Professional Documents

Culture Documents

Arf Swga 20mm.21

Arf Swga 20mm.21

Uploaded by

GS BOOMIKOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Arf Swga 20mm.21

Arf Swga 20mm.21

Uploaded by

GS BOOMIKCopyright:

Available Formats

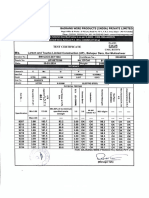

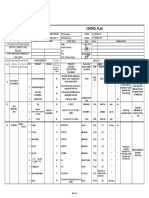

MILL AND TEST CERTIFICATE Report No: LONZ2020030401

ARITA Date: 20/Jul/2020

MILL CERTIFICATE ( EN 10204:2004 - 3.1) SHEET 1 1 OF 1 OF 1

Other Mainly Material

MECHANICAL PROPERTIES &

CHEMICAL ANALYSIS % (Max.) IMPACT TEST AT -46°C SEATING BASE FACE HB

HARDNESS (Min.)

Material Grade

Specification

Heat No. (*)

Part Name

SURFACE

C. eq Joule MTL MTL (MIN)

Yield EL. RED. Material

C Si Mn P S Cr Ni Mo Tensile HB

Point 1 2 3 AVG

% % BDDY A105

≥ 27

1 BODY A105 0.021 0.190 0.860 0.017 0.007 0.031 0.045 0.015 310 560 32 60

CAP A105

BONNET A105 0.200 0.220 0.810 0.017 0.008 0.022 0.041 0.020 300 550 30 52

SEAT 13Cr

WEDGE 13Cr + STL

STEM F6a

HEAT TREATMENT: A: Solution B: Annealed C: Tempered D: Q + Tempered E: Quench F: Normalized

We hereby certify that the material was

MULTIPLEX CONTROL & manufactured, sampled, tested and inspected in

VALVE DESCRIPTION CUSTOMER: PRESSURE TEST (AS PER API598) accordance with the material specification, and the

ENGINEERING SERVICES PTE LTD

information contained in this report is true and

ARITA FORGED STEEL A105 GATE VALVE, ITEM NO. Item Test Pressure (MPA) Test Duration (S) Allowable Leakage Rate (max) Result correct.

800#, HALF STELLITED, SOCKET WELD PO. NO. PO-2021-0406 Shell test 19.5 15 / OK

SIZE & DESCRIPTION 3/4'' Seal test 14.3 15 / OK

QUANTITY 10 Hydro / / / /

Seat

IDENTIFICATION NO. Air 0.6 15 / OK

REMARKS / TAGS

Quality Control Dept.

You might also like

- No: Trai/Pd/Mwi/71: Toprun Automotive India PVT LTDDocument2 pagesNo: Trai/Pd/Mwi/71: Toprun Automotive India PVT LTDubraghuNo ratings yet

- 3rd Quarter W4 LECTURE On Protein Synthesis in DNA and MutationDocument53 pages3rd Quarter W4 LECTURE On Protein Synthesis in DNA and MutationMorante GeraldineNo ratings yet

- Electrode SelectionDocument1 pageElectrode SelectionRachel ThompsonNo ratings yet

- Laboratory Waste Management GuideDocument54 pagesLaboratory Waste Management GuideMei YeeNo ratings yet

- Design Basis MemorandumDocument87 pagesDesign Basis MemorandumGiovanny Ruiz100% (3)

- TVS Jupiter RMC - 19.3.19Document60 pagesTVS Jupiter RMC - 19.3.19vinodNo ratings yet

- 1710 FD PI 3 SPE 3003 - Piping Material SpecificationDocument22 pages1710 FD PI 3 SPE 3003 - Piping Material SpecificationQuỳnh Chi DươngNo ratings yet

- MCQ Collection Nucleic Acid Dr. Mohamed Khomsi 2022Document14 pagesMCQ Collection Nucleic Acid Dr. Mohamed Khomsi 2022Abdulhadi AlhabroushNo ratings yet

- Anup SS304L TC 1Document2 pagesAnup SS304L TC 1B.M Industrial Works100% (1)

- The Bioleaching of Sulphide MineralsDocument28 pagesThe Bioleaching of Sulphide MineralstonyagevNo ratings yet

- Beverage ContainersDocument14 pagesBeverage Containersadilneu0% (1)

- Photosynthesis & Cellular Respiration Review: K A L E BDocument7 pagesPhotosynthesis & Cellular Respiration Review: K A L E BDestiny DunkleyNo ratings yet

- Arf Swga 40mm.21Document1 pageArf Swga 40mm.21GS BOOMIKNo ratings yet

- Arf Swga 15mm.21Document1 pageArf Swga 15mm.21GS BOOMIKNo ratings yet

- Arf SWGL 20mm.21Document1 pageArf SWGL 20mm.21GS BOOMIKNo ratings yet

- Sky Mqap1Document1 pageSky Mqap1Kumara SubramanianNo ratings yet

- Summary of Sub Grade Test Result.... 2Document8 pagesSummary of Sub Grade Test Result.... 2AshebirNo ratings yet

- MSS - Definitions - Coating MaterialsDocument4 pagesMSS - Definitions - Coating MaterialsIsmailEmreCanbolatNo ratings yet

- Apl Apollo Tubes Limited Unit-Iii: Works-Vill-Kudavali Plot No-M-1, Murbad, 421401, Thane (MS)Document1 pageApl Apollo Tubes Limited Unit-Iii: Works-Vill-Kudavali Plot No-M-1, Murbad, 421401, Thane (MS)devanshbhuvansht.823No ratings yet

- Mahenvr ) : .Nspalac13La3Document1 pageMahenvr ) : .Nspalac13La3ajanta6788No ratings yet

- TC PC WireDocument3 pagesTC PC WireSM AreaNo ratings yet

- 9686-PO0025-CPP-PL-001 - Honeywell Reply Confirmance For PL 26-Dec-2020 - CPPE ReplyDocument2 pages9686-PO0025-CPP-PL-001 - Honeywell Reply Confirmance For PL 26-Dec-2020 - CPPE ReplyANIL PLAMOOTTILNo ratings yet

- Certificados - Mtc-Po 23040-Req 14989Document98 pagesCertificados - Mtc-Po 23040-Req 14989MissionPetroleum InfoNo ratings yet

- Iso TemplateDocument4 pagesIso TemplateMark Darrel AranasNo ratings yet

- Assignment 8Document4 pagesAssignment 8interncp23No ratings yet

- Tsr-Sd22e Bd106 TurrbocharrgeDocument2 pagesTsr-Sd22e Bd106 Turrbocharrgedwi supraptoNo ratings yet

- Eqt Summary-22.07.2019Document2 pagesEqt Summary-22.07.2019Biplab MondalNo ratings yet

- Vessel Summary: MT-VESS Rev.4.5.0Document18 pagesVessel Summary: MT-VESS Rev.4.5.0Ale NotNo ratings yet

- Vessel Summary: MT-VESS Rev.4.5.0Document38 pagesVessel Summary: MT-VESS Rev.4.5.0Ale NotNo ratings yet

- Apl Apollo Tubes Limited Unit-Iii: Works-Vill-Kudavali Plot No-M-1, Murbad, 421401, Thane (MS)Document1 pageApl Apollo Tubes Limited Unit-Iii: Works-Vill-Kudavali Plot No-M-1, Murbad, 421401, Thane (MS)devanshbhuvansht.823No ratings yet

- 0127 R8B 04 WP 311 01Document1 page0127 R8B 04 WP 311 01ABDERRAZZAKNo ratings yet

- 27 1317 131 SR 9103 Acb6b05sc01 01 - 02PDF 00 BiDocument1 page27 1317 131 SR 9103 Acb6b05sc01 01 - 02PDF 00 BiSajin Chacko NinanNo ratings yet

- Bin71004034 02 B-Pillar Lower Crash Support BKT LH Bin71004034 02-B-Pillar Lower Crash Support BKT LHDocument1 pageBin71004034 02 B-Pillar Lower Crash Support BKT LH Bin71004034 02-B-Pillar Lower Crash Support BKT LHTrần Văn Lynh100% (1)

- RB 624590 001Document1 pageRB 624590 001Er Md AamirNo ratings yet

- Project Title: Detailed Engineering of Methanol Export Line To New Liquid JettyDocument3 pagesProject Title: Detailed Engineering of Methanol Export Line To New Liquid JettypavanNo ratings yet

- Omega Bright Steel: Test CertificateDocument1 pageOmega Bright Steel: Test CertificateBHUSHANNo ratings yet

- Annexure 2A - ITP For CS LTCS Welded Fittings To A 234 WPBW A 420WPL6W For Normal NACE IBRDocument3 pagesAnnexure 2A - ITP For CS LTCS Welded Fittings To A 234 WPBW A 420WPL6W For Normal NACE IBRPranav JadhavNo ratings yet

- 23045-Gp-Twm-Gf-Ip-Sd-202 - MepDocument1 page23045-Gp-Twm-Gf-Ip-Sd-202 - MepArun UdayabhanuNo ratings yet

- BH 01Document1 pageBH 01Suvashis PaulNo ratings yet

- Tal Wsa PNG Iso 1P020807 - 00 - A01 - 00Document1 pageTal Wsa PNG Iso 1P020807 - 00 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- M6x1.0x23 Long HHS Control PlanDocument2 pagesM6x1.0x23 Long HHS Control PlanDhanluxmi AutomaticsNo ratings yet

- Bin71004032 02 B-Pillar Upper Crash Support BKT LH Bin71004032-B-Pillar Upper Crash Support BKT LHDocument1 pageBin71004032 02 B-Pillar Upper Crash Support BKT LH Bin71004032-B-Pillar Upper Crash Support BKT LHTrần Văn Lynh0% (1)

- Printing & Pouching Film Matte, Non Heat Sealable: PCT-2 (M)Document1 pagePrinting & Pouching Film Matte, Non Heat Sealable: PCT-2 (M)U KsNo ratings yet

- Painting SpecificationDocument11 pagesPainting SpecificationgaurangNo ratings yet

- 04351-En-30 SC and KF DiagramDocument1 page04351-En-30 SC and KF Diagramjefry sitorusNo ratings yet

- FJC KP 01R 03 Jan 23Document1 pageFJC KP 01R 03 Jan 23Aulia AchmadNo ratings yet

- Transfame SDN BHD Paint Matrix Provision of Hook Up & Commissioning (Huc) Works For Murphy'S FacilitiesDocument2 pagesTransfame SDN BHD Paint Matrix Provision of Hook Up & Commissioning (Huc) Works For Murphy'S FacilitiesSupport RFZ2 EngineeringNo ratings yet

- General Description: % Ir Min (S) Max (S)Document1 pageGeneral Description: % Ir Min (S) Max (S)muhammetNo ratings yet

- 17CVL47Document2 pages17CVL47AnupEkboteNo ratings yet

- 123Document1 page123beyondborders010No ratings yet

- Precio de Scrap Mes de Mayo 2020Document1 pagePrecio de Scrap Mes de Mayo 2020Angelica RamosNo ratings yet

- 0127 R8B 07 WP 311 01Document1 page0127 R8B 07 WP 311 01ABDERRAZZAKNo ratings yet

- OklahomaDocument21 pagesOklahomaYusuf ÜnlüsoyNo ratings yet

- MTA Megacompact Technical Data Sheet v00Document1 pageMTA Megacompact Technical Data Sheet v00muhammetNo ratings yet

- Ramakrishna Mission Vivekananda (Evening) College (Autonomous)Document1 pageRamakrishna Mission Vivekananda (Evening) College (Autonomous)Raja Rajan NkaNo ratings yet

- Machine Condition D85ESS - 2: GroupDocument1 pageMachine Condition D85ESS - 2: GrouplilikNo ratings yet

- Certificado Calidad-Canal CDocument1 pageCertificado Calidad-Canal CALENo ratings yet

- MTA M8compact Technical Data Sheet v00Document1 pageMTA M8compact Technical Data Sheet v00muhammetNo ratings yet

- TSR Sd22e Bd108Document3 pagesTSR Sd22e Bd108dwi supraptoNo ratings yet

- External/Internal Painting Specification For Carbon Steel VesselsDocument5 pagesExternal/Internal Painting Specification For Carbon Steel VesselsgaurangNo ratings yet

- CSP123D000021410 15 07 2023 (36) SRKDocument1 pageCSP123D000021410 15 07 2023 (36) SRKpmmahobaNo ratings yet

- Utility-Summary MINE EDITEDDocument1 pageUtility-Summary MINE EDITEDMichael J. BaneNo ratings yet

- TR24030625 2Document1 pageTR24030625 2shubhNo ratings yet

- Pub 120 Table 7 PDFDocument2 pagesPub 120 Table 7 PDFОливер АндовскиNo ratings yet

- Mill T CDocument3 pagesMill T CSM AreaNo ratings yet

- Arf Swga 40mm.21Document1 pageArf Swga 40mm.21GS BOOMIKNo ratings yet

- Arf SWGL 20mm.21Document1 pageArf SWGL 20mm.21GS BOOMIKNo ratings yet

- 2215 001Document14 pages2215 001GS BOOMIKNo ratings yet

- Arf Swga 15mm.21Document1 pageArf Swga 15mm.21GS BOOMIKNo ratings yet

- 2213 001Document15 pages2213 001GS BOOMIKNo ratings yet

- 2214 - 001 Mill CertificateDocument10 pages2214 - 001 Mill CertificateGS BOOMIKNo ratings yet

- Mill CertificateDocument2 pagesMill CertificateGS BOOMIKNo ratings yet

- Save The Penguins Storyboard UseDocument20 pagesSave The Penguins Storyboard Useapi-295900495No ratings yet

- FiltrationDocument30 pagesFiltrationMurong MedinaNo ratings yet

- 2 Quarter Examination S.Y. 2019-2020: Earth Life and Science - Grade 11Document6 pages2 Quarter Examination S.Y. 2019-2020: Earth Life and Science - Grade 11Mihatsu TakiNo ratings yet

- PG Karl Fischer Titration SystemsDocument4 pagesPG Karl Fischer Titration Systemspurin phokhunNo ratings yet

- Methods of Separation Lesson PlanDocument3 pagesMethods of Separation Lesson PlanJenniferWongNo ratings yet

- Answers To SQ Behind Respiration Concept MapDocument3 pagesAnswers To SQ Behind Respiration Concept MapAnnabel SeahNo ratings yet

- Additive ManufacturingDocument9 pagesAdditive ManufacturingEsteban EroNo ratings yet

- Aisi 1335 Alloy Steel (Uns g13350)Document2 pagesAisi 1335 Alloy Steel (Uns g13350)Marcelo CarvalhoNo ratings yet

- Industrial Hygiene PPTDocument62 pagesIndustrial Hygiene PPTricardo martinezNo ratings yet

- Physics XIIDocument54 pagesPhysics XIIMalcolmDowNo ratings yet

- Section 6.0 MatterDocument46 pagesSection 6.0 MatterKennedy MudawarimaNo ratings yet

- Masterseal HLM 5000 India v2 PDFDocument2 pagesMasterseal HLM 5000 India v2 PDFshashiNo ratings yet

- Chemical KineticsDocument50 pagesChemical KineticsMohammadHussainKhanNo ratings yet

- Clearance CalculationDocument12 pagesClearance CalculationshazanNo ratings yet

- The Life & Work of Marie CurieDocument3 pagesThe Life & Work of Marie CurieDhāraṇe KusalaNo ratings yet

- Tuv Rheinland Morocco Voc Productlist en v2Document92 pagesTuv Rheinland Morocco Voc Productlist en v2scagiranNo ratings yet

- X T K Q: Visit Us At: WWW - Nodia.co - inDocument1 pageX T K Q: Visit Us At: WWW - Nodia.co - inSameerChauhanNo ratings yet

- Bombay HighDocument36 pagesBombay HighHarshit SharmaNo ratings yet

- Protein SynthesisDocument19 pagesProtein SynthesisRara Aulia IINo ratings yet

- BITSAT OnlineDocument51 pagesBITSAT OnlineUroojNo ratings yet

- Mix Design FormatDocument3 pagesMix Design FormatAkshay MitraNo ratings yet

- Carbopol Formulation'sDocument10 pagesCarbopol Formulation'sgibran santa cruz ruizNo ratings yet

- Effect of Current On Metal Transfer in SAW Part 2: AC: Welding Journal August 2017Document9 pagesEffect of Current On Metal Transfer in SAW Part 2: AC: Welding Journal August 2017Andrés Mauricio UribeNo ratings yet