Professional Documents

Culture Documents

LP-7 Problems of Piston Pins Done

Uploaded by

Kashif Usman0 ratings0% found this document useful (0 votes)

4 views2 pagesOriginal Title

LP-7 Problems of piston pins done

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views2 pagesLP-7 Problems of Piston Pins Done

Uploaded by

Kashif UsmanCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

LESSON PLAN

Week: 06 Taught By: Engr. Kashif Usman

Subject: Problem in Internal Combustion Engine Class: 2nd Year

Mechanical Department Time: 70 minutes

Topic: Problems of Piston Pins

Objective(s): Students will be able to:

Understand Expansion

Understand Contraction

Understand Floating and Knock

Skill focused on: Piston Pins

Resources:

White Board, Marker, PowerPoint Presentations

Methodology:

Importance and Problems Related To Piston Pin:

Piston pin, also called wrist pin allows the piston swing in the connection rod.

It is a thermal fit in piston bosses in the modem engines. Knocking of the pin is a problem due to

excessive clearance in the piston boss.

Piston pins in modern engines are normally held in the piston by one or two means: snap rings or

pressure fit, both are common.

Expansion and Contraction of Piston Pin:

In many modem engines the gudgeon pin or piston pin is made a thermal fit in the piston bosses.

Thus when the piston is heated to the temperature of boiling water, the holes in the bosses

expand sufficiently to enable the cold piston pin to be pushed readily to its working position.

The piston pin is usually made hollow to save weight and to give as much bearing surface as

possible. The material used is a high-grade carbon or low nickel content steel, casehardened and

ground to size.

Various methods have been used, in the past to secure the pin in piston bosses. Of these only

with split spring ring has survived.

The usual method employed in modern aluminum alloy piston is to make the pin a push fit in the

small end bearing and piston bosses. It is secured against end movement by means of spring clips

or with a special design of clip known as circlip this has lugs at its ends for facilitating its removal

with a pair of round-nosed pliers. The circlip springs into a groove turned in the piston boss.

In certain modem designs the piston pin is centrally clamped tightly in the small end of

connecting rod and allows to rock in the piston bosses.

When the piston is made of high strength aluminum alloy, the floating piston pin will operate

satisfactorily in this alloy without the necessity for bronze bushes.

Floating and Knocking of Piston Pin:

Depending upon the type and make of engine, the piston may either be free-floating pin will turn

in both rod and piston or press-fit (pin force’ fitted on rod but turn in piston).

Piston pin knock occurs when too much clearance exists between the piston pin and piston bore

or connecting rod bushing. Excessive clearance allows the pin to hammer against the rod or

piston as the piston changes direction the cylinder.

Piston pin knock will usually make a DOUBLE KNOCK (two rapid knocks and then a short pause). Ii

does NOT change much with engine load.

Problems of Piston Pin and Their Remedies:

Defects of piston pins (gudgeon pin) are wear or breakage. Theses give rise to small end knock, or

much more serious damage if the rod detaches itself.

Due to wear of the piston pin clearance occurs on both floating and pressed in pins.

In free floating, when the pin is worn, it should be replaced. If the pin bore in the piston measure

larger than specified replace the piston. The pin bore may also be reamed larger. Oversize piston

pins can than be used.

In case of pressed in pin service measure pin and pin bore wear compare to specify and replace or

repair parts as needed. Many shops send new pistons and pins to a machine shop for fitting

Activity– 1:Discussion on engine overheating by Group-1

Success Criteria:

C.W: Nil

H.W: Maintain Practical Notebook

HoD Sign: ______________ Date: __________________

You might also like

- LP-9 Piston Problems DoneDocument2 pagesLP-9 Piston Problems DoneKashif UsmanNo ratings yet

- LP-8 Connecting Rod Problems DoneDocument3 pagesLP-8 Connecting Rod Problems DoneKashif UsmanNo ratings yet

- LP-10 Piston Ring Problems DoneDocument3 pagesLP-10 Piston Ring Problems DoneKashif UsmanNo ratings yet

- Piston and Connecting RodDocument54 pagesPiston and Connecting RodWebsoft Tech-HydNo ratings yet

- Cast vs Forged Pistons: Which is BetterDocument4 pagesCast vs Forged Pistons: Which is BetterDebasis SoorNo ratings yet

- Case Study I1Document9 pagesCase Study I1Nabin BaskotaNo ratings yet

- Literature Review On Connecting RodDocument6 pagesLiterature Review On Connecting Rodaflspyogf100% (1)

- PistonDocument7 pagesPistongauravarora93100% (1)

- Practical Manual on Farm Machinery and PowerDocument50 pagesPractical Manual on Farm Machinery and PowerJustus VenterNo ratings yet

- Discussion: How To Do The Crankshaft Deflection and Draw The Deflection DiagramDocument11 pagesDiscussion: How To Do The Crankshaft Deflection and Draw The Deflection DiagramMani RajNo ratings yet

- Internal Combustion Engines: Internal Combustion Engine Piston, Sectioned To Show The Gudgeon PinDocument3 pagesInternal Combustion Engines: Internal Combustion Engine Piston, Sectioned To Show The Gudgeon PinThariqNo ratings yet

- 4 ReportDocument89 pages4 ReportRajesh KesapragadaNo ratings yet

- Piston ReportDocument59 pagesPiston ReportPidikiti Surendra BabuNo ratings yet

- Engine Construction 1Document11 pagesEngine Construction 1collins arogoNo ratings yet

- How Will You Calculate The Piston Speed If You Know The Stroke Length and Engine Speed?Document23 pagesHow Will You Calculate The Piston Speed If You Know The Stroke Length and Engine Speed?ERKATHIRNo ratings yet

- 03 Engine Bottom EndDocument31 pages03 Engine Bottom EndRohit Raj100% (1)

- Problem Description DescriptionDocument5 pagesProblem Description DescriptiongordensteinNo ratings yet

- Engine Component 2Document6 pagesEngine Component 2anuradhaNo ratings yet

- Student's MdedhDocument86 pagesStudent's MdedhthomasdilirionNo ratings yet

- Piston - Definition, Components or Parts, Types, Material, Function, Property (Notes & PDF)Document7 pagesPiston - Definition, Components or Parts, Types, Material, Function, Property (Notes & PDF)NITHISH KUMAR M SNo ratings yet

- Piston of Large Marine EngineDocument3 pagesPiston of Large Marine EngineRuwan SusanthaNo ratings yet

- Make Piston ModelDocument8 pagesMake Piston ModelSaurabh AwacharNo ratings yet

- LP-3 Cylinder Problems DoneDocument3 pagesLP-3 Cylinder Problems DoneKashif UsmanNo ratings yet

- Connecting Rod DetailsDocument16 pagesConnecting Rod DetailsMohammed SaleemNo ratings yet

- Internal Combustion Engine TypesDocument11 pagesInternal Combustion Engine Typesaruna MoonNo ratings yet

- Bracket Calc NewDocument5 pagesBracket Calc NewgordensteinNo ratings yet

- Cilinderkopbouten EngelsDocument18 pagesCilinderkopbouten EngelsBabei Ionut-MihaiNo ratings yet

- Student's MdedhDocument85 pagesStudent's Mdedhtankistmisha.vNo ratings yet

- Crack Detection & RepairDocument5 pagesCrack Detection & RepairHaftay100% (1)

- Delhi Transport Corporation Internship Report.Document45 pagesDelhi Transport Corporation Internship Report.Somesh KumarNo ratings yet

- Cylinder TechnologyDocument4 pagesCylinder TechnologyHady SundayanaNo ratings yet

- Piston: Parts, Types, Working, Piston Clearance, Shape and MoreDocument12 pagesPiston: Parts, Types, Working, Piston Clearance, Shape and MoreAndre RichardNo ratings yet

- Piston - Hce First ReviewDocument23 pagesPiston - Hce First ReviewLAKKANABOINA LAKSHMANARAONo ratings yet

- Multiple Ply BellowsDocument1 pageMultiple Ply BellowsSeungmin PaekNo ratings yet

- MLD TheoryDocument96 pagesMLD TheorySheik Abdullah100% (1)

- ICE Pistons 2023Document7 pagesICE Pistons 2023Sanjay PatelNo ratings yet

- Alfa 164 Electronic Suspension Rebuild ManualDocument29 pagesAlfa 164 Electronic Suspension Rebuild ManualJavier0043No ratings yet

- Piston: Jump To Navigationjump To SearchDocument37 pagesPiston: Jump To Navigationjump To SearchBHAVESH JOSHINo ratings yet

- Slotted Pin InflexibilityDocument2 pagesSlotted Pin InflexibilityGPNo ratings yet

- Main Parts of An Internal Combustion EngineDocument9 pagesMain Parts of An Internal Combustion EngineVenkatNo ratings yet

- 07 Connecting Rod & Cross HeadDocument18 pages07 Connecting Rod & Cross Headnaresh100% (1)

- Boge RebuildDocument29 pagesBoge RebuildRaja Sekaran SajjaNo ratings yet

- ME080 Section 8 - Other Hydraulic ComponentsDocument101 pagesME080 Section 8 - Other Hydraulic ComponentsAhmed FaragNo ratings yet

- SKF - Plummer Block Bearing-HousingDocument84 pagesSKF - Plummer Block Bearing-HousingneeleshvmNo ratings yet

- Piston - WikipediaDocument30 pagesPiston - WikipediaLAliNo ratings yet

- Service Experience MC EnginesDocument124 pagesService Experience MC EnginesStanislav RekyvchakNo ratings yet

- Findings Summary TemplateDocument6 pagesFindings Summary TemplateZohaib HassanNo ratings yet

- Valve SpringDocument6 pagesValve SpringSaddam LemuNo ratings yet

- UNIT Three Bahasa InggrisDocument2 pagesUNIT Three Bahasa InggrisAgung SupraptoNo ratings yet

- Piston RingDocument8 pagesPiston RingashokkumarNo ratings yet

- Structural Analysis of IC Engine Piston: R.Sabariselvan, K.Ranjith, S.Chandru, U.SeyedhusaiboorrahmanDocument6 pagesStructural Analysis of IC Engine Piston: R.Sabariselvan, K.Ranjith, S.Chandru, U.Seyedhusaiboorrahmanvikas rathoreNo ratings yet

- Function 4BDocument55 pagesFunction 4BSiva PrakasamNo ratings yet

- A Presentation On Connecting-Rod: University of Kirkuk College of Engineering Mech. Dept. - Third StageDocument19 pagesA Presentation On Connecting-Rod: University of Kirkuk College of Engineering Mech. Dept. - Third StageTara NafihNo ratings yet

- Piston RingsDocument7 pagesPiston RingsMudassir HussainNo ratings yet

- Ek156 FR Chen Fiaschetti KahalyDocument18 pagesEk156 FR Chen Fiaschetti Kahalyapi-402347036No ratings yet

- Crank Gear MechanismDocument21 pagesCrank Gear MechanismkanyamahazawilsonNo ratings yet

- Chapter-1: Savitribai Phule Pune UniversityDocument68 pagesChapter-1: Savitribai Phule Pune UniversityPramod DhaigudeNo ratings yet

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- Challan Information And Instructions: ربمن نلاچ:/ Challan Number: ربمن لیریس / Serial Number: 112169Document1 pageChallan Information And Instructions: ربمن نلاچ:/ Challan Number: ربمن لیریس / Serial Number: 112169muhammadshakeel348No ratings yet

- Intake & Exhaust System IdentificationDocument2 pagesIntake & Exhaust System IdentificationKashif UsmanNo ratings yet

- Project ListDocument1 pageProject ListKashif UsmanNo ratings yet

- LP 7Document2 pagesLP 7Kashif UsmanNo ratings yet

- PDF 20230502 134157 0000Document1 pagePDF 20230502 134157 0000Kashif UsmanNo ratings yet

- 3D Lab Course DevelopmentDocument1 page3D Lab Course DevelopmentKashif UsmanNo ratings yet

- HBL UmarDocument1 pageHBL UmarKashif UsmanNo ratings yet

- 03 New Month Course Power Generator Mechanic CourseDocument3 pages03 New Month Course Power Generator Mechanic CourseKashif UsmanNo ratings yet

- LP-5 Lubrication Problems DoneDocument4 pagesLP-5 Lubrication Problems DoneKashif UsmanNo ratings yet

- LP-3 Cylinder Problems DoneDocument3 pagesLP-3 Cylinder Problems DoneKashif UsmanNo ratings yet

- Project ListDocument1 pageProject ListKashif UsmanNo ratings yet

- LP-4 Crankshaft Balance DoneDocument3 pagesLP-4 Crankshaft Balance DoneKashif UsmanNo ratings yet

- LP-1 Engine Problem Symptoms DoneDocument4 pagesLP-1 Engine Problem Symptoms DoneKashif UsmanNo ratings yet

- LP-2 Factors Influencing Power DoneDocument5 pagesLP-2 Factors Influencing Power DoneKashif UsmanNo ratings yet

- Emissions and Fuels - HalfDocument43 pagesEmissions and Fuels - HalfKashif UsmanNo ratings yet

- L0 PicDocument7 pagesL0 PicKashif UsmanNo ratings yet

- BudgetDocument3 pagesBudgetKashif UsmanNo ratings yet

- LP-6 Cooling System Problems DoneDocument5 pagesLP-6 Cooling System Problems DoneKashif UsmanNo ratings yet

- Performans ParametreleriDocument18 pagesPerformans ParametreleriHerman AhmadNo ratings yet

- L0 FdupDocument8 pagesL0 FdupKashif UsmanNo ratings yet

- ECE Certification Cycle For Euro 96 1.2/RTA/RTEDocument11 pagesECE Certification Cycle For Euro 96 1.2/RTA/RTEKashif UsmanNo ratings yet

- Fitting 1 PDFDocument23 pagesFitting 1 PDFKashif UsmanNo ratings yet

- BudgetDocument3 pagesBudgetKashif UsmanNo ratings yet

- ECE Certification Cycle For Euro 96 1.2/RTA/RTEDocument13 pagesECE Certification Cycle For Euro 96 1.2/RTA/RTEKashif UsmanNo ratings yet

- Mechanisms Course ProgressDocument4 pagesMechanisms Course ProgressKashif UsmanNo ratings yet

- Lecture 4 Ferrous MetalDocument26 pagesLecture 4 Ferrous MetalKashif UsmanNo ratings yet

- Mule Pro DXT PDFDocument159 pagesMule Pro DXT PDFCamilaNo ratings yet

- Staffa Fixed Displacement Hydraulic Motor: Kawasaki Motors Corp., U.S.ADocument12 pagesStaffa Fixed Displacement Hydraulic Motor: Kawasaki Motors Corp., U.S.AtitanwlxNo ratings yet

- RockdrillDocument140 pagesRockdrillJuan EspitiaNo ratings yet

- Zapex - ZN DentadoDocument14 pagesZapex - ZN DentadoJose Patricio Obreque RiosNo ratings yet

- GEN-005-SAS#18Document1 pageGEN-005-SAS#18AC CepadaNo ratings yet

- STARGAZER 3 VariantDocument4 pagesSTARGAZER 3 VariantLucy BarbaronaNo ratings yet

- Denso PDFDocument2 pagesDenso PDFDmitriy GavrilovNo ratings yet

- CAT C32 Marine Parts BookDocument685 pagesCAT C32 Marine Parts BookDidik100% (2)

- Akrapovic Slip On Exhaust Ducati8991199 PanigaleDocument18 pagesAkrapovic Slip On Exhaust Ducati8991199 PanigaleDeSmO ManUNo ratings yet

- Part-Turn Gearboxes GS 50.3 - GS 250.3: Assembly, Operation, Commissioning Operation InstructionsDocument44 pagesPart-Turn Gearboxes GS 50.3 - GS 250.3: Assembly, Operation, Commissioning Operation InstructionshamzaNo ratings yet

- 6217874a167aaa56f57893cd T1000Document2 pages6217874a167aaa56f57893cd T1000Ibidhi EskanderNo ratings yet

- F210R Riser CheckDocument1 pageF210R Riser CheckLibi SFNo ratings yet

- Stellana Power 400x8 A4 FinalDocument2 pagesStellana Power 400x8 A4 Finalsalesmkt36No ratings yet

- 821g - Wheel Loader - Tier 4b (Na) (10/16 - ) 10 - Engine 10.400.010 (01) - Var - 482585 - 482931 - Cooling System Line InstallationDocument3 pages821g - Wheel Loader - Tier 4b (Na) (10/16 - ) 10 - Engine 10.400.010 (01) - Var - 482585 - 482931 - Cooling System Line InstallationVladimirCarrilloNo ratings yet

- Resfri Ar Expo CatalogueDocument24 pagesResfri Ar Expo CatalogueRenan BiasibettiNo ratings yet

- Mech - DrivesDocument89 pagesMech - DrivesankurNo ratings yet

- Caterpillar Contamination Control Neng7004Document132 pagesCaterpillar Contamination Control Neng7004Сергей КурильчикNo ratings yet

- Construction Kit Annexes PDFDocument16 pagesConstruction Kit Annexes PDFEdrian Louis Manalo TavasNo ratings yet

- Jacobs Brake 310 312 Parts Book On Caterpillar C10 C12 022040BDocument4 pagesJacobs Brake 310 312 Parts Book On Caterpillar C10 C12 022040Bvasanth kumar100% (1)

- Steering System: Tilt MechanismDocument26 pagesSteering System: Tilt MechanismarbutacNo ratings yet

- Test Instructions For Overrunning Alternator Pulleys (OAP/OAD)Document2 pagesTest Instructions For Overrunning Alternator Pulleys (OAP/OAD)venothNo ratings yet

- Bulbs - PN and LocationDocument6 pagesBulbs - PN and LocationDanielNo ratings yet

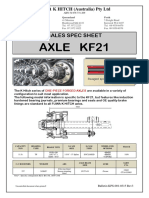

- KF21 11.5t, Sales Spec Sheet Bulletin KPS 001 0315 Rev3Document2 pagesKF21 11.5t, Sales Spec Sheet Bulletin KPS 001 0315 Rev3vương Nguyễn HồngNo ratings yet

- Pantalla Anterior Bienvenido: r120pm2Document2 pagesPantalla Anterior Bienvenido: r120pm2Eliecer godoyNo ratings yet

- 693 030127914 HSL Strand Jack Brochure En-Us 0Document8 pages693 030127914 HSL Strand Jack Brochure En-Us 0Alfredo JkpNo ratings yet

- VVT-i (Variable Valve Timing-Intelligent) SystemDocument4 pagesVVT-i (Variable Valve Timing-Intelligent) SystemJorge Armando VelázquezNo ratings yet

- AudiDocument13 pagesAudiGaurav KumarNo ratings yet

- 2013 Hurricane CatalogDocument23 pages2013 Hurricane CatalogTim0% (1)

- User Manual Toyota Supra MK4Document192 pagesUser Manual Toyota Supra MK4Wisnel Lara0% (1)

- Wiper, Washer & Horn: SectionDocument22 pagesWiper, Washer & Horn: SectionminaryNo ratings yet