Professional Documents

Culture Documents

Brazing Procedure

Uploaded by

Noel Delos Santos0 ratings0% found this document useful (0 votes)

104 views2 pagesOriginal Title

BRAZING PROCEDURE

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

104 views2 pagesBrazing Procedure

Uploaded by

Noel Delos SantosCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

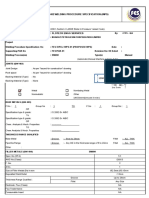

BRAZING PROCEDURE

SPECIFICATION (BPS)

Procedure Qualification Record (PQR): None Welding Process: Manual torch brazing (TB)

Scope: For welder qualification only Prior Qualification Requirements: None

BASE MATERIAL (QB-402) FILLER METALS (QB-403)

Test coupon type: Tube to Coupling Filler Metal F No.: F-103

Material Spec, type or Grade: Copper K K AWS specification: A5.8

SAMS (01-547-119) AWS Classification: Bag-3

Diameter of tube: 28.6mm" OD SAMS Stock Number: 20-724-454 (Bag-3)

Thickness of tube: 1.3 mmt

To Material spec. type or grade: Copper Product Form: Rod

SAMS (03-620-472) Size: 2 mm (Bag-3)

POST WELD HEAT TREATMENT (QB-404) BRAZING PROCESS (QB-405)

Temperature: 718°C - 816°C H-No: 101

Time: Other:

Other:

BRAZING FLUX (QB-406) FLOW (QB-407)

Flux Type: Granular Position: Vertical up Flow “C” Horizontal Flow

Flux Trade Name: "HARRIS 0" “D”

SAMS Stock Number: Position of Groove: 6G

JOINT (QB-408) TECHNIQUE

Type: SOCKET String or weave: Stringer or Weave

Joint Clearance: 0.3 – 0.13mm Oscillation:

Lap Length: Half Length of Socket (24mm) Multiple or Single pass per side: Multiple

Others: N/A Single or multiple electrode: Single

Prebraze Cleaning: Abrasive or mechanical

means

Filler Application: Face feed

Post Braze Heat Treatment: None

Post Braze Cleaning: None

Other:

BRAZING PROCEDURE

SPECIFICATION (BPS)

Joint Design: Socket

Joint Clearance: 0.3 – 0.13mm

WELDER PROCESS FILLER CURRENT VOLTAGE TRAVEL

LAYER METAL SPEED

Class Dia Polarity Amps.

(mm)

Root `Manual Torch F-103 N/A N/A N/A N/A

Brazing (TB)

You might also like

- Pocket Welding Guide PDFDocument186 pagesPocket Welding Guide PDFJairo Contreras100% (2)

- Asme BPVC - Ssc.iv - Ii.v.ix - Xiii-2023Document42 pagesAsme BPVC - Ssc.iv - Ii.v.ix - Xiii-2023mmendozagNo ratings yet

- 23 Application and Control of Pre-HeatDocument18 pages23 Application and Control of Pre-HeatAdhanom G.No ratings yet

- QC - Consumables Colour Coding and IdentificationDocument3 pagesQC - Consumables Colour Coding and IdentificationfizanlaminNo ratings yet

- QW - 482 Welding Procedure Specification (WPS)Document5 pagesQW - 482 Welding Procedure Specification (WPS)Arijit GhoshNo ratings yet

- Ko-111-01 Repair Welding+Manual e (20201207)Document156 pagesKo-111-01 Repair Welding+Manual e (20201207)Prudz100% (1)

- Metallography LabDocument17 pagesMetallography LabKamal Manchanda100% (2)

- Position of Welds ComparisonDocument3 pagesPosition of Welds ComparisonYuvaraj SathishNo ratings yet

- WPS and PQR For SAW (Butt Welding)Document8 pagesWPS and PQR For SAW (Butt Welding)魏利强No ratings yet

- Sheet Metal and TinsmithryDocument22 pagesSheet Metal and TinsmithryVictor EvangelioNo ratings yet

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviNo ratings yet

- DNV RU SHIP Pt2Ch4Document144 pagesDNV RU SHIP Pt2Ch4Rahul KamillaNo ratings yet

- WPS - 012Document11 pagesWPS - 012MAT-LIONNo ratings yet

- Astm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersDocument6 pagesAstm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenershoannhuNo ratings yet

- 3 Jim MansfieldDocument22 pages3 Jim MansfieldjoebriffaNo ratings yet

- API Welding ProcedureDocument2 pagesAPI Welding ProcedureSamarakoon BandaNo ratings yet

- Demolition PlanDocument4 pagesDemolition PlanNoel Delos Santos100% (1)

- Procurement Services: Industry & Facilities DivisionDocument10 pagesProcurement Services: Industry & Facilities Divisionkbpatel123No ratings yet

- Hitachi - High Speed Tools SteelDocument11 pagesHitachi - High Speed Tools SteelWahyu Ibnu Nur HudaNo ratings yet

- Course Module 4Document6 pagesCourse Module 4Makise AghataNo ratings yet

- Welding Defects and RemediesDocument20 pagesWelding Defects and RemediesChristine SeletariaNo ratings yet

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- PQR For Gmaw Saw 15.88Document3 pagesPQR For Gmaw Saw 15.88Kumawat PrakashNo ratings yet

- WPS - 007Document11 pagesWPS - 007MAT-LIONNo ratings yet

- Material Dissimilar JointsDocument7 pagesMaterial Dissimilar JointsPemburu JablayNo ratings yet

- Brief of Variables: Smaw Gtaw Gmaw SawDocument3 pagesBrief of Variables: Smaw Gtaw Gmaw SawAdilMunirNo ratings yet

- How To Choose Electrodes For Joining High-Strength SteelsDocument3 pagesHow To Choose Electrodes For Joining High-Strength SteelsmakcodetechNo ratings yet

- British Standard 5289: 1976: Visual InspectionDocument10 pagesBritish Standard 5289: 1976: Visual InspectionMarcelo Rodriguez FujimotoNo ratings yet

- InteractiveFormQB 482Document1 pageInteractiveFormQB 482Afriadi Budi PrasetyoNo ratings yet

- Alstom IRDocument4 pagesAlstom IRkasi reddyNo ratings yet

- Standard 3834 Si Audit AtasatDocument107 pagesStandard 3834 Si Audit AtasatIon PlesaNo ratings yet

- Qw-483 (Back) : Specimen No. Width Thickness Area Ultimate Total Load Ultimate Unit Stress, (Psi or Mpa)Document8 pagesQw-483 (Back) : Specimen No. Width Thickness Area Ultimate Total Load Ultimate Unit Stress, (Psi or Mpa)Aries MarteNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document8 pagesQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad HannanNo ratings yet

- Ball MillDocument4 pagesBall Millmohan804No ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- A Review of Postweld Heat Treatment Code ExemptionDocument16 pagesA Review of Postweld Heat Treatment Code ExemptionrajaramcNo ratings yet

- Welding Procedure Specification (WPS) : JointsDocument2 pagesWelding Procedure Specification (WPS) : JointsNielNo ratings yet

- WPS - 006Document13 pagesWPS - 006MAT-LIONNo ratings yet

- WPS - 008Document11 pagesWPS - 008MAT-LIONNo ratings yet

- Mce Gulf Contracting Co. Welder Performance QualificationDocument2 pagesMce Gulf Contracting Co. Welder Performance QualificationhamidjoyiaNo ratings yet

- Tabla de Referencia de Materiales: Material Reference ChartDocument2 pagesTabla de Referencia de Materiales: Material Reference Chartsateesh chandNo ratings yet

- Saic W 2011Document3 pagesSaic W 2011munnaNo ratings yet

- BohlerThyssen PDFDocument386 pagesBohlerThyssen PDFElMacheteDelHuesoNo ratings yet

- Manual Bios Intel Dp35dpDocument32 pagesManual Bios Intel Dp35dpMarcelo CheloNo ratings yet

- Material Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocument3 pagesMaterial Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyNo ratings yet

- Introduction To WeldingDocument12 pagesIntroduction To WeldingveljasheNo ratings yet

- dpvc-09 Petrobras PDFDocument47 pagesdpvc-09 Petrobras PDFBilly TanNo ratings yet

- Chem-Wps - PQR - WPQ-003 CS-CS 08-08 Gtaw-SmawDocument5 pagesChem-Wps - PQR - WPQ-003 CS-CS 08-08 Gtaw-Smawvijay padaleNo ratings yet

- WPS PQR FormulirDocument2 pagesWPS PQR FormulirAZaiNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- Valve - Material EquivalentDocument3 pagesValve - Material Equivalentrenji_dannyNo ratings yet

- Astm A514 GR SDocument9 pagesAstm A514 GR SMario GaytanNo ratings yet

- Nickel Alloy Based Filler MetalDocument1 pageNickel Alloy Based Filler MetaljoehodohNo ratings yet

- Dissimilar Metal Weldingv2 HERBST PDFDocument23 pagesDissimilar Metal Weldingv2 HERBST PDFAnonymous q2HC0zyfa2No ratings yet

- Selection of Filler Metal For WeldingDocument21 pagesSelection of Filler Metal For WeldingRegu vlogsNo ratings yet

- Appendix B3-03 Welding Procedure Specification ENB-MA-WPS-3 Rev. 0 - A4A2E2Document14 pagesAppendix B3-03 Welding Procedure Specification ENB-MA-WPS-3 Rev. 0 - A4A2E2Jobaer ShaonNo ratings yet

- Qualification of Welding Procedures For Steel Constructions According TO EN 1090-2Document8 pagesQualification of Welding Procedures For Steel Constructions According TO EN 1090-2manno200No ratings yet

- Saic L 2004Document18 pagesSaic L 2004ejazNo ratings yet

- Material With Electrode SelectionDocument2 pagesMaterial With Electrode SelectionAhmadiBinAhmadNo ratings yet

- SF188 Rev 1 - Welder Qualification Test CertificateDocument1 pageSF188 Rev 1 - Welder Qualification Test CertificateMike BoyesNo ratings yet

- Parametros de SoldaduraDocument17 pagesParametros de SoldaduraBenjamin Alvarez MedinaNo ratings yet

- Eng052 20erw 000 Qa WQS 0015 000 - 01Document6 pagesEng052 20erw 000 Qa WQS 0015 000 - 01Mohammed ShehinNo ratings yet

- EN 15614-1 Welding Procedure Qualification Record List: F - 7.5.1 - TI - (R00) - 02Document6 pagesEN 15614-1 Welding Procedure Qualification Record List: F - 7.5.1 - TI - (R00) - 02BasarNo ratings yet

- Asme Y14.5m GD&T (Chs-En)Document82 pagesAsme Y14.5m GD&T (Chs-En)VQuadrosNo ratings yet

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 pagesSample Wps Carbon Steel GTAW SMAW PDFirwanNo ratings yet

- Oteluri Inoxidabile Si Refractare Tabel de Identificare Materiale Dupa WerkstoffDocument30 pagesOteluri Inoxidabile Si Refractare Tabel de Identificare Materiale Dupa WerkstoffStefanArtemonMocanuNo ratings yet

- PQR Babbit SCDocument34 pagesPQR Babbit SCagustinusNo ratings yet

- CTHB Cont Copy SHTDocument2 pagesCTHB Cont Copy SHTNoel Delos SantosNo ratings yet

- Asphalt Installn ProcedureDocument5 pagesAsphalt Installn ProcedureNoel Delos SantosNo ratings yet

- 01 OHS-SD-01 PlanningDocument6 pages01 OHS-SD-01 PlanningNoel Delos SantosNo ratings yet

- A Brief Introduction About The PlaceDocument2 pagesA Brief Introduction About The PlaceMohd FahmiNo ratings yet

- Assignment 1 ENG 173 METAL FORMING First 2023 2024Document2 pagesAssignment 1 ENG 173 METAL FORMING First 2023 2024toursena44No ratings yet

- AMP MicroprojectDocument7 pagesAMP MicroprojectNight fade100% (1)

- 34 CR Mo 4Document2 pages34 CR Mo 4ceca nikolicNo ratings yet

- Hardox 450: General Product DescriptionDocument2 pagesHardox 450: General Product DescriptionJaime PérezNo ratings yet

- Jadwal Pelatihan HousekeepingDocument1 pageJadwal Pelatihan Housekeepingasep heriyadi susantoNo ratings yet

- Steel MillDocument6 pagesSteel MillRenato Gigliotti MPhNo ratings yet

- Material For Lanai RoofDocument5 pagesMaterial For Lanai RoofElsa Rafal - LabragueNo ratings yet

- Maintenance Checklist (EML2322L)Document8 pagesMaintenance Checklist (EML2322L)waqas khanNo ratings yet

- RT - Casting DefectsDocument5 pagesRT - Casting DefectsShanawas Abdul RazakNo ratings yet

- "Designing & Teaching Learning Goals & Objectives" SummaryDocument10 pages"Designing & Teaching Learning Goals & Objectives" SummaryAltamira International School100% (1)

- Final Presentation PS (IOCL) PDFDocument13 pagesFinal Presentation PS (IOCL) PDFAmol Champ AgarwalNo ratings yet

- MOOG Repair of Leaks Completion ReportDocument17 pagesMOOG Repair of Leaks Completion ReportJohn Rheynor MayoNo ratings yet

- RC2-30-GENE-JSD-00-000-1001-3 CoatingDocument60 pagesRC2-30-GENE-JSD-00-000-1001-3 Coatingaslam.ambNo ratings yet

- Most Common Types of Welding Defects: Incomplete PenetrationDocument4 pagesMost Common Types of Welding Defects: Incomplete PenetrationMaddyNo ratings yet

- ME18402 - MACHINE Tools and Machining Process Assignment - 2Document6 pagesME18402 - MACHINE Tools and Machining Process Assignment - 2gopi sankarNo ratings yet

- THI Products CatalogueDocument12 pagesTHI Products CatalogueAngelus129No ratings yet

- Processing Metals Questions1Document32 pagesProcessing Metals Questions1Mudiwa GashupareNo ratings yet

- EMG 4102 Lecture 2Document5 pagesEMG 4102 Lecture 2MaxwellNo ratings yet

- Fabricating and Machining UHMWPE PDFDocument2 pagesFabricating and Machining UHMWPE PDFganeshNo ratings yet

- Microsoft Word - Introduction To Foundry - 1 - 1Document12 pagesMicrosoft Word - Introduction To Foundry - 1 - 1Prashant ParshivnikarNo ratings yet

- Training Activity Matrix SMAW NC I-COREDocument52 pagesTraining Activity Matrix SMAW NC I-COREEugenio Mates Jr.No ratings yet

- POM C (Blue) : Rev. Reviser Date DescriptionDocument1 pagePOM C (Blue) : Rev. Reviser Date DescriptionMaria DragoiNo ratings yet