Professional Documents

Culture Documents

3.scope Location 1 CC-2706

Uploaded by

Ravichandran DOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3.scope Location 1 CC-2706

Uploaded by

Ravichandran DCopyright:

Available Formats

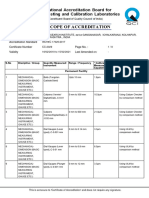

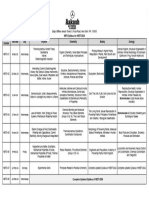

Laboratory Accurate Engineering Co. Pvt. Ltd.

, 3/842, Avadi Poonamallee Road,

Senneerkuppam, Poonamallee, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2706 Page 1 of 8

Validity 28.05.2018 to 27.05.2020 Last Amended on -

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

MEC

HANICAL CALIBRATION

I. DIMENSION (BASIC MEASURING INSTRUMENT, GAUGE ETC.)

1. Gauge Blocks$ Upto 25 mm 0.12 µm Using Gauge Block

(Grade “0” & >25 up to 50 mm 0.16 µm Comparator & Grade “K”

Coarser) > 50 up to 100 mm 0.22 µm Gauge Blocks By

Comparison Method

2. Thread Measuring Ø 0.17 mm to 6.35 mm 1.1 µm Using Electronic

Wires$ Comparator & Gauge

Blocks By Comparison

Method

3. Cylindrical Setting Ø 1 mm to 100 mm 1.0 µm Using Electronic

Master$ Above 100 mm 3.0 µm Comparator & Gauge

Up to 200 mm Blocks By Comparison

Method

4. Measuring Pins $ 0.3 mm to 25 mm 1.0 µm Using Electronic

(Grade “1” & Comparator & Gauge

Coarser) Blocks By Comparison

Method

5. Plain / Setting / Ø 3 mm to 100 mm 1.5 µm Using Universal Length

Master Ring Gauge$ > Ø 100 mm to 200 mm 2.5 µm Measuring M/c & Setting

Ring Gauge By

Comparison Method

6. Micrometer Setting 25 mm up to 450 mm (1+5X) µm “X” in m Using Electronic

Standards$ Comparator & Gauge

Blocks / ULM By

Comparison Method

Sangeeta Kunwar Avijit Das

Convenor Program Director

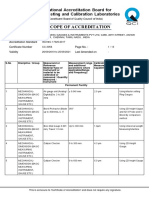

Laboratory Accurate Engineering Co. Pvt. Ltd., 3/842, Avadi Poonamallee Road,

Senneerkuppam, Poonamallee, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2706 Page 2 of 8

Validity 28.05.2018 to 27.05.2020 Last Amended on -

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

7. Thread Measuring A/B/C/D 1.0 µm Using Electronic

Prism$ Comparator By

Comparison Method

8. Riser Block$ Up to 150 mm 2.0 µm Using Lever Type

> 150 mm to 300 mm 3.0 µm Indicator, Surface Plate

& Stand By Comparison

Method

9. Feeler Gauge$ 0.1 mm to 2.0 mm 1.0 µm Using Electronic

Comparator By

Comparison Method

10. Master Foil for Up to 1.25 mm 1.0 µm Using Electronic

Coating Thickness Comparator Comparison

Gauge$ Method

11. Radius Gauge$ Up to 25 mm 13.2 µm Using Video Measuring

System By Comparison

Method

12. Gauge Block Up to 250 mm 1.0 µm Using Electronic

Accessories$ Comparator & Gauge

Blocks By Comparison

Method

13. V-Block $ 300 mm x 100 mm x 6.5 µm Using Co-ordinate

(Perpendicularity, 100 mm Measuring Machine By

Flatness, Parallelism Comparison Method

& Symmetry)

14. Engineers Square / Upto 400 mm 6.0 µm Using Co-ordinate

Try Square$ Measuring Machine By

Comparison Method

Sangeeta Kunwar Avijit Das

Convenor Program Director

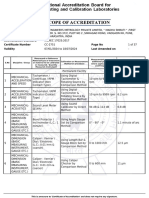

Laboratory Accurate Engineering Co. Pvt. Ltd., 3/842, Avadi Poonamallee Road,

Senneerkuppam, Poonamallee, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2706 Page 3 of 8

Validity 28.05.2018 to 27.05.2020 Last Amended on -

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

15. Plain Plug Gauge / Upto 100 mm 1.4 µm Using Electronic

Setting Master / > Ø 100 mm to 2.0 µm Comparator & Gauge

Width Gauge / Ø 250 mm Blocks by Comparison

Thickness Gauge$ Method

16. Snap Gauge / Dial 1.2 mm to 50 mm 2.0 µm Using Gauge Blocks By

Snap Gauge / > 50 mm to 100 mm 3.0 µm Comparison Method

Adjustable Snap >100 mm to 250 mm 4.0 µm

Gauge / Plain Gap

Gauge$

17. Thread Plug Gauge$ Ø 2 mm to 200 mm 2.8 µm Using Floating Carriage

Dia. Measuring Machine,

Thread Measuring wires/

ULM By Comparison

Method

18. Thread Ring Gauge$ Ø 3 mm to 100 mm 1.9 µm Using Length Measuring

> Ø 100 mm to 200 mm 4.0 µm Machine By Comparison

Method

19. Taper Thread Plug Ø 2 mm to 100 mm 6.5 µm Using Floating Carriage

Gauge$ Dia. Measuring Machine,

Setting Master & Thread

Measuring wires / ULM

By Comparison Method

20. Taper Thread Ring Ø 3 mm to 100 mm 2.0 µm Using Universal Length

Gauge$ Measuring Machine By

Comparison Method

21. Calipers$ Up to 1000 mm (5+10x) µm “x” in m Using Caliper Checker /

(Vernier/Dial/Digital) Gauge Blocks / Length

L.C.: 0.01 mm Bars By Comparison

Method

Sangeeta Kunwar Avijit Das

Convenor Program Director

Laboratory Accurate Engineering Co. Pvt. Ltd., 3/842, Avadi Poonamallee Road,

Senneerkuppam, Poonamallee, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2706 Page 4 of 8

Validity 28.05.2018 to 27.05.2020 Last Amended on -

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

22. Depth Gauge$ Up to 600 mm (5+10x) µm “x” in m Using Depth Micro

(Vernier/Dial/Digital) Checker & Lever type

L.C.: 0.01 mm Indicator By Comparison

Method

23. Height Gauge$ Up to 1000 mm (1+4x) µm “x” in m Using Caliper Checker /

(Vernier /Dial/ Digital) Gauge Blocks / Length

L.C.: 0.001mm Bars Comparison

Method

24. External Micrometer$ Up to 100 mm 1.5 µm Using Grade “1” Gauge

L.C.: 0.001mm >100 mm to 250 mm 7.0 µm Blocks & Optical Flat By

> 250 mm to 500 mm 9.0 µm Comparison Method

25. Internal Micrometer$ 5 mm to 100 mm 7.0 µm Using Master Ring

L.C.: 0.01 mm 100 mm to 250 mm 9.0 µm Gauges by Comparison

Method

26. Depth Micrometer$ Up to 150 mm 7.0 µm Using Depth Micro

LC.: 0.001 mm > 150 mm to 250 mm 8.0 µm Checker & Gauge

Blocks By Comparison

Method

27. Micrometer Head$ Up to 25 mm 1.0 µm Using Electronic

L.C.: 0.0002 mm Comparator By

Comparison Method

28. Height Micrometer$ Up to 300 mm 3.0 µm Using Gauge Blocks &

0.0005 mm Lever type Indicator by

Comparison Method

29. Dial Calibration Using Electronic

Tester$ Comparator By

L.C.: 0.0001 mm Up to 25 mm 1.0 µm Comparison method

Sangeeta Kunwar Avijit Das

Convenor Program Director

Laboratory Accurate Engineering Co. Pvt. Ltd., 3/842, Avadi Poonamallee Road,

Senneerkuppam, Poonamallee, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2706 Page 5 of 8

Validity 28.05.2018 to 27.05.2020 Last Amended on -

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

30. Dial Gauge Plunger Up to 25 mm 1.2 µm Using Electronic Dial

Type$ Up to 50 mm 2.7 µm Calibration Tester

L.C.: 0.001 mm By Comparison Method

31. Dial Gauge Lever Up to 2 mm 1.0 µm Using Electronic

Type$ Calibration Tester

L.C.: 0.001mm By Comparison Method

32. Bore Gauge$ Up to 2 mm 2.7 µm Using Electronic

(For Transmission) (Ø 20 mm to 400 mm) Calibration Tester

L.C.: 0.001 mm By Comparison Method

33. Dial Snap Gauge / Up to 200 mm 4.23 µm Using Gauge Blocks

Dial Thickness By Comparison Method

Gauge/Pistol

Caliper $

0.001 mm

34. Comparator Stand$ Up to 300 mm 1.53 µm Using Gauge Blocks &

Lever type Indicator By

Comparison based on

IS: 14271

35. Electronic Probe$ Up to 300 mm 1.0 µm Using Gauge Blocks by

Resolution: 0.1µm Comparison method

36. Straight Edge$ Up to 600 mm 8.0 µm Using CMM by

Comparison method

37. Three Point Bore Using Master Ring

Gauge$ Gauges by Comparison

L.C.: 0.001 mm Ø 6 mm Up to 100 mm 4.7 µm method

38. Sine Bar/Sine Centre$ Up to 300 mm & 6ʺ Arc Using 3D Co-ordinate

Up to 60º 4.0 µm Measuring Machine By

Center distance between In-Direct Method

Roller

Sangeeta Kunwar Avijit Das

Convenor Program Director

Laboratory Accurate Engineering Co. Pvt. Ltd., 3/842, Avadi Poonamallee Road,

Senneerkuppam, Poonamallee, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2706 Page 6 of 8

Validity 28.05.2018 to 27.05.2020 Last Amended on -

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

39. Angle Plate$ Upto 300 mm & 6.7 µm Using 3D Co-ordinate

Upto 90º Measuring Machine By

In-direct Method

40. Spirit Level$ ± 0.1 mm/m 0.01 mm/m Using Electronic Level

Sensitivity: By Comparison method

0.01mm/m

41. Bevel Protector / 0 to 360º 5ʹ Arc Using 3D Co-ordinate

Combination Set$ Measuring Machine By

L.C.: 5 Arc Mins In-direct Method

42. Pitch Micrometer For 0 to 25 mm 1.6 µm Using Gauge Blocks and

Anvil$ Angle 7’ 48” Video measuring

L.C.: 0.001 mm Machine By Comparison

Method

43. Thread Pitch Gauge$ Flank Angle – 55º, 60º 7’ 48” Using Video Measuring

(Angle) Machine By Direct

Pitch 0.3 mm to 6.0 mm 10 µm Method

44. Coating Thickness Up to 2 mm 4.5 µm Using Master foils by

Gauge$ Comparison Method

L.C.: 0.001 mm

45. Lobbing Micrometer / Up to 25 mm 1.5 µm Using Cylindrical Setting

V – Anvil Micrometer$ Masters By Comparison

L.C.: 0.001 mm Method

46. Spline Gauges$ Up to 100 mm 2.0 µm Using Gauge Blocks

(Internal) By Comparison Method

47. Spline Gauges$ Up to 100 mm 2.5 µm Using FCDM / ULM

(External) By Comparison Method

Sangeeta Kunwar Avijit Das

Convenor Program Director

Laboratory Accurate Engineering Co. Pvt. Ltd., 3/842, Avadi Poonamallee Road,

Senneerkuppam, Poonamallee, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2706 Page 7 of 8

Validity 28.05.2018 to 27.05.2020 Last Amended on -

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

48. Test Mandrel$ Up to 150 mm Using Electronic

Diameter 1.2 µm Comparator Probe By

Run Out 5.0 µm Comparison Method

49. Surface Plate♣ 2500 mm x 1600 mm W +L Using Electronic Level

01.36 √ 100

m

W=Width, L=Length

In-direct Method

50. Electronic Height Up to 600 mm 4.0 µm Using Step Gauge /

Gauge ♣ Up to 1000 mm 7.0 µm Check Master / Gauge

L.C.: 0.0001 mm Blocks By Comparison

Method

51. Metallurgical 100 x to 1000 x 0.4% Using Glass Scale By

Microscope♣ Comparison Method

II. DIMENSION (PRECISION INSTRUMENTS)

1. Caliper Checker / Up to 300 mm 7.2 µm Using Co-ordinate

Depth Micro – Above 300 mm to 8.0 µm Measuring Machine

Checker / Internal 600 mm (CMM) by Comparison

Micro Checker$ Method

2. Floating Carriage Up to 175 mm 2.0 µm Using Cylinder Setting

Dia. Measuring Master & Electronic

Machine$ Probe By Comparison

L.C.: 0.0001µm Method

3. Length Bars$ Up to 500 mm 3.8 µm Using ULM By

Comparison Method

4. Reference Sphere Dia 50 mm 1.5 µm Using ULM By

Dia Measurement$ Comparison Method

Sangeeta Kunwar Avijit Das

Convenor Program Director

Laboratory Accurate Engineering Co. Pvt. Ltd., 3/842, Avadi Poonamallee Road,

Senneerkuppam, Poonamallee, Chennai, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2706 Page 8 of 8

Validity 28.05.2018 to 27.05.2020 Last Amended on -

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

5. Profile Projector Up to 100 mm 2.0 µm Using Linear Glass

Linear♣ Scale, Angular Glass

L.C.: 0.1 µm Above 100 mm 7.0 µm Protractor By

Up to 200 mm Comparison Method

Angular 0 to 360º 2ʺ Arc

L.C.: 1ʺ Arc

Magnification 10 x to 100 x 0.8 %

6. 3-D Coordinate 1000 mm x1000 mm x (2.3+2L) µm Using Check Master &

Measuring Machine♣ 1000 mm L in m Length Bars by

L.C.: 0.1 µm Comparison Method

7. Length Measuring Up to 300 mm 0.5 µm Up to100 mm Using “K” Grade Gauge

Machine ♣ 3.0 µm Above100 mm Blocks & Length Bar By

L.C.: 0.0001 mm Up to 300 mm Comparison Method

* Measurement Capability is expressed as an uncertainty () at a confidence probability of 95%

$

Only in Permanent Laboratory

♣

Only for Site Calibration

Sangeeta Kunwar Avijit Das

Convenor Program Director

You might also like

- Laboratory Accurate Instruments Calibration CapabilitiesDocument8 pagesLaboratory Accurate Instruments Calibration CapabilitiesRavichandran DNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument18 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument12 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNo ratings yet

- Laboratory Mikronix Associates Calibration CapabilitiesDocument3 pagesLaboratory Mikronix Associates Calibration CapabilitiesrohanmanimaniNo ratings yet

- 24.scope Location 1 CC-2833Document4 pages24.scope Location 1 CC-2833Ravichandran DNo ratings yet

- Reliance 333Document7 pagesReliance 333Ravichandran DNo ratings yet

- Accurate Pune.C0052Document12 pagesAccurate Pune.C0052Ravichandran DNo ratings yet

- Accurate Chennai ScopeDocument7 pagesAccurate Chennai ScopeRavichandran DNo ratings yet

- 6092 01Document8 pages6092 01Laura MarquezNo ratings yet

- Laboratory Calibration Capabilities for Measuring InstrumentsDocument12 pagesLaboratory Calibration Capabilities for Measuring InstrumentsVAIBHAV INSTRUMENTATIONNo ratings yet

- ISO 17025 Accredited Laboratory Calibration Certification BMI IndiaDocument2 pagesISO 17025 Accredited Laboratory Calibration Certification BMI IndiarohanmanimaniNo ratings yet

- G.B.Central Laboratory, TrichyDocument3 pagesG.B.Central Laboratory, TrichyRavichandran DNo ratings yet

- CMTI ScopeDocument13 pagesCMTI ScopeRavichandran DNo ratings yet

- FIE Research InstituteDocument8 pagesFIE Research InstituteAcuteNo ratings yet

- Godrej Nabl ScopeDocument11 pagesGodrej Nabl ScopeRavichandran DNo ratings yet

- Using Gauge Block Set, Length Bar & Caliper Checker by Comparison Method As Per IS 3651Document13 pagesUsing Gauge Block Set, Length Bar & Caliper Checker by Comparison Method As Per IS 3651rohanmanimaniNo ratings yet

- Laboratory NameDocument13 pagesLaboratory NameVikram BillalNo ratings yet

- Scope-CC-2331Document5 pagesScope-CC-2331snsarangi06No ratings yet

- 2658Document7 pages2658rohanmanimaniNo ratings yet

- Laboratory Calibration Services ISO/IEC 17025:2005Document6 pagesLaboratory Calibration Services ISO/IEC 17025:2005Ravichandran DNo ratings yet

- Perfect 684Document4 pagesPerfect 684Ravichandran DNo ratings yet

- Sitarc - C - 0135Document7 pagesSitarc - C - 0135Ravichandran DNo ratings yet

- Metrology Labortory Tata Motors Limited Jamshedpur Scope 14594876972533Document5 pagesMetrology Labortory Tata Motors Limited Jamshedpur Scope 14594876972533Gowtham Raj KNo ratings yet

- Measured Qty / Instrument Range Calibration Measurement Capability ( ) RemarksDocument4 pagesMeasured Qty / Instrument Range Calibration Measurement Capability ( ) RemarksRavichandran DNo ratings yet

- Edoc - Pub Occult ScienceDocument4 pagesEdoc - Pub Occult ScienceSaraswantoNo ratings yet

- Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) % RemarksDocument3 pagesQuantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) % RemarksrohanmanimaniNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument9 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksSyarif MaulanaNo ratings yet

- Physics Homework 4Document1 pagePhysics Homework 4ChristianNo ratings yet

- Scope CC 3131Document6 pagesScope CC 3131Assistant Director KHRINo ratings yet

- 5666 01Document18 pages5666 01Laura MarquezNo ratings yet

- Scope CC 3399Document10 pagesScope CC 3399dheeraj chawlaNo ratings yet

- Metravi PRO 7273 10A Microohms Meter Catalogue WebDocument3 pagesMetravi PRO 7273 10A Microohms Meter Catalogue WebGaurav kumarNo ratings yet

- Laboratory Alfa Machine Tools ISO/IEC 17025 CalibrationDocument3 pagesLaboratory Alfa Machine Tools ISO/IEC 17025 CalibrationRavichandran DNo ratings yet

- Indoshell - C - 0400Document2 pagesIndoshell - C - 0400Ravichandran DNo ratings yet

- Micro Ohm Meter: 10 Amps CurrentDocument2 pagesMicro Ohm Meter: 10 Amps CurrentudhayNo ratings yet

- Dimensinal Metrology Lab DMLDocument3 pagesDimensinal Metrology Lab DMLDoulat RamNo ratings yet

- ScopeANAB ACDM-2814-Ver.6Document58 pagesScopeANAB ACDM-2814-Ver.6tsarayuth1.2017No ratings yet

- CRM 100A: Contact Resistance MeterDocument2 pagesCRM 100A: Contact Resistance Meteramiya_driemsNo ratings yet

- CL 222 CertDocument5 pagesCL 222 CertS SHALUNo ratings yet

- Miliometro para Comprobar Exitencia Ficha de DatosDocument1 pageMiliometro para Comprobar Exitencia Ficha de DatosbubdiaNo ratings yet

- Micrometers - Measurement System Types and Characteristics - Measurement Fundamentals - KEYENCE AmericaDocument1 pageMicrometers - Measurement System Types and Characteristics - Measurement Fundamentals - KEYENCE AmericaTatsNo ratings yet

- Traceable Roughness of ProductsDocument7 pagesTraceable Roughness of ProductsSaraswantoNo ratings yet

- Quantum IkeDocument1 pageQuantum IkeMedoBoudyNo ratings yet

- Laboratory Calibration Centre AccreditationDocument8 pagesLaboratory Calibration Centre AccreditationRavichandran DNo ratings yet

- Scope CC 2008 - ERTLDocument59 pagesScope CC 2008 - ERTLAnirban DasNo ratings yet

- Lab Scope Certificate ISO 17025-2017Document33 pagesLab Scope Certificate ISO 17025-2017Khan SattrakulvongNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument26 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksBALAJINo ratings yet

- ISO/IEC 17025 Calibration Services AccreditationDocument15 pagesISO/IEC 17025 Calibration Services AccreditationDhinagaran ANo ratings yet

- IQ Conductivity MeterDocument10 pagesIQ Conductivity MeterMohsin AliNo ratings yet

- Single Electrode Dielectric/Conductivity Sensor SpecificationsDocument11 pagesSingle Electrode Dielectric/Conductivity Sensor SpecificationsTasfikNo ratings yet

- Free Digital Multimeter Calibration ProcedureDocument10 pagesFree Digital Multimeter Calibration ProcedureGordinhorsNo ratings yet

- Scope CC 2751Document37 pagesScope CC 2751Vishal ShindeNo ratings yet

- AvijitDocument2 pagesAvijitBAlaNo ratings yet

- Northlab HosurDocument25 pagesNorthlab HosurVikram BillalNo ratings yet

- Sea 2007Document21 pagesSea 2007juan zamoraNo ratings yet

- LK-097-IDN (Length)Document1 pageLK-097-IDN (Length)Aries SupiyantoNo ratings yet

- EM2210 Manual enDocument18 pagesEM2210 Manual enPeter SuNo ratings yet

- ANALOG METER VAW - 95 (For Iron Loss Measurement)Document1 pageANALOG METER VAW - 95 (For Iron Loss Measurement)Silverio AcuñaNo ratings yet

- Product Data Sheet Opm 3000 Opacity Dust Density Monitor Rosemount en 71978Document12 pagesProduct Data Sheet Opm 3000 Opacity Dust Density Monitor Rosemount en 71978Tito Saul PerezNo ratings yet

- Is 1364 5 2002 PDFDocument13 pagesIs 1364 5 2002 PDFBimal DeyNo ratings yet

- Is 15 (1973)Document14 pagesIs 15 (1973)Ravichandran DNo ratings yet

- Is 1 (1968)Document23 pagesIs 1 (1968)Ravichandran DNo ratings yet

- Is 1344 (1981) PDFDocument15 pagesIs 1344 (1981) PDFRavichandran DNo ratings yet

- Is 10-2 (1996) PDFDocument14 pagesIs 10-2 (1996) PDFRavichandran DNo ratings yet

- IS 2102 Part 1 (1993) ISO 2768-1 (1989)Document8 pagesIS 2102 Part 1 (1993) ISO 2768-1 (1989)Ravichandran DNo ratings yet

- Shanmugha Precision Forging Control PlanDocument4 pagesShanmugha Precision Forging Control PlanRavichandran D100% (1)

- Is 5939 (1970) PDFDocument6 pagesIs 5939 (1970) PDFRavichandran DNo ratings yet

- Is 15423-2 (2003) Iso 5436-2 (2001)Document21 pagesIs 15423-2 (2003) Iso 5436-2 (2001)Ravichandran DNo ratings yet

- Precision Parts Quality ReportDocument1 pagePrecision Parts Quality ReportRavichandran DNo ratings yet

- Disclosure To Promote The Right To InformationDocument5 pagesDisclosure To Promote The Right To InformationRavichandran DNo ratings yet

- Is 11498 1985 PDFDocument8 pagesIs 11498 1985 PDFAcuteNo ratings yet

- Shanmugha Precision Forging Non - Conformance Report: Total Cost:1340Document2 pagesShanmugha Precision Forging Non - Conformance Report: Total Cost:1340Ravichandran DNo ratings yet

- Is 5812 (1970) PDFDocument3 pagesIs 5812 (1970) PDFRavichandran DNo ratings yet

- WORKSDocument1 pageWORKSRavichandran DNo ratings yet

- NCR F10 15Document1 pageNCR F10 15Ravichandran DNo ratings yet

- QUALITY QN. For OPERATORSDocument2 pagesQUALITY QN. For OPERATORSRavichandran DNo ratings yet

- Shanmugha Precision Forging Non - Conformance ReportDocument2 pagesShanmugha Precision Forging Non - Conformance ReportRavichandran DNo ratings yet

- Shanmugha Precision Forging Non - Conformance Report: RejectedDocument2 pagesShanmugha Precision Forging Non - Conformance Report: RejectedRavichandran DNo ratings yet

- Precision Forging Non-Conformance ReportDocument2 pagesPrecision Forging Non-Conformance ReportRavichandran DNo ratings yet

- NC44 45 GauravDocument2 pagesNC44 45 GauravRavichandran DNo ratings yet

- Non Conformance Report (Audit) : Description of Non-ConformamceDocument16 pagesNon Conformance Report (Audit) : Description of Non-ConformamceRavichandran DNo ratings yet

- NC43 - 64 - Shell TechDocument2 pagesNC43 - 64 - Shell TechRavichandran DNo ratings yet

- Shanmugha Precision Forging Non - Conformance Report: RejectedDocument2 pagesShanmugha Precision Forging Non - Conformance Report: RejectedRavichandran DNo ratings yet

- Precision Forging NCR ReportDocument3 pagesPrecision Forging NCR ReportRavichandran DNo ratings yet

- Precision Forging Non-Conformance ReportDocument2 pagesPrecision Forging Non-Conformance ReportRavichandran DNo ratings yet

- C Number Stage Number Revisio N Locatio N Client Number Record Date Total Quantit yDocument32 pagesC Number Stage Number Revisio N Locatio N Client Number Record Date Total Quantit yRavichandran DNo ratings yet

- Shanmugha Precision Forging Non - Conformance Report: Rejection Cost 516Document2 pagesShanmugha Precision Forging Non - Conformance Report: Rejection Cost 516Ravichandran DNo ratings yet

- Precision Forging Non-Conformance ReportDocument1 pagePrecision Forging Non-Conformance ReportRavichandran DNo ratings yet

- Defect Information for Nonconformance: NC-EXT220347-01 - Thread Size Attribute Issue on 1/4-28 Threads Due to BurrsDocument1 pageDefect Information for Nonconformance: NC-EXT220347-01 - Thread Size Attribute Issue on 1/4-28 Threads Due to BurrsRavichandran DNo ratings yet

- Chemistry Lab Report 2Document4 pagesChemistry Lab Report 2Sahaj SinghNo ratings yet

- A Systematic Review of Enablers of Collaboration Among The Participants in Construction ProjectsDocument14 pagesA Systematic Review of Enablers of Collaboration Among The Participants in Construction ProjectsShumank SrivastavaNo ratings yet

- Brand Guidelines ShortDocument9 pagesBrand Guidelines ShortFarhan SaeedNo ratings yet

- 2NS SEMESTER Self Instructured Module in Community EngagementDocument31 pages2NS SEMESTER Self Instructured Module in Community EngagementEditha FernandezNo ratings yet

- Ceramage: Light-Curing Microhybrid CompositeDocument3 pagesCeramage: Light-Curing Microhybrid CompositeVero GrambergNo ratings yet

- Research 3Document76 pagesResearch 3Jackson IbascoNo ratings yet

- Yousefi 2018Document10 pagesYousefi 2018Yuzar StuffNo ratings yet

- LS Lpli SMS El V1.8Document2 pagesLS Lpli SMS El V1.8adelgcNo ratings yet

- Loraine Chemutai Koskei LAW/MG/1139/09/19 Enviromental and Natural Resource Law - Cat2 Hazardous WasteDocument4 pagesLoraine Chemutai Koskei LAW/MG/1139/09/19 Enviromental and Natural Resource Law - Cat2 Hazardous Wasteloraine koskeiNo ratings yet

- System Dynamics IntroductionDocument8 pagesSystem Dynamics IntroductionDavid Abraham Jiménez MartínezNo ratings yet

- I've Got To Be MeDocument35 pagesI've Got To Be MeRosejen MangubatNo ratings yet

- Bacon on Marriage and Single LifeDocument2 pagesBacon on Marriage and Single LifeLijimol GeorgeNo ratings yet

- Unit 4 Idea ElaborationDocument36 pagesUnit 4 Idea ElaborationSai TejaNo ratings yet

- Effects of Single ParentingDocument3 pagesEffects of Single Parentingmaria mariaNo ratings yet

- Math Success - Percents and RatiosDocument64 pagesMath Success - Percents and RatiosLớp Văn BằngNo ratings yet

- Preliminary Examination - Attempt Review1 PDFDocument11 pagesPreliminary Examination - Attempt Review1 PDFPeter Eclevia0% (1)

- Traffic Signals PuzzleDocument11 pagesTraffic Signals Puzzlesabir aliNo ratings yet

- LPS Training - 2015 Update FINALDocument65 pagesLPS Training - 2015 Update FINALAsriSaffuan86% (7)

- Module 1 - Numerical Problems: Dr. M. Akhila MaheswariDocument14 pagesModule 1 - Numerical Problems: Dr. M. Akhila MaheswariShaunak bagadeNo ratings yet

- Cec 208 Lecture Notes 1Document9 pagesCec 208 Lecture Notes 1Zaid Habibu100% (1)

- Risk Assessment For Purified WaterDocument53 pagesRisk Assessment For Purified WaterparuchurietindraNo ratings yet

- Self-Operated Pressure Regulators ANSI Version: T 2513 EN Type 41-23 Universal Pressure Reducing ValveDocument6 pagesSelf-Operated Pressure Regulators ANSI Version: T 2513 EN Type 41-23 Universal Pressure Reducing ValveagrovadoNo ratings yet

- (MIÑOZA - Wen Roniel Badayos) - PKYF 2023 Application EssayDocument3 pages(MIÑOZA - Wen Roniel Badayos) - PKYF 2023 Application EssayWen MinozaNo ratings yet

- GR 12 Notes On Audit Reports Eng AfrDocument2 pagesGR 12 Notes On Audit Reports Eng AfrmvelonhlemsimangoNo ratings yet

- Syllabus of NCERT Booster Test Series - CoE NEET-2024 - 071157Document1 pageSyllabus of NCERT Booster Test Series - CoE NEET-2024 - 071157bishnuprasadmohapatra01No ratings yet

- Evita Infinity v500 SW 2n Ifu 9052161 Ingles PDFDocument384 pagesEvita Infinity v500 SW 2n Ifu 9052161 Ingles PDFTu Papa2411No ratings yet

- The Laryngeal Nerve of The Giraffe: Does It Prove Evolution?Document13 pagesThe Laryngeal Nerve of The Giraffe: Does It Prove Evolution?ShwazaraNo ratings yet

- Roots of EquationsDocument31 pagesRoots of EquationsGzim RamadaniNo ratings yet

- Minerals Engineering: Duncan M. Smythe, Annegret Lombard, Louis L. CoetzeeDocument10 pagesMinerals Engineering: Duncan M. Smythe, Annegret Lombard, Louis L. Coetzeefaouzi rachidNo ratings yet