Professional Documents

Culture Documents

Ts Tpsodl Gi Wire

Uploaded by

Jainco Transmission LimitedOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ts Tpsodl Gi Wire

Uploaded by

Jainco Transmission LimitedCopyright:

Available Formats

TP SOUTHERN ODISHA DISTRIBUITION LIMITED, BERHAMPUR

TECHNICAL SPECIFICATION

Doc. Title SPECIFICATION FOR SWG GI WIRE

Doc. No ENG-HV-23 Eff. Date: 01/03/2021

Rev. No 00 Page 3 of 7

Prepared by: Reviewed by: Approved By: Issued By:

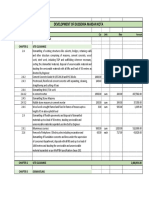

4.0 GENERAL TECHNICAL REQUIREMENTS

Sl. Technical Particulars GI WIRE 4 GI WIRE 6 SWG GI WIRE 8 SWG GI WIRE 10 GI WIRE 16

No. SWG SWG SWG

1 Diameter of Wire 5.6 mm 5 mm 4 mm 3.15 mm 1.6 mm

±2.5% with a ±2.5% with a ±2.5% with a ±2.5% with a ±2.5% with a

2 Tolerance minimum of minimum of minimum of minimum of minimum of

±0.025 ±0.025 ±0.025 ±0.025 ±0.025

300 to 550 300 to 550

3 Tensile Strength of wire 300 to 550 Mpa 300 to 550 Mpa 300 to 550 Mpa

Mpa Mpa

230

290

4 Weight of zinc coating 290 gms/meter² 290 gms/meter² 270 gms/meter² gms/meter²

gms/meter²

5 Process of Galvanizing Hot dipped Hot dipped Hot dipped Hot dipped Hot dipped

Heavily

6 Type of Coating Heavily coated Heavily coated Heavily coated Heavily coated

coated

Soft & Soft &

7 Quality Soft & Annealed Soft & Annealed Soft & Annealed

Annealed Annealed

5.0 GENERAL CONSTRUCTION

All material shall be as per IS: 280:1978. The wire shall be drawn from the wire rods conforming

to IS 7887.The process of zinc coating should be as per IS 2629. Zinc coating on hot dip galvanized wire

should be uniform. All finished wires shall be well and cleanly drawn to the dimensions specified. The wire

shall be sound, free from splits, surface flaws, rough jagged and imperfect edges and other harmful surface

defects.

6.0 MARKING

NA.

7.0 TESTS

All routine, acceptance and type tests of GI Wire shall be carried out in accordance with the relevant IS 280

standards. All routine/acceptance tests shall be witnessed by the Purchaser/his authorized representative.

Following tests shall be necessarily conducted on the GI wire as specified in IS standards.

TYPE TESTS

a) Diameter of the individual wire.

b) Tensile Strength.

c) Wrapping test of the wire.

d) Bend test (Applicable for wire of 5mm diameter and above).

e) Mass of zinc coating.

f) Uniformity of zinc coating.

g) Adhesion of zinc coating.

Property of TPSODL – Not to be reproduced without permission of TPSODL

You might also like

- M. Statment Lines - Cable Instal & TestingDocument45 pagesM. Statment Lines - Cable Instal & Testingahmedshah512No ratings yet

- List Price W.E.F 30th Oct 2020: 22nd June, 2020Document20 pagesList Price W.E.F 30th Oct 2020: 22nd June, 2020Sahili SalveNo ratings yet

- Estimate With NIT2020-21Document23 pagesEstimate With NIT2020-21BL AHIRWARNo ratings yet

- Ronak India PVT LTD New 1Document34 pagesRonak India PVT LTD New 1Ronak FireNo ratings yet

- Finolex Wire Price List 714Document22 pagesFinolex Wire Price List 714ramancs1985No ratings yet

- Company Profile KE - 2020Document35 pagesCompany Profile KE - 2020fuadymfNo ratings yet

- Is 1897 2008Document12 pagesIs 1897 2008Santosh KumarNo ratings yet

- Response To EOIDocument29 pagesResponse To EOIAnuj IwarkarNo ratings yet

- CGCEL LED PRICELIST 2019-20 Wef 1st Nov 2019 PDFDocument72 pagesCGCEL LED PRICELIST 2019-20 Wef 1st Nov 2019 PDFRavish RamNo ratings yet

- StainlessSteel Fasteners Manufacturer in IndiaDocument2 pagesStainlessSteel Fasteners Manufacturer in Indiaviha steelNo ratings yet

- AWWCE Unit Rates For Pipe Work - LegaDocument24 pagesAWWCE Unit Rates For Pipe Work - LegaMiko Abi0% (1)

- CIF Opening Form I 02082018Document4 pagesCIF Opening Form I 02082018GAYATHRINo ratings yet

- VMT ERT 03 REPORT 220 KV LUCKNOWDocument27 pagesVMT ERT 03 REPORT 220 KV LUCKNOWAnoop DikshitNo ratings yet

- Gis Manual FinalDocument290 pagesGis Manual FinalAkbarNo ratings yet

- Cescom - Schedule of Rates PDFDocument178 pagesCescom - Schedule of Rates PDFPunith S MurthyNo ratings yet

- Schedule HDocument36 pagesSchedule HAizuddin RosliNo ratings yet

- Development of Dussehra Maidan Kota: Part A - Civil WorksDocument91 pagesDevelopment of Dussehra Maidan Kota: Part A - Civil WorksShruti KabraNo ratings yet

- Ieee 80-2000 PDFDocument199 pagesIeee 80-2000 PDFKishore KumarNo ratings yet

- Final Audit Format - 2022Document130 pagesFinal Audit Format - 2022VickyNo ratings yet

- Connectwell Terminal BlocksDocument30 pagesConnectwell Terminal BlockssourabhNo ratings yet

- HPCL - GEC - C - EL - 014 - Rev.0B - ELECTRICAL SOQDocument10 pagesHPCL - GEC - C - EL - 014 - Rev.0B - ELECTRICAL SOQbecpavanNo ratings yet

- Raysan CatalogueDocument56 pagesRaysan Catalogueفارس معتوقNo ratings yet

- MVS205 Multi-Variable Sensor: Transducer and Interface CircuitDocument8 pagesMVS205 Multi-Variable Sensor: Transducer and Interface CircuitDiego Saravia JordanNo ratings yet

- Electrical BOQ Sahiwal OfficeDocument17 pagesElectrical BOQ Sahiwal OfficeNawazih AliNo ratings yet

- ACP Service Providers in San FranciscoDocument1 pageACP Service Providers in San FranciscoMissionLocalNo ratings yet

- Technical Datasheet 0027141131 003Document4 pagesTechnical Datasheet 0027141131 003Faizal SetiawanNo ratings yet

- On-Site Testing With Compact Ac Test-System at The First 500 KV Xlpe Cable Project in South AmericaDocument6 pagesOn-Site Testing With Compact Ac Test-System at The First 500 KV Xlpe Cable Project in South AmericalatifNo ratings yet

- Chian XD GroupDocument46 pagesChian XD GroupAkinrinmade Daniel100% (1)

- TTR Doc - CRP Sas-Kbl PKG - r0Document2 pagesTTR Doc - CRP Sas-Kbl PKG - r0Anonymous EVFw59No ratings yet

- Control and Relay PanelsDocument122 pagesControl and Relay Panelsmfm tendersNo ratings yet

- Info Iec60099-4Document31 pagesInfo Iec60099-4Huỳnh Thanh LiêmNo ratings yet

- Compact SubstationDocument2 pagesCompact SubstationnijhumbNo ratings yet

- 6vcb Indoor PanelDocument3 pages6vcb Indoor PanelMajeed aliNo ratings yet

- Invoice 2Document1 pageInvoice 2Ajay MarwalNo ratings yet

- Policy Schedule: Chola Ms Bharat Sookshma Udyam Suraksha PolicyDocument18 pagesPolicy Schedule: Chola Ms Bharat Sookshma Udyam Suraksha PolicyShuvajoy RebornNo ratings yet

- FDN Design of G TowerDocument64 pagesFDN Design of G Towerraj mNo ratings yet

- Stakeholder Management Plan Rev. 00Document9 pagesStakeholder Management Plan Rev. 00rajaNo ratings yet

- Sukam Online UpsDocument12 pagesSukam Online Upsharsh.mehta1745100% (1)

- CTs & VTsDocument4 pagesCTs & VTsSuresh ArulrajNo ratings yet

- Indian Standard: Recommended Current Ratings For CablesDocument30 pagesIndian Standard: Recommended Current Ratings For CablesYASHASHWYNo ratings yet

- Hipot Test Protocol Rev 01 PDFDocument13 pagesHipot Test Protocol Rev 01 PDFAfanda RodgersNo ratings yet

- S-AAA-SWG-MV-GIS (Rev.0-2015)Document28 pagesS-AAA-SWG-MV-GIS (Rev.0-2015)Muhammad hussainNo ratings yet

- D. Martin - Further Studies of A Vegetable-Oil-Filled Power TransformerDocument8 pagesD. Martin - Further Studies of A Vegetable-Oil-Filled Power Transformernamsaigon316No ratings yet

- Wesman GBC GbsDocument4 pagesWesman GBC GbsHardik PanchalNo ratings yet

- Earthing Schemes FOR Terminals and DepotsDocument31 pagesEarthing Schemes FOR Terminals and DepotsYash Bardhan SinghNo ratings yet

- Comparison of PWM VFDs Versus Resonant Link Converters For Oilfield ESP Duty. PaDocument27 pagesComparison of PWM VFDs Versus Resonant Link Converters For Oilfield ESP Duty. Pajhon mambyNo ratings yet

- DC Power Supply: Instruction ManualDocument5 pagesDC Power Supply: Instruction Manual-No ratings yet

- Pre-Commissioning Checklist For New Assets Water Sites: Page 1 of 5Document5 pagesPre-Commissioning Checklist For New Assets Water Sites: Page 1 of 5u nizami0% (1)

- Wastewater Pump Station GuidelinesDocument86 pagesWastewater Pump Station Guidelinese cubeNo ratings yet

- Draft Cost Data 2022-23Document172 pagesDraft Cost Data 2022-23Moturi Vinod KumarNo ratings yet

- CELMaharashtra 44 MWDocument81 pagesCELMaharashtra 44 MWGururaj KanjikerNo ratings yet

- TechRentals Equipment Solutions Guide PDFDocument168 pagesTechRentals Equipment Solutions Guide PDFPrashant Ramesh BurhadeNo ratings yet

- Lower Fars Heavy Oil FieldDocument6 pagesLower Fars Heavy Oil Fieldsalman KhanNo ratings yet

- Preventive Maintenance of A Building and Electrical DesignDocument69 pagesPreventive Maintenance of A Building and Electrical DesignRafael SerranoNo ratings yet

- Ringmaster: Catalogue 2021Document184 pagesRingmaster: Catalogue 2021Daniel AgurtoNo ratings yet

- Uptime Institute Global Data Center Survey 2021: Growth Stretches An Evolving SectorDocument26 pagesUptime Institute Global Data Center Survey 2021: Growth Stretches An Evolving SectorSAmpleNo ratings yet

- Li Student Placement 2015 v5Document198 pagesLi Student Placement 2015 v5Azrul Nizar0% (1)

- PCC LP No. 2 DTD 1st May 2018Document8 pagesPCC LP No. 2 DTD 1st May 2018Srinivas KosuruNo ratings yet

- Battery Charger PDFDocument27 pagesBattery Charger PDFVarada Radjou CNo ratings yet

- Welding Consumable DSMW-0024.1 - WokaDur - S80-Ni-TIG - ElectrodeDocument3 pagesWelding Consumable DSMW-0024.1 - WokaDur - S80-Ni-TIG - ElectrodeJOLLY JAYA SENTOSANo ratings yet

- BSPTCLDocument10 pagesBSPTCLJainco Transmission LimitedNo ratings yet

- m12 Anchor BoltDocument1 pagem12 Anchor BoltJainco Transmission LimitedNo ratings yet

- Approved Drawing of Hardware Fitting With Clamp and Connector - 86 (B)Document22 pagesApproved Drawing of Hardware Fitting With Clamp and Connector - 86 (B)Jainco Transmission LimitedNo ratings yet

- Approved Drawing of H.fitting and Clamp Connector - 86C)Document31 pagesApproved Drawing of H.fitting and Clamp Connector - 86C)Jainco Transmission LimitedNo ratings yet

- Approved Drawing of Hardware Fitting With Clamp and Connector For Nit-86 (A)Document3 pagesApproved Drawing of Hardware Fitting With Clamp and Connector For Nit-86 (A)Jainco Transmission LimitedNo ratings yet

- Polymer Post Insulator 20 07Document13 pagesPolymer Post Insulator 20 07Jainco Transmission LimitedNo ratings yet

- Technical SpecificationDocument1 pageTechnical SpecificationJainco Transmission LimitedNo ratings yet

- TS TPSODL Mini Wedge ConnectorDocument1 pageTS TPSODL Mini Wedge ConnectorJainco Transmission LimitedNo ratings yet

- GTP Format For OdsspDocument12 pagesGTP Format For OdsspJainco Transmission LimitedNo ratings yet

- 05 - Circuit DiagramsDocument82 pages05 - Circuit DiagramsJarrod DebonoNo ratings yet

- Nigalex Standard Sections - Angles and TubesDocument21 pagesNigalex Standard Sections - Angles and TubesRamez Bou-RizkNo ratings yet

- Textile Wet Processing UNIT - 1Document14 pagesTextile Wet Processing UNIT - 1Chaarvi SaranyaNo ratings yet

- Belt GrinderDocument37 pagesBelt GrindermecanicaycompeticionNo ratings yet

- BioGecko - A Review On Recent Studies On Concrete 3D Printer Issues and RecommendationsDocument11 pagesBioGecko - A Review On Recent Studies On Concrete 3D Printer Issues and RecommendationsSam SalahNo ratings yet

- E864x6 Ed3Document19 pagesE864x6 Ed3HARINo ratings yet

- Concrete DeckingDocument8 pagesConcrete DeckingEliasNo ratings yet

- Sikadur 52 Method StatementDocument2 pagesSikadur 52 Method StatementYong Zhi XiangNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument19 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For Scientistsvenkatesh198910No ratings yet

- ASTM A895-89 - Standard SpecificationDocument2 pagesASTM A895-89 - Standard SpecificationMarian Joyce MacadineNo ratings yet

- Strip - Cladding - System - 2P R0 2018 11 19Document2 pagesStrip - Cladding - System - 2P R0 2018 11 19gikkederkiNo ratings yet

- Concrete Technology MCQ For Mid SemDocument8 pagesConcrete Technology MCQ For Mid SemAkshayNo ratings yet

- Sonhar Balagopalan-Rapidest Prototyping Automotive Prototype Castings With 3D PrintingDocument36 pagesSonhar Balagopalan-Rapidest Prototyping Automotive Prototype Castings With 3D PrintingAC DWNo ratings yet

- Dye Penetrant Test Procedure HRRLDocument4 pagesDye Penetrant Test Procedure HRRLAshok TiwariNo ratings yet

- Mounting Dream Living Room TV Mount MD2380 ManualDocument11 pagesMounting Dream Living Room TV Mount MD2380 ManualMarcelo MeiraNo ratings yet

- The Use of Reinforced Thermoplastic Pipe in Co2 Flood Enhanced Oil RecoveryDocument7 pagesThe Use of Reinforced Thermoplastic Pipe in Co2 Flood Enhanced Oil RecoveryOsama AshourNo ratings yet

- General Spec Sheet Power Crusher PC 1270Document2 pagesGeneral Spec Sheet Power Crusher PC 1270ion_zloteaNo ratings yet

- How To Clean Circuit Board CorrosionDocument7 pagesHow To Clean Circuit Board CorrosionjackNo ratings yet

- Is 1865 - 8Document1 pageIs 1865 - 8Svapnesh ParikhNo ratings yet

- Astm B163Document11 pagesAstm B163mmlingNo ratings yet

- Ultrasonic Machining by M.8601685.PowerpointDocument8 pagesUltrasonic Machining by M.8601685.PowerpointSheikh waleedNo ratings yet

- Lecture Notes: Volume-1Document109 pagesLecture Notes: Volume-1jitendra23157No ratings yet

- Precious Plastic Basic MachinesDocument1 pagePrecious Plastic Basic MachinesAlma AdentroNo ratings yet

- Solarban Vitro Temperable Low-E Glass Manual Rev 1sep21Document46 pagesSolarban Vitro Temperable Low-E Glass Manual Rev 1sep21marcioperinni1975No ratings yet

- VSM Cylindrical Grinding Brochure ENDocument6 pagesVSM Cylindrical Grinding Brochure ENforough sardarzadehNo ratings yet

- Resume Rojikin - Mechanical EngineeringDocument1 pageResume Rojikin - Mechanical EngineeringMuhammad ParhanNo ratings yet

- DS Wear Creusabro Superten 2020 1Document3 pagesDS Wear Creusabro Superten 2020 1Erdinc BayatNo ratings yet

- Catalog Bride UKDocument104 pagesCatalog Bride UKSoimaresti DraganestiNo ratings yet

- Havoline Xtended Life Antifreeze Coolant PDSDocument5 pagesHavoline Xtended Life Antifreeze Coolant PDSmmorkee.19No ratings yet

- 10 Welding Defect (LSNG PRINT)Document45 pages10 Welding Defect (LSNG PRINT)rahmad musliadiNo ratings yet