Professional Documents

Culture Documents

6092 01

Uploaded by

Laura MarquezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6092 01

Uploaded by

Laura MarquezCopyright:

Available Formats

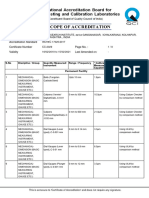

SCOPE OF ACCREDITATION TO ISO/IEC 17025:2017

ACCUREASY METROLOGIA ABSOLUTA S. DE R.L. DE C.V.

Av. Don Bosco No. 41 Int. 31,

Col. El Pueblito, Corregidora

Querétaro CP 76900 México

Edgar Oswaldo Luna Calzada Phone: 52 442 7443593

CALIBRATION

Valid To: May 31, 2023 Certificate Number: 6092.01

In recognition of the successful completion of the A2LA evaluation process, accreditation is granted to this

laboratory to perform the following calibrations1, 6:

I. Dimensional

Parameter/Equipment Range CMC2, 4 (±) Comments

Vernier, Dial and Digital Up to 1000 mm (11 + 0.0086L) μm Method: direct comparison

Calipers3 –

Gage blocks

Vernier, Dial and Digital Up to 750 mm (12 + 0.0064L) μm Method: direct comparison

Depth Gauges –

Gage blocks, surface plate

Vernier, Dial and Digital Method: direct comparison

Height Gauges –

Linearity

Measuring Up to 600 mm (12 + 0.0045L) μm Gage blocks

Face Scriber Parallelism Up to 30 mm 1.3 μm Surface plate

Beam Squareness Up to 500 mm 5.8 μm Master square

Base Flatness Up to 200 mm 1.3 μm Indicator

(A2LA Cert. No. 6092.01) 03/25/2022 Page 1 of 7

Parameter/Equipment Range CMC2, 4 (±) Comments

Height Gauges3 Up to 600 mm (0.44 + 0.0027L) μm Method: direct comparison

Gage blocks, surface plate

Outside Micrometers3 Up to 500 mm (1.1 + 0.0068L) μm Method: direct comparison

Gage blocks, optical flats

Depth Micrometers3 Up to 300 mm (1.7 + 0.0057L) μm Method: direct comparison

Gage blocks

Length Indicators

(Thickness, Digital, Dial, Up to 100 mm (1.1 + 0.034L) μm Method: direct comparison

Test, Lever) – External

Measure3 Gage blocks

Length Indicators Up to 100 mm (4.8 + 0.027L) μm Method: direct comparison

(Digital, Dial, Test, Lever)

– Internal Measure3 Gage blocks

Steel Feeler Gauges3 Up to 3 mm 0.5 μm Method: direct comparison

High accuracy micrometer

Master Discs or Up to 5 mm 0.5 μm Method: direct comparison

Cylindrical Plug Gages (>5 to 25) mm 0.6 μm

Class: Z, ZZ or High accuracy micrometer

Unmarked3

Radius Gages Up to 50.8 mm 4.5 μm Method: direct comparison

Vision system

Rules – Method: direct comparison

Steel Up to 300 mm 7.5 μm Vision system

Aluminum Up to 300 mm 13 μm

(A2LA Cert. No. 6092.01) 03/25/2022 Page 2 of 7

Parameter/Equipment Range CMC2, 4, 5 (±) Comments

Glass Standard Scales Up to 300 mm (1.5 + 0.0077L) μm Method: direct comparison

Vision system

Vision Systems3 Method: direct comparison

Linear Axis X: Up to 300 mm (0.79 + 0.0065L) μm Glass scales

Y: Up to 300 mm (0.79 + 0.0065L) μm Gage blocks

Z: Up to 150 mm 2.7 μm

Profile Projectors, Optical Method: direct comparison

Comparators3

Linear Axis X: Up to 300 mm (1.6 + 0.0097L) μm Glass scales

Y: Up to 300 mm (1.6 + 0.0097L) μm Angle reticle

Angle Up to 360° 2.4’ (0.04°)

Magnification 5X to 20X 0.02 %

Microscopes3 Method: direct comparison

Linear Axis X: Up to 300 mm (0.68 + 0.0081L) μm Glass scales

Y: Up to 300 mm (0.68 + 0.0081L) μm Angle reticle

Angle Up to 360° 2.4’ (0.04°)

Magnification Up to 4000X 0.08 %

Coating Thickness Gages Up to 0.1 mm 0.70 μm Method: direct comparison

(Ferrous Metals and Non- (>0.1 to 1.5) mm 1.9 μm

Ferrous Metals)3 Plastic shims

Ultrasonic Thickness Up to 25.4 mm 14 μm Method: direct comparison

Gage3

Step gage

(A2LA Cert. No. 6092.01) 03/25/2022 Page 3 of 7

Parameter/Equipment Range CMC2, 4 (±) Comments

CMM3 – Method: direct

comparison

Length Measurement Up to 1500 mm (0.37 + 0.0032L) μm ISO 10360-2; section

Error (EL) 6.3, 6.4 and 6.5 -

gage blocks

Single and Multiple 20 mm 0.28 μm ISO 10360-5; section

Stylus Contacting 6.3 and 6.5 - test

Probing Error (Discrete sphere

Point Measuring Mode)

II. Dimensional Testing/Calibration8

Parameter/Equipment Range CMC2, 4, 7 (±) Comments

Length – Measure3, 9 Method: direct

measurement

1D Up to 2500 mm (29 + 0.0041L) μm Articulated

measuring arm

2D (2500 X 2500) mm (29 + 0.0041L) μm

3D (2500 X 2500 X 2500) mm (29 + 0.0041L) μm

Angle Up to 360° 0.04°

Length – Measure9 Method: direct

measurement

1D Up to 300 mm (1.5 + 0.0096L) μm Vision system

2D (300 X 200) mm (1.5 + 0.0096L) μm

Angle Up to 360° 0.02°

(A2LA Cert. No. 6092.01) 03/25/2022 Page 4 of 7

III. Dimensional Testing10

Parameter Range Technique / Method

Workpiece Measurement3, 10

–

1D Up to 2500 mm Articulated measuring arm

2D (2500 X 2500) mm

3D (2500 X 2500 X 2500) mm

Angle Up to 360°

Workpiece Measurement10 –

1D

Up to 300 mm Vision system

2D

(300 X 200) mm

Angle

Up to 360°

III. Mechanical

Parameter/Equipment Range CMC2 (±) Comments

Rockwell Hardness HRBW:

Testers3 Low 1.1 HRBW Method: indirect

Medium 1.0 HRBW verification per

High 0.52 HRBW ISO 6508-2

HRC: Hardness test

Low 0.48 HRC blocks

Medium 0.38 HRC

High 0.38 HRC

HR30N:

Low 0.62 HR30N

Medium 0.45 HR30N

High 0.46 HR30N

(A2LA Cert. No. 6092.01) 03/25/2022 Page 5 of 7

Parameter/Equipment Range CMC2 (±) Comments

Rockwell Hardness HR45N:

Testers3 (cont) Low 0.58 HR45N Method: indirect

Medium 0.43 HR45N verification per

High 0.40 HR45N ISO 6508-2

Hardness test

blocks

Brinell Hardness Testers3 HBW 5/750:

Low 3.1 HBW 5/750 Method: indirect

Medium 7.8 HBW 5/750 verification per

High 12 HBW 5/750 ISO 6506-2

HBW 10/3000:

Low 1.7 HBW 10/3000 Hardness test

Medium 4.0 HBW 10/3000 blocks

High 8.4 HBW 10/3000

_______________________________________________________________

1

This laboratory offers commercial calibration and field calibration services, where noted.

2

Calibration and Measurement Capability Uncertainty (CMC) is the smallest uncertainty of measurement

that a laboratory can achieve within its scope of accreditation when performing more or less routine

calibrations of nearly ideal measurement standards or nearly ideal measuring equipment. CMCs represent

expanded uncertainties expressed at approximately the 95 % level of confidence, usually using a coverage

factor of k = 2. The actual measurement uncertainty of a specific calibration performed by the laboratory

may be greater than the CMC due to the behavior of the customer’s device and to influences from the

circumstances of the specific calibration.

3

Field calibration service is available for this calibration. Please note the actual measurement uncertainties

achievable on a customer's site can normally be expected to be larger than the CMC found on the A2LA

Scope. Allowance must be made for aspects such as the environment at the place of calibration and for

other possible adverse effects such as those caused by transportation of the calibration equipment. The

usual allowance for the actual uncertainty introduced by the item being calibrated, (e.g., resolution) must

also be considered and this, on its own, could result in the actual measurement uncertainty achievable on

a customer’s site being larger than the CMC.

4

In the statement of CMC, L is the numerical value of the nominal length of the device measured in

millimeters.

5

In the statement of CMC, percentages are percentage of reading, unless otherwise indicated.

6

This scope meets A2LA’s P112 Flexible Scope Policy.

7

The type of instrument or material being calibrated is defined by the parameter. This indicates the

laboratory is capable of calibrating instruments that measure or generate the values in the ranges indicated

for the listed measurement parameter.

(A2LA Cert. No. 6092.01) 03/25/2022 Page 6 of 7

8

This laboratory offers commercial dimensional testing/calibration service.

9

This laboratory meets R205 – Specific Requirements: Calibration Laboratory Accreditation Program for

the types of dimensional tests listed above and is considered equivalent to that of a calibration.

10

This test is not equivalent to that of a calibration.

(A2LA Cert. No. 6092.01) 03/25/2022 Page 7 of 7

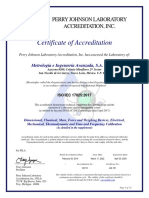

Accredited Laboratory

A2LA has accredited

ACCUREASY METROLOGIA ABSOLUTA S. DE R.L. DE C.V.

Querétaro, MEXICO

for technical competence in the field of

Calibration

This laboratory is accredited in accordance with the recognized International Standard ISO/IEC 17025:2017 General requirements

for the competence of testing and calibration laboratories. This laboratory also meets R205 – Specific Requirements: Calibration

Laboratory Accreditation Program. This accreditation demonstrates technical competence for a defined scope and the

operation of a laboratory quality management system (refer to joint ISO-ILAC-IAF Communiqué dated April 2017).

Presented this 25th day of March 2022.

_______________________

Vice President, Accreditation Services

For the Accreditation Council

Certificate Number 6092.01

Valid to May 31, 2023

For the calibrations to which this accreditation applies, please refer to the laboratory’s Calibration Scope of Accreditation.

You might also like

- McGraw-Hill Education TOEFL iBT With 3 Practice Tests and DVD (Ebook) (2014) PDFDocument905 pagesMcGraw-Hill Education TOEFL iBT With 3 Practice Tests and DVD (Ebook) (2014) PDFlooks4tranz100% (3)

- Ready IMU ModulesDocument6 pagesReady IMU ModulesYonas GhiwotNo ratings yet

- SMT0019-8.6 SynPAKDocument126 pagesSMT0019-8.6 SynPAKhadiNo ratings yet

- MENTALISM THEORY EMPHASIZES INNATE LANGUAGE CAPACITYDocument5 pagesMENTALISM THEORY EMPHASIZES INNATE LANGUAGE CAPACITYBilingual Capricon100% (6)

- 5666 01Document18 pages5666 01Laura MarquezNo ratings yet

- 5825 01Document100 pages5825 01OSCAR YOBANY VEGA HERNANDEZNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument12 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNo ratings yet

- 1078 01Document51 pages1078 01Jessica ChiluisaNo ratings yet

- Laboratory Mikronix Associates Calibration CapabilitiesDocument3 pagesLaboratory Mikronix Associates Calibration CapabilitiesrohanmanimaniNo ratings yet

- 1182 01Document11 pages1182 01Anonymous y3tPCbVrNo ratings yet

- EGV Calibration CertificateDocument11 pagesEGV Calibration CertificatePhuong NguyenNo ratings yet

- Laboratory Calibration Services ISO/IEC 17025:2005Document6 pagesLaboratory Calibration Services ISO/IEC 17025:2005Ravichandran DNo ratings yet

- ISO/IEC 17025 Scope of Accreditation for Calibration LabDocument33 pagesISO/IEC 17025 Scope of Accreditation for Calibration LabAmitNo ratings yet

- Laboratory Calibration Capabilities for Measuring InstrumentsDocument12 pagesLaboratory Calibration Capabilities for Measuring InstrumentsVAIBHAV INSTRUMENTATIONNo ratings yet

- A2LA Accredits Alpha Technologies Services Laboratory for Calibration CompetenceDocument5 pagesA2LA Accredits Alpha Technologies Services Laboratory for Calibration CompetenceNg Wei LihNo ratings yet

- Godrej Nabl ScopeDocument11 pagesGodrej Nabl ScopeRavichandran DNo ratings yet

- ScopeDocument25 pagesScopeAlbert E. Cairns JrNo ratings yet

- Accurate Chennai ScopeDocument7 pagesAccurate Chennai ScopeRavichandran DNo ratings yet

- 1741 14Document22 pages1741 14Laura MarquezNo ratings yet

- Proposed New Tests For Evaluating CMM PerformanceDocument6 pagesProposed New Tests For Evaluating CMM PerformanceharipachanNo ratings yet

- L22-51 Sistemas M Meril Cal MK Approval (3)Document8 pagesL22-51 Sistemas M Meril Cal MK Approval (3)IsaacNo ratings yet

- 3642 01Document4 pages3642 01Egemet SatisNo ratings yet

- ISO 17025 Accredited Laboratory Calibration Certification BMI IndiaDocument2 pagesISO 17025 Accredited Laboratory Calibration Certification BMI IndiarohanmanimaniNo ratings yet

- Tube InspectionDocument6 pagesTube InspectionaamirsaddiqNo ratings yet

- Perfect 684Document4 pagesPerfect 684Ravichandran DNo ratings yet

- IDM Lab1Document5 pagesIDM Lab1gudursrinath11No ratings yet

- Flaw Detector Scope Sample PG 4-4150-01Document22 pagesFlaw Detector Scope Sample PG 4-4150-01ebbasinghNo ratings yet

- Measured Qty / Instrument Range Calibration Measurement Capability ( ) RemarksDocument4 pagesMeasured Qty / Instrument Range Calibration Measurement Capability ( ) RemarksRavichandran DNo ratings yet

- G.B.Central Laboratory, TrichyDocument3 pagesG.B.Central Laboratory, TrichyRavichandran DNo ratings yet

- Overview On Optical Measurements of Shaft Diameter DetectionDocument4 pagesOverview On Optical Measurements of Shaft Diameter DetectionPranav karnNo ratings yet

- Laboratory NameDocument13 pagesLaboratory NameVikram BillalNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument18 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNo ratings yet

- 24K Mech Lab-IS ExtDocument3 pages24K Mech Lab-IS ExtVikasNo ratings yet

- 3.scope Location 1 CC-2706Document8 pages3.scope Location 1 CC-2706Ravichandran DNo ratings yet

- Khosaca Calibration Lab, Chennai ISO/IEC 17025 certificateDocument4 pagesKhosaca Calibration Lab, Chennai ISO/IEC 17025 certificateRavichandran DNo ratings yet

- Lab Procedure Wi 71Document3 pagesLab Procedure Wi 71VikasNo ratings yet

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDocument32 pagesCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncOSCAR YOBANY VEGA HERNANDEZNo ratings yet

- FIE Research InstituteDocument8 pagesFIE Research InstituteAcuteNo ratings yet

- Telemeter Laser Bosch-Glm-100-25cDocument2 pagesTelemeter Laser Bosch-Glm-100-25cylecorreNo ratings yet

- Freescan UEDocument6 pagesFreescan UEAndakara Edo WardhanaNo ratings yet

- 3467 01Document20 pages3467 01Laura MarquezNo ratings yet

- Phy433 Lab Report 1Document9 pagesPhy433 Lab Report 1rabbani abdul rahimNo ratings yet

- Asth 5Document31 pagesAsth 5huidhyiuodghNo ratings yet

- 1888 03Document36 pages1888 03Laura MarquezNo ratings yet

- Certificate of Accreditation: Perry Johnson Laboratory Accreditation, IncDocument12 pagesCertificate of Accreditation: Perry Johnson Laboratory Accreditation, IncVictor Arciga GranadosNo ratings yet

- Reliance 333Document7 pagesReliance 333Ravichandran DNo ratings yet

- NDW Series Computer Controlled Torsion Testing MachineDocument5 pagesNDW Series Computer Controlled Torsion Testing Machinegosaye desalegnNo ratings yet

- FreeScan UEDocument6 pagesFreeScan UESamirNo ratings yet

- Block PagenumberDocument10 pagesBlock PagenumberMotaz Ahmad AmeenNo ratings yet

- Calibration PDFDocument20 pagesCalibration PDFHakim HakimNo ratings yet

- Test CMM 2016 Hand-OutDocument42 pagesTest CMM 2016 Hand-OutHernanda ImawanNo ratings yet

- Tps1200plus-Databasem AlkohlanyDocument16 pagesTps1200plus-Databasem AlkohlanyAyman Al-samawyNo ratings yet

- Laboratory Calibration Centre AccreditationDocument8 pagesLaboratory Calibration Centre AccreditationRavichandran DNo ratings yet

- Digital Horizontal Inclinometer SystemDocument2 pagesDigital Horizontal Inclinometer SystemFaisal AwadNo ratings yet

- Cygnus6plus Data Sheet Issue1aDocument2 pagesCygnus6plus Data Sheet Issue1aopremapodpritisokNo ratings yet

- 3467 01Document19 pages3467 01Sheik Mohamed AliNo ratings yet

- Ar200adfasdasd Daadfasdasdta SheetDocument2 pagesAr200adfasdasd Daadfasdasdta SheetsdfssfwefsNo ratings yet

- CTS 30Document1 pageCTS 30Maria T YateNo ratings yet

- Hardness TesterDocument2 pagesHardness TesterDhanbad Lab Instruments India Pvt LtdNo ratings yet

- Pixelr Hardness Tester CatalogueDocument4 pagesPixelr Hardness Tester CatalogueTechnosys SalesNo ratings yet

- Supply Digimatic Micrometer PDFDocument3 pagesSupply Digimatic Micrometer PDFBonage DattaNo ratings yet

- StepToolCalibrationReport L-CHR 3900 2023-12!14!173815Document2 pagesStepToolCalibrationReport L-CHR 3900 2023-12!14!173815Yassine jbiliNo ratings yet

- 1888 03Document36 pages1888 03Laura MarquezNo ratings yet

- 3467 01Document20 pages3467 01Laura MarquezNo ratings yet

- 1741 14Document22 pages1741 14Laura MarquezNo ratings yet

- 3781 01Document17 pages3781 01Laura MarquezNo ratings yet

- 1888 03Document36 pages1888 03Laura MarquezNo ratings yet

- GR 12 Notes On Audit Reports Eng AfrDocument2 pagesGR 12 Notes On Audit Reports Eng AfrmvelonhlemsimangoNo ratings yet

- First Task in EFYL by Merlina Santi.Document10 pagesFirst Task in EFYL by Merlina Santi.Merlin SantiNo ratings yet

- Group 7 - English For TOEFL PreparationDocument26 pagesGroup 7 - English For TOEFL PreparationNindySJaNo ratings yet

- Sonopet BrochureDocument4 pagesSonopet Brochurecarolina bermudezNo ratings yet

- Effects of Kahramanmaras Earthquakes in South of Turkey On Livestock ActivitiesDocument10 pagesEffects of Kahramanmaras Earthquakes in South of Turkey On Livestock ActivitiesIJAR JOURNALNo ratings yet

- FAW-Guidance Note-2 PDFDocument2 pagesFAW-Guidance Note-2 PDFaiktiplarNo ratings yet

- Seismic Retrofit in Hospitals Using Fluid ViscousDocument6 pagesSeismic Retrofit in Hospitals Using Fluid ViscousDeyanira Sayuri Yangali HerreraNo ratings yet

- Chemistry Lab Report 2Document4 pagesChemistry Lab Report 2Sahaj SinghNo ratings yet

- Barangay Lokeb Norte Trycicle Booking SystemDocument19 pagesBarangay Lokeb Norte Trycicle Booking SystemMark Jumel DomantayNo ratings yet

- RPT-E3: Analog and Networking SystemsDocument2 pagesRPT-E3: Analog and Networking SystemsenriquealugovNo ratings yet

- Empirical Correlation Between CaliforniaDocument94 pagesEmpirical Correlation Between CaliforniaRefilwe MoorosiNo ratings yet

- Preent Simple TenseDocument3 pagesPreent Simple TenseHenrique Pires SantosNo ratings yet

- Supergene Mineralisation of The Boyongan Porphyry Copper-Gold Deposit, Surigao Del Norte, PhilippinesDocument176 pagesSupergene Mineralisation of The Boyongan Porphyry Copper-Gold Deposit, Surigao Del Norte, PhilippinesGuillermo Hermoza MedinaNo ratings yet

- 1685594478BScFinalCompleted 2016-17andonwardDocument115 pages1685594478BScFinalCompleted 2016-17andonwardTanjina Tarannum PrithulaNo ratings yet

- Russian Common AdjectivesDocument8 pagesRussian Common Adjectivesmoniquebateman20No ratings yet

- Introduction To Oil and Gas IndustryDocument4 pagesIntroduction To Oil and Gas IndustryJustice GodsonNo ratings yet

- The No Cry Sleep Solution PDFDocument273 pagesThe No Cry Sleep Solution PDFanastaufan MrNo ratings yet

- Lesson 4 Rainforest CharacteristicsDocument14 pagesLesson 4 Rainforest CharacteristicsLabib Kamal Year 11No ratings yet

- CH 2Document28 pagesCH 2CWHNo ratings yet

- 15.production and Productivity Improvement Measures at MOIL-MOILDocument8 pages15.production and Productivity Improvement Measures at MOIL-MOILkatta_sridharNo ratings yet

- Impact of Performance Management at InfosysDocument8 pagesImpact of Performance Management at InfosysN Pritam DasNo ratings yet

- Mixture: Learning SectionDocument19 pagesMixture: Learning SectionMd. Asif Islam UdayNo ratings yet

- Competitive Club Soccer: Parents' Assessments of Children's Early and Later Sport Specialization - PDocument12 pagesCompetitive Club Soccer: Parents' Assessments of Children's Early and Later Sport Specialization - PAodhan Jane MooneyNo ratings yet

- Bolted Flanged Joint Creep/Relaxation Results at High TemperaturesDocument7 pagesBolted Flanged Joint Creep/Relaxation Results at High TemperaturesjlbarretoaNo ratings yet

- PNC121 Caring CommunicationDocument32 pagesPNC121 Caring CommunicationMateo Giraldo GomezNo ratings yet

- Nguyễn Thị Kim Ngân - Giảng Viên ĐHSPHN - 0904731900 Facebook Page: Miss Ngân Panda English ClassDocument16 pagesNguyễn Thị Kim Ngân - Giảng Viên ĐHSPHN - 0904731900 Facebook Page: Miss Ngân Panda English ClassactuallynhatNo ratings yet

- Logical FallaciesDocument15 pagesLogical FallaciesLouis Marvil AbalaNo ratings yet