Professional Documents

Culture Documents

#025 Installation of Anodes in W.B.T. (New)

Uploaded by

Tolias EgwOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

#025 Installation of Anodes in W.B.T. (New)

Uploaded by

Tolias EgwCopyright:

Available Formats

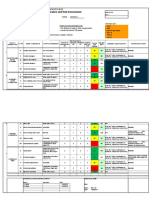

AKRON RISK ASSESSMENT R/A NO : 025

TYPE OF ACTIVITY: ROUTINE / NON- DESCRIPTION OF ACTIVITY : INSTALLATION OF ANODES IN W.B.T.

ROUTINE

RISK ASSESSMENT GUIDE : RISK MUST BE REDUCED TO AS LOW AS REASONABLY PRACTICABLE (ALARP)

STEP 1 : CONSIDER SEVERITY OF HARM (S) STEP 2 : CONSIDER LIKELIHOOD (L) STEP 3:CALCULATE RISK

1: NEGLIGIBLE: Near Miss or Simple First Aid/ Simple Repairs by ship staff/ Spill within spill trays 1: IMPROBABLE-Event not expected to occur RISK RATING RR = S x L

2: MINOR : Injury require Medical Treatment; MTC/ Repair need external assistance / Spill on deck < 1 m3 2 : RARE: Expected to occur in exceptional situations

RR RISK CATEGORY

MODERATE: Serious injury or multiple minor injuries; LTI / Repairs affecting seaworthiness of ship leading

3: 3: POSSIBLE: May occur at some time / occurred in the past

to CoC / Spill on deck > 1 m3 1- 5 L - LOW

CRITICAL : Single fatality, Serious injuries, permanent disability / Requires lay up repairs or extensive

4: 4: LIKELY : Possibility of occurrence of isolated incidents

drydockings, 3rd party claims/ Spill overboard < 100L 6 - 10 M - MEDIUM

CATASTROPHIC : Mutiple Fatalaities or Long Term disabilities/ Total Loss of ship or immediate layup/dry-

5: 5: CERTAIN: Is expected to occur in most situations

docking for major repairs / Major overboard spill > 100 L 11 - 25 H - HIGH

NO HAZARD DESCRIPTION RISK EXISTING CONTROLS RISK RATING RISK ADDITIONAL CONTROLS RESIDUAL RISK RESI-

(WITH CONTROLS IN CATEG (IF NOT REQUIRED, WRITE "N". RATING DUAL

PLACE) IF REQUIRED, LIST OUT THE ADDITIONAL CONTROLS )

L/M/H (WITH ADDIT'L RISK

CONTROLS)

CAT.

( S x L= RR) (S x L = RR) L/M/H

S L RR S L RR

1 Slippery surface. Serious injury to Procedures, PPE, Safety 4 3 12 H Ensure that the working area is clean from mud, 4 1 4 L

personnel arrangements water or any other slippery material and free of

any obstruction.

2 Working at a height. Serious injury to Procedures, PPE, Safety 4 3 12 H Any staging to be used should be properly 4 1 4 L

personnel arrangements secured.

3 Lack of oxygen, possible exposure to Human loss Procedures, PPE, Safety 3 4 12 H At least one member of the work team in the tank 3 1 3 L

hazardous gases. arrangements, Regular checks on should wear a personal multi-gas detection

ventilation, Drills instrument.

4 Inadequate ventilation. Human loss Procedures, PPE, Safety 3 4 12 H Adequate ventilation should be ensured by the 3 1 3 L

arrangements use of a portable water-driven fan and flexible air-

duct.

5 Inadequate illumination. Serious injury to Procedures, PPE, Safety 4 2 8 M A. Adequate illumination should be ensured by 4 1 4 L

personnel arrangements the use of portable gastight/Ex lights.

B. Pneumatic gastight turbo lamps or gastight cap

lamps to be used to provide illumination in the

area.

FORM NO: S-20 / REV. 0 / 01 MAR 2010 Page 1 / 3 R/A NO :411

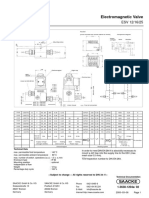

NO HAZARD DESCRIPTION RISK EXISTING CONTROLS RISK RATING RISK ADDITIONAL CONTROLS RESIDUAL RISK RESI-

(WITH CONTROLS IN CATEG (IF NOT REQUIRED, WRITE "N". RATING DUAL

PLACE) IF REQUIRED, LIST OUT THE ADDITIONAL CONTROLS )

L/M/H (WITH ADDIT'L RISK

CONTROLS)

CAT.

( S x L= RR) (S x L = RR) L/M/H

S L RR S L RR

6 Adverse weather/sea condition. - Serious Procedures, PPE, Safety 4 3 12 H A. The work should be carried out only in good 4 1 4 L

injury to arrangements weather and sea condition.

personnel B. Weather conditions-forecast to be monitored

- Moderate and in case of deterioration the Master/Chief

cost or Officer should be advised.

7 Inadequate coordination/supervision / c - Serious Procedures, PPE, Safety 4 3 12 H A. A work planning/safety meeting should be 4 1 4 L

injury to arrangements, crew familiarisation carried out with the participation of all involved

personnel personnel with the aim of discussing, amongst

- Moderate others: (a) job procedure; (b) tool transferring

cost or arrangements; (c) lifting arrangements; (d) safety

damage procedures/work permits; (e) individual work

responsibilities; (f) means of communication.

B. The Chief Officer should be in charge

supervising the job.

C. Bridge OOW should be informed of the

commencement/completion of the work.

D. During lowering/transferring tools in the tank

from the tank hatch, it should be ensured that

nobody is underneath

8 Lifting/transferring heavy objects Human loss Procedures, PPE, Safety 3 4 12 H A. The lifting/transferring/securing procedure to 3 1 3 L

(anodes). arrangements be applied should be properly planned and

communicated to the involved personnel.

B. Adequate manpower should be ensured for the

transferring/lifting of the anodes.

C. During lifting heavy objects (anodes), all

personnel should keep clear from the “dangerous

zone.

D. During lowering/transferring tools in the tank

from the tank hatch, it should be ensured that

nobody is underneath

9 High temperature/humidity in the Serious injury to Procedures, PPE, Safety 3 3 9 M A. Adequate work rest periods should be provided 3 1 3 L

working area. personnel arrangements and precautions against dehydration should be

taken. B. Any

involved personnel showing signs of fatigue

should be released from duty and replaced at

once.

FORM NO: S-20 / REV. 0 / 01 MAR 2010 Page 2 / 3 R/A NO :411

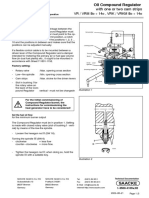

NO HAZARD DESCRIPTION RISK EXISTING CONTROLS RISK RATING RISK ADDITIONAL CONTROLS RESIDUAL RISK RESI-

(WITH CONTROLS IN CATEG (IF NOT REQUIRED, WRITE "N". RATING DUAL

PLACE) IF REQUIRED, LIST OUT THE ADDITIONAL CONTROLS )

L/M/H (WITH ADDIT'L RISK

CONTROLS)

CAT.

( S x L= RR) (S x L = RR) L/M/H

S L RR S L RR

Final Asesssment : Provided no deviations from the recommended control measures, the residual risk assessed is As Low As Resonably Practicable (ALARP).

Supplementary measures include correct use of PPE & Tool Box talks that ensure all workers are fully aware of the control measures.

Residual risk - HIGH : If RR is "High" category, written instructions for conducting the job and approval shall be obtained from the shore office to commence the operation.

Residual risk - MEDIUM: If RR is "Medium" , a constant monitoring of events shall be maintained and ensure all identified preventative and mitigating measures are always in place.

PREPARED BY: OPERATION DEPT , S & Q DEPT. APPROVED BY: S & Q MANAGER

01 03 2010

FORM NO: S-20 / REV. 0 / 01 MAR 2010 Page 3 / 3 R/A NO :411

You might also like

- #024 Hot Work On Fixture - Fittings in The Main Deck Area (New)Document1 page#024 Hot Work On Fixture - Fittings in The Main Deck Area (New)Tolias EgwNo ratings yet

- #023 Welding Cutting Work - Avoidance of Relevant Risks (New)Document2 pages#023 Welding Cutting Work - Avoidance of Relevant Risks (New)Tolias EgwNo ratings yet

- #026 Winch Brake Test (New)Document2 pages#026 Winch Brake Test (New)Tolias EgwNo ratings yet

- #411 Work On Pipelines or Systems Under Pressure or Flammable MediumDocument2 pages#411 Work On Pipelines or Systems Under Pressure or Flammable MediumTolias EgwNo ratings yet

- #404 Emergency Fire Pump Maintenance (Revised)Document4 pages#404 Emergency Fire Pump Maintenance (Revised)Tolias EgwNo ratings yet

- #015 Working OversideDocument2 pages#015 Working OversideTolias EgwNo ratings yet

- #307 Cargo Operations - Flexible Cargo Hoses (New)Document1 page#307 Cargo Operations - Flexible Cargo Hoses (New)Tolias EgwNo ratings yet

- #020 Use of Portable Framo Pump (New)Document2 pages#020 Use of Portable Framo Pump (New)Tolias EgwNo ratings yet

- #019 WBT - Inspection (New)Document3 pages#019 WBT - Inspection (New)Tolias EgwNo ratings yet

- #101 Anchoring & Weighing AnchorDocument6 pages#101 Anchoring & Weighing AnchorTolias Egw100% (1)

- #007 Hot Work Welding On Cargo Tank & Main Deck-01-03-10Document6 pages#007 Hot Work Welding On Cargo Tank & Main Deck-01-03-10Tolias EgwNo ratings yet

- #402 Valve Overhauling in A Cargo TankDocument4 pages#402 Valve Overhauling in A Cargo TankTolias EgwNo ratings yet

- #008 HotWork - Cutting in Cargo Tank & Main Deck 01-03-10Document6 pages#008 HotWork - Cutting in Cargo Tank & Main Deck 01-03-10Tolias EgwNo ratings yet

- #106 Embarkation or Disembarkation Via LaunchesDocument4 pages#106 Embarkation or Disembarkation Via LaunchesTolias EgwNo ratings yet

- #202 Navigation in Restricted VisibilityDocument2 pages#202 Navigation in Restricted VisibilityTolias EgwNo ratings yet

- #301 Ship To Ship OperationDocument8 pages#301 Ship To Ship OperationTolias EgwNo ratings yet

- #410 Heavy LiftDocument3 pages#410 Heavy LiftTolias EgwNo ratings yet

- #201 Navigation in Heavy Marine Traffic ChannelDocument4 pages#201 Navigation in Heavy Marine Traffic ChannelTolias EgwNo ratings yet

- #102 Mooring-Unmooring OperationsDocument5 pages#102 Mooring-Unmooring OperationsTolias EgwNo ratings yet

- #206 UKC Policy BreachDocument2 pages#206 UKC Policy BreachTolias EgwNo ratings yet

- #401 Odme Mal Operation Due To Lack of Maintenace (Revised)Document2 pages#401 Odme Mal Operation Due To Lack of Maintenace (Revised)Tolias EgwNo ratings yet

- #030 Mast Riser Venting Post Painting (New)Document1 page#030 Mast Riser Venting Post Painting (New)Tolias EgwNo ratings yet

- #005 Hot Work Welding Above Deck-01-03-10Document4 pages#005 Hot Work Welding Above Deck-01-03-10Tolias EgwNo ratings yet

- #006 Hot Work Cutting Above Deck-01-03-10Document4 pages#006 Hot Work Cutting Above Deck-01-03-10Tolias EgwNo ratings yet

- #403 Aux - Engine MaintenanceDocument3 pages#403 Aux - Engine MaintenanceTolias EgwNo ratings yet

- #104 Abondonship Drill - Davit Type LifeboatsDocument3 pages#104 Abondonship Drill - Davit Type LifeboatsTolias EgwNo ratings yet

- #018 Hot Work in A Fresh Water Tank - E.R Ballast Water Tank (New)Document7 pages#018 Hot Work in A Fresh Water Tank - E.R Ballast Water Tank (New)Tolias EgwNo ratings yet

- #002 Hot Work ER Workshop Cutting 01-03-10Document3 pages#002 Hot Work ER Workshop Cutting 01-03-10Tolias EgwNo ratings yet

- #304 Cargo Operation - DischargingDocument3 pages#304 Cargo Operation - DischargingTolias EgwNo ratings yet

- #407 Spray PaintingDocument2 pages#407 Spray PaintingTolias EgwNo ratings yet

- #010 Hotwork-Cutting in Pump Room - 01-03-10Document6 pages#010 Hotwork-Cutting in Pump Room - 01-03-10Tolias EgwNo ratings yet

- #405 Maintenance of Emergency GeneratorDocument2 pages#405 Maintenance of Emergency GeneratorTolias EgwNo ratings yet

- #306 Ballasting - Deballasting OperationDocument3 pages#306 Ballasting - Deballasting OperationTolias EgwNo ratings yet

- #308 Cargo Operations - Failure of No . Cot Remote Ullaging and Temperature MonitoringDocument1 page#308 Cargo Operations - Failure of No . Cot Remote Ullaging and Temperature MonitoringTolias EgwNo ratings yet

- #502 Tank Cleaning Operations - Engine DeptDocument3 pages#502 Tank Cleaning Operations - Engine DeptTolias EgwNo ratings yet

- #303 Cargo Operation - LoadingDocument3 pages#303 Cargo Operation - LoadingTolias EgwNo ratings yet

- #302 Gas Freeing of A Cargo TankDocument4 pages#302 Gas Freeing of A Cargo TankTolias EgwNo ratings yet

- #012 Hot Work-Cutting Machinery Spaces - 01-03-10Document4 pages#012 Hot Work-Cutting Machinery Spaces - 01-03-10Tolias EgwNo ratings yet

- #016 Underwater OperationsDocument3 pages#016 Underwater OperationsTolias Egw100% (1)

- #013 Enclosed Space Entry 01-03-10Document4 pages#013 Enclosed Space Entry 01-03-10Tolias EgwNo ratings yet

- #408 Steering Gear Overhaul or MaintenanceDocument3 pages#408 Steering Gear Overhaul or MaintenanceTolias EgwNo ratings yet

- #011 Hotwork-Welding Machinery Spaces - 01-03-10Document4 pages#011 Hotwork-Welding Machinery Spaces - 01-03-10Tolias EgwNo ratings yet

- #409 Electrical Equipment MaintenanceDocument3 pages#409 Electrical Equipment MaintenanceTolias EgwNo ratings yet

- #014 Working AloftDocument4 pages#014 Working AloftTolias EgwNo ratings yet

- #009 Hotwork-Welding On Pump Room - 01-03-10Document5 pages#009 Hotwork-Welding On Pump Room - 01-03-10Tolias EgwNo ratings yet

- #205 Maneuvering Alongside Both Ships Under PowerDocument5 pages#205 Maneuvering Alongside Both Ships Under PowerTolias EgwNo ratings yet

- #004 Hot Work Cutting-Poop Deck Aft-01-03-10Document4 pages#004 Hot Work Cutting-Poop Deck Aft-01-03-10Tolias EgwNo ratings yet

- #103 Mooring-Unmooring TermnalDocument3 pages#103 Mooring-Unmooring TermnalTolias EgwNo ratings yet

- #501 Bunkering OperationsDocument5 pages#501 Bunkering OperationsTolias EgwNo ratings yet

- #305 Tank Cleaning Operations - Cargo TanksDocument3 pages#305 Tank Cleaning Operations - Cargo TanksTolias EgwNo ratings yet

- #406 Maintenance On Main EngineDocument3 pages#406 Maintenance On Main EngineTolias Egw100% (1)

- #003 Hot Work Welding On Poop Deck-AFt Accm-01-03-10Document4 pages#003 Hot Work Welding On Poop Deck-AFt Accm-01-03-10Tolias EgwNo ratings yet

- #204 Navigation Through High Risk Piracy AreaDocument2 pages#204 Navigation Through High Risk Piracy AreaTolias EgwNo ratings yet

- #107 Manual Handling - Deck DeptDocument6 pages#107 Manual Handling - Deck DeptTolias EgwNo ratings yet

- #412 Identification of Critical Equipment and Spares LevelsDocument3 pages#412 Identification of Critical Equipment and Spares LevelsTolias EgwNo ratings yet

- Rondom Accex WDocument3 pagesRondom Accex Wrichard celinoNo ratings yet

- Hirac Operations Pipeline Cleaning and Pressure TestDocument7 pagesHirac Operations Pipeline Cleaning and Pressure TestNur Alisha Alisha100% (1)

- Daily Checks (Floorman)Document1 pageDaily Checks (Floorman)Abdul Hameed OmarNo ratings yet

- Rondom Accex DwqeqDocument2 pagesRondom Accex Dwqeqrichard celinoNo ratings yet

- 1-DD-Akron-CORA-9519705-PROP-60 Months Technical Specification 2018-07-18 PDFDocument8 pages1-DD-Akron-CORA-9519705-PROP-60 Months Technical Specification 2018-07-18 PDFTolias EgwNo ratings yet

- 3.6 - EM CK 06 - Man Overboard and Recovery From WaterDocument1 page3.6 - EM CK 06 - Man Overboard and Recovery From WaterTolias EgwNo ratings yet

- 2 Threshold Voltage PDFDocument8 pages2 Threshold Voltage PDFTolias EgwNo ratings yet

- 1 3638 5012a 02 PDFDocument2 pages1 3638 5012a 02 PDFTolias EgwNo ratings yet

- 3.1.4 - EM CK 01 D - Fire in EngineroomDocument1 page3.1.4 - EM CK 01 D - Fire in EngineroomTolias EgwNo ratings yet

- 2 Ballast Level Flowchart PDFDocument1 page2 Ballast Level Flowchart PDFTolias EgwNo ratings yet

- 1.apexior 3 PDFDocument1 page1.apexior 3 PDFTolias EgwNo ratings yet

- 02.1 - HSE - Policy-01 03 16 PDFDocument1 page02.1 - HSE - Policy-01 03 16 PDFTolias EgwNo ratings yet

- 2.PC Jotun Chart1011 PDFDocument3 pages2.PC Jotun Chart1011 PDFTolias EgwNo ratings yet

- 1..FLOW DRAW MT CHER SW600 Kalooo PDFDocument1 page1..FLOW DRAW MT CHER SW600 Kalooo PDFTolias EgwNo ratings yet

- 1-DD-Akron-CORA-9519705-PROP-60 Months Commercial Paint Delivery 2018-07-18 PDFDocument3 pages1-DD-Akron-CORA-9519705-PROP-60 Months Commercial Paint Delivery 2018-07-18 PDFTolias EgwNo ratings yet

- 1 Cot Slop Level Flowchart PDFDocument1 page1 Cot Slop Level Flowchart PDFTolias EgwNo ratings yet

- 1 3638 3074a 02 PDFDocument1 page1 3638 3074a 02 PDFTolias EgwNo ratings yet

- 1 3638 1204a 02 PDFDocument1 page1 3638 1204a 02 PDFTolias EgwNo ratings yet

- 1.unimarine Equivalent List PDFDocument3 pages1.unimarine Equivalent List PDFTolias EgwNo ratings yet

- 01 General Conditions PDFDocument5 pages01 General Conditions PDFTolias EgwNo ratings yet

- 1st Page PDFDocument1 page1st Page PDFTolias EgwNo ratings yet

- 01-6 Complaint Procedures-R0-15 05 13-Ud 01 07 13 - RINA - PDFDocument5 pages01-6 Complaint Procedures-R0-15 05 13-Ud 01 07 13 - RINA - PDFTolias EgwNo ratings yet

- #408 Steering Gear Overhaul or MaintenanceDocument3 pages#408 Steering Gear Overhaul or MaintenanceTolias EgwNo ratings yet

- 02.2 - D&A Policy-01 03 16 PDFDocument1 page02.2 - D&A Policy-01 03 16 PDFTolias EgwNo ratings yet

- 1 3500 4109a 02 PDFDocument3 pages1 3500 4109a 02 PDFTolias EgwNo ratings yet

- Oxy-Acetelyne Regulation SIRE Vessel Inspection Questionnaire - VIQ 7 PDFDocument1 pageOxy-Acetelyne Regulation SIRE Vessel Inspection Questionnaire - VIQ 7 PDFTolias EgwNo ratings yet

- 1 3500 1183a 02 PDFDocument3 pages1 3500 1183a 02 PDFTolias EgwNo ratings yet

- 00 ContentsDocument6 pages00 ContentsTolias EgwNo ratings yet

- #412 Identification of Critical Equipment and Spares LevelsDocument3 pages#412 Identification of Critical Equipment and Spares LevelsTolias EgwNo ratings yet

- #405 Maintenance of Emergency GeneratorDocument2 pages#405 Maintenance of Emergency GeneratorTolias EgwNo ratings yet

- 0service Bulletin List ForDocument3 pages0service Bulletin List ForTolias Egw100% (1)

- #502 Tank Cleaning Operations - Engine DeptDocument3 pages#502 Tank Cleaning Operations - Engine DeptTolias EgwNo ratings yet