Professional Documents

Culture Documents

BBB 03010plustf

Uploaded by

ahmad batrOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BBB 03010plustf

Uploaded by

ahmad batrCopyright:

Available Formats

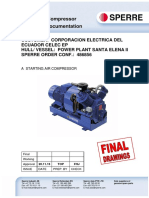

Specification Sheets

Model: PLUS 3010 TF Code: BBB-03010PLUSTF Cat. Ref: BE01

Compressor Package Electric Motor

Model: Plus 3010 TF Type: TEFC

Make: Fini Power (kW): 22

Country of origin: Italy Power (HP): 30

Free Air Delivery (lit/min / cfm @ 1000kPa): 2890 / 102 Voltage / Hz / Ph: 400 / 50 / 3

Rated Working Pressure (kPa): 1000 Full load amps: 43

Load / Unload (kPa) Adjustable Motor Protection: IP55

Continuous /

Operation: Motor Insulation class: F

Stop Start

Noise level (PNEUROP PN8NTC2.2) (dB(A): 72 Max. Start-up per hour (n0): 10

Air cooled Aftercooler: Included Motor Speed: 2 - Pole

Final air discharge temp above ambient (0C): 11 Breaker Size: 80 Amps Curve D

Max. Ambient temperature (0C): 50 Cable Size (under 15m) (mm2): 10

Min. Ambient temperature (0C): 5

Automatic Star Delta Starter: Included

Max. Oil content in the air at discharge (mg/m3): 4 Key Dimensions (mm)

Drive: Poly-vee

Air End model: FS50 TF A 750

Number of stages: 1 B 656

Total Heat removed (kJ/h): 75240 C 1220

Fan flow rate (m3/h): 3369 D 1046

Discharge air temp. shutdown (0C): 110 E 1310

Discharge air temp. warning (0C): 105 F 165

Qty oil fill (lt): 7

Qty oil for topping-up (lt): 0.5

Air outlet connection (bsp): 3/4" Key Parts - Description Code

Air Filter: CTB-017026000

Dimensions Oil Filter: CTB-048033000B

Oil 5lt: KBA-ROTENERGY-005L

Dimensions (L.W.H. mm) (No Packing): 1220 X 750 X 1310

Mass (kg) (No Packing): 386

Approx Dimensions (L.W.H. mm) (Packaged): 1240 X 770 X 1330

Approx Mass (kg) (Packaged): 401

POSITIONING THE COMPRESSOR

The room chosen for the installation of the compressor should meet the following

requirements and comply with what is specified in the current safety and accident prevention

regulations:

· low percentage of fine dust,

· proper room ventilation and size so to keep room temperature under 50 0C.

In the event of inadequate hot air discharge, fit one or more exhaust fans. Fit the

exhaust fans as high as possible.

Exhaust flow rate "2000 cu.m./h" part no. 020041000

Exhaust flow rate "4000 cu.m./h" part no. 020042000

A drainage pit or cab shall be used to collect tank condensate.

Dimensions are just approximate. Try nevertheless to respect them as much as possible.

OPERATION

WORKING CYCLE

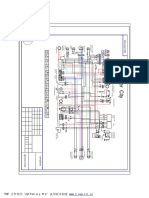

· At first start-up, the motor starts in the "star" configuration.

In this phase the compressor starter slowly, the solenoid valve

(1) is open and the suction regulator (2) is closed.

· The compressor remains in this condition for about 5-7

seconds.

· This time over, motor is "delta" powered. The solenoid

valve (1) is energized; it closes and enables suction regulator

(2) opening, which sucks in air through filter (3).

· At this stage, the compressor runs at full speed and begins

to compress the air in the tank (6).

· The compressed air cannot come out from the minimum

pressure valve, which is set at 3-4 bar

· The compressed air compresses the oil in the tank (6) and

forces it to flow towards the tube (7) through filter (9) and tube

(8) through filter (9) and tube (8).

· If oil temperature is over 71 0C, the thermostat closes the

tube line (8) so that the oil reaches the radiator (11) through the

tube (10).

· Cooled oil returns to the compressor through tubes (12) and (8) via filter (9).

· The oil reaches the compressor (4) mixing with the intake air and creating an air/oil mixture which ensures the seal and the lubrication of the

moving parts of the compressor.

· The air/oil mixture returns to the tank (6) where the air is pre-separated through spinning and is finally separated from the oil by the oil

separator tank (13).

· As a result, the tank (6) will deliver only air to radiator (11) through tube (15). Air is then conveyed to mains thorugh a cut-off cock (16).

START-UP

FIRST START-UP

Before starting the machine up for the first time, make sure that:

· the mains voltage is the same as the voltage on the CE plate;

· the electric connections have been made using cables of proper cross-section;

· the (wall) main power switch has suitable fuses;

· the oil level is over the minimum level - top up with the same type of oil if necessary;

· the air outlet cock is completely open.

CONNECT THE TANK WITH A HOSE

· Only specialised technicians can start the compressor (on-site testing) for the first time.

If the machine does not start and the display shows the alarm message "Wrong direction of rotation", proceed as follows:

break power supply through the wall switch;

open the electric box door and reverse the two phases in the terminal board;

close the door, power on and start the machine.

Display status during compressor operation

Display status at start (shown for 5 seconds)

software Easy Tronic II oil temp. 100 0C 9.5 Bar Pressure

release V.0.0.0 GG/MM/AA date Status = stand-by

compressor

status

Press the Δ key to see hours and minutes operation; the information is displayed for 20 seconds.

You might also like

- Data Sheet 1013ec PumpDocument6 pagesData Sheet 1013ec PumpJulio Alvarado MoralesNo ratings yet

- S12A2-Y1PTA-1 Mitsubishi Diesel Generator EngineDocument3 pagesS12A2-Y1PTA-1 Mitsubishi Diesel Generator Enginejabed habib100% (1)

- 500 MW Turbine Design DataDocument19 pages500 MW Turbine Design Datasanjay kumar100% (1)

- Mitsubishi Modelo S12h-Y1pta-3 - Mny1000 PDFDocument3 pagesMitsubishi Modelo S12h-Y1pta-3 - Mny1000 PDFSalvador Millán EstradaNo ratings yet

- TMC 54-8 EWNA - Water Cooled - F011262Document135 pagesTMC 54-8 EWNA - Water Cooled - F011262Zeevenhooven EquipmentNo ratings yet

- Cpi Oliver City EldiagramDocument1 pageCpi Oliver City EldiagramHenry BraunNo ratings yet

- Eng 99C6778 PDFDocument551 pagesEng 99C6778 PDFFroylan Ochoa93% (14)

- Sperre PDFDocument28 pagesSperre PDFluis100% (2)

- Data Sheet - CompressorDocument2 pagesData Sheet - CompressorPruthviraj JuniNo ratings yet

- Daikin JT160L P8Y1 Teknik DokumanDocument18 pagesDaikin JT160L P8Y1 Teknik DokumanShuanglai LiuNo ratings yet

- Technical Data Sheet EG75-10 BarDocument1 pageTechnical Data Sheet EG75-10 Barabdur rohmanNo ratings yet

- General Features: Diesel Generating Set Powered byDocument4 pagesGeneral Features: Diesel Generating Set Powered bySynchro Power MyanmarNo ratings yet

- Rolls Royce (Mtu) 12V2000DS1000 800kVA Prime 3BDocument5 pagesRolls Royce (Mtu) 12V2000DS1000 800kVA Prime 3Bخطاب الشامي0% (1)

- File 54df24301f3e7Document1 pageFile 54df24301f3e7chukyNo ratings yet

- Carrier - 50eh 415v R410a Mwc10 - Shell AdasevacDocument12 pagesCarrier - 50eh 415v R410a Mwc10 - Shell Adasevacveljko2008No ratings yet

- XG110 160kWWDocument29 pagesXG110 160kWWAgeng A. PooNo ratings yet

- Diesel Generator Set Optimized for Low Fuel Consumption and NOx EmissionsDocument5 pagesDiesel Generator Set Optimized for Low Fuel Consumption and NOx Emissionsshady rashedNo ratings yet

- 100 EDRS71M4 FG 2GD B KCC TF AL ProductData en DEDocument2 pages100 EDRS71M4 FG 2GD B KCC TF AL ProductData en DEMahesh Daxini ThakkerNo ratings yet

- FX-FC-Y /SL-T+ /3202 /EC: Technical Selection - en 14511 - en 14825Document4 pagesFX-FC-Y /SL-T+ /3202 /EC: Technical Selection - en 14511 - en 14825Milos HrvacaninNo ratings yet

- R134a compressor specificationDocument4 pagesR134a compressor specificationBenyoucef SmainiNo ratings yet

- Specifications: DaikinDocument17 pagesSpecifications: DaikinyoyokNo ratings yet

- Kata-0150-Tac 800Document1 pageKata-0150-Tac 800Guillermo Forero MoncayoNo ratings yet

- 1000 KVA-datasheetDocument4 pages1000 KVA-datasheetPriyanathan ThayalanNo ratings yet

- 2010-5 Service lcn246hv Ceiling-Cassette Indoor mfl62129309 20120105132900Document7 pages2010-5 Service lcn246hv Ceiling-Cassette Indoor mfl62129309 20120105132900joko riyantoNo ratings yet

- General Features: Diesel Generating Set Powered byDocument4 pagesGeneral Features: Diesel Generating Set Powered bySynchro Power MyanmarNo ratings yet

- Spesifikasi Atlas Copco ZT 30Document5 pagesSpesifikasi Atlas Copco ZT 30Fithrul MubarokNo ratings yet

- File 54de526820b3cDocument1 pageFile 54de526820b3cAdriano MoysesNo ratings yet

- Tehnicheskie Harakteristiki Kompressora SIAM NN37YCAMTDocument3 pagesTehnicheskie Harakteristiki Kompressora SIAM NN37YCAMTEvandro Jva compressoresNo ratings yet

- CR60K5-PFV: Mechanical PerformanceDocument1 pageCR60K5-PFV: Mechanical PerformanceReinerio AGUDELONo ratings yet

- DS 825 PDFDocument6 pagesDS 825 PDFvuongNo ratings yet

- Sliding Stem Control Valve SpecificationDocument2 pagesSliding Stem Control Valve SpecificationJackNo ratings yet

- General Features: Diesel Generating Set Powered byDocument4 pagesGeneral Features: Diesel Generating Set Powered bySynchro Power MyanmarNo ratings yet

- Technical Data 50 HZ: TCG 2016 V08 C, Bio Gas 55/45%, 500 NoxDocument1 pageTechnical Data 50 HZ: TCG 2016 V08 C, Bio Gas 55/45%, 500 NoxVladimir VoronovNo ratings yet

- Alternator: Engine:: BF6M 1013 FCG2 ECP38-2SNDocument7 pagesAlternator: Engine:: BF6M 1013 FCG2 ECP38-2SNalutttNo ratings yet

- PG Spec 16V2000DS1250 800kVA 3A FC 50HzDocument5 pagesPG Spec 16V2000DS1250 800kVA 3A FC 50HzLucas PereiraNo ratings yet

- JD220M Generator SetDocument4 pagesJD220M Generator SetUzair kazmiNo ratings yet

- Copeland-Cr42k6-Pfv-Recip-Compressor-Technical SpecificationsDocument1 pageCopeland-Cr42k6-Pfv-Recip-Compressor-Technical SpecificationscarlosmochimaNo ratings yet

- BF6M 1013 FCG3 PDFDocument6 pagesBF6M 1013 FCG3 PDFEdwin Alfonso Hernandez MontesNo ratings yet

- S12H-engine - PDF SPECSDocument3 pagesS12H-engine - PDF SPECSMarcos Vinicio StizzioliNo ratings yet

- Working Principle of A TransformerDocument67 pagesWorking Principle of A TransformerkrishnandrkNo ratings yet

- XG110 160kWADocument27 pagesXG110 160kWAAgeng A. PooNo ratings yet

- Qty. Description CR 10-2 A-A-A-E-HQQE: Further Product DetailsDocument7 pagesQty. Description CR 10-2 A-A-A-E-HQQE: Further Product DetailsBrata PatandeanNo ratings yet

- Data Book: Automotive TechnicalDocument1 pageData Book: Automotive Technicallucian07No ratings yet

- General Features: Diesel Generating Set Powered byDocument4 pagesGeneral Features: Diesel Generating Set Powered bySynchro Power MyanmarNo ratings yet

- General Features: Diesel Generating Set Powered byDocument4 pagesGeneral Features: Diesel Generating Set Powered byjipunNo ratings yet

- General Features: Diesel Generating Set Powered byDocument4 pagesGeneral Features: Diesel Generating Set Powered byRashedul IslamNo ratings yet

- 27735677TWoVx_GHsE1PQHs_f4-LxeI86cSummary (1)Document1 page27735677TWoVx_GHsE1PQHs_f4-LxeI86cSummary (1)Marcelo AngelottiNo ratings yet

- Cummins Engine Co - LTD: General Engine Data CPL 1519 CPL 6BT5.9G1 6BT5.9G2Document3 pagesCummins Engine Co - LTD: General Engine Data CPL 1519 CPL 6BT5.9G1 6BT5.9G2mardalan nabisukNo ratings yet

- 05 Fuel SystemDocument124 pages05 Fuel SystemJajat PermanaNo ratings yet

- NT 2178 GKDocument3 pagesNT 2178 GKAlla weerNo ratings yet

- GL50AA1Document4 pagesGL50AA1أبو زينب المهندسNo ratings yet

- Copeland CR22K6E PFV 875 Submittal SheetDocument3 pagesCopeland CR22K6E PFV 875 Submittal SheetDraganNo ratings yet

- Final Documentation Sungdong SY Hull S3109, S3109 Air Compressor SSM 41010956Document23 pagesFinal Documentation Sungdong SY Hull S3109, S3109 Air Compressor SSM 41010956Raúl Oscar LedesmaNo ratings yet

- Compact Rooftop Heat Pump Technical SpecificationsDocument10 pagesCompact Rooftop Heat Pump Technical SpecificationsRonald MonzónNo ratings yet

- S12H PtaDocument4 pagesS12H PtaThanh Trúc Đặng HuỳnhNo ratings yet

- Workshop Manual 1B EnglishDocument218 pagesWorkshop Manual 1B EnglishalabalaNo ratings yet

- Compresor KAKA-0200-TACDocument1 pageCompresor KAKA-0200-TACLuis BermudezNo ratings yet

- Spec en 4K40Z02306P1-06Document23 pagesSpec en 4K40Z02306P1-06Ageng A. PooNo ratings yet

- Copeland Scroll ZF and ZF KVE Compressor Technical DetailsDocument2 pagesCopeland Scroll ZF and ZF KVE Compressor Technical DetailsCrypto LegendNo ratings yet

- Diesel Generating Set BF-C350: Standby Power 50Hz 260KW / 325KVA Prime Power 50Hz 240KW / 300KVADocument5 pagesDiesel Generating Set BF-C350: Standby Power 50Hz 260KW / 325KVA Prime Power 50Hz 240KW / 300KVAkevindelmonte1996No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- CBR500R Owner'S Manual: 32MKPF10 00X32-MKP-F100Document134 pagesCBR500R Owner'S Manual: 32MKPF10 00X32-MKP-F100edwinNo ratings yet

- Hi 8596 - V Rev L PDFDocument12 pagesHi 8596 - V Rev L PDFVarshaNo ratings yet

- 40PFL3705D F7Document85 pages40PFL3705D F7wandag2010No ratings yet

- PFC Strategies in Light of en 61000-3-2Document9 pagesPFC Strategies in Light of en 61000-3-2allex_liuNo ratings yet

- Five Meter Radio TelescopeDocument17 pagesFive Meter Radio TelescopeaishaNo ratings yet

- Oracle® Goldengate: Tutorial For Oracle To OracleDocument19 pagesOracle® Goldengate: Tutorial For Oracle To OracleNainika KedarisettiNo ratings yet

- Glitch Catalogue Final 2019Document36 pagesGlitch Catalogue Final 2019Adrian JankowiakNo ratings yet

- Design and Build An Automatic PCB Drilling MachineDocument4 pagesDesign and Build An Automatic PCB Drilling MachinemoysesdutraNo ratings yet

- Digital Signal and Image Processing FundamentalsDocument51 pagesDigital Signal and Image Processing FundamentalsLaxmi VathariNo ratings yet

- Variables and Data Types in CDocument4 pagesVariables and Data Types in C7mood 102No ratings yet

- GNS430W Pilots Guide and ReferenceDocument218 pagesGNS430W Pilots Guide and Referenceniben16No ratings yet

- Loan Prediction SystemDocument31 pagesLoan Prediction SystemFakorede Akinwande alexNo ratings yet

- Anomaly Detection Using A Self-Sufficient Ad Hoc Electrical Impedance Tomography Sensor Deployed Within Imaged SpaceDocument5 pagesAnomaly Detection Using A Self-Sufficient Ad Hoc Electrical Impedance Tomography Sensor Deployed Within Imaged Spaceaibramai3No ratings yet

- A Corona Ring Is A Conducting Ring Mounted On The End of or RadiallyDocument6 pagesA Corona Ring Is A Conducting Ring Mounted On The End of or RadiallygopalNo ratings yet

- Directional Driller X CVDocument2 pagesDirectional Driller X CVMino MinoNo ratings yet

- AnnabellaBracco Resume 2021Document1 pageAnnabellaBracco Resume 2021ANNABELLA BRACCONo ratings yet

- Building 8 CO PDFDocument5 pagesBuilding 8 CO PDFDelmar GicaNo ratings yet

- The Design and Implementation of A Computer Based Testing System Using Component-Based Software EngineeringDocument8 pagesThe Design and Implementation of A Computer Based Testing System Using Component-Based Software EngineeringSalis KhanNo ratings yet

- C-Arrays & Strings and FunctionsDocument33 pagesC-Arrays & Strings and FunctionsSambhaviNo ratings yet

- 4 Suspension BenchDocument5 pages4 Suspension BenchTecnicas Reunidas de AutomociónNo ratings yet

- Engine Performance Test ResultsDocument6 pagesEngine Performance Test Resultsayie74100% (1)

- Cisco Intersight HandbookDocument409 pagesCisco Intersight HandbookHsueh KevinNo ratings yet

- SANTRO Hatchback BrochureDocument10 pagesSANTRO Hatchback Brochureronak chandranNo ratings yet

- Replacement AlgoDocument13 pagesReplacement AlgoTejaswi SuryaNo ratings yet

- "Flexible Bench": S.P.M Polytechnic Kumathe, Solapur 2018-2019Document3 pages"Flexible Bench": S.P.M Polytechnic Kumathe, Solapur 2018-2019Abhijeet DhavaleNo ratings yet

- TEC3r Manual 1.9.FDocument130 pagesTEC3r Manual 1.9.FerasmolsdiasNo ratings yet

- IBM Cognos 10.1 Framework ManagerDocument635 pagesIBM Cognos 10.1 Framework ManagerAlex Marcelo Valenzuela FloresNo ratings yet

- DATA ONTAP Simulate 8.1.1 C-Mode Installation (NetappU Labs)Document45 pagesDATA ONTAP Simulate 8.1.1 C-Mode Installation (NetappU Labs)Gaurav SachanNo ratings yet