Professional Documents

Culture Documents

Assurance Volume III

Assurance Volume III

Uploaded by

Gnanavel GCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assurance Volume III

Assurance Volume III

Uploaded by

Gnanavel GCopyright:

Available Formats

PROJECT QUALITY ASSURANCE

VOLUME- III

PROJECT QUALITY ASSURANCE Volume –III Rev. 02

Sterlite Power Grid Ventures Ltd. Page 1

1.0 General Quality Assurance requirements

1.1 The contractor shall develop a quality assurance plan and program as per

ISO 10005 – 2005 or latest edition and submit it for SPGVL review and

approval. The document will be a binding document for ensuring the

project quality throughout the project execution.

1.2 The following assurance documents shall be submitted for approval before

commencing of any work.

a. Project Organization.

b. Quality assurance organization for Supply inspection, field inspection

& corporate.

c. Project Quality Plan

d. Categorization of material critical to Quality.

e. Construction manual and relevant procedure which shall include.

1. Foundation concrete

2. Structural erection

3. Stringing – Conductor & OPGW

4. Field final checking

5. Pre commissioning & commissioning

f. MQP for all the equipment’s

g. Field Quality Plan

h. Store Management & Store layout plan

i. Inspection checklist for field quality which shall include foundation,

structural erection, stringing, pre commissioning and commissioning.

j. Work instruction for key activities.

k. Final documentation procedure.

1.3 Contractor shall nominate project quality Lead and Quality coordinator

who will be single nodal personnel for all communication and

coordination.

1.4 The Contractor shall ensure the vendors are proposed during the pre-bid

discussion. The credentials of such vendors shall be approved by SPGVL.

It is the contractor’s responsibility to ensure that the vendors are finalized

before signing of the contract.

1.5 In case of any additional vendor approval derived after awarding the

contract, the following minimum requirement shall be met by the vendor.

Also contractor should justify the reasons for additional vendor proposal

with clear documentary evidences and audit report performed by

contractor.

a. Valid ISO 9001 / 14001 certifications

b. BIS or other product certification as applicable

PROJECT QUALITY ASSURANCE Volume –III Rev. 02

Sterlite Power Grid Ventures Ltd. Page 2

c. Minimum 10 years in supply of product proposed.

d. Should have supplied order to major public sector & private

sectors like PGCIL / NTPC / BHEL / Reliance / Adani etc...

e. In house manufacturing & testing facilities.

1.6 Equipment Categorization plan guidelines:

a. Category – I: Critical Items / Equipments are covered under this

category. SPGVL will be involved during Stage / Final inspection.

b. Category – II: Important items / Equipments are covered under this

category. Contractor will witness stage & final inspection.

SPGVL will review the witness report and provide dispatch

clearance.

c. Category – III: Non-Critical items are covered under this category.

SPGVL & contractor will review the manufacturer test reports and

provide clearance for dispatch.

** Any Item not covered in the list shall be discussed and finalized

during Kick Off Meeting.

MQP:

a. For category I & II items, contractor should submit MQP for

SPGVL review and approval.

b. For category III items, contractor will approve the MQP and

submit to SPGVL for information.

c. Final “Factory Acceptance Test” for Category I & II items as per

agreed categorization plan – Witness Point

d. Type test: If valid type test report is not available (or) combination

of the new manufacturer products - Witness Point

FQP:

a. Raw material source approval – Hold Point

b. Slump Test – Witness Point

c. Cube Compression test – Witness Point

d. Foundation Final Inspection & Clearance for Tower Erection –

Hold Point

e. Welder Qualification – Hold Point

f. TFR (Tower Footing Resistance) – Witness Point

g. Tower completeness inspection & Clearance for Stringing – Hold

Point

h. Visual & IR value test of Insulators before hoisting – Witness point

i. Stringing completeness including Jumper and all accessories –

Hold Point

PROJECT QUALITY ASSURANCE Volume –III Rev. 02

Sterlite Power Grid Ventures Ltd. Page 3

j. All critical clearances (Jumper, Ground, Earth wire & Tree) – Hold

Point

k. Line Healthiness (Signature Analysis & Meggar test) – Hold Point

l. Project Quality Documentation – Hold Point

Witness Point – Identified point in the process where the Owner

Engineer or Owner appointed TPIA may witness. The activities

however may proceed.

Hold Point – This is a mandatory verification point beyond which a

work cannot proceed without approval by the Owner Engineer. The

work cannot proceed until the Owner Engineer is able to verify the

quality of the completed work and releases the Hold by means of

written approval.

1.7 The procedure for purchase of materials, parts components and selection

of sub-Contractor’s services including vendor analysis, source inspection,

incoming raw material inspection, verification of material purchases etc.

shall be submitted for Owner approval

1.8 Valid Type test reports for combination of materials as applicable shall be

submitted to Owner for review. If any combination of materials differs,

type test shall be carried out before taking mass production.

1.9 The contractor shall be responsible for all supply materials inspection

irrespective of category and the inspection and certification of supply

materials should be from any of the following inspection agencies.

a. Bureau Veritas

b. Tata Project Limited

c. DNV

d. TUV Nord

1.10 The contractor shall appoint one FQA in-charge with 15 years’ TL

experience at project site, one field quality graduate engineer with

minimum of 10 years of TL experience with 3 technicians of 5 to 8 years’

experience shall be deployed for every 75 KM of stretch to ensure all the

activities performed at site are as per the specification and FQP.

1.11 The cube compression testing machine shall be installed at every 100 KM

for cube testing. The same shall be calibrated and records shall be

maintained for Owner verification.

PROJECT QUALITY ASSURANCE Volume –III Rev. 02

Sterlite Power Grid Ventures Ltd. Page 4

2.0 Inspection & Testing at manufacture place

2.1 Inspection by Owner: In respect of the inspection/ testing stages envisaged

as Witness/ Hold point by the Owner, the Contractor shall raise inspection

call to the Owner with advance notice period of 7 working days. In case of

Overseas inspection 30 days advance notice shall be provided.

2.2 The Contractor shall provide to the representatives of Owner, at all

reasonable time, a free access to the manufacturing works and related

premises of the Contractor and vendors.

2.3 The Contractor shall keep the Owner informed in advance about the time

of starting and of the progress of manufacture and fabrication of various

tower parts / equipments at various stages, so that arrangements could be

made for inspection.

2.4 The acceptance of any part of items shall in no way relieve the Contractor

of any part of his responsibility for meeting all the requirements of the

Tender Specification.

2.5 The norms and procedure of sampling for lot testing shall be as per the

ISO 2500. The Level of acceptance shall be discussed with the Owners

and agreed upon.

2.6 The contractor representative shall associate in the inspection with

Owner’s inspector.

2.7 The contractor shall be intimate to owner in writing before 24 hours, in

case of inspection rescheduled. Otherwise the cost of QC inspector visit

shall be recovered from the contractor monthly bill.

2.8 Any repairable defect identified during fabrication / manufacturing which

shall be made rectified only with the consent of the Owner.

2.9 The Contractor shall dispose any non-conformity observed in the products

or services only with due approval from the Owner.

2.10 Material release note will be issued by the representative of the Owner

after satisfactory compliance of inspection and testing requirements. For

further issuing of dispatch instruction will be issued by the SCM or

Project Management. This will be agreed during the KOM with the

contractor.

2.11 In case of any dispute in acceptance criteria, the Tender specification and

Technical specification will be the binding references.

PROJECT QUALITY ASSURANCE Volume –III Rev. 02

Sterlite Power Grid Ventures Ltd. Page 5

2.12 Any material testing shall be carried out at Owner approved NABL

accredited laboratory only.

2.13 The manufacturer shall ensure only calibrated testing equipment’s are

used for conformity test.

2.14 Type Tests shall mean those tests which are to be carried out to prove the

process of manufacture and general conformity of the material to this

Specification. These tests shall be carried out on samples prior to

commencement of commercial production against the order. The Supplier

/ contractor shall indicate his schedule for carrying out these tests.

3 Field Quality Assurance

3.1 All field quality activity shall be carried out in accordance with Owner

approved field quality plan. All field check details shall be recorded /

documented in approved field quality check list at site and duly approved

by SPGVL field quality engineer at site.

3.2 The Contractor shall provide relevant technical inputs and documents to

the Owner for activities related to Field Quality at project site in line with

the recommendations, standards and practices of the original equipment

manufacturers.

3.3 Construction raw material source approval shall be taken before starting

the construction work at site.

3.4 The contractor shall provide the store management system and Store

layout plan for SPGVL approval before starting of the construction.

3.5 The credentials of the subcontractors engaged at site shall be provided to

Owner for approval. The contractor shall ensure all the subcontractors are

evaluates as per evaluation process as defined in ISO 9001.

3.6 The Civil foundation requirements shall be as per IS 456 latest edition.

The minimum and maximum temperature requirement of concrete during

pouring is to be as per code. The procedure shall be submitted for

approval before starting of the concrete.

3.7 The contractor shall be responsible and accountable for the following.

i. Foundation checks and documentation;

PROJECT QUALITY ASSURANCE Volume –III Rev. 02

Sterlite Power Grid Ventures Ltd. Page 6

a. Pit marking, pit excavation, PCC, template alignment,

reinforcement and formwork.

b. Slump check

c. Cube sample

d. Earth strip fixed (if pipe earthing).

e. Curing and back filling.

ii. Tower erection checks and documentation;

a. All structure members are fixed on their positions as per approved

drawing and no fabricated, damaged and rust member is erected.

b. All Bolt & nuts, spring and pack washers are used as per size /

approved drawing and tightened.

c. Tower tightness as per “Torque schedule”

d. Take welding up to Bottom X – Arm.

e. Tower verticality.

f. Tower earthing.

g. Tower footing resistance test before and after earthing connection.

h. Inspection report shall be submitted to owner FQA team once

completed the stretch or 10-15 towers. Owner FQA team shall be

inspected after receipt of inspection call from contractor FAQ team.

iii. Stringing checks and documentation;

a. The contractor shall be started stringing once all foundation and

tower related NCRs are closed of that stretch.

b. Insulator, hardware, earth wire, OPGW and conductor installation

checks should be done before and after as per owner approved FQP.

c. Each insulator visual and IR test at site.

d. Hardware and conductor visual check at site.

e. Scratch, cut, repair sleeve, mid span joint checks.

f. Clamps compressing witness.

g. Sag and tension measurements checks

h. Electrical clearances ground, phase, jumpers, tree etc.

i. Insulator damages and locking pins etc.

j. Fixing of earth-links.

k. OPGW pre installation OTDR checks

l. OPGW OTDR check after installation.

m. OPGW every joint splicing loss checks.

n. OPGW OTDR checks for every 60 km stretch and trace reports.

o. OPGW fiber continuity check of both ends and OTDR check.

p. Photo graphs to be submitted the contractor wherever conductor and

earth wire joints and repair sleeves are installed.

PROJECT QUALITY ASSURANCE Volume –III Rev. 02

Sterlite Power Grid Ventures Ltd. Page 7

iv. Sub Station Equipments installation:

a. Foundations as per drawing and applicable code requirement.

b. Equipment installation checks should be done before and after as

per owner approved FQP.

c. Stage inspections as per approved FQP

d. Pre-commissioning & Trial run checks as per FQP.

e. Commissioning checks as per FQP.

3.8 The cubes for casting shall be drawn as per IS 456 considering the volume

of concrete on day basis as detained in code.

3.9 Curing of concreting shall be as per IS 456 and only OPC shall be used

for concreting.

3.10 All stage of construction is to be certified by the respective Quality

Assurance and control team of the contractor before proceeding to the

next stage. The report shall be submitted to the Owner for review and

approval.

3.11 All construction & supply bills of contractor will be certified by Owner

Field Quality Engineer.

3.12 The Owner or his duly authorized representatives reserves the right to

carry out Quality Audit and quality surveillance of the systems and

procedures of the Contractor's / his vendor's Quality Management and

Control Activities.

3.13 The contractor shall carry out technical audit during construction through

in-house or through external agencies every three months. The report shall

be submitted to Owner for review. The audit shall cover all the aspects of

construction including foundation, tower erection, stringing activities,

contractual obligations, applicable process & procedures, FQP &

procedures implementation, material handling, material storage and

technical competent manpower availability etc…

3.14 Owner will conduct Technical audit of manufacturing facilities and site

function of the contractor. If any non-conformity or observation is noted

the same shall be implemented or resolved within 2 days of notification.

In case of any critical non conformity the work shall not proceed without

taking corrective and preventive action.

3.15 If any NCR observed, the contractor shall propose corrective & preventive

action, analysis the root cause and submit the detailed report.

PROJECT QUALITY ASSURANCE Volume –III Rev. 02

Sterlite Power Grid Ventures Ltd. Page 8

3.16 The contractor shall conduct quality tool box every fortnight at site to

provide awareness to the workforce and supervisors on the importance of

construction quality. The records of such meeting shall be maintained and

owner shall review the same on monthly basis.

3.17 The contractor shall generate monthly quality report detailing all the

activity performed at site & submit the same to SPGVL Quality Head on

or before 5th of every month.

3.18 The contractor shall submit the Project quality assurance documentations

after project completion including Mechanical completion report, as built

drawing, pre commissioning and commissioning reports. The format and

detailed content of the report shall be discussed with the owner during

KOM.

3.19 Implementation of QA Management System shall be monthly reviewed

jointly by the Contractor and the Owner at Corporate and Project site

level. The meeting shall be attended by contractors Project Manager,

Construction Manager and senior management from Quality Assurance

department.

4 Final Documentation

4.0 The contractor shall submit the Project Quality Assurance document

dossier after project completion. The format and detailed content of the

report shall be discussed with owner during KOM. The Project Quality

Assurance document dossier should contain the following documents.

a. As built drawing (Both Manufacturing & field drawings)

a. Material categorization plan

b. Approved vendor list – Item wise

c. Approved MQPs

d. All inspection reports as per MQP – Item wise & Inspection

call wise

e. Material Release Note

f. Approved FQP

g. All Field check list & inspection reports as per FQP

h. Approved source List – Item wise

i. Signature Analysis report

j. Pre-Commissioning & Commissioning check list

k. Copy of MoM

PROJECT QUALITY ASSURANCE Volume –III Rev. 02

Sterlite Power Grid Ventures Ltd. Page 9

5 Standard Formats

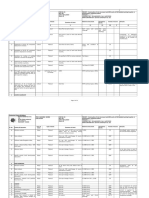

Manufacturing Quality Plan:

Title Sheet:

Control checks content sheet:

Manufacturer’s Customer: Project: Item : M.Q.P No & Rev.: Valid from:

Details: Valid up to:

S Components Type of Quantum of Reference Acceptance Type of Manufacturer Supplier Client/ Remarks

N / Operation & check check / document Criteria record TPI

o. Description sampling

of test with basis

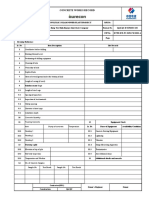

Field Quality Plan:

Title Sheet:

PROJECT QUALITY ASSURANCE Volume –III Rev. 02

Sterlite Power Grid Ventures Ltd. Page 10

Field checks content sheet:

PROJECT QUALITY ASSURANCE Volume –III Rev. 02

Sterlite Power Grid Ventures Ltd. Page 11

You might also like

- QAQC Electrical Inspection: A Beginner's GuideFrom EverandQAQC Electrical Inspection: A Beginner's GuideRating: 4 out of 5 stars4/5 (1)

- Itp For Electrical WorksDocument22 pagesItp For Electrical Worksirfan vpNo ratings yet

- Amazon Test PDFDocument1 pageAmazon Test PDFSubha Lakshmi100% (6)

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical WorkDocument53 pagesA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical WorkDan CosacNo ratings yet

- 33kV Transmission Line (Field Quality Plan)Document6 pages33kV Transmission Line (Field Quality Plan)farhan100% (1)

- E&I Quality PlanDocument9 pagesE&I Quality PlanJithuRajNo ratings yet

- Before Dispatch Before Dispatch On The Day of Receipt at The Earliest After Receipt. Design, Engineering Standard DocumentsDocument24 pagesBefore Dispatch Before Dispatch On The Day of Receipt at The Earliest After Receipt. Design, Engineering Standard Documentsnarinder100% (1)

- Contractor Quality Control Plan For Electrical Equipment InstallationDocument7 pagesContractor Quality Control Plan For Electrical Equipment Installationhasan_6764896160% (1)

- Itp Installation of Fiber Optic CablesDocument4 pagesItp Installation of Fiber Optic Cablesqasim078100% (2)

- NSC-400-CE-3230-Transmission Line Checklist MasterlistsDocument2 pagesNSC-400-CE-3230-Transmission Line Checklist MasterlistsElisco Pher SalmasanNo ratings yet

- Tds Oetc 400kv Cab SsDocument23 pagesTds Oetc 400kv Cab SsantaryamisinghNo ratings yet

- 8 Field Quality PlanDocument18 pages8 Field Quality Plangeorge_hem100% (1)

- ITP Work DownDocument5 pagesITP Work DownMuralimohan Pandian100% (1)

- Itp - Building WorksDocument15 pagesItp - Building WorksVasilica BArbarasaNo ratings yet

- Approvals and Permits Required For Work ExecutionDocument2 pagesApprovals and Permits Required For Work ExecutionkamarajinNo ratings yet

- 04-2-TS vOL-II, Sec-IV, FQP R1 PDFDocument20 pages04-2-TS vOL-II, Sec-IV, FQP R1 PDFsanjeevchhabraNo ratings yet

- Right Factorz Projects PVT LTD Checklist For Cable InstallationDocument9 pagesRight Factorz Projects PVT LTD Checklist For Cable InstallationRajesh RaghunathanNo ratings yet

- Fieid Quality Plan: DC Industrial Plant Services Pvt. Ltd. KOLKATA - 700 016Document4 pagesFieid Quality Plan: DC Industrial Plant Services Pvt. Ltd. KOLKATA - 700 016Sam100% (1)

- Portacabin Inspection ChecklistDocument2 pagesPortacabin Inspection ChecklistApm FoumilNo ratings yet

- Project Internal Audit Procedure: SheetalkumarDocument4 pagesProject Internal Audit Procedure: SheetalkumarTwin BullsNo ratings yet

- FQP GeneralDocument21 pagesFQP GeneralgaladrialNo ratings yet

- Installation Checklist LARPAZEEDocument7 pagesInstallation Checklist LARPAZEEDimgba ProgressNo ratings yet

- A Qac Pro 000 38951Document30 pagesA Qac Pro 000 38951Amin GNo ratings yet

- QA&QC-DT-FRMC-020 Foundation Work of Transmission LineDocument2 pagesQA&QC-DT-FRMC-020 Foundation Work of Transmission LineTariq Ali SialNo ratings yet

- MOS-Construction of OHTL From SS 8768 Layla PVDocument45 pagesMOS-Construction of OHTL From SS 8768 Layla PVEngr Muhammad Azam ThaheemNo ratings yet

- Request For Inspection: Fixing of Tower Crane Tie-Ins at ColumnsDocument3 pagesRequest For Inspection: Fixing of Tower Crane Tie-Ins at ColumnsUr FriendNo ratings yet

- 835a) Method Statement For Ceramic Tile Marble Works - R0-SignedDocument23 pages835a) Method Statement For Ceramic Tile Marble Works - R0-Signedwaseq911No ratings yet

- 5 Clamps Connectors 220 400kv SsDocument12 pages5 Clamps Connectors 220 400kv SsJaswanth SaiNo ratings yet

- Inspected by QCP Approval 1-APC 1-Employer APC 2 - DAR 2-Engineer DAR 3 - Contractor NEGEMCO 4 - Vendor 5 - Third PartyDocument2 pagesInspected by QCP Approval 1-APC 1-Employer APC 2 - DAR 2-Engineer DAR 3 - Contractor NEGEMCO 4 - Vendor 5 - Third PartyAhmad DagamsehNo ratings yet

- Inspection and Test Plan For SwitchgearDocument12 pagesInspection and Test Plan For SwitchgearShahadat HossainNo ratings yet

- PO No 2037-PL-PL-0058 Inspection Notification No-015 r1 PDFDocument1 pagePO No 2037-PL-PL-0058 Inspection Notification No-015 r1 PDFDadaso Baburao JamdarNo ratings yet

- Sample Manufacturing Quality Plan Format: (Logo of Manufacturer)Document12 pagesSample Manufacturing Quality Plan Format: (Logo of Manufacturer)P.Manna100% (1)

- Field Quality Plan For LgfsDocument7 pagesField Quality Plan For LgfsUday PratapNo ratings yet

- Q A P (Qap) - DCCC: Uality Ssurance LANDocument4 pagesQ A P (Qap) - DCCC: Uality Ssurance LANsasikumarNo ratings yet

- Field Quality Plan of EHV Power CablesDocument10 pagesField Quality Plan of EHV Power CablesMohammed TauseefNo ratings yet

- Inspection and Test Plan For Electrical Works - AttachmentsDocument51 pagesInspection and Test Plan For Electrical Works - Attachmentsimoudu benjaminNo ratings yet

- Module6-Detailed Project Report and EPCDocument10 pagesModule6-Detailed Project Report and EPCJames K. BitokNo ratings yet

- Cable Tray InstallationDocument1 pageCable Tray InstallationNaeemNo ratings yet

- QA/QCDocument2 pagesQA/QCapi-78981986No ratings yet

- 5.8 QA-QC OrganisationChartDocument44 pages5.8 QA-QC OrganisationChartFahim AfrozeNo ratings yet

- 00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkDocument12 pages00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkAbdul Mohid SheikhNo ratings yet

- Itp - Inspection and Testing Plan (Creation and Management)Document10 pagesItp - Inspection and Testing Plan (Creation and Management)Luffy11100% (1)

- 13.11.2023 SKD - DEC - QAC - ITP - 054 - ITP - of Cable Installation and TerminationDocument20 pages13.11.2023 SKD - DEC - QAC - ITP - 054 - ITP - of Cable Installation and Terminationsokhib.salimov1992No ratings yet

- E&I QAP's - Submitted To Contractor HZADocument33 pagesE&I QAP's - Submitted To Contractor HZASuraj ShettyNo ratings yet

- LPS-01-HTI-MST-EL-009 - Light FixturesDocument18 pagesLPS-01-HTI-MST-EL-009 - Light FixturesJomy JohnyNo ratings yet

- Inspection and Test Plan (ITP) - Grounding WorksDocument2 pagesInspection and Test Plan (ITP) - Grounding WorksElisco Pher SalmasanNo ratings yet

- 1.request For Inspection (HEMT FO QC 01)Document1 page1.request For Inspection (HEMT FO QC 01)Balasai SabarinathNo ratings yet

- Attachment 12.4 - QA - QC Checklist - FDBDocument3 pagesAttachment 12.4 - QA - QC Checklist - FDBehteshamNo ratings yet

- Technical Proposal: BKT Wellhead PlatformDocument43 pagesTechnical Proposal: BKT Wellhead PlatformMaina MathengeNo ratings yet

- Inspection and Test Procedure Rev.0aDocument14 pagesInspection and Test Procedure Rev.0ahalim_kidNo ratings yet

- QAP ITP Bhogat - REV-01Document8 pagesQAP ITP Bhogat - REV-01Ramkunwar YadavNo ratings yet

- Rays Power Infra PVT LTD: Quality Assurance Plan For Photovoltaic Structural SystemDocument92 pagesRays Power Infra PVT LTD: Quality Assurance Plan For Photovoltaic Structural SystemPioneer Power SystemsNo ratings yet

- Typical QA&QC Execution Plan and Management SystemDocument31 pagesTypical QA&QC Execution Plan and Management Systemchao gaoNo ratings yet

- Manufacturing Quality Plan (MQP)Document2 pagesManufacturing Quality Plan (MQP)Ranjit SinghNo ratings yet

- Essentials Electrical Quality Control Plan Sample PDFDocument13 pagesEssentials Electrical Quality Control Plan Sample PDFSalman HameedNo ratings yet

- Installation of LV Cables: Inspection and Test Plan ForDocument1 pageInstallation of LV Cables: Inspection and Test Plan ForHussainShabbirNo ratings yet

- Sop of StringingDocument7 pagesSop of Stringingshubham shindeNo ratings yet

- Quality Induction Training-No 1Document22 pagesQuality Induction Training-No 1Kannan Murugesan100% (1)

- Satr-P-3210 Rev 7 FinalDocument11 pagesSatr-P-3210 Rev 7 FinalzhangNo ratings yet

- QM-R83-PL-4051 Procedure For Concrete Surface Preparation and Coating Rev. 01Document11 pagesQM-R83-PL-4051 Procedure For Concrete Surface Preparation and Coating Rev. 01GaneshNo ratings yet

- Qam RDSSDocument32 pagesQam RDSSAshish bhattNo ratings yet

- EHS AgreementDocument37 pagesEHS AgreementSantosh KumarNo ratings yet

- DPR Clearance GuidlinesDocument11 pagesDPR Clearance GuidlinesSantosh KumarNo ratings yet

- CEA Manual-TD PlanningDocument50 pagesCEA Manual-TD PlanningSaravanan Elumalai0% (1)

- TM 43000132Document590 pagesTM 43000132Santosh KumarNo ratings yet

- CBIP-Desgn of Earth Mat For HV SSDocument31 pagesCBIP-Desgn of Earth Mat For HV SSSantosh Kumar83% (6)

- Capability Document LAST UPDATEDDocument137 pagesCapability Document LAST UPDATEDABOOBAKKERNo ratings yet

- Pmi Acp QuizDocument124 pagesPmi Acp QuizSumana Nanjundaiah100% (1)

- Computation Revised DeepakDocument3 pagesComputation Revised DeepakRaghav SharmaNo ratings yet

- Cities and Urbanization PandR Issue 4Document80 pagesCities and Urbanization PandR Issue 4Ahsan ZebNo ratings yet

- Sample 3 WeetabixDocument21 pagesSample 3 Weetabixjack stauberNo ratings yet

- 5RST Assessment GuidanceDocument10 pages5RST Assessment GuidanceIsraa Hani100% (1)

- Minimized Data Inconsistency. Data Inconsistency Exists When Different Versions of The Same Data AppearDocument4 pagesMinimized Data Inconsistency. Data Inconsistency Exists When Different Versions of The Same Data AppearmengistuNo ratings yet

- Uns W Student GuideDocument27 pagesUns W Student Guidemmm123No ratings yet

- BSBWRT411 - Task 2 - ProjectDocument8 pagesBSBWRT411 - Task 2 - ProjectCheryl Pham0% (1)

- Exxon Mobil Company AnalysisDocument6 pagesExxon Mobil Company AnalysisMacharia NgunjiriNo ratings yet

- What Is The Right Supply ChainDocument1 pageWhat Is The Right Supply Chainmanshi choudhuryNo ratings yet

- Motion Pictures & Television & Music Industry: Reading SampleDocument54 pagesMotion Pictures & Television & Music Industry: Reading SampleCah MakNo ratings yet

- Aec-44 - Course Outline (Strategic-Cost-Management)Document6 pagesAec-44 - Course Outline (Strategic-Cost-Management)Hyacinth FNo ratings yet

- SP18Document74 pagesSP18bbNo ratings yet

- H01 - Principles of TaxationDocument9 pagesH01 - Principles of TaxationRachel FuentesNo ratings yet

- Hardware Cal - U.S - BellowsDocument13 pagesHardware Cal - U.S - Bellowsaraz_1985No ratings yet

- Hansen 1965 - The Structure and Determinants of Local Public Investment ExpendituresDocument14 pagesHansen 1965 - The Structure and Determinants of Local Public Investment ExpendituresPabloNeudörferNo ratings yet

- Zara Case StudyDocument5 pagesZara Case StudySaraVeronicaSitinjakNo ratings yet

- Portfolio IMDocument8 pagesPortfolio IMtikvicfNo ratings yet

- Filipino3 q2 Modyol7 Pagsunod-Sa-Panuto v3Document18 pagesFilipino3 q2 Modyol7 Pagsunod-Sa-Panuto v3Ish SantillanNo ratings yet

- Problem Set: Exchange Rates: International EconomicsDocument16 pagesProblem Set: Exchange Rates: International EconomicsLucia Yuste MoreiraNo ratings yet

- Case Study - School App - Project CharterDocument3 pagesCase Study - School App - Project CharterAmir3112No ratings yet

- Open Group Standard: Togaf 9.1 Translation Glossary: English - FrenchDocument45 pagesOpen Group Standard: Togaf 9.1 Translation Glossary: English - FrenchhananNo ratings yet

- HCL at RudrapurDocument13 pagesHCL at RudrapurJyoti TripathiNo ratings yet

- A Culture Guide For Organizations - Gallup 4Document17 pagesA Culture Guide For Organizations - Gallup 4tonilagnada0929@gmail.comNo ratings yet

- Job DesignDocument2 pagesJob DesignSamek BhamboreNo ratings yet

- TIỂU LUẬN KINH TẾ VĨ MÔ CHƯƠNG 7Document6 pagesTIỂU LUẬN KINH TẾ VĨ MÔ CHƯƠNG 7Duy VănNo ratings yet

- Implementing Enterprise Structures and General LedgerDocument602 pagesImplementing Enterprise Structures and General LedgerErikaNo ratings yet

- Attachement JDocument23 pagesAttachement JMehari Temesgen50% (2)