Professional Documents

Culture Documents

Henkel Loctite Engineering Manual Loctite GC 10 Solder Paste PDF

Uploaded by

VICTOR MARCOSOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Henkel Loctite Engineering Manual Loctite GC 10 Solder Paste PDF

Uploaded by

VICTOR MARCOSCopyright:

Available Formats

Engineering Manual

Global Distributor of Henkel LOCTITE

(800) 888-0698 info@ellsworth.com

LOCTITE GC 10 Solder Paste

Suitable for use with: Standard SAC Alloys

GC 10 – The Game Changer

Contents

1. Performance Summary

2. Introduction: Properties, Features & Benefits

3. Operating Parameters

• Printing: Process Window

• Printing: Continuous and Abandon Time Testing

• Slump Testing

• Tack-Life Force

• Reflow Process Window

• Reflow Performance Testing

• Voiding Data

4. Reliability and Specification Testing

5. Operating Parameters: Storage

• Printing & Reflow Performance

6. Product Summary

2 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Contents

1. Performance Summary

2. Introduction: Properties, Features & Benefits

3. Operating Parameters

• Printing: Process Window

• Printing: Continuous and Abandon Time Testing

• Slump Testing

• Tack-Life Force

• Reflow Process Window

• Reflow Performance Testing

• Voiding Data

4. Reliability and Specification Testing

5. Operating Parameters: Storage

• Printing & Reflow Performance

6. Product Summary

3 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

GC 10: Performance Summary

Flux

• Halogen-free flux: passes IC with pretreatment IPC-TM-650

2.3.34/EN14582

• Halogen-free flux classification: ANSI/J-STD-004 Rev. B for

a type ROL0 classification

Paste

• Suitable for fine pitch, high speed printing up to 125mm/s (5”/s)

• Optimized for long hot soak reflow profiles

• Excellent fine pitch coalescence in air & nitrogen atmosphere

• Excellent humidity resistance

• Excellent solderability on challenging surface finishes,

including CuNiZn

• Colorless residues for easy post-reflow inspection

• Long 12month shelf-life when stored below 26.5°C

4 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Contents

1. Performance Summary

2. Introduction: Properties, Features & Benefits

3. Operating Parameters

• Printing: Process Window

• Printing: Continuous and Abandon Time Testing

• Slump Testing

• Tack-Life Force

• Reflow Process Window

• Reflow Performance Testing

• Voiding Data

4. Reliability and Specification Testing

5. Operating Parameters: Storage

• Printing & Reflow Performance

6. Product Summary

5 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Introduction

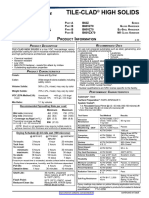

Basic Solder Paste Properties

Flux Description GC 10

Alloy SAC305

Henkel Powder Size Type 4

Powder Size range, µm 38-20

Metal Content, % 88.5

Malcom Viscosity, 10rpm Pa.s 190

TI 0.50

IPC slump @182°C (0.33mm x 2.03mm) 0.20

first space no bridge

IPC Solder Balling preferred

6 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Introduction

GC 10 Features & Benefits

Product Attribute Process Benefit

Halogen Free • No added halogen

• Measured <900ppm chlorine and bromine and <1,500ppm total by

oxygen (O2) bomb test

Halide Free • Flux classification ROL0 in accordance to J-STD-004B

Application • Designed for printing and pin-in-paste

• Excellent wetting to a broad range of metallisations, even through

long hot soak profiles in an air atmosphere

• Compatible with existing halogen free solutions

• Suitable for medium to large board assemblies

• Designed for long 12 month shelf-life stability without impact to

printing or reflow

7 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Introduction

GC 10 Features & Benefits

Product Attribute Process Benefit

Technology Printing • Wide process window for printing and minimal slump

Advantages • Fine pitch abandon time of up to 2 hours; work life > 16 hours

• Fine pitch capability and reduction in solder bridging

• Suited for high throughput production, where yield consistency on print

deposits is key

• Improved paste transfer efficiency

• Allows on line paste utilisation protocols to be re-written

Technology Reflow • Optimised for long hot soak reflow processes

Advantages • Very shiny Pb-free solder joints over wide range of reflow

• Excellent fine pitch coalescence

• Excellent humidity resistance

• Excellent solderability on challenging surface finishes (ENIG, Copper OSP,

CuNiZn and Imm Ag)

Low Voiding • Low void levels increases solder joint reliability

• New chemistries allow pursuit of class 3 void levels in accordance to IPC7095B

on industry surface finishes: ENIG, Copper OSP, CuNiZn and Imm Ag

• Low voiding in CSP

Residues • Clear, transparent and colourless

• Pin testable after 5x reflows

8 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Contents

1. Performance Summary

2. Introduction: Properties, Features & Benefits

3. Operating Parameters

• Printing: Process Window

• Printing: Continuous and Abandon Time Testing

• Slump Testing

• Tack-Life Force

• Reflow Process Window

• Reflow Performance Testing

• Voiding Data

4. Reliability and Specification Testing

5. Operating Parameters: Storage

• Printing & Reflow Performance

6. Product Summary

9 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters

Print Process Window

(LOCTITE GC 10 SAC305 T4 885V)

• Excellent printing in the Contour Plot of 0.8mmBGA Cpk Contour Plot of 0.4mmCSP56 (300um aperture) Cpk

range 25 – 125mm/s 0.8mmBGA 0.4mmCSP56

Cpk Cpk

< 1.33 < 1.33

1.33 – 1.67 1.33 – 1.67

0.04 1.67 – 2.00 0.04 1.67 – 2.00

> 2.00 > 2.00

Pressure kg/mm

Pressure kg/mm

0.03 0.03

0.02 0.02

40 60 80 100 120 40 60 80 100 120

Speed mm/s Speed mm/s

Contour Plot of 0.5mmBGA (266um aperture) Cpk Contour Plot of 0201 Cpk

0.5mmBGA 0201 Cpk

Cpk < 1.33

< 1.33 1.33 – 1.67

1.33 – 1.67 1.67 – 2.00

0.04 1.67 – 2.00 0.04 > 2.00

> 2.00

Pressure kg/mm

Pressure kg/mm

0.03 0.03

0.02 0.02

40 60 80 100 120 40 60 80 100 120

Speed mm/s Speed mm/s

0.8mm, 0.5mm & 0.4mm round apertures, 0201 (100µm stencil)

10 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters

Print Process Window

(LOCTITE GC 10 SAC305 T4 885V)

• Excellent printing in the Contour Plot of 0.22mm diam Cpk Contour Plot of 0.20mm diam Cpk

range 25 – 125mm/s, 0.22mm 0.20mm

diam Cpk diam Cpk

0.18-0.22mm round < 1.33

1.33 – 1.67

< 1.33

1.33 – 1.67

apertures 0.04 1.67 – 2.00

> 2.00

0.04 1.67 – 2.00

> 2.00

Pressure kg/mm

Pressure kg/mm

0.03 0.03

0.02 0.02

40 60 80 100 120 40 60 80 100 120

Speed mm/s Speed mm/s

Contour Plot of 0.18mm diam Cpk Contour Plot of 0.15mm diam Cpk

0.18mm 0.15mm

diam Cpk diam Cpk

< 1.33 < 1.33

1.33 – 1.67 1.33 – 1.67

0.04 1.67 – 2.00 0.04 1.67 – 2.00

> 2.00 > 2.00

Pressure kg/mm

Pressure kg/mm

0.03 0.03

0.02 0.02

40 60 80 100 120 40 60 80 100 120

Speed mm/s Speed mm/s

0.22mm – 0.15mm round apertures, (100µm stencil)

11 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters – Separation Speed

Print Process Window

(LOCTITE GC 10 SAC305 T4 885V)

• Excellent printing in the

range down to 0.18mm Separation Speed, Cpk

round apertures. Loctite GC10 T4

• Fast separation speed is

preferable. 5 Variable

Fast

Medium

4 Slow

3

Cpk

2

1.67 ref

1.33 ref

1

A ) ) m m m m

G ap ap dia di a dia di a

8B

0. mm mm m m m m

30 66 2m 0m 8m 5m

( 0. .2 0.2 0. 2 0.1 0.1

56 (0

A

SP G

mC 5B

0.

4m

0.

Component_Cpk

0.8mm BGA – 0.15mm round apertures, (100µm stencil) 100µm stencil thickness,

60mm/s

12 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters

Continuous Print and Abandon Stability Assessment

Henkel Board 0.8mm BGA to 0.15mm diameter circles Process flow for Henkel print test as shown below

Paste Paste Dry under Print 15 PCBs,

added to stencil kneaded stencil wipe dry wipe every 5

Print 5 PCBs 2hr pause Print 5 PCBs 1hr pause

Blank stencil

Volumes Print 15 PCBs, Volumes

1000 or 2000

Measured dry wipe every 5 Measured

cycles

• Printing • 250mm, 60° squeegee

• DEK Europa • 60mm/s squeegee speed

• Stainless steel, laser cut • 20mm/s separation speed

• 100µm thickness • Conditions Typical, 22C, 40% RH

• Vacuum tooling • Koh Young KY-8020T volume measurement

13 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters

Printing

• GC 10 solder pastes show exceptional print quality

• On 0.18mm diameter fine pitch devices only one knead stroke is required after 2hour machine down times

• On coarser pitch deposits it is expected that the first print after abandon can in normal circumstances be

perfectly acceptable for production quality

0402 0201 01005

0.4mm TQFP120 0.5mm CSP56 0.4mm BGA432

14 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters

– Abandon Stability 22°C/40%RH

Print Process Window (LOCTITE GC 10 SAC305 T4 885V)

• Excellent printing in the

range down to 0.18mm Abandon Time 1hr, 2hr, 2hr +1 knead

round apertures GC10 T4

• Single knead cycle required

5 Variable

after 2hr abandon at

initial

0.18mm round apertures 1hr

4 2hr

2hr + 1 knead

Cpk 3

2

1.67 ref

1.33 ref

1

0

A ) )

BG ap ap am am am a m

8 di di di di

0. m

m

m

m m m m m

30 66 m m m m

(0

. . 2 22 20 18 15

6 (0 0. 0. 0. 0.

P5 A

CS 5BG

m 0.

4m

0.

0.8mm BGA – 0.15mm round apertures, (100µm stencil)

100µm stencil thickness, 60mm/s, Fast separation, 250mm squeegee, 8kg

15 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters

– Abandon Stability 30°C/50%RH

Print Process Window (LOCTITE GC 10 SAC305 T4 885V)

• Excellent abandon time

resistance Abandon Time 1hr, 2hr, 2hr + 1 knead

• No knead cycle required GC10 T4 30C/50%RH

after 2hrs abandon down to

5

0.20mm round apertures. Variable

• Single knead stroke

4

initial

1hr

required after 2hr abandon 2hr

at 0.18mm round apertures 2hr + 1 knead

Cpk 3

2

1.67 ref

1.33 ref

1

0

A ) )

BG ap ap am am am am

8 di di di di

0. m

m

m

m m m m m

. 30 266 2m 0m 8m 5m

(0 . 2 2 1 1

6 (0 0. 0. 0. 0.

P5 A

G

CS 5B

m 0.

4m

0.

0.8mm BGA – 0.15mm round apertures, (100µm stencil)

100µm stencil thickness,60mm/s, Fast separation, 250mm squeegee, 8kg

16 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters

– Continuous Print Stability

Print Process Window (LOCTITE GC 10 SAC305 T4 885V)

• No impact on print

performance after 4 hours Continuous Print Stability 1000 cycles, 2000 cycles

(1000 cycles) and 8 hours GC10 T4

(2000 cycles) printing

5 Variable

initial

1000 cycles

4

2000 cycles

Cpk 3

2

1.67 ref

1.33 ref

1

0

A ) )

BG ap ap am am am am

8 di di di di

0. m

m

m

m

m m m m

. 30 266 22

m

20m 18

m

15

m

(0 (0

. 0. 0. 0. 0.

6

S P5 BG

A

C 5

m 0.

4m

0.

0.8mm BGA – 0.15mm round apertures, (100µm stencil)

100µm stencil thickness, 60mm/s, Fast separation, 250mm squeegee, 8kg

17 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters

Paste Properties After Continuous Printing

Viscosity after Continuous Print TI Change After Continuous Print

300 1.0

Conditions Conditions

22°C, 30%RH 22°C, 30%RH

30°C, 40-50%RH 30°C, 40-50%RH

250

0.8

200

10rpm (Pa.s)

0.6

150

TI

0.4

100

0.2

50

0 0.0

0 1000 2000 0 1000 2000

Cycles Cycles

IPC Slump @ 182C After Continuous Printing IPC Slump @ 182C After Continuous Printing

0.33mm x 2.03mm, 200um stencil thickness 0.63mm x 2.03mm, 200um stencil thickness

0.4 Conditions

Conditions 0.38

22°C, 30%RH

22°C, 30%RH

30°C, 40-50%RH

Minimum Gap not Bridged (mm)

30°C, 40-50%RH

Minimum Gap not Bridged (mm)

0.36

0.3

0.34

0.2

0.32

0.1 0.30

0.28

0.0

0 1000 2000 0 1000 2000

Cycles Cycles

18 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters

Slump

• Slump evaluation was performed in accordance with J-STD-005A, IPC-TM-650 2.4.35

• First spacing with no bridge recorded after 10 minutes at 182°C (35°C below melting point 217°C)

Stencil A 21 A 20

Design/ 200µm 100µm

thickness

Aperture 0.63 x 0.33 x 0.33 x 0.20 x

2.03mm 2.03mm 2.03mm 2.03mm

Pass

0.63mm 0.30mm 0.30mm 0.25mm

mark

GC 10

0.33mm 0.10mm 0.08mm 0.075mm

25°C

GC 10

0.33mm 0.20mm 0.15mm 0.125mm

182°C

A21 A20

200µm 100µm

19 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters

Tack Force

• Slump Tackiness evaluation was performed in accordance with

J-STD-005A, IPC-TM-650 2.4.44

• GC 10 tack-life >48hours

Malcom TK1 Tackiness Tester

Preload 300g

Preload time 5 secs

Retraction Speed 2.5mm/sec

Deposit diameter 5.1mm

Deposit height 0.25mm

20 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters

Solder Balling

• Solder balling performance as been assessed in accordance with

an extended version of IPC-TM-650 2.4.4.3

• Clear and colourless residues observed post-reflow

Initial 24hrs 25°C 50% RH

Preferred Pass Preferred Pass

21 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters

Reflow Process Window (Air)

• LOCTITE GC 10 solder paste offers halogen containing reflow performance in a

truly halogen free formulation

• GC 10 shows excellent coalescence onto a range of PCB and component finishes

especially during long-hot profiles

• There is no single profile that works for all applications and each process should be

assessed individually, under laboratory conditions the following profiles have been

found to give good results

• These process window guidelines are suitable for Type 4 SAC powder

Reflow Profiles Profile 1 2 3 4

300

Profile 1

250

Profile

Profile

2

3 Peak Temp (°C) 244 254 260 255

Profile 4

217°C

Time to Peak (min) 3.3 4.5 5.1 6.0

Temperature (°C)

200

150 (No

Soak Time (150-200°C) (min) Soak) 2.35 2.80 3.44

100

1.0

50

Time above Liquidus (min) 0.62 1.46 1.75 1.45

0

0 1 2 3 4

Time (minutes)

5 6 7 Time above Liquidus (sec) 37.2 87.6 105.0 87.0

22 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters (Reflow)

Reflow Profiles

Reflow Profile

300

Profile 1

Profile 2

250 Profile 3

Profile 4

217°C

Temperature (°C)

200

1 2 3 4

150

100

50

0.5mm CSP56

0

0 1 2 3 4 5 6 7

Time (minutes)

0201

0402

23 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters (Reflow)

Reflow Profiles

Reflow Profile

300

Profile 1

Profile 2

250 Profile 3

Profile 4

217°C

Temperature (°C)

200

1 2 3 4

150

100

50

0

0 1 2 3 4 5 6 7

Time (minutes)

Overprinted

0.4mm TQFP120

0.4mm TQFP120

24 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters (Reflow)

Reflow Profiles

Reflow Profile

300

Profile 1

Profile 2

250 Profile 3

Profile 4

217°C

Temperature (°C)

200

1 2 3 4

150

100

50

0

0 1 2 3 4 5 6 7

0.5mm CSP56

Time (minutes)

0.4mm TQFP120

0.4mm TQFP120

25 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters (Reflow)

Reflow Profiles

Reflow Profile

300

Profile 1

Profile 2

250 Profile 3

Profile 4

217°C

Temperature (°C)

200

1 2 3 4

150

100

50

01005 Capacitors

0

0 1 2 3 4 5 6 7

Time (minutes)

01005 Resistors

26 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters (Reflow)

Paste Properties After Continuous Printing

Profile 2

1,000 cycles 2,000 cycles 1,000 cycles 300

250

22°C, 30%RH 22°C, 30%RH 30°C, 40-50%RH 217°C

Temperature (°C)

200

150

100

50

0

0.5mm CSP

0 1 2 3 4 5 6

Time (min)

6.5mm Overprint

• No change to reflow performance after 8hours

printing (2000 print cycles)

27 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters (Reflow – GC10)

Reflow Profiles

Reflow Profile

Profile 1

250 Profile 2

217°C

200

Temperature (°C)

1 2

150

100

50

01005 Resistors

0 1 2 3 4 5 6

Time (minutes)

01005 Resistors

0.5mm CSP & 0.4mm QFP

28 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters

Voiding

• Void performance assessed using 4 different reflow profiles

• GC 10 shows low levels of voiding over a range of profiles

Reflow Profiles

300

Profile 1

Profile 2

250 Profile 3

• Void Percentage analysed in accordance with IPC7095B

Profile 4

217°C

Temperature (°C)

200

150

100

50

0

0 1 2 3 4 5 6 7

Time (minutes)

Boxplot of IPC Voiding Percentage Boxplot of Void Size

0.50

20 Class 1

15 Class 2 0.45

Average Diameter (mm)

IPC Voiding %

10 Class 3 0.40

5 0.35

0 0.30

Profile 1 Profile 2 Profile 3 Profile 4 Profile 1 Profile 2 Profile 3 Profile 4

GC 10 meets IPC7095B class 3

29 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters

Pin Testing

Reflow Profiles

300

Before After

Profile 1

Profile 2

250 Profile 3

Profile 4

217°C

Test Test

Temperature (°C)

200

150

100

50

0

0 1 2 3 4 5 6 7

Time (minutes)

Board

Stencil 100µm

Pads 500 pads per board, 2 boards tested

Probe 0.9mm 4 point plain crown light spring probe 100g spring force

Profiles 4 reflow profiles

No. of reflow 1, 2, 3 & 4 passes through oven

Atmosphere Air & 1000ppm O2

Time after reflow 1 day, 1 week

30 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters

Pin Testing

Reflow Profiles

Reflow Profile (% after 1000 tests)

300

Profile 1

Profile 2

250 Profile 3

Profile 4

217°C

Temperature (°C)

200

1 2 3 4

150

100

50

100% 100% 100% 99.5% 0

0 1 2 3 4 5 6 7

1 reflow

Time (minutes)

100% 100% 99.6% 99.9%

2 reflows

99.9% 100% 100% 98.9%

3 reflows

99.9% 100% 100% 98.5%

4 reflows

31 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters

Pin Testing

Reflow Profiles

Reflow Profile (% after 1000 tests)

300

Profile 1

Profile 2

250 Profile 3

Profile 4

217°C

Temperature (°C)

200

1 2 3 4

150

100

50

100% 100% 100% 100% 0

Reflowed in N2

0 1 2 3 4 5 6 7

Time (minutes)

100% 99.9% 99.8% 99.6%

1 day after reflow

100% 99.8% 99.3% 99.6%

1 week after reflow

32 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters

Surface Finish

Reflow Profiles

Reflow Profile (0.5mm CSP56)

300

Profile 1

Profile 2

250 Profile 3

Profile 4

217°C

Temperature (°C)

200

1 2 3 4

150

100

50

0

0 1 2 3 4 5 6 7

Time (minutes)

OSP Finish

Silver Finish

Tin Finish

33 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters

Surface Finish

Reflow Profiles

Reflow Profile (0201)

300

Profile 1

Profile 2

250 Profile 3

Profile 4

217°C

Temperature (°C)

200

1 2 3 4

150

100

50

0

0 1 2 3 4 5 6 7

Time (minutes)

OSP Finish

Silver Finish

Tin Finish

34 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters

Surface Finish

Reflow Profiles

Reflow Profile (0402)

300

Profile 1

Profile 2

250 Profile 3

Profile 4

217°C

Temperature (°C)

200

1 2 3 4

150

100

50

0

0 1 2 3 4 5 6 7

Time (minutes)

OSP Finish

Silver Finish

Tin Finish

35 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters

Surface Finish

Reflow Profiles

Reflow Profile (6.5mm overprint)

300

Profile 1

Profile 2

250 Profile 3

Profile 4

217°C

Temperature (°C)

200

1 2 3 4

150

100

50

0

0 1 2 3 4 5 6 7

Time (minutes)

OSP Finish

Silver Finish

Tin Finish

36 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters

Voiding Different Surface Finishes 0.5mm CSP56

• Void performance on OSP Cu and Immersion Sn surface finishes assessed using 4 Reflow Profiles

different reflow profiles

300

Profile 1

Profile 2

250 Profile 3

Profile 4

217°C

Temperature (°C)

200

150

100

50

0

0 1 2 3 4 5 6 7

Time (minutes)

Boxplot of IPC Voiding Percentage Boxplot of Void Size

0.50

20 Class 1

0.45

Average Diameter (mm)

15 Class 2

IPC Voiding %

10 Class 3 0.40

5

0.35

0

0.30

Profile Profile 1 Profile 2 Profile 3 Profile 4 Profile 1 Profile 2 Profile 3 Profile 4 Profile Profile 1 Profile 2 Profile 3 Profile 4 Profile 1 Profile 2 Profile 3 Profile 4

Finish Imm Sn OSP Cu Finish Imm Sn OSP Cu

GC 10 meets IPC7095B class 3

37 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Contents

1. Performance Summary

2. Introduction: Properties, Features & Benefits

3. Operating Parameters

• Printing: Process Window

• Printing: Continuous and Abandon Time Testing

• Slump Testing

• Tack-Life Force

• Reflow Process Window

• Reflow Performance Testing

• Voiding Data

4. Reliability and Specification Testing

5. Operating Parameters: Storage

• Printing & Reflow Performance

6. Product Summary

38 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Reliability and Specification Testing

Head- in Pillow Test

• Print solder paste on a Cu plate, 0402 pad, stencil thickness 125µm. Head In Pillow

• When the solder paste starts to melt, place a solder sphere (SAC305, 18

Time to First Defect

0.76mm diameter) on the printed solder paste 16

14

Average Time (s)

• Place another sphere after 3sec, 6 sec, 9sec… until the solder sphere 12

10

no-longer coalesces 8

6

4

2

0

al °C A B C D E F G

iti 40 st

e te st

e

st

e st

e

st

e

st

e

In s

10 th pa pa pa pa pa pa pa

GC 1m ce ce ce ce ce ce ce

10 en en en en en en en

er er fe

r

fe

r er er fe

r

GC re

f

re

f

re re re

f

re

f

re

Paste

Place a solder

sphere onto

printed paste

250+/-5˚C

…..

…..

250+/-5˚C

Copper plate Initial 10sec 20sec First

Solder paste 1st sphere 2nd sphere 3rd sphere Defect

Solder sphere

39 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Reliability and Specification Testing

Head- in Pillow Test

Standard Test Result

Pass

Cu Corrosion

GC 10 Control

ANSI/ Pass

Cu Mirror

J-STD-004B

Halogen Pass (no added halogen)

6.0x1011 Ohms after 7days

Surface Insulation Resistance Pass

Electromigration Pass 5.0x1010 Ohms after 21days

GC 10 J-STD-004B classification ROL0

40 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Reliability and Specification Testing

3rd Party Testing

• SGS report for GC 10

• Sample reflowed flux residue

• Reference EN14582/IC Analysis

• To meet halogen free requirements

• Br<900ppm, Cl <900ppm, and combined <1500ppm

• Halogen – Fluorine - ND

• Halogen – Chorine - ND

• Halogen – Bromine – ND

• Halogen – Iodine – ND

GC 10 has no detectable halogen and is designated as halogen free

41 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Reliability and Specification Testing

IPC J-STD 004B

Reflow Profiles

Profile 1

250 Profile 2

217°C

200

Temperature (°C)

150

100

50

0 1 2 3 4 5 6

Time (minutes)

42 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Contents

1. Performance Summary

2. Introduction: Properties, Features & Benefits

3. Operating Parameters

• Printing: Process Window

• Printing: Continuous and Abandon Time Testing

• Slump Testing

• Tack-Life Force

• Reflow Process Window

• Reflow Performance Testing

• Voiding Data

4. Reliability and Specification Testing

5. Operating Parameters: Storage

• Printing & Reflow Performance

6. Product Summary

43 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters: Storage

Printing After Storage 1month 40°C

• Excellent print capability

after storage for 1 month @ Continuous Print & Abandon Time After Storage

40°C GC10 T4 1 month 40C

• No knead cycle required

after 2hrs abandon down to Variable

5 initial

0.20mm round apertures 1000 cy cles

1hr abandon

4 2hr abandon

3

Cpk

2

1.67 ref

1.33 ref

1

0

Abandon Time Continuous

Test

0.4mm BGA ,100µm stencil thickness, 60mm/s, Fast separation,

250mm squeegee, 8kg

44 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters: Storage

Printing After Storage 6months 25°C

• Excellent print capability

after storage for 6 months Continuous Print & Abandon Time After Storage

@ 25°C GC10 T4 6 month 25C

• No knead cycle required

after 2hrs abandon down to Variable

5 initial

0.20mm round apertures 1000 cycles

1hr abandon

4 2hr abandon

3

Cpk

2

1.67 ref

1.33 ref

1

0

Abandon Time Continuous

Test

0.4mm BGA ,100µm stencil thickness, 60mm/s, Fast separation,

250mm squeegee, 8kg

45 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters: Storage

Printing After Storage 12months 25°C

• Excellent print capability

after storage for 12 months Continuous Print & Abandon Time After Storage

@ 25°C GC10 T4 12 month 25C

• No knead cycle required

after 2hrs abandon down to Variable

5 initial

0.20mm round apertures 1000 cycles

1hr abandon

4 2hr abandon

3

Cpk

2

1.67 ref

1.33 ref

1

0

Abandon Time Continuous

Test

0.4mm BGA ,100µm stencil thickness, 60mm/s, Fast separation,

250mm squeegee, 8kg

46 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters: Storage

Profile 2

After Paste storage 300

250

217°C

Temperature (°C)

200

Initial 1m 40°C 6m 25°C

150

100

50

0

0 1 2 3 4 5 6

0.5mm CSP

Time (min)

0201

0402

47 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Operating Parameters: Storage

After storage and 2nd side/pre-reflow

Profile 3

0.5mmCSP 0201

300

250

217°C

Temperature (°C)

200

Initial 1 Month 40°C Initial 1 Month 40°C

150

100

50

0

0 1 2 3 4 5 6

Time (min)

Fresh PCB

Pre-reflowed PCB

48 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Contents

1. Performance Summary

2. Introduction: Properties, Features & Benefits

3. Operating Parameters

• Printing: Process Window

• Printing: Continuous and Abandon Time Testing

• Slump Testing

• Tack-Life Force

• Reflow Process Window

• Reflow Performance Testing

• Voiding Data

4. Reliability and Specification Testing

5. Operating Parameters: Storage

• Printing & Reflow Performance

6. Product Summary

49 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

GC 10: Performance Summary

Flux

• Halogen-free flux: passes IC with pretreatment IPC-TM-650

2.3.34/EN14582

• Halogen-free flux classification: ANSI/J-STD-004 Rev. B for

a type ROL0 classification

Paste

• Suitable for fine pitch, high speed printing up to 125mm/s (5”/s)

• Optimized for long hot soak reflow profiles

• Excellent fine pitch coalescence in air & nitrogen atmosphere

• Excellent humidity resistance

• Excellent solderability on challenging surface finishes,

including CuNiZn

• Colorless residues for easy post-reflow inspection

• Long 12month shelf-life when stored below 26.5°C

50 Februar 23, 2015 Engineering Manual GC 10 Solder Paste

Thank you! Global Distributor of Henkel LOCTITE

(800) 888-0698 info@ellsworth.com

You might also like

- Superior Performance Through Innovative Technology - VEGA IndustriesDocument72 pagesSuperior Performance Through Innovative Technology - VEGA IndustriesNael50% (2)

- PCBD 1211 PDFDocument99 pagesPCBD 1211 PDFVICTOR MARCOSNo ratings yet

- Fun Python For KidsDocument42 pagesFun Python For KidsArun RaoNo ratings yet

- API 682 3rd For TrainingDocument46 pagesAPI 682 3rd For TrainingSyed Ghazali MashhadiNo ratings yet

- IOT Based Home AutomationDocument23 pagesIOT Based Home AutomationAkash Surve100% (2)

- Ppt-Sugarcane Bagasse AshDocument27 pagesPpt-Sugarcane Bagasse AshHegdeVenugopalNo ratings yet

- TCDPDocument88 pagesTCDPPrakash KumarNo ratings yet

- Laboratory Evaluation of Modified Bitumen Using Superpave Methodology Under Indian ConditionsDocument35 pagesLaboratory Evaluation of Modified Bitumen Using Superpave Methodology Under Indian ConditionsMd.imthiyazNo ratings yet

- VEGA - Indonesia PresentationDocument62 pagesVEGA - Indonesia PresentationSteve WanNo ratings yet

- Ebook - Proteus LibraryDocument67 pagesEbook - Proteus LibraryAkhmad GuiNo ratings yet

- FAQ - How To Auto Approve Specific Override Raised Via IRIS APIDocument3 pagesFAQ - How To Auto Approve Specific Override Raised Via IRIS APIMrCHANTHANo ratings yet

- Engineering Manual LOCTITE GC 10 T3 Solder Paste: Suitable For Use With: Standard SAC AlloysDocument51 pagesEngineering Manual LOCTITE GC 10 T3 Solder Paste: Suitable For Use With: Standard SAC AlloysVICTOR MARCOSNo ratings yet

- 3048421Document2 pages3048421Philippe VelhaNo ratings yet

- NC257 SN100C: Lead-Free Solder Paste FeaturesDocument3 pagesNC257 SN100C: Lead-Free Solder Paste Featureshuynh thi y viNo ratings yet

- 3289310Document2 pages3289310Philippe VelhaNo ratings yet

- Engineering Manual HF212 v13Document28 pagesEngineering Manual HF212 v13Fernando MaturanoNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 Hshector gomezNo ratings yet

- Ivan Wan ResinDocument3 pagesIvan Wan ResinmuhannadNo ratings yet

- EagleBurgmann - Teflon Bellows Seal Y29 - ENDocument3 pagesEagleBurgmann - Teflon Bellows Seal Y29 - ENOmar SunasaraNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- Material Data Sheet NC 259 Sn100c Solder Paste Rev 1Document3 pagesMaterial Data Sheet NC 259 Sn100c Solder Paste Rev 1vkmsNo ratings yet

- H010995 WellheadDesanderDocument2 pagesH010995 WellheadDesanderslbclqrkNo ratings yet

- Loctite HF 212Document3 pagesLoctite HF 212Mahir AlsadiNo ratings yet

- Senju OZSeries - 63 221CM ZDocument1 pageSenju OZSeries - 63 221CM ZAlexsander CamargoNo ratings yet

- Essentials For Durable ConcreteDocument40 pagesEssentials For Durable ConcretekarthiksampNo ratings yet

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- ZL-15B, ZL-19, ZL-60C, ZL-60D, ZL-67B, ZL-56: Water-Washable Fluorescent PenetrantsDocument4 pagesZL-15B, ZL-19, ZL-60C, ZL-60D, ZL-67B, ZL-56: Water-Washable Fluorescent PenetrantsChoice OrganoNo ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- Eutectic 19400: Atomized Martensitic Stainless Steel Alloy PowderDocument2 pagesEutectic 19400: Atomized Martensitic Stainless Steel Alloy PowderYeison Piedrahita PérezNo ratings yet

- IC3MT RibeiroDocument7 pagesIC3MT RibeiroSecond Home CateringNo ratings yet

- HPHTGaps-FinalReport 2006Document16 pagesHPHTGaps-FinalReport 2006Waleed Barakat MariaNo ratings yet

- GL XX Mobiltemp SHC SeriesDocument3 pagesGL XX Mobiltemp SHC Seriestatoddo2017No ratings yet

- Scotch-W Scotch-Weld ProductDocument24 pagesScotch-W Scotch-Weld ProductAnca AnghelNo ratings yet

- Metal Cored Wires BÖHLER HL 46 MC BÖHLER HL 51-FD (EN)Document4 pagesMetal Cored Wires BÖHLER HL 46 MC BÖHLER HL 51-FD (EN)lazaroccsNo ratings yet

- Melwa (Western Provice) 2018-03-22Document89 pagesMelwa (Western Provice) 2018-03-22Lakshan FonsekaNo ratings yet

- Gear Compound Plus Iso - 68 - enDocument1 pageGear Compound Plus Iso - 68 - enSedin MurtićNo ratings yet

- Gear Compound Plus Iso - 68 - enDocument1 pageGear Compound Plus Iso - 68 - enSedin MurtićNo ratings yet

- Polylon HP PDSDocument4 pagesPolylon HP PDSJose MachadoNo ratings yet

- Solder Paste Specification: No-Clean Xjs-638Document6 pagesSolder Paste Specification: No-Clean Xjs-638Guilherme Dos Santos MoreiraNo ratings yet

- TDS Castrol Perfecto XPG - Power VersionDocument2 pagesTDS Castrol Perfecto XPG - Power VersionTeguh SNo ratings yet

- 4622 Product InfoDocument4 pages4622 Product InfoVendy KurniawanNo ratings yet

- SMD291AX50T3Document2 pagesSMD291AX50T3Jonatan SmithNo ratings yet

- High Workability, High Durability Concrete in The Middle East - A Case StudyDocument31 pagesHigh Workability, High Durability Concrete in The Middle East - A Case StudySanko KosanNo ratings yet

- Drosera MsDocument1 pageDrosera MsCinta IndonesiaNo ratings yet

- Carter XepDocument2 pagesCarter XepSami KahtaniNo ratings yet

- Solder PasteDocument2 pagesSolder PasteEdgar DauzonNo ratings yet

- IOCL Steel Conference 070618Document31 pagesIOCL Steel Conference 070618prasad24488No ratings yet

- EagleBurgmann LY9DZTT ENDocument3 pagesEagleBurgmann LY9DZTT ENimtiyazNo ratings yet

- Renolin CLP - enDocument7 pagesRenolin CLP - enDANE80No ratings yet

- 01 - Snyder JT ICPA DNV2019 PDFDocument87 pages01 - Snyder JT ICPA DNV2019 PDFMarløn SánchezNo ratings yet

- Product Data Sheet: Optimol OptipitDocument2 pagesProduct Data Sheet: Optimol OptipitFBNo ratings yet

- 4622 Monolec® Multiplex Lubricant - TDSDocument4 pages4622 Monolec® Multiplex Lubricant - TDSEngineering MP CikupaNo ratings yet

- Ucmp Unit Iv Part ADocument6 pagesUcmp Unit Iv Part Arx135rakeshNo ratings yet

- SP Eng NLGI 1,2,3 2012 OctDocument3 pagesSP Eng NLGI 1,2,3 2012 OctundraazolbayarNo ratings yet

- Gengear Series SPL-A Up To 320Document3 pagesGengear Series SPL-A Up To 320Hakim AmmorNo ratings yet

- Abrasive Jet MachiningDocument15 pagesAbrasive Jet MachiningWaleed KhanNo ratings yet

- Amercoat® 240 / Sigmacover™ 240: Product Data SheetDocument7 pagesAmercoat® 240 / Sigmacover™ 240: Product Data SheetAmila Udara GunasingheNo ratings yet

- CARBOTECH - Technical PresentationDocument37 pagesCARBOTECH - Technical PresentationpiojeziorNo ratings yet

- Pintura Epoxica Sherwin Willians Hoja SeguridadDocument4 pagesPintura Epoxica Sherwin Willians Hoja Seguridad1No ratings yet

- Duratomic TP Brochure GT15-214 PDFDocument24 pagesDuratomic TP Brochure GT15-214 PDFDeysi CardenasNo ratings yet

- Acrolon 218 FTDocument4 pagesAcrolon 218 FTEdwin VSNo ratings yet

- Alpha CVP-390 CNP TB 1068-18 English 20171208Document7 pagesAlpha CVP-390 CNP TB 1068-18 English 20171208Sérgio TavaresNo ratings yet

- Technical Sheet Blue Connect Go-179242Document2 pagesTechnical Sheet Blue Connect Go-179242VICTOR MARCOSNo ratings yet

- SW-250 Rev.1.0Document1 pageSW-250 Rev.1.0VICTOR MARCOSNo ratings yet

- Top Coat Blue Pool Iso-Npg enDocument4 pagesTop Coat Blue Pool Iso-Npg enVICTOR MARCOSNo ratings yet

- LT 8250 Brochure Game Changers Solder Pastes PDFDocument24 pagesLT 8250 Brochure Game Changers Solder Pastes PDFVICTOR MARCOSNo ratings yet

- Design Rules Basic CBT en PDFDocument8 pagesDesign Rules Basic CBT en PDFVICTOR MARCOSNo ratings yet

- Abm3B: Parameters Standard SpecificationsDocument3 pagesAbm3B: Parameters Standard SpecificationsVICTOR MARCOSNo ratings yet

- A800 DataSheetDocument2 pagesA800 DataSheetVICTOR MARCOSNo ratings yet

- NIBP Simulator White Paper II Oct07Document9 pagesNIBP Simulator White Paper II Oct07VICTOR MARCOSNo ratings yet

- Non-Isolated DC/DC Converter (POL) TSR 1 Series, 1 A: ModelsDocument3 pagesNon-Isolated DC/DC Converter (POL) TSR 1 Series, 1 A: ModelsVICTOR MARCOSNo ratings yet

- Lfemp BookDocument354 pagesLfemp BookVICTOR MARCOSNo ratings yet

- Clinical UseDocument2 pagesClinical UseVICTOR MARCOSNo ratings yet

- Healthcare Analog Front End (AFE) Reference Platform: Fact SheetDocument2 pagesHealthcare Analog Front End (AFE) Reference Platform: Fact SheetVICTOR MARCOSNo ratings yet

- DC 1621 AfDocument6 pagesDC 1621 AfVICTOR MARCOSNo ratings yet

- Xavier LeroyDocument63 pagesXavier LeroyVICTOR MARCOSNo ratings yet

- bq24650 PDFDocument38 pagesbq24650 PDFVICTOR MARCOSNo ratings yet

- GS R400 FamilyDocument5 pagesGS R400 FamilyVICTOR MARCOSNo ratings yet

- 32PB Μmodule Web Reduced SizeDocument32 pages32PB Μmodule Web Reduced SizeVICTOR MARCOSNo ratings yet

- Mounting of Surface Mount Components: Application ReportDocument18 pagesMounting of Surface Mount Components: Application ReportVICTOR MARCOSNo ratings yet

- Volume BoostersDocument12 pagesVolume BoostersMaurício SousaNo ratings yet

- Chemical Feed Tank Levels - Birkenberger - 122908Document2 pagesChemical Feed Tank Levels - Birkenberger - 122908Brian McMorrisNo ratings yet

- IECU-U0100, Data Link: Integrated Electronic Control UnitDocument7 pagesIECU-U0100, Data Link: Integrated Electronic Control UnitBùi Xuân ĐứcNo ratings yet

- Rabindranath Though On ScienceDocument9 pagesRabindranath Though On ScienceMatiyar Rahaman KhanNo ratings yet

- Jose Raul Capablanca With White (1901-1941)Document249 pagesJose Raul Capablanca With White (1901-1941)Odysseas 57No ratings yet

- Antenna:: How Antennas Works????Document11 pagesAntenna:: How Antennas Works????Rajat NegiNo ratings yet

- 5.the Gamma Function (Factorial Function) : 5.1 Definition, Simple PropertiesDocument16 pages5.the Gamma Function (Factorial Function) : 5.1 Definition, Simple PropertiesOliver58No ratings yet

- SCINT 9181 4f LowendDocument152 pagesSCINT 9181 4f LowendImam BuchairiNo ratings yet

- Question Text: Ammeter Is Connected Parallel in A Device. Select One: True FalseDocument15 pagesQuestion Text: Ammeter Is Connected Parallel in A Device. Select One: True FalseMelanie BuñalesNo ratings yet

- Mock Test-4Document19 pagesMock Test-4Bhavish ParkalaNo ratings yet

- Department of Computer Applications Syllabus For B.C.A. Under Choice Based Credit System (CBCS) For Candidates Admitted From 2019 - 2020Document39 pagesDepartment of Computer Applications Syllabus For B.C.A. Under Choice Based Credit System (CBCS) For Candidates Admitted From 2019 - 2020Saran VNo ratings yet

- LSM6DS3HTR Sensor LightsaberDocument108 pagesLSM6DS3HTR Sensor Lightsabersebastiao regos freitasNo ratings yet

- Ilyte: Automated Electrolyte AnalyzersDocument6 pagesIlyte: Automated Electrolyte AnalyzersAlejandro CabreraNo ratings yet

- Unit 6 Point Estimation: StructureDocument18 pagesUnit 6 Point Estimation: StructurePrabhakar KushwahaNo ratings yet

- A 15 Resolution 601Document13 pagesA 15 Resolution 601mfazioliNo ratings yet

- XOOPS: Module Structure FunctionDocument7 pagesXOOPS: Module Structure Functionxoops100% (3)

- FH18 35(21)英文说明书Document16 pagesFH18 35(21)英文说明书ADM MTCNo ratings yet

- Adding Sub Screen in CS01: RequirementDocument10 pagesAdding Sub Screen in CS01: Requirementshansparrowmusic officialNo ratings yet

- Answers To Selected Exercises: Ix) Ix)Document34 pagesAnswers To Selected Exercises: Ix) Ix)s_adhyaNo ratings yet

- 2copy SHS Life Science WorksheetsDocument87 pages2copy SHS Life Science WorksheetsJohnmar FortesNo ratings yet

- Chapter 2 - SolutionsDocument10 pagesChapter 2 - SolutionsShubh MishraNo ratings yet

- HWY - AIR Brochure (Web)Document16 pagesHWY - AIR Brochure (Web)MudduKrishna shettyNo ratings yet

- TS300P-1800 Installation Guide D501109 Ver.1.50Document60 pagesTS300P-1800 Installation Guide D501109 Ver.1.50Alexander GonzálezNo ratings yet

- Scale Tm-Xa Series PDFDocument153 pagesScale Tm-Xa Series PDFArmen ManasyanNo ratings yet

- Tally ERP 9 Short Cuts 2Document3 pagesTally ERP 9 Short Cuts 2SAN1258No ratings yet

- 02 Asae 101892Document1 page02 Asae 101892raviteja036No ratings yet