Professional Documents

Culture Documents

E-SLOPE Typical Details Details Rev 4 PDF

Uploaded by

Khalil MachkourOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E-SLOPE Typical Details Details Rev 4 PDF

Uploaded by

Khalil MachkourCopyright:

Available Formats

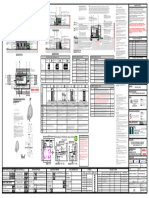

This drawing is the copyright of Cerana Limited, no unauthorised copying is permitted without the permission of Cerana Limited.

The design and specifications of gabions and associated materials are limited to materials sourced from Cerana Ltd. NOTES:

1. E-SLOPE design must be read in conjunction with

the accompanying design proposal if provided.

2. All wire mesh as supplied by:-

Enviromesh

Unit 4, Cartwright Industrial Estate

Spring Garden Road, Longton, Staffs. ST3 2TE

tel:01782 692 310 fax: 01782 692 318

Minimum 1000 email: enquiries@enviro-mesh.com

www.enviro-mesh.com

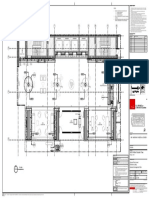

Top lid pulled below topsoil line Finished Ground Level

3. Mesh wire to have a tensile strength in the

range of 540 to 770 N/mm²

4. E-SLOPE units to comprise of Galfan+PVC

coated or Galfan alone, welded mesh in

accordance with BSEN 10244-2: 2009 (Class A)

Structural backfill to be in accordance with and BS EN 10245 parts 1 & 2 (2011)

Erosion control matting available

in coir or polymer 3D matting SFHW 6I/6J or 7D compacted to 95% dry density 5. E-SLOPE units are constructed from 75 x 75mm,

square welded mesh, in either 3mm Ø Galfan

coating or 2.70/3.20mm Ø Galfan with Green

PVC coated wire. An additional 150mm x 150mm

steel panel provides rigidity to the face. All units

Base of second unit connected to lid 300mm seeded topsoil placed are factory assembled and supplied as a flat pack

for rapid deployment.

of lower unit using CL50 clips behind the facing units Geogrid reinforcement, length, strength

and vertical spacing to be determined by design 6. Unit assembly & installation must be in

strict accordance with the Enviromesh's

H

guidance.

Internal braces maintain 70° angle

7. E-SLOPE units to site assembled with lacing wire

Drainage Geo-composite outfalling into 100mmØ and/or 'C' clips to all joints.

perforated drain at heel of structure prevents water 8. Structural backfill to be in accordance with SFHW

ingress into reinforced soil block. Outfall location by others. class 6I/6J or 7D compacted to 95% dry density.

9. E-SLOPE units to be formed on a level, proofed

GL rolled surface with the required minimum bearing

capacity. Any local soft areas in the foundations

70

shall be excavated out and replaced with

675

650

°

compacted granular material (eg. 6F5).

450

10. The maximum weight of compaction plant to

be used within 2m of the structure is as

follows:-

Vibratory roller:

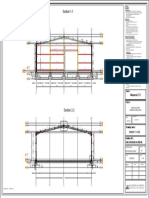

Typical Section & Details Secondary Geogrid Reinforcement 0.7 to 1 x H maximum dead weight 1300kg/m width

maximum total mass 1000 kg

(Scale 1:50) Vibrating plate:

maximum total mass 1000 kg

300mm of seeded topsoil placed behind Vibro tamper:

maximum total mass 75 kg

front face to promote vegetation Integrated Reinforcement Tail

13. Uniaxial geogrids must be placed with the roll

direction laid perpendicular to the face of the

Additional geogrids used gabions.

to provide continuous

reinforcement layer

Geogrid tails overlap

6I/6J structural backfill placed and

compacted to 95% dry density in

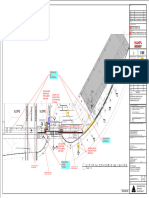

layers not exceeding 150mm External Radius

Internal Radius (Scale 1:100)

(Scale 1:100)

675

External Corner

(Scale 1:100)

Additional geogrids used

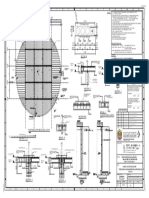

Uniaxial geogrid to provide continuous

Pin & pre-fitted reinforcement layer Geogrid tails overlap

Helicoil Connection

E-SLOPE panel placed on top of geogrid Internal Corner DRAWN RPK SCALE @ A3 AS SHOWN PROJECT TITLE

(Scale 1:100) REVISIONS DATE Typical Section & Details

Isometric Construction Sequence

00 - First Issue - Concept Only - Not For Construction 21.10.19 E-SLOPE System

01 - Second Issue - Concept Only - Not For Construction 25.10.19

(Scale 1:50) 02 - Third Issue - Concept Only - Not For Construction 29.01.20

Reinforced Soil Design Proposal Garner Street Business Park, Etruria, Stoke-on-Trent, Staffordshire, ST4 7BH

Tel: +44 (0)1782 692 310 Fax: +44 (0)1782 692 318

www.enviro-mesh.com

Due care and attention has been taken in the preparation of the design of the gabion structures and is based on the information received. It is the contactor/clients responsibility to ensure that the details provided encompass all aspects of the required works and the limits of construction

03 - Fourth Issue - Concept Only - Not For Construction 03.02.20 PROJECT NUMBER REVISION DATE STATUS

and levels shown on the drawing are correct prior to placing of material orders. Enviromesh does not accept liability for errors or omissions once an order is placed.Where further amendments are required due to additional requirements or variation in the structure line and/or levels, the

design time will be chargeable. 04 - Fith Issue - Concept Only - Not For Construction 14.02.20 28914-01 04 14.02.20 CONCEPT ONLY

You might also like

- Restaurant Floor Plan (1st Floor)Document1 pageRestaurant Floor Plan (1st Floor)Ma. Isabel RodriguezNo ratings yet

- Sight Glass Selection Guide PDFDocument7 pagesSight Glass Selection Guide PDFani_datNo ratings yet

- Diode Fundamentals and BiasingDocument36 pagesDiode Fundamentals and BiasingSherwin VasquezNo ratings yet

- NDT Structural SteelDocument35 pagesNDT Structural Steeltinz_3100% (2)

- Post Weld Heat Treatment Inspection Question and AnswersDocument2 pagesPost Weld Heat Treatment Inspection Question and AnswersRajesh Kumar RaviNo ratings yet

- Types of Fire Extinguishers PDFDocument25 pagesTypes of Fire Extinguishers PDFRiyan SyedNo ratings yet

- Astm F 1852Document8 pagesAstm F 1852luis100% (1)

- Warehouse DrawingsDocument6 pagesWarehouse DrawingsnokoNo ratings yet

- Fpso OverviewDocument1 pageFpso OverviewSean ChoiNo ratings yet

- Refractories For Heat Treating: Industrial CeramicsDocument6 pagesRefractories For Heat Treating: Industrial CeramicsMatias MancillaNo ratings yet

- P4283-340-DRG-ME-016_B_ReviewedDocument1 pageP4283-340-DRG-ME-016_B_ReviewedalimfakihsalehNo ratings yet

- NCGM XX XX D Aec DR 930 1103Document1 pageNCGM XX XX D Aec DR 930 1103yusufuNo ratings yet

- NCGM XX XX D Aec DR 930 1103Document1 pageNCGM XX XX D Aec DR 930 1103yusufuNo ratings yet

- 07 Section 1-1,2-2Document1 page07 Section 1-1,2-2ismet mehmetiNo ratings yet

- 08.section 3-3Document1 page08.section 3-3ismet mehmetiNo ratings yet

- Saipim Indonesia electrical schematicDocument1 pageSaipim Indonesia electrical schematicWasis Muharam BhayangkaraNo ratings yet

- 2790300-BE-9203- OUTBOUND DOCK OFFICE LOAD SCHEDULE-REV 0Document1 page2790300-BE-9203- OUTBOUND DOCK OFFICE LOAD SCHEDULE-REV 0Charlie MendozaNo ratings yet

- Sentron: Technological Leader Amongst The Circuit-Breakers: SENTRON CommunicationDocument186 pagesSentron: Technological Leader Amongst The Circuit-Breakers: SENTRON Communicationsatelite54No ratings yet

- Sample BOS IoT Lite BMS Topology DiagramDocument2 pagesSample BOS IoT Lite BMS Topology DiagramWalter BarbaNo ratings yet

- Unifilar MT BJL11Document1 pageUnifilar MT BJL11Reinan AssisNo ratings yet

- General Arrangement of PilingDocument8 pagesGeneral Arrangement of PilingPNo ratings yet

- P4283-340-DRG-ME-002_B_ReviewedDocument1 pageP4283-340-DRG-ME-002_B_ReviewedalimfakihsalehNo ratings yet

- Design of structural members and connectionsDocument1 pageDesign of structural members and connectionsDolzMaGiCzNo ratings yet

- 2023-09-22 Link Bridge AIPDocument6 pages2023-09-22 Link Bridge AIPMorris KwokNo ratings yet

- Hs CD 23 00187-Landscpe Layout 2 of 4 - 946589Document1 pageHs CD 23 00187-Landscpe Layout 2 of 4 - 946589api-193778159No ratings yet

- Drawing 3.Document1 pageDrawing 3.tiyaniNo ratings yet

- Folder EuromaxDocument2 pagesFolder EuromaxHugo de LimaNo ratings yet

- 49216-12-Coedmore-Bridge---F-shape-Barrier-&-End-Block-Sheet-1-Of-2Document1 page49216-12-Coedmore-Bridge---F-shape-Barrier-&-End-Block-Sheet-1-Of-2Malibongwe MbamboNo ratings yet

- Manpower 15 Steel Fixers 15 Carpenters: Steel Work Fixing Steel at Retaining WallDocument2 pagesManpower 15 Steel Fixers 15 Carpenters: Steel Work Fixing Steel at Retaining WallHamza QudahNo ratings yet

- Mwaura 03 - 19 Sheet 1Document1 pageMwaura 03 - 19 Sheet 1alexNo ratings yet

- PS-1 PS-2 PS-3: Side View Elevation Side Viev Elevation Side Viev ElevationDocument1 pagePS-1 PS-2 PS-3: Side View Elevation Side Viev Elevation Side Viev ElevationYusuf HungundNo ratings yet

- 07 - 11. ITB-2023-45343 VAC Drawing PDFDocument7 pages07 - 11. ITB-2023-45343 VAC Drawing PDFxuseen maxamedNo ratings yet

- 57 Chandos Street (Existing and Proposed Plans) 04.02.2020 PDFDocument1 page57 Chandos Street (Existing and Proposed Plans) 04.02.2020 PDFFaraz HussainNo ratings yet

- LS Fence 1Document1 pageLS Fence 1jimNo ratings yet

- 1M05 (B) TECTON-C-010 (REV-AB-1) SHEET No.1 OF 3-ModelDocument1 page1M05 (B) TECTON-C-010 (REV-AB-1) SHEET No.1 OF 3-ModelmannshiNo ratings yet

- Tcbrochure enDocument4 pagesTcbrochure enyazedNo ratings yet

- 6 - Purlin & Sagrod Plan - Rev 0Document1 page6 - Purlin & Sagrod Plan - Rev 0hafis fadliNo ratings yet

- Irr-For Apr 2019Document1 pageIrr-For Apr 2019richrd villanuevaNo ratings yet

- Lobby Floor Plan (Ground)Document1 pageLobby Floor Plan (Ground)Ma. Isabel RodriguezNo ratings yet

- B14 L3A & 3B Carpark Steel & Perimeter Columns PDFDocument1 pageB14 L3A & 3B Carpark Steel & Perimeter Columns PDFPeter ThomsonNo ratings yet

- Roo Oo2m06 Acc XX XX SDW FL 05001 Main Kitchen Shura Red Sea c3Document1 pageRoo Oo2m06 Acc XX XX SDW FL 05001 Main Kitchen Shura Red Sea c3Waleed AwanNo ratings yet

- Toilet DetailDocument1 pageToilet DetailMoumi DharaNo ratings yet

- P4283-340-DRG-ME-015_B_ReviewedDocument1 pageP4283-340-DRG-ME-015_B_ReviewedalimfakihsalehNo ratings yet

- SCR 005075Document1 pageSCR 005075jeplgpbmcNo ratings yet

- FS0654-DOD-XX-00-DR-P-4002 - Ground Floor Domestic Water Services Sheet 2 of 2 - Construction - C01 - 0Document1 pageFS0654-DOD-XX-00-DR-P-4002 - Ground Floor Domestic Water Services Sheet 2 of 2 - Construction - C01 - 0mvrisleyNo ratings yet

- FS0654-DOD-XX-00-DR-P-4001 - Ground Floor Domestic Water Services Sheet 1 of 2 - Construction - C01 - 0Document1 pageFS0654-DOD-XX-00-DR-P-4001 - Ground Floor Domestic Water Services Sheet 1 of 2 - Construction - C01 - 0mvrisleyNo ratings yet

- It5 ElecDocument1 pageIt5 Elecmanhasr80No ratings yet

- Civil Work & Finishes ServicesDocument1 pageCivil Work & Finishes ServicesdadaraoNo ratings yet

- D038 Evs Co000 1091 - 00Document1 pageD038 Evs Co000 1091 - 00Mussarat BabasahebNo ratings yet

- Wh-1088pe DrawingDocument1 pageWh-1088pe Drawingom sai quality developmentNo ratings yet

- Atr SPLL (Max) El DWG It l34 6045Document1 pageAtr SPLL (Max) El DWG It l34 6045Hirushan MenukaNo ratings yet

- 21057423-Cs-csd-5000-0040 Weighing Scale Control Room Structural and Foundation Detail Drawing Rev.0Document1 page21057423-Cs-csd-5000-0040 Weighing Scale Control Room Structural and Foundation Detail Drawing Rev.0arjunNo ratings yet

- Piping DWGDocument1 pagePiping DWGkapsarcNo ratings yet

- Restaurant Floor Plan 1st Floor - CompressDocument2 pagesRestaurant Floor Plan 1st Floor - CompressCyrus De LeonNo ratings yet

- Cold Formed Channel Design NotesDocument1 pageCold Formed Channel Design NotesHammer HeadNo ratings yet

- SpeedhumpDocument1 pageSpeedhumpCarlos MakheleNo ratings yet

- Stair Obstructing Roadway VehiclesDocument1 pageStair Obstructing Roadway VehiclesAhmed Saber NassarNo ratings yet

- 9946Z - 0657-SP-SL-PL-C-G20-001(P3) - Proposed Levels Plan (Sheet 1 of 2)Document1 page9946Z - 0657-SP-SL-PL-C-G20-001(P3) - Proposed Levels Plan (Sheet 1 of 2)jmdavies.isNo ratings yet

- Drawing 2.Document1 pageDrawing 2.tiyaniNo ratings yet

- Mpeomo 2022Document35 pagesMpeomo 2022arkondxNo ratings yet

- 9d3 - Uukumwe School Hall-Roof LayoutDocument1 page9d3 - Uukumwe School Hall-Roof LayoutshaimenneNo ratings yet

- WWW - Tme.eu: Transfer Multisort ElektronikDocument3 pagesWWW - Tme.eu: Transfer Multisort Elektronikk.saikumarNo ratings yet

- Aykut TeknikDocument3 pagesAykut TeknikMurat SuakNo ratings yet

- Material Site WisataDocument1 pageMaterial Site Wisatadany hamdaniNo ratings yet

- Tourism Benefits The World - Debating MattersDocument9 pagesTourism Benefits The World - Debating MattersKhalil MachkourNo ratings yet

- Western Museums Should Repatriate Cultural Artefacts - Debating MattersDocument10 pagesWestern Museums Should Repatriate Cultural Artefacts - Debating MattersKhalil MachkourNo ratings yet

- Technological Progress and Environmental Issues DebateDocument8 pagesTechnological Progress and Environmental Issues DebateKhalil MachkourNo ratings yet

- Autonomous Vehicles Will Make Driving Safer - Debating MattersDocument9 pagesAutonomous Vehicles Will Make Driving Safer - Debating MattersKhalil MachkourNo ratings yet

- Geomembrane Rock PEC GEOLONDocument7 pagesGeomembrane Rock PEC GEOLONKhalil MachkourNo ratings yet

- LTC North Road Embankments With Flood Bunds Considered WiP 14112022Document27 pagesLTC North Road Embankments With Flood Bunds Considered WiP 14112022Khalil MachkourNo ratings yet

- ACSR Conductor IS: 3981976Document2 pagesACSR Conductor IS: 3981976SahanShrestha100% (2)

- Multi-Disciplinary Design Optimization of A Composite Car Door For Structural Performance, NVH, Crash Worthiness, Durability and ManufacturabilityDocument59 pagesMulti-Disciplinary Design Optimization of A Composite Car Door For Structural Performance, NVH, Crash Worthiness, Durability and Manufacturabilitymarc271986100% (1)

- Handbook of Residual StressDocument8 pagesHandbook of Residual StressDownNo ratings yet

- Lecture Plan For Jee - Chemistry (2021) S. No. Chapter Name Topics Name No. of Lecture Date of LectureDocument6 pagesLecture Plan For Jee - Chemistry (2021) S. No. Chapter Name Topics Name No. of Lecture Date of LectureSurendra SinghNo ratings yet

- Determination of Creep Compliance of Asphalt ConcreteDocument11 pagesDetermination of Creep Compliance of Asphalt ConcreteLoyda MarcelaNo ratings yet

- Phase DiagramDocument48 pagesPhase DiagramBrian RichardNo ratings yet

- EL 1900 TDS 英文Document2 pagesEL 1900 TDS 英文Nancy HoNo ratings yet

- CHE 3161 Test 3 solution incompressible fluid RK EOS ethylene propertiesDocument2 pagesCHE 3161 Test 3 solution incompressible fluid RK EOS ethylene propertiesManishaa Varatha RajuNo ratings yet

- Tyfrtreerwetqet WW1111Document4 pagesTyfrtreerwetqet WW1111John Heidrix AntonioNo ratings yet

- Engraving of Roller PrintingDocument24 pagesEngraving of Roller Printingapi-3817839100% (3)

- GT Generator Step-Up Transformer Inc. Auxiliary System Installation ITPL 燃气轮机升压变压器包括辅助系统安装Document23 pagesGT Generator Step-Up Transformer Inc. Auxiliary System Installation ITPL 燃气轮机升压变压器包括辅助系统安装rakibnjtechNo ratings yet

- Technical Data For Bailey Platinum Plus Interior Drywall Framing SystemDocument2 pagesTechnical Data For Bailey Platinum Plus Interior Drywall Framing SystemhahaerNo ratings yet

- Marcet Boiler Lab Analyzes Steam PropertiesDocument14 pagesMarcet Boiler Lab Analyzes Steam PropertiesSims Gift ShibaNo ratings yet

- Effect of powder properties and storage conditions on the flowability of milk powdersDocument10 pagesEffect of powder properties and storage conditions on the flowability of milk powdersTháila PimentelNo ratings yet

- UV-Curing Coatings: A Concise OverviewDocument10 pagesUV-Curing Coatings: A Concise OverviewIsmail BayraktarNo ratings yet

- Brosur Pt. Srirejeki Perdana Steel-1Document16 pagesBrosur Pt. Srirejeki Perdana Steel-1Agus SofiansyahNo ratings yet

- Katalog Koncowki Rurowe ABB Wersja en 08.2017Document36 pagesKatalog Koncowki Rurowe ABB Wersja en 08.2017nnNo ratings yet

- DAXXXDocument11 pagesDAXXXMichael WoodNo ratings yet

- Southern Tier Bridges - Chemung CountyDocument6 pagesSouthern Tier Bridges - Chemung CountyGeorge StockburgerNo ratings yet

- Cold Rolling and Tensile Testing Effects on MetalsDocument14 pagesCold Rolling and Tensile Testing Effects on MetalsSean BiseNo ratings yet

- Technical Data Sheet for AeroShell Fluid 41 (IndiaDocument3 pagesTechnical Data Sheet for AeroShell Fluid 41 (IndiaAaron ChanNo ratings yet

- Ransom & Randolph - Jewelry Casting - Investing FAQsDocument2 pagesRansom & Randolph - Jewelry Casting - Investing FAQsGabrielNo ratings yet

- Hypro 1300X13 CTBN & 1300X13F CTBN Carboxyl-Terminated Butadiene-AcrylonitrileDocument4 pagesHypro 1300X13 CTBN & 1300X13F CTBN Carboxyl-Terminated Butadiene-Acrylonitrileuzzy2No ratings yet