Professional Documents

Culture Documents

T 6000 Dop Eng

Uploaded by

dario_791473996Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T 6000 Dop Eng

Uploaded by

dario_791473996Copyright:

Available Formats

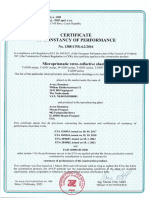

DECLARATION OF PERFORMANCE

Construction Products Regulation 305/2011

No. 6000-1611

High Intensity Prismatic Retroreflective Sheeting:

T-6500 HIP Series

T-6500 HIP Series with OL-2000 Transparent EC Film

T-6500 HIP Series with 4930 Screen Ink

T-6500 HIP Series with UVTS Screen Ink

T-6500 HIP Series with 3801 Black Opaque Film

T-6500 HIP Series with TrafficJet Ecosolvent Ink & Clear

Overlay

T-6500 HIP Series with TrafficJet UV Ink & Clear Overlay

T-6000 HIP Series is a high-quality, 10-year durable, microprismatic retroreflective material with a

pressure sensitive adhesive. This product is intended for use on permanent or temporary highway

safety devices that require robust Class 2 retroreflective performance.

Manufactured by: Avery Dennison, Reflective Solutions

Willem Einthovenstraat 11, 2342 BH 902 Feehanville Rd.

Oegstgeest, The Netherlands Mt. Prospect, IL 60056 USA

Avery Dennison performed factory product control and product sampling per assessment and

verification of constancy of performance under System 1. Silniční vývoj - ZDZ spol. s r. o. Notified

Body 1388 performed initial type testing, inspection of manufacturing facilities and factory products

controls under system 1. Tzus, 060-045345 issued ETA 15/0919 dated 18/09/2017 & ETA 18/0544

dated 15/10/2018& ETA 20/0687, ETA 20/0882 dated 18/01/2021.

Essential Characteristics Performance Assessment Document

Daylight Chromaticity Per Table 3

Luminance Factor Per Table 3

Coefficient of retro-reflection, Per Tables 4 & 5,

Rotational Symmetry Variation < 10%

Impact Resistance No Effect EAD 12001-01-0106,

Visibility after Retroreflection 80% of Initial Requirement September 2016

Weathering,

Natural & Chromaticity &

Accelerated Luminance Per Table 2

Artificial Factor

Adhesion Peel < 50 mm

The performance of T-6500 HIP Series is in conformance with declarations herein when evaluated per

EAD 120001-01-0106. This declaration of performance is issued for performance clarity under the sole

discretion of Avery Dennison.

Signed for on behalf of Avery Dennison by: Lara Pearson, Quality Manager

Date: 02February, 2021, Illinois, USA

Classification: Avery Dennison - Internal

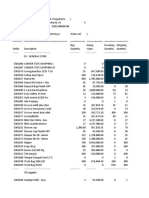

Table 2: Daytime Chromaticity and Luminance Factors A CR1

Colour Box Coordinates Luminance Factor ß

Colour

1 2 3 4

White x 0,355 0,305 0,285 0,335

≥ 0,27

y 0,355 0,305 0,325 0,375

Yellow x 0,545 0,487 0,427 0,465

≥ 0,16

y 0,454 0,423 0,483 0,534

Red x 0,735 0,674 0,569 0,655

≥ 0,03

y 0,265 0,236 0,341 0,345

Orange x 0,631 0,560 0,506 0,570

≥ 0,14

y 0,369 0,360 0.404 0,429

Green x 0,007 0,248 0,177 0,026

≥ 0,03

y 0,703 0,409 0,362 0,399

Green 2 x 0,313 0,313 0,248 0,127

0,01 ≤ β ≤ 0,07

(Worboy Green) y 0,682 0,453 0,409 0,557

Brown x 0,455 0,523 0,558 0,479

0,01 ≤ β ≤ 0,09

y 0,397 0,429 0.394 0,373

Blue x 0,078 0,150 0,210 0,137

≥ 0,01

y 0,171 0,220 0,160 0,038

Grey x 0,355 0,305 0,285 0,335

0,11 ≤ β ≤ 0,18

y 0,355 0,305 0,325 0,375

Black x 0,385 0,275 0,235 0,345

≤0,03

y 0,355 0,250 0,290 0,395

Notes: A – When material is sampled, processed and tested per Avery Dennison Product Data Bulletins,

Instructional Bulletins,and EAD 120001-01-0106, Section 2.2.1.

Classification: Avery Dennison - Internal

Table 3: Daytime Chromaticity and Luminance FactorsA CR2

Colour Box Coordinates Luminance Factor ß

Colour

1 2 3 4

White x 0,305 0,335 0,325 0,295

≥ 0,27

y 0,315 0,345 0,355 0,325

Yellow x 0,494 0,470 0,513 0,545

≥ 0,16

y 0,505 0,480 0,437 0,454

Red x 0,735 0,700 0,610 0,660

≥ 0,03

y 0,265 0,250 0,340 0,340

Orange x 0,631 0,560 0,506 0,570

≥ 0,14

y 0,369 0,360 0.404 0,429

Green x 0,110 0,170 0,170 0,110

≥ 0,03

y 0,415 0,415 0,500 0,500

Green 2 x 0,313 0,313 0,248 0,127

0,01 ≤ β ≤ 0,07

(Worboy Green) y 0,682 0,453 0,409 0,557

Brown x 0,455 0,523 0,479 0,558

0,03 ≤ β ≤ 0,09

y 0,397 0,429 0.373 0,394

Blue x 0,130 0,160 0,160 0,130

≥ 0,01

y 0,090 0,090 0,140 0,140

Grey x 0,305 0,335 0,325 0,295

0,11 ≤ β ≤ 0,18

y 0,315 0,345 0,355 0,325

Black x 0,385 0,300 0,260 0,345

≤0,03

y 0,355 0,270 0,310 0,395

Notes: A – When material is sampled, processed and tested per Avery Dennison Product Data Bulletins,

Instructional Bulletins, and EN 12899-1:2007, Section 4.1.1.3.

Classification: Avery Dennison - Internal

Table 4: Coefficients of Retroreflection1, RA (cd/lux/m2)

RA

Entrance Observati White Yellow Orange Green Red Blue Brow Worb

Angle (β1, on Angle n oy

β2=0°) (α) Green

5° 360 270 145 50 65 30 18 20

30° 0.2° 30 15

170 135 68 25 14 8.5

5° 180 120 65 21 25 14 8 14

0.33°

30° 100 70 40 12 14 8 5 11

5° 150 110 60 21 27 13 7.5 7.5

0.5°

30° 72 54 28 10 13 6 3.5 3.5

5° 35 26 12 4 5.2 2 1 1

1.0°

30° 20 15 6.8 2 3 1 0.6 0.6

Notes: 1 – When material is sampled, processed and tested per Avery Dennison Product Data

Bulletins, Instructional Bulletins, and EAD 120001-01-0106, Section 2.2.3 with averaging of

ε=0° and 90°

Table 5: Coefficients of Retroreflection2, RA (cd/lux/m2)

(Includes RA2/R2 Requirements)

RA

Entrance Observa White Yellow Orange Gree Red Blue Brow Worb Grey

Angle (β1, tion n n oy

β2=0°) Angle Gree

n

(α)

5° 250 170 100 45 45 20 12 20 125

30° 0.2° 150 100 60 25 25 11 8.5 15 75

40° 110 70 29 12 15 8 5 6 55

5° 180 120 65 21 25 14 8 14 90

30° 0.33° 100 70 40 12 14 8 5 11 50

40° 95 60 20 11 13 7 3 5 47

5° 5 3 1.5 0.5 1 0.2 0.2 0.5 2.5

30° 2.0° 2.5 1.5 1 0.3 0.4 - - 0.3 1.2

40° 1.5 1 - 0.2 0.3 - - 0.2 0.7

Notes: 2 – When material is sampled, processed and tested per Avery Dennison Product Data

Bulletins, Instructional Bulletins, and EAD 120001–01–0106, Section 2.2.3 at ε=0° only.

Classification: Avery Dennison - Internal

Table 6: Component Performance Detail

Product

and Product Combination, Color and Detailed Retroreflective

Signing Component

Compone Number Performance

nt Names

T-6500 White

T-6501 Yellow

W-6504 Orange with OL-2000 Clear

T-6500

Native Sheeting T-6505 Blue Per Tables 4 & 5

Series

T-6507 Green

T-6508 Red

T-6509 Brown

OL-2000/1000 Clear applied to White

& Yellow Native Sheeting

OL-2001 Yellow Ƌ

OL-2004 Orange Ƌ

OL-2000

OL-2005 Blue Ƌ

Electronic Cuttable EC Film

OL-2007 Green Ƌ 70% of Tables 4 & 5

Overlay# & 3801

OL-2008 Red Ƌ

Black

OL-2008 Red applied to Yellow

T-6501+

OL-2009 Brown Ƌ

3801 Black^

^Standard Avery Dennison product code is 801, the prefix 3(801) denotes special watermark print for

Germany only

Yellow Ƌ*

Orange with OL-2000 Clear Ƌ

4930 Blue Ƌ

Solvent Screen Ink# 70% of Tables 4 & 5

Series Green Ƌ

Red Ƌ

Red applied to Yellow T-6501,+

Blue

UVTS

Red

UV Screen Ink# with UV 70% of Tables 4 & 5

Red onto Yellow T-6501,+

Clearcoat

Black

Yellow 70% of Tables 4 & 5

Blue

TrafficJet Green

with Red

Digital Printing OL-1000 Red onto T-6501 Yellow

Ecosolvent# or Brown

OL-2000 Worboy Green with OL1000 only

Clear Grey with OL-1000 only

Black

Black onto T-6501 Yellow

Yellow Ƌ

BlueƋ

TrafficJet

Green Ƌ

with

Red Ƌ

# OL-1000

Digital Printing UV Red onto Yellow T-6501+ 70% of Tables 4 & 5

or

Worboy Green Ƌ with OL-1000 only

OL-2000

Brown Ƌ

Clear

Black

Black onto Yellow T-6501

Notes: # - Declared performance for components assumes application to white native sheeting

unless otherwise noted.

Ƌ – Declared performance is 100% of Table 5 values when processed per German

Classification: Avery Dennison - Internal

requirements.

* – Avery Dennison recommends a 15% thinning of the 4930 Yellow ink to meet 100%

requirement of table 4.

+ - Declared performance is 50% of red values stated in Tables 4 & 5.

Classification: Avery Dennison - Internal

You might also like

- Libro Top Notch 1Document3 pagesLibro Top Notch 1Jesus Martinez20% (5)

- BPI reports ‘internal data processing errorDocument9 pagesBPI reports ‘internal data processing errorJillian Bermoy100% (1)

- Functionality Behind Rejection Reason (Reason For Rejection)Document8 pagesFunctionality Behind Rejection Reason (Reason For Rejection)Anupa Wijesinghe96% (23)

- Sar Analysis in CSTDocument25 pagesSar Analysis in CSTMat ハフィズヂン100% (2)

- CIE GraphDocument4 pagesCIE GraphHelder BezerraNo ratings yet

- Mesh To Micron ConverterDocument1 pageMesh To Micron ConverterAniket royNo ratings yet

- Entities Relevant AttributesDocument4 pagesEntities Relevant AttributesAnish AnandNo ratings yet

- Business Report ANDocument39 pagesBusiness Report ANKrishnaveni RajNo ratings yet

- PrincipalsandRatings - 5.2.2021 Part 5Document9 pagesPrincipalsandRatings - 5.2.2021 Part 5mitchellhockinNo ratings yet

- Group 7 - Data SheetDocument9 pagesGroup 7 - Data SheetJeremy Kyle Edson AustriaNo ratings yet

- OkesipDocument9 pagesOkesipEcha TesarNo ratings yet

- Dosier de Calidad de Señales Informativas Data Sheet T9300Document8 pagesDosier de Calidad de Señales Informativas Data Sheet T9300Diana Zulema Enrico RodriguezNo ratings yet

- Generic TST Protocol Distributed Annexes KNCVDocument14 pagesGeneric TST Protocol Distributed Annexes KNCVtheresiaNo ratings yet

- CalcuDocument4 pagesCalcumarkNo ratings yet

- Color Spectrum Analysis and Beer's Law ValidationDocument4 pagesColor Spectrum Analysis and Beer's Law ValidationSherald AgustinNo ratings yet

- Farol Led - 3693-18a-Toyota-Etios-H4Document6 pagesFarol Led - 3693-18a-Toyota-Etios-H4LeoNo ratings yet

- CineonDocument25 pagesCineonzcreamNo ratings yet

- Enzyme activity and substrate concentrationDocument9 pagesEnzyme activity and substrate concentration健伟No ratings yet

- Technical DataDocument19 pagesTechnical Datamustafa nasihNo ratings yet

- Curva de CalibraciónDocument4 pagesCurva de CalibraciónValderrama Ayllon Yarazet SusanaNo ratings yet

- DHP M1 Materi 5Document3 pagesDHP M1 Materi 5Mya RahmiNo ratings yet

- Armored Cable SeriesDocument4 pagesArmored Cable SeriesTarek DeghedyNo ratings yet

- COLLUMNA1Document11 pagesCOLLUMNA1Jholsvin CastilloNo ratings yet

- COLUMNADocument11 pagesCOLUMNALuis Jhasmany Saez CastilloNo ratings yet

- Pengolahan Data Sektor Barang Baku - LOGDocument9 pagesPengolahan Data Sektor Barang Baku - LOGNikolai WenNo ratings yet

- Diffraction GratingDocument8 pagesDiffraction GratingClintDoesMusicNo ratings yet

- Removing Stationarity (Beer Production Data-8years) : Vipin Himani Deepak MananDocument12 pagesRemoving Stationarity (Beer Production Data-8years) : Vipin Himani Deepak MananVM MonuNo ratings yet

- Summarizing Data - Statistical HydrologyDocument6 pagesSummarizing Data - Statistical HydrologyJavier Avila100% (1)

- Snell's Law Experiment: Lab Report 1 Part 1: No. 2Document8 pagesSnell's Law Experiment: Lab Report 1 Part 1: No. 2AINA TATYANANo ratings yet

- Syringe Needle Conversion Chart: Nominal O.D. Nominal I.D. Nominal WallDocument1 pageSyringe Needle Conversion Chart: Nominal O.D. Nominal I.D. Nominal WallAndréRochaNo ratings yet

- crmDocument2 pagescrmFalcon LabNo ratings yet

- Waktu (menit) Ekstrak Rafinat x x* Δx Δx Log Mean Driving Force Mass Transfer CoefficientDocument1 pageWaktu (menit) Ekstrak Rafinat x x* Δx Δx Log Mean Driving Force Mass Transfer CoefficientMella Frandista KNo ratings yet

- EJEMPLO: Calcular Los Desplazamientos de La Siguiente EstructuraDocument3 pagesEJEMPLO: Calcular Los Desplazamientos de La Siguiente EstructuraAlex Bustamante LaraNo ratings yet

- Super Welding CablesDocument1 pageSuper Welding CablesNarasimha Rao JaggarapuNo ratings yet

- Latihan Soal Rancob Senin 23 Sept 19 FixDocument46 pagesLatihan Soal Rancob Senin 23 Sept 19 FixFebri YaniNo ratings yet

- Calibration For The Absorbance of Blue Dye No.1: Jalissa Thomas and Jessica Nicholson Experiment 6 Data TA: Lisa RamirezDocument2 pagesCalibration For The Absorbance of Blue Dye No.1: Jalissa Thomas and Jessica Nicholson Experiment 6 Data TA: Lisa RamirezJessica NicholsonNo ratings yet

- Results and Discussion Dan Banh Data Table: BCA Assay Standard CurveDocument2 pagesResults and Discussion Dan Banh Data Table: BCA Assay Standard Curve15071996No ratings yet

- Perubahan Bobot: Perlakuan Ulangan Awal Akhir Selisih SD (%)Document9 pagesPerubahan Bobot: Perlakuan Ulangan Awal Akhir Selisih SD (%)efendiNo ratings yet

- Trapezoidal (Equally Spaced) and Simpsons RuleDocument6 pagesTrapezoidal (Equally Spaced) and Simpsons RuleRushane MirandaNo ratings yet

- CHM 414: Errors, Statistics, and Calibration (Homework 1) : Computed Using Excel and Scientific CalculatorDocument3 pagesCHM 414: Errors, Statistics, and Calibration (Homework 1) : Computed Using Excel and Scientific CalculatorPre by JeriNo ratings yet

- Sampling MaterialDocument35 pagesSampling MaterialDummy BegoNo ratings yet

- ESR127G EN0228-AdultsDocument2 pagesESR127G EN0228-AdultsLễ Phan ThịNo ratings yet

- Farol Led - 3690-18a-GM-Onix-H4Document6 pagesFarol Led - 3690-18a-GM-Onix-H4LeoNo ratings yet

- Experiment 3 Bradford AssayDocument12 pagesExperiment 3 Bradford AssaySayre BongoNo ratings yet

- DN027B Led3nw L100 SQDocument1 pageDN027B Led3nw L100 SQHaianh PhamNo ratings yet

- Absorbance-concentration calibration curve for unknown sample analysisDocument5 pagesAbsorbance-concentration calibration curve for unknown sample analysisDalvaMNo ratings yet

- Task 7aDocument3 pagesTask 7aJun Hao ChongNo ratings yet

- Book1 (Recovered)Document5 pagesBook1 (Recovered)AliNo ratings yet

- Probit Analysis: Mortallitas N Versus Konsentrasi: Response InformationDocument3 pagesProbit Analysis: Mortallitas N Versus Konsentrasi: Response InformationeristapfNo ratings yet

- Table Statistics: Database: Database - BX Table: AssayDocument1 pageTable Statistics: Database: Database - BX Table: AssayAgung HidayantoNo ratings yet

- Tugas QC Dan ValidasiDocument4 pagesTugas QC Dan ValidasiJuw EllahNo ratings yet

- Hasil Regresi Eviews Panel B - GrowthDocument7 pagesHasil Regresi Eviews Panel B - GrowthPrinika RafiuningtyasNo ratings yet

- AGRD03-16 Guide To Road Design Part 3 Geometric Design Ed3.4Document390 pagesAGRD03-16 Guide To Road Design Part 3 Geometric Design Ed3.4yusveriNo ratings yet

- LASER FERITI CERTIFICATE OF QUALITYDocument1 pageLASER FERITI CERTIFICATE OF QUALITYdario_791473996No ratings yet

- Chevron Alignemt SignDocument1 pageChevron Alignemt Signdario_791473996No ratings yet

- Traffic Signs Inspection IB35MPBR 22122022Document1 pageTraffic Signs Inspection IB35MPBR 22122022dario_791473996No ratings yet

- EC Certificate T 6500 EN - 2021Document4 pagesEC Certificate T 6500 EN - 2021dario_791473996No ratings yet

- Brochure Concrete Safety Barriers A Safe and Sustainable ChoiceDocument17 pagesBrochure Concrete Safety Barriers A Safe and Sustainable Choicedario_791473996No ratings yet

- SRPS Z.S2.150Document6 pagesSRPS Z.S2.150dario_791473996No ratings yet

- Archimedes Deliverable d11 7Document29 pagesArchimedes Deliverable d11 7dario_791473996No ratings yet

- New Doc 2018-10-02 14.13.53Document61 pagesNew Doc 2018-10-02 14.13.53dario_791473996No ratings yet

- 2 Introduction To Road Safety InspectionsDocument122 pages2 Introduction To Road Safety Inspectionsdario_791473996No ratings yet

- 9 Safety at Road WorksDocument83 pages9 Safety at Road Worksdario_791473996No ratings yet

- Summary of Dammam WorkshopDocument58 pagesSummary of Dammam Workshopdario_791473996No ratings yet

- 20 1 1 1 02 Decision Support Framework For Cyclin Investment PrioritizationDocument16 pages20 1 1 1 02 Decision Support Framework For Cyclin Investment Prioritizationdario_791473996No ratings yet

- Presto Policy Guide Cycling Infrastructure en PDFDocument49 pagesPresto Policy Guide Cycling Infrastructure en PDFDiego MárquezNo ratings yet

- 6c08 PDFDocument14 pages6c08 PDFdario_791473996No ratings yet

- Thinking of Pedestrian Safety During Your Road Safety InspectionsDocument76 pagesThinking of Pedestrian Safety During Your Road Safety Inspectionsdario_791473996No ratings yet

- Pedestrian and Bicyclist Intersection Safety Indices: User GuideDocument62 pagesPedestrian and Bicyclist Intersection Safety Indices: User Guidedario_791473996No ratings yet

- 1804 - Cyclinguk - Cycle Safety Make It Simple PDFDocument24 pages1804 - Cyclinguk - Cycle Safety Make It Simple PDFdario_791473996No ratings yet

- 10 2385 s2 - Misc - 2 3 2011b PDFDocument144 pages10 2385 s2 - Misc - 2 3 2011b PDFdario_791473996No ratings yet

- 3 Key Steps in A Road Safety InspectionDocument37 pages3 Key Steps in A Road Safety Inspectiondario_791473996No ratings yet

- Risk of Injury For Bicycling On Cycle Tracks Versus in The StreetDocument5 pagesRisk of Injury For Bicycling On Cycle Tracks Versus in The Streetdario_791473996No ratings yet

- FIDIC Model Ugovora o Pruzanju UslugaDocument50 pagesFIDIC Model Ugovora o Pruzanju UslugaJelena Peric100% (7)

- The National Academies Press: Guidelines For Guardrail Implementation (2009)Document39 pagesThe National Academies Press: Guidelines For Guardrail Implementation (2009)dario_791473996No ratings yet

- NCHRP RPT350 WmodifiedDocument39 pagesNCHRP RPT350 Wmodifiedjcacho68No ratings yet

- The National Academies Press: Guidelines For Guardrail Implementation (2009)Document39 pagesThe National Academies Press: Guidelines For Guardrail Implementation (2009)dario_791473996No ratings yet

- The National Academies Press: Guidelines For Guardrail Implementation (2009)Document39 pagesThe National Academies Press: Guidelines For Guardrail Implementation (2009)dario_791473996No ratings yet

- Final Practical Guide For Road Safety Auditors and Inspectors EN PDFDocument70 pagesFinal Practical Guide For Road Safety Auditors and Inspectors EN PDFSasa KocicNo ratings yet

- The National Academies Press: Guidelines For Guardrail Implementation (2009)Document39 pagesThe National Academies Press: Guidelines For Guardrail Implementation (2009)dario_791473996No ratings yet

- NCHRP Report 350 Test 3-11 of The Long-Span Guardrail With 5.7 M Clear Span and Nested W-Beams Over 11.4 MDocument53 pagesNCHRP Report 350 Test 3-11 of The Long-Span Guardrail With 5.7 M Clear Span and Nested W-Beams Over 11.4 Mdario_791473996No ratings yet

- Ardruino 6DOF Motion Platform LoResDocument13 pagesArdruino 6DOF Motion Platform LoResFabio PedroNo ratings yet

- Capture The Scene: LizardqDocument4 pagesCapture The Scene: Lizardqjuk expertNo ratings yet

- Beamforming Overview DL and UL Beamforming Performance ConclusionsDocument37 pagesBeamforming Overview DL and UL Beamforming Performance ConclusionsAhed AlhamadeenNo ratings yet

- Introduction To Nonlinear Control Lecture # 4 PassivityDocument69 pagesIntroduction To Nonlinear Control Lecture # 4 PassivityZain BhattiNo ratings yet

- How To Create in 5 Minutes A SQL Tuning Test Case Using SQLTXPLAINDocument45 pagesHow To Create in 5 Minutes A SQL Tuning Test Case Using SQLTXPLAINvevaradhNo ratings yet

- To: From: Date: ReDocument2 pagesTo: From: Date: Repml1028No ratings yet

- Electronic Records Management System Adoption ReadDocument9 pagesElectronic Records Management System Adoption ReadAININA SYAZWINA ZAINUL AZMANNo ratings yet

- SAM Registration Guide International Compressed v1Document47 pagesSAM Registration Guide International Compressed v1Cherry Rose MontojoNo ratings yet

- CS 101 Lecture 1 PDFDocument31 pagesCS 101 Lecture 1 PDFMohammad ArafatNo ratings yet

- Boiler Control Process OverviewDocument27 pagesBoiler Control Process OverviewSandeep Kumar Krishnaraj100% (1)

- Virtual conference on robotics, automationDocument3 pagesVirtual conference on robotics, automationAditya AnirudhNo ratings yet

- SDH Multiplexing BY: Tx-I Faculty Alttc, GZBDocument57 pagesSDH Multiplexing BY: Tx-I Faculty Alttc, GZBAjay Dagar100% (1)

- Approach To ChangeDocument5 pagesApproach To ChangeFingerlin Angelisa KilisNo ratings yet

- R PackageDocument123 pagesR PackagePhani Thota0% (1)

- Module 2 - Introduction To BusinessDocument4 pagesModule 2 - Introduction To BusinessMarjorie Rose GuarinoNo ratings yet

- Record Writing - Practicals - Digital DocumentationDocument2 pagesRecord Writing - Practicals - Digital DocumentationVidath KunaNo ratings yet

- Microsoft AzureDocument13 pagesMicrosoft AzureKomal SamdariyaNo ratings yet

- 2SA1357Document2 pages2SA1357Kike VillasurNo ratings yet

- MPEG4 DVR with 500GB HDD and 170 Days RecordingDocument2 pagesMPEG4 DVR with 500GB HDD and 170 Days RecordingEduardo Daniel Medina AlvarezNo ratings yet

- Color Monitor Service ManualDocument49 pagesColor Monitor Service ManualAlexandre MagriNo ratings yet

- Premax CatalogueDocument8 pagesPremax CatalogueBasil Le BõrgnëNo ratings yet

- Hydrins2 0510ukDocument4 pagesHydrins2 0510uklwarlocklNo ratings yet

- Sets PythonDocument20 pagesSets Pythonrbharati078No ratings yet

- Turbo Pascal Version 4.0 Owners Manual 1987Document715 pagesTurbo Pascal Version 4.0 Owners Manual 1987Ionut PateleaNo ratings yet

- RCD 2010 GillesaniaDocument223 pagesRCD 2010 GillesaniaMatt Julius CorpuzNo ratings yet

- Skype BruteDocument2 pagesSkype BruteMarko SavicNo ratings yet