialsfirasalthiyaby100% (1)

- 3000 MRLDocument23 pages3000 MRLNguyễn Thân100% (1)

- 《NICE3000new电梯一体化控制器用户手册》英文19010735 A00Document367 pages《NICE3000new电梯一体化控制器用户手册》英文19010735 A00Иван АндреевNo ratings yet

- Fuji Driver Gearless EnglishDocument3 pagesFuji Driver Gearless EnglishBojan DrljachaNo ratings yet

- Machine p420p450Document4 pagesMachine p420p450sy_toshibaNo ratings yet

- Eco-Mpu: Application GuideDocument23 pagesEco-Mpu: Application GuideAssir El DjazairiNo ratings yet

- Manual Ecw l200 Load CellDocument15 pagesManual Ecw l200 Load Cellabdul100% (1)

- Mitsuindo Jaya Teknik M3P1 Wering PDFDocument18 pagesMitsuindo Jaya Teknik M3P1 Wering PDFWinNo ratings yet

- TK 103 UserManualDocument8 pagesTK 103 UserManualYusuf OzkayNo ratings yet

- 004 VDL200, Functions Description and Parameters ListDocument112 pages004 VDL200, Functions Description and Parameters Listmohammad ghassanNo ratings yet

- Winone Elevator Connection DiagramDocument40 pagesWinone Elevator Connection DiagramMuhammad Rashid75% (4)

- A6000 Integrated Elevator Controller: QMA (Shanghai) Electric Co., LTDDocument197 pagesA6000 Integrated Elevator Controller: QMA (Shanghai) Electric Co., LTDJesús David Diaz MontesNo ratings yet

- Loadcell DZK-CP MớiDocument12 pagesLoadcell DZK-CP MớiQuang Pham Duy50% (2)

- U-STO Parameter Manual V1.02 EngDocument36 pagesU-STO Parameter Manual V1.02 EngYacine MaricheNo ratings yet

- Braking Resistor For FRENIC-Lift - ECOMSADocument5 pagesBraking Resistor For FRENIC-Lift - ECOMSAsd23100% (1)

- Mldoorplus Automatic Door Control CardDocument4 pagesMldoorplus Automatic Door Control CardDmitriy ShevchenkoNo ratings yet

- Manual Pesacargas OM-560Document2 pagesManual Pesacargas OM-560Jenssy Sayago83% (6)

- BG202-OE31E: 1、Functional keys introductionDocument10 pagesBG202-OE31E: 1、Functional keys introductionQuang Pham DuyNo ratings yet

- HATMSI47 1811 E - OPC LM1 PR - ManualDocument14 pagesHATMSI47 1811 E - OPC LM1 PR - ManualMahran Mastouri100% (1)

- Main Control Board User ManualDocument15 pagesMain Control Board User Manualmohammedalathwary100% (1)

- Mabara Alift V3F Auto Door Down Collective PanelDocument1 pageMabara Alift V3F Auto Door Down Collective Panelخالدعبدالله100% (1)

- 201604201039062023Document205 pages201604201039062023younes100% (2)

- AAD03061D Door Controller Quick GuideDocument9 pagesAAD03061D Door Controller Quick GuidelacNo ratings yet

- AGL 50-OMKAR Controller Parameters - Rev 0Document2 pagesAGL 50-OMKAR Controller Parameters - Rev 0mozhi selvam100% (1)

- BG202 XM Ii (E)Document10 pagesBG202 XM Ii (E)Quang Pham DuyNo ratings yet

- Powernet Elevators BroucherDocument16 pagesPowernet Elevators BroucherDEEPU KRISHNAN0% (1)

- MicelectDocument1 pageMicelectJuanNo ratings yet

- Support-Glcd Cop Lop RevbDocument1 pageSupport-Glcd Cop Lop RevbhabibullaNo ratings yet

- Door Dive: User ManualDocument67 pagesDoor Dive: User ManualRoyal AkashNo ratings yet

- NICE3000new Error Code ENDocument16 pagesNICE3000new Error Code ENBrahim CherguiNo ratings yet

- ServosanDocument4 pagesServosanyounesNo ratings yet

- G&Z SD Card Reconfiguration - V1.1 - enDocument8 pagesG&Z SD Card Reconfiguration - V1.1 - enAbenetherNo ratings yet

- Fegure de 01Document1 pageFegure de 01Raouf ToutouNo ratings yet

- Headlight Door AutoDocument4 pagesHeadlight Door AutoToua YajNo ratings yet

- MC33030 DC Servo Motor Controller/Driver: Marking DiagramsDocument17 pagesMC33030 DC Servo Motor Controller/Driver: Marking DiagramsAndrés ThompsonNo ratings yet

- I-250 Spool Replacement Ver3Document7 pagesI-250 Spool Replacement Ver3paul masakuNo ratings yet

- IValve Pilot FilterDocument2 pagesIValve Pilot Filterpaul masakuNo ratings yet

- Escalator MaintenanceDocument4 pagesEscalator Maintenancepaul masakuNo ratings yet

- Frenic Inverter Pole Tuning ProcedureDocument2 pagesFrenic Inverter Pole Tuning Procedurepaul masakuNo ratings yet