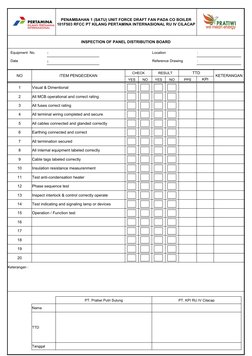

PENAMBAHAN 1 (SATU) UNIT FORCE DRAFT FAN PADA CO BOILER

101F503 RFCC PT KILANG PERTAMINA INTERNASIONAL RU IV CILACAP

INSPECTION OF PANEL DISTRIBUTION BOARD

Equipment No. : Location :

Date : Reference Drawing :

CHECK RESULT TTD

NO ITEM PENGECEKAN KETERANGAN

YES NO YES NO PPS KPI

1 Visual & Dimentional

2 All MCB operational and correct rating

3 All fuses correct rating

4 All terminal wiring completed and secure

5 All cables connected and glanded correctly

6 Earthing connected and correct

7 All termination secured

8 All internal equipment labeled correctly

9 Cable tags labeled correctly

10 Insulation resistance measurenment

11 Test anti-condensation heater

12 Phase sequence test

13 Inspect interlock & control correctly operate

14 Test indicating and signaling lamp or devices

15 Operation / Function test

16

17

18

19

20

Keterangan :

PT. Pratiwi Putri Sulung PT. KPI RU IV Cilacap

Nama

TTD

Tanggal

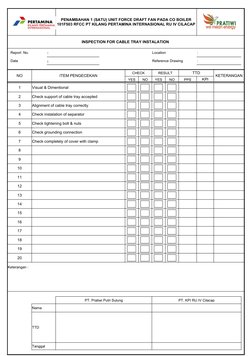

� PENAMBAHAN 1 (SATU) UNIT FORCE DRAFT FAN PADA CO BOILER

101F503 RFCC PT KILANG PERTAMINA INTERNASIONAL RU IV CILACAP

INSPECTION FOR CABLE TRAY INSTALATION

Report No. : Location :

Date : Reference Drawing :

CHECK RESULT TTD

NO ITEM PENGECEKAN KETERANGAN

YES NO YES NO PPS KPI

1 Visual & Dimentional

2 Check support of cable tray accepted

3 Alignment of cable tray correctly

4 Check instalation of separator

5 Check tightening bolt & nuts

6 Check grounding connection

7 Check completely of cover with clamp

10

11

12

13

14

15

16

17

18

19

20

Keterangan :

PT. Pratiwi Putri Sulung PT. KPI RU IV Cilacap

Nama

TTD

Tanggal

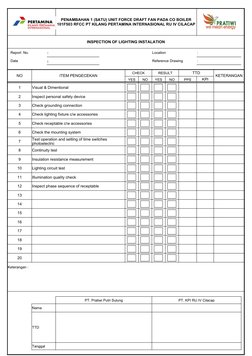

� PENAMBAHAN 1 (SATU) UNIT FORCE DRAFT FAN PADA CO BOILER

101F503 RFCC PT KILANG PERTAMINA INTERNASIONAL RU IV CILACAP

INSPECTION OF LIGHTING INSTALATION

Report No. : Location :

Date : Reference Drawing :

CHECK RESULT TTD

NO ITEM PENGECEKAN KETERANGAN

YES NO YES NO PPS KPI

1 Visual & Dimentional

2 Inspect personal safety device

3 Check grounding connection

4 Check lighting fixture c/w accessories

5 Check receptable c/w accessories

6 Check the mounting system

Test operation and setting of time switches

7

photoelectric

8 Continuity test

9 Insulation resistance measurement

10 Lighting circuit test

11 Illumination quality check

12 Inspect phase sequence of receptable

13

14

15

16

17

18

19

20

Keterangan :

PT. Pratiwi Putri Sulung PT. KPI RU IV Cilacap

Nama

TTD

Tanggal

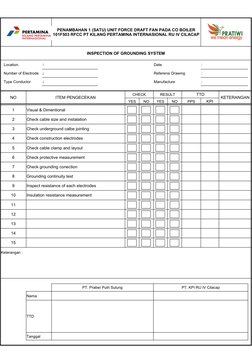

� PENAMBAHAN 1 (SATU) UNIT FORCE DRAFT FAN PADA CO BOILER

101F503 RFCC PT KILANG PERTAMINA INTERNASIONAL RU IV CILACAP

INSPECTION OF GROUNDING SYSTEM

Location. : Date :

Number of Electrode : Referensi Drawing :

Type Conductor : Manufacture :

CHECK RESULT TTD

NO ITEM PENGECEKAN KETERANGAN

YES NO YES NO PPS KPI

1 Visual & Dimentional

2 Check cable size and instalation

3 Check underground calbe jointing

4 Check construction electrodes

5 Check cable clamp and layout

6 Check protective measurement

7 Check grounding conection

8 Grounding continuity test

9 Inspect resistance of each electrodes

10 Insulation resistance measurement

11

12

13

14

15

Keterangan :

PT. Pratiwi Putri Sulung PT. KPI RU IV Cilacap

Nama

TTD

Tanggal

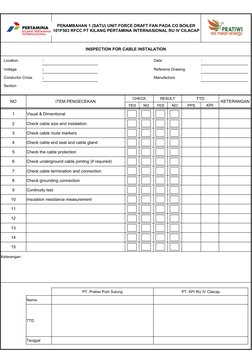

� PENAMBAHAN 1 (SATU) UNIT FORCE DRAFT FAN PADA CO BOILER

101F503 RFCC PT KILANG PERTAMINA INTERNASIONAL RU IV CILACAP

INSPECTION FOR CABLE INSTALATION

Location. : Date :

Voltage : Referensi Drawing :

Conductor Cross : Manufacture :

Section

CHECK RESULT TTD

NO ITEM PENGECEKAN KETERANGAN

YES NO YES NO PPS KPI

1 Visual & Dimentional

2 Check cable size and instalation

3 Check cable route markers

4 Check cable end seal and cable gland

5 Check the cable protection

6 Check underground cable jointing (if required)

7 Check cable termination and connection

8 Check grounding connection

9 Continuity test

10 Insulation resistance measurement

11

12

13

14

15

Keterangan :

PT. Pratiwi Putri Sulung PT. KPI RU IV Cilacap

Nama

TTD

Tanggal

� PENAMBAHAN 1 (SATU) UNIT FORCE DRAFT FAN PADA CO BOILER

101F503 RFCC PT KILANG PERTAMINA INTERNASIONAL RU IV CILACAP

INSPECTION FOR SWITCHGEAR / MCC

Equipment No. : Date :

Location : Referensi Drawing :

Voltage : Manufacture :

CHECK RESULT TTD

NO ITEM PENGECEKAN KETERANGAN

YES NO YES NO PPS KPI

1 Visual & Dimentional

2 Board assembly and bolting

3 Busbars bolted connection

4 Fuse ratings and gauge rings

5 Contact alignment of draw-out mechanism

6 Cable gland, clamping and termination

7 Tag and wire number

8 Check grounding connection

9 Check rating and capacity of CT, PT.

10 The ralays have complete final setting

11 Insulation resistance measurement

12 Test anti-condensation heater

13 PT's polarity & phase rotation

14 Inspect interlock & control correctly operate

15 Test indicating and signaling lamps or devices

16 Switchgear function test

17 Phase sequence test

Keterangan :

PT. Pratiwi Putri Sulung PT. KPI RU IV Cilacap

Nama

TTD

Tanggal