Professional Documents

Culture Documents

Laboratory Accurate Instruments Calibration Capabilities

Uploaded by

Ravichandran DOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Laboratory Accurate Instruments Calibration Capabilities

Uploaded by

Ravichandran DCopyright:

Available Formats

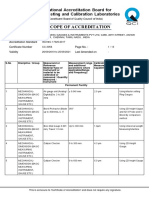

Laboratory Accurate India Instruments, No.

33, SLV Nagar, Zuzuwadi, Sipcot,

Hosur, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2878 Page 1 of 8

Validity 26.10.2018 to 25.10.2020 Last Amended on 03.12.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

MECHANICAL CALIBRATION

I. DIMENSION (BASIC MEASURING INSTRUMENT, GAUGE ETC.)

1. Cylindrical Measuring 0.1 mm to 20 mm 0.84 m Using Electronic Probe

Pins (Grade 1 & & Slip Gauge Blocks by

Coarser)$ Comparison Method

2. Setting Standard$ Upto 100 mm 1.2 m Using Gauge Blocks,

100 mm to 600 mm 9.3 m Electronic Probe and Long

Gauge Block by

Comparison Method

3. Feeler Gauges$ 0.01mm to 2 mm 2.4 m Using Digital Micrometer by

Comparison Method

4. Plain Plug Gauges$ 0.1 mm to 100 mm 1.8 m Using Electronic Probe &

100 mm to 200mm 4.4 mm Slip Gauge by Comparison

Method

5. Snap/ Gap Gauges$ Upto 100 mm 2.5 mm Using Gauge Blocks,

100 mm to 400 mm 6.1 mm Long Gauge Blocks by

Comparison Method

6. V – Blocks$ Upto 300 mm

Flatness 3.3 m Using Lever Dial & Mandrel,

Parallelism 4.9 m Square Master & Surface

Symmetricity 4.9 m Plate by Comparison

Method

7. Width Gauge$ Upto 50 mm 2.6 m Using Electronic Probe &

Rajeshwar Kumar Avijit Das

Convenor Program Manager

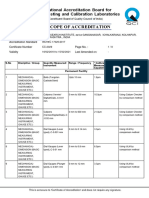

Laboratory Accurate India Instruments, No. 33, SLV Nagar, Zuzuwadi, Sipcot,

Hosur, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2878 Page 2 of 8

Validity 26.10.2018 to 25.10.2020 Last Amended on 03.12.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

Gauge Blocks by

Comparison Method

8. Thread Measuring 0.17 mm to 20 mm 0.5 m Using Electronic Probe &

Wires / Gauge Blocks by

Three Wire Set$ Comparison Method

9. Cylindrical Setting / 0.1 mm to 100 mm 1.5 m Using Electronic Probe &

Masters$ Gauge Blocks by

(Only Diameter) Comparison Method

10. Flush Pin Gauge$ 0.1 mm to 100 mm 2.0 m Using Electronic Probe &

Gauge Blocks by

Comparison Method

11. Calipers$ Using Caliper Checker/

Vernier / Dial / Gauge Blocks/ Long Gauge

Electronic Blocks by Comparison

L. C. 0.001mmф Upto 600 mm 11.1 m Method

12. Height Gauge$ Using Caliper Checker/

Vernier / Dial / Gauge Blocks/ Long Gauge

Electronic Blocks by Comparison

L. C. 0.01mmф Upto 600 mm 12.0m Method

13. Depth Gauges$

Vernier / Dial /

Electronic

L. C. 0.01mmф Upto 300 mm 7.9 m Using Gauge Blocks/ Long

Gauge Blocks by

Comparison Method

14. External Micrometer$

Rajeshwar Kumar Avijit Das

Convenor Program Manager

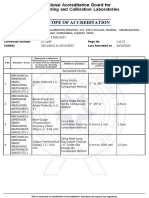

Laboratory Accurate India Instruments, No. 33, SLV Nagar, Zuzuwadi, Sipcot,

Hosur, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2878 Page 3 of 8

Validity 26.10.2018 to 25.10.2020 Last Amended on 03.12.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

L. C. 0.001mmф Upto 600 mm 6.4 m Using Caliper Checker/

Gauge Blocks/ Long Gauge

Blocks by Comparison

Method

15. Depth Micrometer$

L. C. 0.001mmф Upto 300 mm 2.7m Using Gauge Blocks by

Comparison Method

16. Plunger Dial Gauge$

L. C. 0.001mmф Upto 5 mm 2.2 m Using Dial Calibration

L. C. 0.01 mm Upto 50 mm 6.2 m Tester/ Gauge Blocks by

Comparison Method

17. Lever Type Dial Gauge$

L. C. 0.001 mm Upto 0.14 mm 2.2 m Using Dial Calibration

L. C. 0.001 mm Upto 0.2 mm 2.4 m Tester by Comparison

L. C. 0.01 mm Upto 2 mm 6.2 m Method

18. Electronic Indicator$

L. C. 0.001mmф Upto 50 mm 1.5m Using Slip Gauge by

Comparison Method

19. Bore Gauge – Using Dial Calibration

Dia. Range: 6mm to 4.0m

Analog/Digital$ Tester by Comparison

400mm

(Only Transmission Method

Probing Range:

Error )

Upto 1.0mm

Rajeshwar Kumar Avijit Das

Convenor Program Manager

Laboratory Accurate India Instruments, No. 33, SLV Nagar, Zuzuwadi, Sipcot,

Hosur, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2878 Page 4 of 8

Validity 26.10.2018 to 25.10.2020 Last Amended on 03.12.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

20. Dial Thickness Gauge$

L. C. 0.001mmф Upto 2 mm 1.0 m Using Gauge Blocks by

L. C. 0.01mm Upto 50mm 6.0m Comparison Method

21. Dial Snap Gauge$

L. C. 0.001mmф Upto 200 mm 3.1m Using Gauge Blocks by

Comparison Method

22. Micrometer Head$

L. C. 0.0001 mmф Upto 25 mm 1.8 m Using Electronic Probe by

Comparison Method

23. Dial Caliper Gauge$

(External)

L. C. 0.01mmф Upto 500 mm 7.0 m Using Gauge Blocks

Accessories by Comparison

Method

24. Internal Micrometer$

(Two Point)

L. C. 0.001 mmф 0 to 300mm 3.7m Using Slip Gauge &

Slip Gauge Accessories Set

by Comparison Method

25. Dial Calibration Tester$ Using Slip Gauge &

L. C. 0.0001ф Upto 50 mm 1.5 m Slip Gauge Accessories Set

by Comparison Method

26. Dial Caliper Gauge$

(Internal)

L. C. 0.01mmф 5 mm to 300 mm 8.0m Using Slip Gauge Blocks &

Slip Gauge Accessories by

Rajeshwar Kumar Avijit Das

Convenor Program Manager

Laboratory Accurate India Instruments, No. 33, SLV Nagar, Zuzuwadi, Sipcot,

Hosur, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2878 Page 5 of 8

Validity 26.10.2018 to 25.10.2020 Last Amended on 03.12.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

Comparison Method

27. Electronic Probe$

L.C.0.0001ф 0 to 25 mm 0.34m Using Gauge Blocks by

Comparison Method

28. Comparator Stand / Dial Upto 300mm X 3.9 m Using Lever Gauge by

Stand$ 300mm Comparison Method

29. Coating Thickness 0.01mm to 1 mm 2.5m Using Master Foils by

Gauge$ Comparison Method

30. Master Foils$ 0.01mm to 2 mm 1.2m Using Electronic Probe by

Comparison Method

31. Bevel Protractor /

Combination Set$

L.C. 5’ф Upto 360 º 6.5 min. Using Profile Projector by

Comparison Method

32. Floating Carriage

Diameter

Machine$

L.C. 0.0001mm Upto 175 mm 3.3m Using Cylindrical Setting

master and Lever Dial by

Comparison Method

33. Steel Scale$

Rajeshwar Kumar Avijit Das

Convenor Program Manager

Laboratory Accurate India Instruments, No. 33, SLV Nagar, Zuzuwadi, Sipcot,

Hosur, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2878 Page 6 of 8

Validity 26.10.2018 to 25.10.2020 Last Amended on 03.12.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

L.C. 1.0 mm Upto 300 mm 150m Using Profile Projector by

Comparison Method

34. Thread Pitch Gauge$ Pitch: 0.6mm to 7.4m Using Profile Projector by

25mm 10 arc min Comparison Method

Angle: 90º

35. Taper Scale$ 1 mm to 45 mm 13.6 m Using Profile Projector by

Comparison Method

36. Three Point Internal

Micrometer$

L.C 0.001 mm 4mm to 100 mm 5.3 m Using Setting Ring Gauge

by Comparison Method

37. Thread Plug Gauge/ 3 mm to 100 mm 3.5 m Using FCDM & Cylindrical

Wear Check Plug Master and Thread

Gauge$ Measuring Wire by

Comparison Method

38. Taper Thread Plug 3 mm to 100 mm 3.7 m Using FCDM & Cylindrical

Gauge$ Master and Thread

Measuring Wire by

Comparison Method

39. Radius Gauge$ 0.5 mm to 25 mm 7.5 m Using Profile Projector by

Direct Method

40. Surface Plate# 3000mm X 3000mm 1.7 {√(W+L)/100}m Using Electronic Level by

Where W & L are in mm Comparison Method

41. Electronic Height

Gauge#

Rajeshwar Kumar Avijit Das

Convenor Program Manager

Laboratory Accurate India Instruments, No. 33, SLV Nagar, Zuzuwadi, Sipcot,

Hosur, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2878 Page 7 of 8

Validity 26.10.2018 to 25.10.2020 Last Amended on 03.12.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

L.C. 0.1m Upto 600 mm 7.5 m Using Gauge Blocks/ Long

Gauge Blocks by

Comparison Method

42. Bench Center# Upto 600 mm 6.3 m Using Mandrel and Dial

Indicator by Direct Method

II. PRESSURE INDICATING DEVICES

1. Pneumatic 0 bar to 20 bar 0.14 % Using Pressure Calibrator

Pressure Gauge# as per DKD-R-6-1

2. Hydraulic 0 bar to 700 bar 0.14 % Using Pressure Calibrator

Pressure Gauge# as per DKD-R-6-1

3. Vacuum Gauge# (-)1 bar to 0.8 bar 0.91 % Using Pressure Calibrator

as per DKD-R-6-1

III. WEIGHING SCALE AND BALANCE

1. Electronics Weighing

Balance♣

Readability: 0.001g 100mg to 310g 1.6mg Using F1 class standard

0.01g 200mg to 2.1kg 18mg weights for 1mg to 200g

0.2g 100g to 6kg 0.16g Using F2 class standard

1g 500g to 15kg 0.78g weights for 500g to 20kg

Rajeshwar Kumar Avijit Das

Convenor Program Manager

Laboratory Accurate India Instruments, No. 33, SLV Nagar, Zuzuwadi, Sipcot,

Hosur, Tamil Nadu

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2878 Page 8 of 8

Validity 26.10.2018 to 25.10.2020 Last Amended on 03.12.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

10g 500g to 100kg 8.6g as per OIML-R-76

* Measurement Capability is expressed as an uncertainty () at a confidence probability of 95%

$

Only in Permanent Laboratory

♣

Only for Site Calibration

#

The laboratory is also capable for site calibration however, the uncertainty at site depends on the

prevailing actual environmental conditions and master equipment used.

Φ

Laboratory can also calibrate instruments/devices of coarser resolution / least count within the

accredited range using same reference standard/ master equipment under the scope of accreditation.

Rajeshwar Kumar Avijit Das

Convenor Program Manager

You might also like

- 24.scope Location 1 CC-2833Document4 pages24.scope Location 1 CC-2833Ravichandran DNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument18 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNo ratings yet

- 3.scope Location 1 CC-2706Document8 pages3.scope Location 1 CC-2706Ravichandran DNo ratings yet

- Laboratory Mikronix Associates Calibration CapabilitiesDocument3 pagesLaboratory Mikronix Associates Calibration CapabilitiesrohanmanimaniNo ratings yet

- Laboratory Calibration Capabilities for Measuring InstrumentsDocument12 pagesLaboratory Calibration Capabilities for Measuring InstrumentsVAIBHAV INSTRUMENTATIONNo ratings yet

- Reliance 333Document7 pagesReliance 333Ravichandran DNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument12 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNo ratings yet

- CMTI ScopeDocument13 pagesCMTI ScopeRavichandran DNo ratings yet

- Accurate Pune.C0052Document12 pagesAccurate Pune.C0052Ravichandran DNo ratings yet

- 2658Document7 pages2658rohanmanimaniNo ratings yet

- ISO 17025 Accredited Laboratory Calibration Certification BMI IndiaDocument2 pagesISO 17025 Accredited Laboratory Calibration Certification BMI IndiarohanmanimaniNo ratings yet

- Accurate Chennai ScopeDocument7 pagesAccurate Chennai ScopeRavichandran DNo ratings yet

- Using Gauge Block Set, Length Bar & Caliper Checker by Comparison Method As Per IS 3651Document13 pagesUsing Gauge Block Set, Length Bar & Caliper Checker by Comparison Method As Per IS 3651rohanmanimaniNo ratings yet

- Laboratory NameDocument13 pagesLaboratory NameVikram BillalNo ratings yet

- Metrology Labortory Tata Motors Limited Jamshedpur Scope 14594876972533Document5 pagesMetrology Labortory Tata Motors Limited Jamshedpur Scope 14594876972533Gowtham Raj KNo ratings yet

- FIE Research InstituteDocument8 pagesFIE Research InstituteAcuteNo ratings yet

- AvijitDocument2 pagesAvijitBAlaNo ratings yet

- Godrej Nabl ScopeDocument11 pagesGodrej Nabl ScopeRavichandran DNo ratings yet

- G.B.Central Laboratory, TrichyDocument3 pagesG.B.Central Laboratory, TrichyRavichandran DNo ratings yet

- Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) % RemarksDocument3 pagesQuantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) % RemarksrohanmanimaniNo ratings yet

- Scope-CC-2331Document5 pagesScope-CC-2331snsarangi06No ratings yet

- 6092 01Document8 pages6092 01Laura MarquezNo ratings yet

- Laboratory Calibration Services ISO/IEC 17025:2005Document6 pagesLaboratory Calibration Services ISO/IEC 17025:2005Ravichandran DNo ratings yet

- Quantity Measured/ Instrument Range / Frequency Calibration Measurement Capability RemarksDocument8 pagesQuantity Measured/ Instrument Range / Frequency Calibration Measurement Capability RemarksrohanmanimaniNo ratings yet

- Northlab HosurDocument25 pagesNorthlab HosurVikram BillalNo ratings yet

- Sitarc - C - 0135Document7 pagesSitarc - C - 0135Ravichandran DNo ratings yet

- Scope CC 3131Document6 pagesScope CC 3131Assistant Director KHRINo ratings yet

- ISO/IEC 17025 Calibration Services AccreditationDocument15 pagesISO/IEC 17025 Calibration Services AccreditationDhinagaran ANo ratings yet

- Scope 51970 CC 2403 1684006228Document26 pagesScope 51970 CC 2403 1684006228AcuteNo ratings yet

- Scope CC 3399Document10 pagesScope CC 3399dheeraj chawlaNo ratings yet

- Khosaca Calibration Lab, Chennai ISO/IEC 17025 certificateDocument4 pagesKhosaca Calibration Lab, Chennai ISO/IEC 17025 certificateRavichandran DNo ratings yet

- Micrometers - Measurement System Types and Characteristics - Measurement Fundamentals - KEYENCE AmericaDocument1 pageMicrometers - Measurement System Types and Characteristics - Measurement Fundamentals - KEYENCE AmericaTatsNo ratings yet

- Balaji Scope-CC-2405Document26 pagesBalaji Scope-CC-2405VikasNo ratings yet

- LK-097-IDN (Length)Document1 pageLK-097-IDN (Length)Aries SupiyantoNo ratings yet

- 5666 01Document18 pages5666 01Laura MarquezNo ratings yet

- Metravi PRO 7273 10A Microohms Meter Catalogue WebDocument3 pagesMetravi PRO 7273 10A Microohms Meter Catalogue WebGaurav kumarNo ratings yet

- Scope CC 3287Document28 pagesScope CC 3287Indranath MoulickNo ratings yet

- Scope CC 2751Document37 pagesScope CC 2751Vishal ShindeNo ratings yet

- Scope-CC-3287 (6)Document28 pagesScope-CC-3287 (6)rohitprasad7250No ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument26 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksBALAJINo ratings yet

- Perfect 684Document4 pagesPerfect 684Ravichandran DNo ratings yet

- Edoc - Pub Occult ScienceDocument4 pagesEdoc - Pub Occult ScienceSaraswantoNo ratings yet

- Caltek-Iso 17025 AnabDocument21 pagesCaltek-Iso 17025 AnabLê Duy ThăngNo ratings yet

- Eastern Visayas State UniversityDocument6 pagesEastern Visayas State Universityapril jean rojasNo ratings yet

- Scope CC 2008 - ERTLDocument59 pagesScope CC 2008 - ERTLAnirban DasNo ratings yet

- Instruments for Metrology Lab Equipment ListDocument1 pageInstruments for Metrology Lab Equipment ListVrinda NilotpalNo ratings yet

- Scope CC 2503Document91 pagesScope CC 2503Vishal MandlikNo ratings yet

- Caltek - ISO 17025 + ScopeDocument20 pagesCaltek - ISO 17025 + ScopeMai TuanNo ratings yet

- Physics Homework 4Document1 pagePhysics Homework 4ChristianNo ratings yet

- Measured Qty / Instrument Range Calibration Measurement Capability ( ) RemarksDocument4 pagesMeasured Qty / Instrument Range Calibration Measurement Capability ( ) RemarksRavichandran DNo ratings yet

- Me8513 MMDocument2 pagesMe8513 MMSiva RamanNo ratings yet

- SCS - ScopeDocument22 pagesSCS - ScopeRakesh TrentiyaNo ratings yet

- Lecture1424082946 PDFDocument109 pagesLecture1424082946 PDFkaran5singh-12No ratings yet

- Scope CC 2151Document170 pagesScope CC 2151Prakash SellamNo ratings yet

- COC1 LO3-1 MensurationDocument12 pagesCOC1 LO3-1 MensurationReymond P. ParedesNo ratings yet

- CL 222 CertDocument5 pagesCL 222 CertS SHALUNo ratings yet

- Laboratory Name: Accreditation Standard Certificate Number Page No Validity Last Amended OnDocument21 pagesLaboratory Name: Accreditation Standard Certificate Number Page No Validity Last Amended OnMangesh MohiteNo ratings yet

- Perfect 243 - ChennaiDocument11 pagesPerfect 243 - ChennaiRavichandran DNo ratings yet

- Indoshell - C - 0400Document2 pagesIndoshell - C - 0400Ravichandran DNo ratings yet

- Position Sensing: Angle and Distance Measurement for EngineersFrom EverandPosition Sensing: Angle and Distance Measurement for EngineersNo ratings yet

- Is 15 (1973)Document14 pagesIs 15 (1973)Ravichandran DNo ratings yet

- Is 1344 (1981) PDFDocument15 pagesIs 1344 (1981) PDFRavichandran DNo ratings yet

- Is 1364 5 2002 PDFDocument13 pagesIs 1364 5 2002 PDFBimal DeyNo ratings yet

- Disclosure To Promote The Right To InformationDocument5 pagesDisclosure To Promote The Right To InformationRavichandran DNo ratings yet

- Is 1 (1968)Document23 pagesIs 1 (1968)Ravichandran DNo ratings yet

- Is 5812 (1970) PDFDocument3 pagesIs 5812 (1970) PDFRavichandran DNo ratings yet

- Is 11498 1985 PDFDocument8 pagesIs 11498 1985 PDFAcuteNo ratings yet

- Is 10-2 (1996) PDFDocument14 pagesIs 10-2 (1996) PDFRavichandran DNo ratings yet

- Shanmugha Precision Forging Control PlanDocument4 pagesShanmugha Precision Forging Control PlanRavichandran D100% (1)

- Is 15423-2 (2003) Iso 5436-2 (2001)Document21 pagesIs 15423-2 (2003) Iso 5436-2 (2001)Ravichandran DNo ratings yet

- Is 5939 (1970) PDFDocument6 pagesIs 5939 (1970) PDFRavichandran DNo ratings yet

- Shanmugha Precision Forging Non - Conformance ReportDocument2 pagesShanmugha Precision Forging Non - Conformance ReportRavichandran DNo ratings yet

- QUALITY QN. For OPERATORSDocument2 pagesQUALITY QN. For OPERATORSRavichandran DNo ratings yet

- IS 2102 Part 1 (1993) ISO 2768-1 (1989)Document8 pagesIS 2102 Part 1 (1993) ISO 2768-1 (1989)Ravichandran DNo ratings yet

- NCR F10 15Document1 pageNCR F10 15Ravichandran DNo ratings yet

- Precision Parts Quality ReportDocument1 pagePrecision Parts Quality ReportRavichandran DNo ratings yet

- WORKSDocument1 pageWORKSRavichandran DNo ratings yet

- Precision Forging Non-Conformance ReportDocument2 pagesPrecision Forging Non-Conformance ReportRavichandran DNo ratings yet

- Shanmugha Precision Forging Non - Conformance Report: RejectedDocument2 pagesShanmugha Precision Forging Non - Conformance Report: RejectedRavichandran DNo ratings yet

- NC43 - 64 - Shell TechDocument2 pagesNC43 - 64 - Shell TechRavichandran DNo ratings yet

- Precision Forging Non-Conformance ReportDocument1 pagePrecision Forging Non-Conformance ReportRavichandran DNo ratings yet

- Precision Forging NCR ReportDocument3 pagesPrecision Forging NCR ReportRavichandran DNo ratings yet

- Shanmugha Precision Forging Non - Conformance Report: Total Cost:1340Document2 pagesShanmugha Precision Forging Non - Conformance Report: Total Cost:1340Ravichandran DNo ratings yet

- NC44 45 GauravDocument2 pagesNC44 45 GauravRavichandran DNo ratings yet

- Precision Forging Non-Conformance ReportDocument2 pagesPrecision Forging Non-Conformance ReportRavichandran DNo ratings yet

- Non Conformance Report (Audit) : Description of Non-ConformamceDocument16 pagesNon Conformance Report (Audit) : Description of Non-ConformamceRavichandran DNo ratings yet

- C Number Stage Number Revisio N Locatio N Client Number Record Date Total Quantit yDocument32 pagesC Number Stage Number Revisio N Locatio N Client Number Record Date Total Quantit yRavichandran DNo ratings yet

- Defect Information for Nonconformance: NC-EXT220347-01 - Thread Size Attribute Issue on 1/4-28 Threads Due to BurrsDocument1 pageDefect Information for Nonconformance: NC-EXT220347-01 - Thread Size Attribute Issue on 1/4-28 Threads Due to BurrsRavichandran DNo ratings yet

- Shanmugha Precision Forging Non - Conformance Report: Rejection Cost 516Document2 pagesShanmugha Precision Forging Non - Conformance Report: Rejection Cost 516Ravichandran DNo ratings yet

- Shanmugha Precision Forging Non - Conformance Report: RejectedDocument2 pagesShanmugha Precision Forging Non - Conformance Report: RejectedRavichandran DNo ratings yet

- Point 1 Point 0 Point 2: Peta Lokasi 2 Jaringan Daerah Irigasi KarauDocument1 pagePoint 1 Point 0 Point 2: Peta Lokasi 2 Jaringan Daerah Irigasi KarauHARIS FADILLAHNo ratings yet

- KIB Barang Kabupaten KolakaDocument130 pagesKIB Barang Kabupaten KolakaNovriza Catur SetyaNo ratings yet

- ASTM D1298 - DensidadDocument6 pagesASTM D1298 - DensidadMatiasNo ratings yet

- ID Rancang Bangun Sistem Deteksi Pola FrinjDocument6 pagesID Rancang Bangun Sistem Deteksi Pola FrinjDaniSenjaNo ratings yet

- Astrolabe in Theory and Practice - Version 4Document47 pagesAstrolabe in Theory and Practice - Version 4Carlos Nazare100% (3)

- Coast Guard Bridge Navigation Refresher Guidebook (August 2011 Edition)Document88 pagesCoast Guard Bridge Navigation Refresher Guidebook (August 2011 Edition)cdnolan100% (8)

- Nabl 122 06 PDFDocument24 pagesNabl 122 06 PDFmaheshNo ratings yet

- CARRY OUT MEASUREMENTS and CalculationDocument51 pagesCARRY OUT MEASUREMENTS and CalculationSolomon GebruNo ratings yet

- 2 Class KinematicsDocument12 pages2 Class KinematicsEva García DasíNo ratings yet

- See Planets and Stars Clearly with Adaptive Optics TelescopesDocument26 pagesSee Planets and Stars Clearly with Adaptive Optics TelescopesPrasanth NaikNo ratings yet

- Measurement Systems - E. O. Doebelin and D. N. ManikDocument54 pagesMeasurement Systems - E. O. Doebelin and D. N. ManikShekhar YadavNo ratings yet

- TESA Catalogue PDFDocument557 pagesTESA Catalogue PDFIvonne Luna50% (4)

- Calibrate ISO17025 +OIML-HB44Document6 pagesCalibrate ISO17025 +OIML-HB44CALIBRATION TRACKINGNo ratings yet

- Rec20 Rev3 Annex2eDocument57 pagesRec20 Rev3 Annex2eDaynisNo ratings yet

- Trigonometric RatiosDocument19 pagesTrigonometric RatiosRo Jill Palacio OlingNo ratings yet

- Identifying Survey Errors in GNSS Data ProcessingDocument21 pagesIdentifying Survey Errors in GNSS Data ProcessingFx AndrianoNo ratings yet

- Spectrum Peak Report 06/06/2017Document1 pageSpectrum Peak Report 06/06/2017AntonioDeLaCruzNo ratings yet

- Civil Engineering Department DCC 20063 Engineering Survey Field Work ReportDocument19 pagesCivil Engineering Department DCC 20063 Engineering Survey Field Work ReportAmirulHamzah100% (1)

- UVD-3500 eDocument2 pagesUVD-3500 eTarekNo ratings yet

- Chapter 1Document20 pagesChapter 1Hanna JbrNo ratings yet

- RMC Plant Calibration ReportDocument5 pagesRMC Plant Calibration ReportSurendra kumar50% (2)

- Unit 1: General Physics-Making Measurements: Measurements and Scientific ClaimsDocument24 pagesUnit 1: General Physics-Making Measurements: Measurements and Scientific ClaimsAref DahabrahNo ratings yet

- Mine Surveying-Ii M204: Duration of Year Is Considered 28 WeeksDocument4 pagesMine Surveying-Ii M204: Duration of Year Is Considered 28 WeeksShiba Narayan SahuNo ratings yet

- CMA-900 FMS Quick Reference Guide - SampleDocument2 pagesCMA-900 FMS Quick Reference Guide - Sample1n4r51ss50% (2)

- Practical 1Document3 pagesPractical 1Paulus DorlenNo ratings yet

- Locate Stars and Celestial Bodies with Weems & Plath Star Finder No. 2102-DDocument1 pageLocate Stars and Celestial Bodies with Weems & Plath Star Finder No. 2102-DAbu ShabeelNo ratings yet

- Aplac PT 004-Measurement AuditsDocument19 pagesAplac PT 004-Measurement Auditsjose ocanaNo ratings yet

- Vernier ScaleDocument4 pagesVernier ScaleQendrim ZekaNo ratings yet

- Time Zone MapDocument1 pageTime Zone MapdinkoNo ratings yet

- System of Units - MKS, CGS and SI - Karnataka PCS Free Notes PDFDocument11 pagesSystem of Units - MKS, CGS and SI - Karnataka PCS Free Notes PDFdishore312No ratings yet