Professional Documents

Culture Documents

The Examination of The Quality of Chitosan From Bamboo Shell Waste With Variations of Naoh Concentration in The Deacetylation Process

Uploaded by

Nofa Armelia SariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Examination of The Quality of Chitosan From Bamboo Shell Waste With Variations of Naoh Concentration in The Deacetylation Process

Uploaded by

Nofa Armelia SariCopyright:

Available Formats

THE 4th INTERNATIONAL CONFERENCE ON HEALTH POLYTECHNICS OF SURABAYA (ICOHPS)

1st International Conference of Environmental Health (ICoEH)

The Examination of The Quality of Chitosan from Bamboo Shell Waste with

Variations of NaOH Concentration in the Deacetylation Process

Sayyidah Nafysah Ahmad1(CA), Darjati2, Hadi Suryono3

1/(CA) Bachelor of Applied Environmental Sanitation Study Program, Environmental Health Department,

Health Polytechnic Ministry of Health Surabaya, Indonesia; nafysahamd@gmail.com (Corresponding

Author)

2 Environmental Health Department, Health Polytechnic Ministry of Health Surabaya, Indonesia;

Darjati.poltekkes@gmail.com

3 Environmental Health Department, Health Polytechnic Ministry of Health Surabaya, Indonesia;

hadisur@poltekkesdepkes-sby.ac.id

ABSTRACT

The bamboo shells that have been unused will be thrown away. Bamboo shell waste is still not utilized

or processed optimally, better processing and utilization are needed so that the waste does not pollute the

surrounding environment. Bamboo shells can be used as chitosan. The main organic material found in the

mollusca animal group contains organic material that forms chitin and chitosan compounds. This study aims

to determine the quality of chitosan from bamboo shell waste with variations in NaOH 60%, 65%, 70%, 75%.

Analysis of research data using simple regression test. The results of quality inspection of bamboo shell

chitosan showed that yield and degree of deacetylation obtained significance of p = 0.03 and 0.01 (p<0.05) so

NaOH effect on yield quality and degree of deacetylation, water content and ash content are significant p =

0.21 and 0.20 (p>0.05) so NaOH has no effect on the quality of water content and ash content. The conclusion

of this study is chitosan from bamboo shells has the quality standards of SNI 7949 in 2013. Suggestions for

other researchers are to add other variables and parameters, while for industry use chitosan as an absorbent for

heavy metals, cosmetics, food preservatives.

Keywords: Bamboo shellfish, quality of chitosan, NaOH concentration, daecetylation process

INTRODUCTION

The high number of shellfish for consumption by the general public will also be directly proportional

to the amount of shellfish waste produced. If the waste is disposed of continuously without proper treatment,

the environmental balance will be disturbed due to the accumulated waste. Solen sp. often found on the coast

of Madura in Pamekasan district, East coast of Surabaya, Cirebonan Kejawan beach and in the waters of

Tanjung Solok Jambi. Bamboo shells burrow vertically into the sediment and will come to the surface at low

tide. Has a long flat shape like a bamboo for an adult's finger. Its unique shape resembles a razor blade, so it is

also called a knife shell, razor clam or also a jack knife(Muhammad et al, 2017). Bamboo shell waste is still

not utilized or processed optimally, so that better processing and utilization is needed so that the waste does

not pollute the surrounding environment. One of the uses of bamboo shell waste that can be done is to make

the shell as a material for making chitosan. Chitosan is a polysaccharide consisting of D-glucosamine and N-

acetyl-D’glucosamine linked through - (1,4) bonds.

Chitosan has excellent biological properties including biocompatible, biodegradable, non-toxic, and

antioxidant(Huang et al., 2020). Chitosan is derived from chitin compounds produced from the deacetylation

process(Alawiyah and Taufikul, 2016). The transformation of chitin into chitosan is called the deacetylation

step, namely by adding a base at a high concentration. The reaction produced in the deacetylation process using

alkali at high temperatures will cause the release of the acetyl group (-COCH3) from the chitin molecule and

form a free amine group (–NH2) which means that the chitosan molecule has been formed (Wulandari, et al

2020). The benefits of chitosan, especially in the field of environmental health, are also quite broad, such as:

coagulant, flocculant, waste adsorbent, food product preservative, especially fishery.

The benefits of chitosan, especially in the field of environmental health, are also quite broad, such as:

coagulant, flocculant, waste adsorbent, food product preservative, especially fishery. Utilization of waste

bamboo shellfish (Solen sp.) compared to other types of shellfish, such as blood clams, green mussels, and

scallops as chitosan is still very little, so it needs to always be developed. This study aims to determine the

content of chitosan made from waste bamboo shells using a variation of 60% NaOH concentration. 65%, 70%

1st International Conference of Environmental Health ISBN 978-623-97447-4-8| 71

and 75% in the deacetylation process in order to get the best deacetylation degree (DD) results, which is at

least 75% according to SNI 7949 of 2013, this is because the degree of deacetylation (DD) is a very important

chemical characteristic in determining the content and the quality of the chitosan itself(Azhar et al., 2010).

METHODS

The research that will be conducted is experimental research or(experimental research experimental

research). The type of research used in this study is a quasi(quasi-experimental design-experimental design).

The research design used in this study is the One Shot Case Study, where the subject will be given treatment

and then the results of the treatment are observed. The object of the research is the content and characteristics

of chitosan, including: yield, moisture content, ash content, and the degree of deacetylation to determine the

level of chitosan produced based on different concentrations of NaOH in the deacetylation process. Each

variation of NaOH 60%, 65%, 70% and 75% chitosan that will be studied has 6 (six) repetitions without

control. Data collection techniques by means of literature study, observation, and laboratory examination. Data

analysis used a simple regression test on the SPSS application.

The first stage is demineralization, then deproteinization stage to produce chitin. Demineralization

was carried out by giving 100 ml of 1N NaOH solution in 25 grams of the sample of bamboo shell powder.

The powder was heated in a magnetic stirrer for 30 minutes at a temperature of 650C, rinsed with distilled

water and dried in an oven at 1000C for 1 x 24 hours.

The deproteinization stage was carried out after the powder was dry. This stage was carried out by

giving 100 ml of HCL solution, heated in a magnetic stirrer for 30 minutes at a temperature of 750C. The

powder was rinsed with aquased and dried in an oven at 1000C for 1 x 24 hours. The chitin of the bamboo

shells was formed and the chitin yield was calculated.

The transformation of chitin into chitosan was carried out through a deacetylation step using 60%,

65%, 70%, and 75% NaOH solutions. Chitin powder was heated with a magnetic stirrer for 1 hour at a

temperature of 1000C. The powder was rinsed with distilled water and dried in an oven at 1000C for 1 x 24

hours. Chitosan was then examined for yield, moisture content, ash content, FTIR spectro, and determination

of the degree of deacetylation(Laila and Niken, 2012).

RESULTS

Chitin and Chitosan Yield of Bamboo Shells

Table 1. Chitin weight (gr)

No. Result No. Result No. Result No. Result

1. 19,683 7. 20,129 13. 19,614 19. 20,312

2. 17,054 8. 20,312 14. 19,461 20. 22,127

3. 19,278 9. 19,421 15. 20,325 21. 21,079

4. 18,731 10. 19,269 16. 20,211 22. 20,414

5. 21,476 11. 20,224 17. 22,312 23. 18,618

6. 20,379 12. 21,379 18. 20,182 24. 20,312

The table above is the result of shrinkage of bamboo shell powder (chitin) after going through

demineralization and deproteinization resistance. The initial powder sample is 25gr. The following is the result

of measuring the chitin yield with the formula :

Yield = × 100%

72 | 1st International Conference of Environmental Health

THE 4th INTERNATIONAL CONFERENCE ON HEALTH POLYTECHNICS OF SURABAYA (ICOHPS)

1st International Conference of Environmental Health (ICoEH)

Table 2. Chitin weight yield (gr)

No. Result No. Result No. Result No. Result

1. 78,732 7. 80,516 13. 81,248 19. 78,456

2. 68,216 8. 88,508 14. 88,508 20. 77,844

3. 77,112 9. 77,684 15. 84,316 21. 81,3

4. 74,924 10. 77,076 16. 81,656 22. 80,844

5. 85,904 11. 80,896 17. 75,471 23. 89,248

6. 81,526 12. 85,516 18. 81,248 24. 80,728

Total average 80.72%

The variation of NaOH here has not been applied, so the calculation of the average value is carried

out thoroughly. The results of the transformation of chitin into chitosan after going through the deacetylation

stage with various concentrations of NaOH 60%, 65%, 70%, and 75% were then calculated using the same

formula as the previous chitin yield calculation to determine the chitosan yield.

Table 3. Chitosan weight yield (%)

Concentrtion Weight yield chitosn bmboo shell average

of NaOH

1 2 3 4 5 6

60% 78,708 67,876 76,348 71,072 85,868 81,444 76.886

65% 74,856 75,844 76,024 73,664 79,976 83,588 77.325

70% 75,056 72,704 70,596 69,784 79,456 79,488 74.514

75% 67,896 75,564 67,984 78,912 71,872 78,996 73.537

Based on the results in the table above, the highest average yield of bamboo shell chitosan was

obtained by 77.325% with a variation of 65% NaOH concentration, while the lowest average was 73.537%

using a 75% NaOH concentration variation.

Bamboo Shell Chitosan Water Content

The water content examination was carried out using the method Gravimetric/oven. The sample of

chitosan used for measuring the water content is 1 gram.

Table 4. Chitosan water content

Concentrtion Chitosan water content average

of NaOH

1 2 3 4 5 6

60% 1.6 % 1.2 % 0,4 % 0,5 % 0,6 % 0,8 % 0,85 %

65% 1,4 % 1,2 % 0,9 % 0,7 % 0,6 % 0,5 % 0,88 %

70% 0,6 % 1,2 % 0,7 % 0,6 % 0,7 % 0,7 % 0,75 %

75% 0,6 % 0,7 % 0,6 % 0,6 % 0,7 % 1,4% 0,76 %

Based on the table above, it can be seen that the highest average water content in chitosan is 65%

variation, which is 0.88% and the lowest average is 70% variation of 0.75%. It is known that each sample does

not exceed the quality standard of water content in chitosan according to SNI 7949 of 2013 which is a

maximum of 12%.

1st International Conference of Environmental Health ISBN 978-623-97447-4-8| 73

Bamboo Shell Chitosan Ash Concent

Examination of ash content using method Drying Ash. The chitosan samples used for measuring the

water content were 4 grams each.

Table 5. Chitosan ash content

Concentrtion Chitosan ash content average

of NaOH

1 2 3 4 5 6

60% 0,175% 0,15% 0,15% 0,525% 0,175% 0,4% 0,26,%

65% 1,075% 0,575% 0,225% 0,15% 0,4% 0,175% 0,43%

70% 1,95% 1,275% 0,175% 0,925% 0,1% 0,225% 0,77%

75% 1,4% 0,925% 0,35% 0,3% 2,025% 0,25% 0,87%

Based on the measurement results above, it can be seen that the highest average is in the 75% NaOH

concentration variation of 0.87% while the lowest average is in the 60% NaOH concentration of 0.26%. Of the

24 samples, none exceeded the quality standard of ash content in chitosan in accordance with SNI 7949 of

2013 which is a maximum of 5%.

FTIR Spectrophotometry of Bamboo Shell Chitosan

Spectrophotometry FTIR was used to determine the characteristics of the functional groups contained

in chitosan. The wavelength used is 4000-400cm-1. The following is one of the results of FTIR

spectrophotometer on chitosan:

Title: 75% 1 Mon Apr 05 14:28:36 2021 (GMT+07:00)

110

105

3 3 5 8.3 4

1 7 92 .4 6

1 96 2 .1 0

100

95

1 08 2 .73

90

7 1 2 .5 76 00 .1 1

3 64 1 .30

85

80

75

4 3 3 .3 04 0 7.0 6

70

65 8 7 1 .1 48 5 4 .3 7

60

1 4 4 6 .7 9

55

4000 3500 3000 2500 2000 1500 1000 500

Wavenumbers (cm-1)

Figure 1. Chitosan FTIR spectrum

Table 6. FTIR adsorbtion characteristic of chitosan

Type of vibration Wavenumber (cm-1)

Streching vibrtion OH 3450,3340

Streching vibrtion NH 3400

Asymmetric streching vibrtion CH 2926

Symmetric streching vibrtion CH 2864

Streching vibrtion C = O 1650

Bending vibration NH 1596

Streching vibrtion CN 1200 – 1020

Asymmetric bending vibrtion CH 1418

Symmetrical bending vibrtion CH 1377

Asymmetric streching vibrtion C – O 1082

Symmetric streching vibrtion C – O 1033

Streching vibrtion β – 1,4 – glikosidik 850

74 | 1st International Conference of Environmental Health

THE 4th INTERNATIONAL CONFERENCE ON HEALTH POLYTECHNICS OF SURABAYA (ICOHPS)

1st International Conference of Environmental Health (ICoEH)

bamboo shell chitosan deacetylation degree

The calculation or determination of the degree of deacetylation in this study uses the method

Baseline or the equation formula with the formula:

%DD = 100 – × %

,

Description :

A = log

Po = The distance between the baseline and the tangent, the highest peak at wavelengths 1655cm-1 and

3450 cm-1

P = The distance between the baseline and the lowest valley at wavelengths 1655cm-1 and 3450 cm-1

1,33 = Determination of the perfect degree of deacetylation

A1655 = Absorbance of amide/acetamide groups

A3450 = Absorbance of hydroxyl groups

The following is the result of measuring the degree of deacetylation of chitosan from bamboo shells

based on the results of the FTIR spectro:

Table 7. deacetylation degree of chitosan

Concretation of Deacetylstion degree Average

NaOH

1 2 3 4

60% 96,84% 96,67% 96,59% 96,76% 96,71%

65% 97,87% 97,33% 97,47% 97,45% 97,53%

70% 98,47% 97,74% 97,79% 97,84% 97.88%

75% 98,64% 98,94% 98,71% 98,86% 98,78%

Based on the table above, it can be seen that the highest average value of the degree of deacetylation

is 98.78% at 75% NaOH concentration variation, while the lowest average is 96.71% at 60% NaOH

concentration variation. The highest deacetylation degree value from all variations and replications was

98.94% at 75% NaOH concentration variation, then the lowest deacetylation degree value was 96.59% at 60%

NaOH concentration variation. The results of all concentration variations show that there is no value of the

degree of deacetylation below the quality standard of SNI 7949 in 2013. The value of the degree of

deacetylation according to the regulation is 75%.

Characteristics of Bamboo Shell Chitosan

Table 8. Characteristics of Bamboo Shell Chitosan

chitosan SNI 7949 : 2013 Chitosan bamboo shell

Parameter

1st International Conference of Environmental Health ISBN 978-623-97447-4-8| 75

NaOH 60% NaOH 65% NaOH 70% NaOH 75%

Praticle shape Flakes to powder Powder Powder Powder Powder

color Light brown to white Brownish Brownish Brownish Brownish

white white white white

physical Requirement

- Foreign object Negative - - - -

chemical requirement

- Deacetylation Min 75% 96,48 % 97,33 % 97, 79% 98,86 %

degree

Test type requirement

- pH 7-8 7 7 7 7

- Ash content Maks 5% 0,175% 0,575% 0,35% 0,925%

- Water content Maks 12% 1,6 % 1.2 % 0,7 % 0,6 %

Based on the comparison table above, it can be seen that the bamboo shell chitosan in this study has

met the requirements in accordance with SNI 7949 of 2013

DISCUSSION

Bamboo Shell Chitosan Yield

The yield of chitosan in each concentration variation was different. The higher the concentration of

NaOH given, the lower the yield value obtained. The results of different yields can be influenced by several

factors, including: temperature and time of stirring in the deacetylation process, the concentration of alkali

used, as well as the size and thickness of the raw materials used. Alkali concentration and high temperature

can cause a decrease in polymer and yield value(Mursida et al., 2018). In the deacetylation process, alkali can

bind more acetyl groups. The yield produced by the variation of the 75% NaOH concentration is indeed lower

than the 60% NaOH concentration, but the quality of the chitosan obtained is getting better and purer, because

many acetyl groups in chitosan are released from chitin. High temperatures can also affect the resulting yield

value. The concentration of NaOH and high stirring and heating temperatures in the deacetylation process can

accelerate the release of excess acetyl chitin chains, so that finer chitosan particles dissolve in NaOH and can

cause the chitosan mass to decrease(Anggun et al., 2018).

Bamboo Shell Chitosan Water Content

The average ash content produced based on the variation of NaOH concentration was 0.85%, 0.88%,

0.75%, and 0.76%, respectively. The lower the water content produced, the better the quality of chitosan

obtained. A good drying process will produce a low (good) moisture content. The size of the water content

value is fully influenced by the drying method, drying time, means of drying, the amount of chitosan being

dried, and the drying area used so that the concentration of NaOH in chitosan has no effect on the high or low

water content value obtained (Loede Muhammad et al ., 2018).

Bamboo Shell Chitosan Ash Content

Factors that can affect the quality of the ash content in chitosan are the duration of stirring and the

consistency of stirring, as well as washing to a neutral pH during the demineralization process. Ash content is

used to remove mineral residues during the demineralization process. If the ash content obtained is still high,

then the demineralization carried out has not been effective and perfect. Washing the pH to neutral can

minimize the occurrence of acids that are entangled and diffuse with free amino acids and protein residues that

can cause damage during the drying process (Pinta Purbowati, 2016). The demineralization process in this

study was carried out using a stove magnetic, stirrer so that the stirring and the heat that was delivered were

stable or homogeneous. Stable stirring process causes HCL to bind minerals effectively. The low ash content

indicates that the quality and purity of the processed chitosan is good.

FTIR Spectrophotometry of Bamboo Shells

The absorption pattern shows the presence of OH (hydroxyl) and NH (amine) functional groups,

which means that the two groups indicate that the acetyl group (COCH3) has been lost. Another characteristic

of chitosan lies in the amide group at wave number 1655 – 1310 cm-1 and the hydroxyl group at wavenumber

3550 – 3300 cm-1, then there is also a -1,4-glycosidic bond. The results of the FTIR spectrum of bamboo shell

chitosan show the location of the amide group and hydroxyl group at a predetermined wave number, and there

is a -1,4-glycosidic bond so that bamboo shell chitosan has been successfully formed(Sari, 2013).

76 | 1st International Conference of Environmental Health

THE 4th INTERNATIONAL CONFERENCE ON HEALTH POLYTECHNICS OF SURABAYA (ICOHPS)

1st International Conference of Environmental Health (ICoEH)

Bamboo Shell Deacetylation Degree Value

The deacetylation process is the stage of releasing the acetyl group from the chitin molecular chain,

so that if the value of the degree of deacetylation is high, the purer the quality of the chitosan

produced(Fatmawati, 2019). Factors that affect the degree of deacetylation are the concentration of NaOH,

stirring time, and stirring temperature. In this study, the concentration of NaOH in the deacetylation process

used was stratified, namely 60%, 65%, 70%, and 75%. The higher the concentration of NaOH given, the higher

the degree of deacetylation produced will also be.The addition of high NaOH causes the hydroxyl group for

the hydrolysis process (transformation of chitin to chitosan) to be high, so that the acetyl group can be

eliminated properly and the formation of a high amine group is also better(Bahri, 2015).

The higher the degree of deacetylation, the better the quality and purity of the chitosan. The data on

the degree of deacetylation in table 7 shows the highest degree of deacetylation at 98.95% in the 75% NaOH

concentration variation, and the lowest at 96.84% at the 60% NaOH concentration variation, so that the NaOH

concentration affects the value of the chitosan deacetylation degree. Chitosan with a deacetylation degree value

of about 90% can be applied for food quality and pharmaceuticals, as long as the moisture content, ash content

and other standard requirements have been determined(Century Siregar, 2016).

Characteristics of Bamboo Shell Chitosan

The characteristics of chitosan in this study refer to SNI 7949 of 2013 which has several parameters,

including: chitosan powder form, water content, ash content, pH, color, and degree of deacetylation. The results

of the research on the quality of bamboo shell chitosan showed that all of them had met the quality standards.

The form of chitosan in this study was a fine powder. The texture of the powder of the raw material is smooth

and evenly distributed, and can provide good effectiveness during the chitosan manufacturing process, so that

it can absorb evenly and well. The pH of chitosan shells is 7 (neutral). pH that is too acidic or too alkaline will

affect the demineralization process which can cause high ash content values, so rinsing with distilled water

must really be carried out until neutral. In this study, the color of the chitosan produced was brownish white.

The color of chitosan can vary depending on the raw materials used. Chitosan with a degree of deacetylation

of about 90% can be applied for food quality and pharmaceuticals, as long as it takes into account the moisture

content, ash content and other predetermined standard requirements.

CONCLUSION

Examination of the quality of bamboo shell chitosan using the reference of SNI 7949 in 2013. The

results of this study were in accordance with the provisions of quality standards, both the NaOH concentrations

of 60%, 65%, 70%, and 75%. The chemical quality of bamboo shell chitosan from each concentration of NaOH

has met the quality standard requirements. The results of the analysis showed that the concentration of NaOH

had a significant effect on the yield quality and degree of deacetylation, while the water content and ash content

had no significant effect.

REFERENCES

Alawiyah, Tuty and Taufikul Hadi. (2016) ‘Synthesis of Chitosan from Crab Shell Waste as Water Purifier’.

Nahdlatul Ulama University, NTB. ISSN 2442-9511 . JIME, Vol. 2. No. 2.

Anggun, Woro Hastuti and Gunanti Mahasri et al. (2017) ‘The Effect of Combination of NaOH and Different

Temperatures on the Degree of Chitosan Deacetylation from the Shell of Axe Clam (Atrina Pectinata)’.Journal

of Aquaculture and Fish Health, 6(2), 1–9.

Azhar, Minda., et al. (2010) ‘Effect of Concentration of NaOH and KOH on Degree of Chitin Deacetylation

from Shrimp Shell Waste’. Department of Chemistry, Faculty of Mathematics and Natural Sciences, Padang

State University. Eksakta Journal Vol. 1 Year XI February 2010.

Bahri, Rahim, and Syarifuddin. (2015) ‘Degree of Deacetylation of Chitosan from Blood Shells with Gradual

Addition of NaOH’. Journal of Chemical Research. 1 (1).

Etty Centaury Siregar, Suryati, and Luqman Hakim. (2016) ‘Effect of Temperature and Reaction Time on

Chitosan Production from Cuttlefish Bone’. Unimal Journal of Chemical Technology. 5:2 (November 2016)

37-4.

Fatmawati. (2019) ‘The Effect of Different Naoh Concentrations on the Deacetylation Process on the

Characteristics of Fan Shrimp Chitosan (Thenus orientalis)’. Essay. Faculty of Agriculture, Halu Oleo

1st International Conference of Environmental Health ISBN 978-623-97447-4-8| 77

University.

Huang, Liyi. et al. (2020) ‘Preparation And Characterization Of Chitosan From Crab Shell (Portunus

Trituberculatus) By NaOH/Urea Solution Freeze-Thaw Pretreatment Procedure’. International Journal of

Biological Macromolecules, 147:931–936.

Indonesian National Standardization. (2013) ‘Chitosan Quality and Processing Requirements’. SNI 7949-

2013. Jakarta

Laila Nur Fatimah and Niken Wulandari. (2012) ‘Chitosan from Shrimp Skin as Tofu Preservative’.

Department of Chemical Engineering, Faculty of Engineering, Sebelas Maret University, Surakarta.

78 | 1st International Conference of Environmental Health

THE 4th INTERNATIONAL CONFERENCE ON HEALTH POLYTECHNICS OF SURABAYA (ICOHPS)

1st International Conference of Environmental Health (ICoEH)

Laode Muhamad Hazairin Nadia, La Ode Huli, and Laode Abdul Rajab Nadia. (2018) ‘Production and

Characterization of Chitosan from the Shells of Crab (Portunus pelagicus) from Southeast Sulawesi’. J. Fish

Protech 2018, Vol. 1 No. 2.

Muhammad Farizqy Ramadhan, Syafruddin, and Efriyeldi. (2017) ‘Habitat and Population Characteristics of

Bamboo Shells (Solen lamarckii) in the Intertidal Zone of Teluk Lancar Village, Bantan District, Bengkalis

Regency’. Riau University. Journal of Fisheries and Marine Affairs Volume 22 No. 1, June 2017: 36-43.

Mursida, Tasir, and Sahrriawati. (2018) ‘The Effectiveness of Alkaline Solutions in the Deacetylation Process

of Various Chitosan Raw Materials’. Indonesian Journal of Fishery Products Processing. 21(2): 356-366.

Purbowati, Pinta. (2016) ‘Efforts to Increase the Degree of Deacetylation in Chitosan Shell Shells (Atrina

Pectinata) through the Process of Gradual Chitin Deacetylation’. Essay. Faculty of Fisheries and Marine

Affairs, Airlangga University.

Sari, Nofa Armelia. (2020) ‘Comparative Test Methods for Determining the Degree of Chitosan Deacetylation

Using Infrared Spectroscopy and Volumetric Methods’. Essay. Faculty of Mathematics and Natural Sciences,

Islamic University of Indonesia Yogyakarta.

Wulandari, et al. (2020) ‘The Effect of Variations in NaOH Concentration on the Degree of Chitosan

Deacetylation from Green Scallop Shell Waste (Perna Virid L)’. Covalene : chemical research journal, 6(3),

2020: 171-176.

1st International Conference of Environmental Health ISBN 978-623-97447-4-8| 79

You might also like

- Fuels, Chemicals and Materials from the Oceans and Aquatic SourcesFrom EverandFuels, Chemicals and Materials from the Oceans and Aquatic SourcesFrancesca M. KertonNo ratings yet

- William 2019 J. Phys. Conf. Ser. 1358 012002Document8 pagesWilliam 2019 J. Phys. Conf. Ser. 1358 012002ReemaNo ratings yet

- Ijesrt: International Journal of Engineering Sciences & Research TechnologyDocument11 pagesIjesrt: International Journal of Engineering Sciences & Research TechnologyAna MariaNo ratings yet

- Pollution Control and Resource Recovery: Municipal Solid Wastes Incineration: Bottom Ash and Fly AshFrom EverandPollution Control and Resource Recovery: Municipal Solid Wastes Incineration: Bottom Ash and Fly AshNo ratings yet

- Chitosan Extracted From Mud Crab (Scylla Olivicea) Shells - Physicochemical and Antioxidant PropertiesDocument10 pagesChitosan Extracted From Mud Crab (Scylla Olivicea) Shells - Physicochemical and Antioxidant PropertiesChemistryNo ratings yet

- Production of Bioplastic From Cassava Peel With Different Concentrations of Glycerol and Caco As FillerDocument9 pagesProduction of Bioplastic From Cassava Peel With Different Concentrations of Glycerol and Caco As Fillerqueen ann toledoNo ratings yet

- Cangkang Keong Sawah KandunganDocument10 pagesCangkang Keong Sawah KandunganNadirotul RosydahNo ratings yet

- 20 Synthesis of NC From BagasseDocument4 pages20 Synthesis of NC From BagasseVịt Siêu Ngu DốtNo ratings yet

- Chitin Chitosan ProductionDocument19 pagesChitin Chitosan ProductionOmer MukhtarNo ratings yet

- Ethanol PaperDocument6 pagesEthanol PaperDipak PatilNo ratings yet

- Research Journal of Pharmaceutical, Biological and Chemical SciencesDocument13 pagesResearch Journal of Pharmaceutical, Biological and Chemical SciencesMari Fei LagmayNo ratings yet

- Citronellol Based Biodegradable Anionic SurfactantDocument8 pagesCitronellol Based Biodegradable Anionic SurfactantasmnclNo ratings yet

- Preparation and Characterization of Nano ChitosanDocument7 pagesPreparation and Characterization of Nano Chitosanfitriana intanNo ratings yet

- 1 PBDocument12 pages1 PBIqbal PratamaNo ratings yet

- Research Proposal Ni InjelDocument5 pagesResearch Proposal Ni InjelRhodail Andrew CastroNo ratings yet

- Preparation and Characterization of Cellulose and Nanocellulose From Agro-Industrial Waste - Cassava PeelDocument7 pagesPreparation and Characterization of Cellulose and Nanocellulose From Agro-Industrial Waste - Cassava Peelsuzie annNo ratings yet

- The Effect of Drying Expired Sausage Waste On Its Nutrition ContentDocument4 pagesThe Effect of Drying Expired Sausage Waste On Its Nutrition ContentM. Arif NugrahaNo ratings yet

- Chamidah, A., Widiyanti, Ch. H. Dan Fabiyani, N. N: Fakultas Perikanan Dan Ilmu Kelautan Universitas BrawijayaDocument10 pagesChamidah, A., Widiyanti, Ch. H. Dan Fabiyani, N. N: Fakultas Perikanan Dan Ilmu Kelautan Universitas BrawijayaAnik YolandaNo ratings yet

- Journal of Design and Textiles (JDT) : HomepageDocument20 pagesJournal of Design and Textiles (JDT) : HomepageJournal of Design and TextilesNo ratings yet

- 843 FDocument15 pages843 FĐoàn NhiênNo ratings yet

- The Chitosan Cembrane Cffectiveness of Anadara Granosa Clam Shells To Remove Total Coliform in GreywaterDocument7 pagesThe Chitosan Cembrane Cffectiveness of Anadara Granosa Clam Shells To Remove Total Coliform in GreywaterIJPHSNo ratings yet

- ++++ Lignin 020013 - 1 - OnlineDocument6 pages++++ Lignin 020013 - 1 - OnlineKhelil OmarNo ratings yet

- Extraction of Microcrystalline CelluloseDocument7 pagesExtraction of Microcrystalline Cellulosegouri.patil2021No ratings yet

- Production of Bio-Hydrogen From Banana Waste by Using Anaerobic FermentationDocument6 pagesProduction of Bio-Hydrogen From Banana Waste by Using Anaerobic FermentationIJRASETPublicationsNo ratings yet

- Undergraduate Research Proposal: Proposed TitleDocument8 pagesUndergraduate Research Proposal: Proposed TitleHanshiya RagaNo ratings yet

- 27817-Article Text-92478-2-10-20200206Document11 pages27817-Article Text-92478-2-10-20200206siti faridahNo ratings yet

- The Extraction of Brown Algae (Sargassum SP) Through Calcium Path To Produce Sodium AlginateDocument6 pagesThe Extraction of Brown Algae (Sargassum SP) Through Calcium Path To Produce Sodium Alginatenaziva annisaNo ratings yet

- Utilization of Avocado Seeds As Bioplastic Films FDocument6 pagesUtilization of Avocado Seeds As Bioplastic Films FGessianyVictoriaNo ratings yet

- A Process For The Preparation of Chitin and Chitosan From Prawn Shell WasteDocument8 pagesA Process For The Preparation of Chitin and Chitosan From Prawn Shell WasteApt Fitri RosdianaNo ratings yet

- Synthesis of Silica Particles From Rice Straw WastDocument9 pagesSynthesis of Silica Particles From Rice Straw WastMahmoud MazenNo ratings yet

- The Effect of Time Deacetylation To Characterize Chitosan From Waste ShrimpDocument16 pagesThe Effect of Time Deacetylation To Characterize Chitosan From Waste ShrimpIgnatius AgustaNo ratings yet

- Kitosan Sebagai Pengawet (Harjanti 2014)Document8 pagesKitosan Sebagai Pengawet (Harjanti 2014)RinaNo ratings yet

- Bioethanol Production From Cotton Waste Using Cellulase Extracted From SpeciesDocument9 pagesBioethanol Production From Cotton Waste Using Cellulase Extracted From SpeciesDr-Muhammad Asim UmerNo ratings yet

- Utilization of Corn Husk For Tissue PapermakingDocument8 pagesUtilization of Corn Husk For Tissue PapermakingHerlin OrtizNo ratings yet

- Arief 2021 IOP Conf. Ser. Earth Environ. Sci. 679 012013Document7 pagesArief 2021 IOP Conf. Ser. Earth Environ. Sci. 679 012013mochammad diedinNo ratings yet

- 9632 18647 1 SMDocument7 pages9632 18647 1 SMDewi SrianaNo ratings yet

- The Effect of Polysorbate 80 Addition On The Size of Chitosan Nanoparticles From Shrimp Shells Vannamei (Litopenaeus Vannamei) - AIPCP Template PDFDocument8 pagesThe Effect of Polysorbate 80 Addition On The Size of Chitosan Nanoparticles From Shrimp Shells Vannamei (Litopenaeus Vannamei) - AIPCP Template PDFIchan PantsNo ratings yet

- The Production of Ethanol and Hydrogen From Pineapple Peel by Saccharomyces Cerevisiae and Enterobacter AerogenesDocument8 pagesThe Production of Ethanol and Hydrogen From Pineapple Peel by Saccharomyces Cerevisiae and Enterobacter AerogenesInayahWulandariNo ratings yet

- A Green Biorefinery Platform For Cost-Effective Nanocellulose Production Investigation of Hydrodynamic Properties and Biodegradability of Thin FilDocument10 pagesA Green Biorefinery Platform For Cost-Effective Nanocellulose Production Investigation of Hydrodynamic Properties and Biodegradability of Thin FilYi PeiNo ratings yet

- New Process For Synthesizing Chitosan From Snail Shells: Journal of Physics: Conference SeriesDocument7 pagesNew Process For Synthesizing Chitosan From Snail Shells: Journal of Physics: Conference SeriesReemaNo ratings yet

- Faculity of Chemical and Food Engineering Departement of Chemical EngineeringDocument32 pagesFaculity of Chemical and Food Engineering Departement of Chemical Engineeringasnakew mucheNo ratings yet

- Extraction Characterization and Applications of Chitosan From Fish Scales PDFDocument5 pagesExtraction Characterization and Applications of Chitosan From Fish Scales PDFUlfa AriefNo ratings yet

- Preparation, Modification and Characterization of Chitosan-Oxalic Kola Nut Pod AdsorbentDocument8 pagesPreparation, Modification and Characterization of Chitosan-Oxalic Kola Nut Pod AdsorbentIJRASETPublicationsNo ratings yet

- Micro/nanocellulose From Waste Pili (Canarium Ovatum) Pulp As A Potential Anti-Ageing Ingredient For Cosmetic FormulationsDocument6 pagesMicro/nanocellulose From Waste Pili (Canarium Ovatum) Pulp As A Potential Anti-Ageing Ingredient For Cosmetic FormulationsRizki Uhud NasofiNo ratings yet

- Hasan 2020 J. Phys.: Conf. Ser. 1567 032100Document7 pagesHasan 2020 J. Phys.: Conf. Ser. 1567 032100sri IndahNo ratings yet

- (Sici) 1097-4660 (199612) 67 4 362 Aid-Jctb513 3.0.co 2-CDocument5 pages(Sici) 1097-4660 (199612) 67 4 362 Aid-Jctb513 3.0.co 2-CCARMEN ELENA CALDERON MUÑOZNo ratings yet

- Evaluasi Proses Pengolahan Limbah Kulit Udang Untuk Meningkatkan Mutu Kitosan Yang DihasilkanDocument8 pagesEvaluasi Proses Pengolahan Limbah Kulit Udang Untuk Meningkatkan Mutu Kitosan Yang DihasilkanNataliakusumaDewiNo ratings yet

- 995 2157 1 PBDocument11 pages995 2157 1 PBANNISA ZAHRA RAMADHANNo ratings yet

- Zelvi Enzim7Document11 pagesZelvi Enzim7Anonymous ITIYFbIGCNo ratings yet

- Journal BioplasticDocument8 pagesJournal BioplasticSalsabila ArianiNo ratings yet

- Bioethanol Production From Weed Plant Cyperus Rotundus by Enzymatic HydrolysisDocument4 pagesBioethanol Production From Weed Plant Cyperus Rotundus by Enzymatic HydrolysiszalehakNo ratings yet

- 1 OkDocument9 pages1 OkStephanie SalazarNo ratings yet

- Isolation of Cellulosic Materials From Wastes of Fruits of Bangladesh and Their DerivatizationDocument5 pagesIsolation of Cellulosic Materials From Wastes of Fruits of Bangladesh and Their DerivatizationvanbanbinhdinhNo ratings yet

- Chitosan Tres ImportantDocument6 pagesChitosan Tres Importantsacha--16No ratings yet

- Production of Starch Based Bioplastic From Cassava Peel Reinforced With Microcrystalline Celllulose Avicel ph101 Using Sorbitol As PlasticizerDocument8 pagesProduction of Starch Based Bioplastic From Cassava Peel Reinforced With Microcrystalline Celllulose Avicel ph101 Using Sorbitol As PlasticizerShanaiah Charice GanasNo ratings yet

- B Tech Published PaperDocument13 pagesB Tech Published PaperJacko GeaNo ratings yet

- Extraction and Characterization of Chitin and Chitosan From Blue Crab and Synthesis of Chitosan Cryogel ScaffoldsDocument14 pagesExtraction and Characterization of Chitin and Chitosan From Blue Crab and Synthesis of Chitosan Cryogel ScaffoldsApt Fitri RosdianaNo ratings yet

- Yulianti Sampora, Yenni Apriliany Devy, Dewi Sondari, Dan Athanasia Amanda Septevani. 2020. Simultaneous Pretreatment ProceDocument9 pagesYulianti Sampora, Yenni Apriliany Devy, Dewi Sondari, Dan Athanasia Amanda Septevani. 2020. Simultaneous Pretreatment ProceAdhan AkbarNo ratings yet

- Rice Straw JournalDocument8 pagesRice Straw JournalanalyzethepurposeNo ratings yet

- 3 ClearingDocument3 pages3 ClearingAngel RamosNo ratings yet

- Fabrication of Ti3C2Tx Mxene Transparent Thin Films With Tunable Optoelectronic PropertiesDocument8 pagesFabrication of Ti3C2Tx Mxene Transparent Thin Films With Tunable Optoelectronic PropertiesAbu Jafar RaselNo ratings yet

- Molarity: First Add 40G NaohDocument27 pagesMolarity: First Add 40G Naohgyogi1989No ratings yet

- "Toja" Shower Column Set Tx492Stn: Specifications Troubleshooting InstallationDocument1 page"Toja" Shower Column Set Tx492Stn: Specifications Troubleshooting InstallationAndrianus EffendyNo ratings yet

- Fenrg-09-690725 LCA Palm HVODocument10 pagesFenrg-09-690725 LCA Palm HVOphimentNo ratings yet

- Designing A Cable TrayDocument20 pagesDesigning A Cable TraymajesusNo ratings yet

- 3A Metals Edrolo Study NotesDocument22 pages3A Metals Edrolo Study NotesMr FiddleNo ratings yet

- Liquid Resins and Additives: North AmericaDocument48 pagesLiquid Resins and Additives: North AmericaWALTER KLISSMANNo ratings yet

- Volatile Acidity: Ethyl Acetate (EA) Is Typically Perceived As The Odour of Nail Polish RemoverDocument1 pageVolatile Acidity: Ethyl Acetate (EA) Is Typically Perceived As The Odour of Nail Polish RemoverVictoria DíazNo ratings yet

- Phytochemical Analysis of Annona Reticulata L. Leaf ExtractsDocument4 pagesPhytochemical Analysis of Annona Reticulata L. Leaf ExtractsAnneNo ratings yet

- RESEARCHDocument2 pagesRESEARCHLorenzo CohenNo ratings yet

- Mole ConceptDocument62 pagesMole Concepthacker boyNo ratings yet

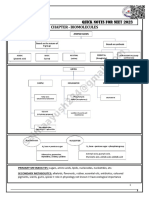

- Biomolecules Crash Course NotesDocument22 pagesBiomolecules Crash Course NotesAayush sainiNo ratings yet

- Organic Compounds Inorganic CompoundsDocument42 pagesOrganic Compounds Inorganic CompoundsBabar NaseerNo ratings yet

- Crystal Imperfections Point DefectsDocument38 pagesCrystal Imperfections Point DefectsPuloma DwibediNo ratings yet

- Full Summary of Edexcel IAL 2018 Chapter 4Document20 pagesFull Summary of Edexcel IAL 2018 Chapter 4North AbordoNo ratings yet

- MSDS PolyurethaneDocument7 pagesMSDS PolyurethaneArif SetiawanNo ratings yet

- Electrochemistry LECTURE NOTESDocument45 pagesElectrochemistry LECTURE NOTESDalitso SimonNo ratings yet

- ALOHA ExamplesDocument57 pagesALOHA Examplesanwar318No ratings yet

- Surface Vehicle Information: Rev. JAN96Document9 pagesSurface Vehicle Information: Rev. JAN96Glauco SantosNo ratings yet

- Physicochemical Properties of Silica Nanoparticles and Health HazardsDocument10 pagesPhysicochemical Properties of Silica Nanoparticles and Health HazardsIJAR JOURNALNo ratings yet

- Ethyl AcetateDocument8 pagesEthyl Acetatevighnesh kumarNo ratings yet

- B2A RevisionNotesEMPTY Biology Edexcel IgcseDocument4 pagesB2A RevisionNotesEMPTY Biology Edexcel IgcseSuki ChanNo ratings yet

- Screw Take-Up Device Ur1 Ur7: Conveyor ComponentsDocument1 pageScrew Take-Up Device Ur1 Ur7: Conveyor ComponentsDxFxNo ratings yet

- Spent Automobile Oil Degradation Potential of Bacteria Isolates Within Makurdi Town Journal of Environmental Science April 2023Document12 pagesSpent Automobile Oil Degradation Potential of Bacteria Isolates Within Makurdi Town Journal of Environmental Science April 2023International Journal of Innovative Science and Research TechnologyNo ratings yet

- Replacement Parts List: Built On InnovationDocument103 pagesReplacement Parts List: Built On Innovationsunday emmanuelNo ratings yet

- Test Bank For Biochemistry 7th Edition Jeremy M BergDocument24 pagesTest Bank For Biochemistry 7th Edition Jeremy M BergNicoleJohnsongobe100% (42)

- Progress and Challenges For Replacing N Methyl 2 Py 2024 Progress in NaturalDocument13 pagesProgress and Challenges For Replacing N Methyl 2 Py 2024 Progress in Naturalmosab.backkupNo ratings yet

- Foods: Effects of Adding Legume Flours On The Rheological and Breadmaking Properties of DoughDocument22 pagesFoods: Effects of Adding Legume Flours On The Rheological and Breadmaking Properties of DoughRebeca Salvador ReyesNo ratings yet

- Instructiuni de Montaj - RoDocument48 pagesInstructiuni de Montaj - Roioan cristian cotorobaiNo ratings yet

- ICH Quality Guidelines: An Implementation GuideFrom EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleNo ratings yet

- Chemistry for Breakfast: The Amazing Science of Everyday LifeFrom EverandChemistry for Breakfast: The Amazing Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (14)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincFrom EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincRating: 3.5 out of 5 stars3.5/5 (137)

- It's Elemental: The Hidden Chemistry in EverythingFrom EverandIt's Elemental: The Hidden Chemistry in EverythingRating: 4 out of 5 stars4/5 (10)

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsFrom EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsRating: 5 out of 5 stars5/5 (3)

- Taste: Surprising Stories and Science About Why Food Tastes GoodFrom EverandTaste: Surprising Stories and Science About Why Food Tastes GoodRating: 3 out of 5 stars3/5 (20)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactFrom EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactRating: 5 out of 5 stars5/5 (5)

- AP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeFrom EverandAP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeRating: 5 out of 5 stars5/5 (1)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactFrom EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactRating: 5 out of 5 stars5/5 (1)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeFrom EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeRating: 4 out of 5 stars4/5 (1)

- The Production of Volatile Oils and Perfumery Plants in the United StatesFrom EverandThe Production of Volatile Oils and Perfumery Plants in the United StatesNo ratings yet

- Guidelines for Defining Process Safety Competency RequirementsFrom EverandGuidelines for Defining Process Safety Competency RequirementsRating: 3 out of 5 stars3/5 (1)

- AP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeFrom EverandAP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeNo ratings yet

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideFrom EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideNo ratings yet

- Chemistry for Breakfast: The Amazing Science of Everyday LifeFrom EverandChemistry for Breakfast: The Amazing Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (90)

- Essential Chemistry for Formulators of Semisolid and Liquid DosagesFrom EverandEssential Chemistry for Formulators of Semisolid and Liquid DosagesRating: 5 out of 5 stars5/5 (2)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeFrom EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeRating: 5 out of 5 stars5/5 (4)

- Formulating, Packaging, and Marketing of Natural Cosmetic ProductsFrom EverandFormulating, Packaging, and Marketing of Natural Cosmetic ProductsNo ratings yet

- The Periodic Table: A Very Short IntroductionFrom EverandThe Periodic Table: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (3)