Professional Documents

Culture Documents

AES Pipes - Engineering Basis.12890711

Uploaded by

Wuttichai PoontanodOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AES Pipes - Engineering Basis.12890711

Uploaded by

Wuttichai PoontanodCopyright:

Available Formats

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

______________________________________________________________________________

Engineering Design Basis

Piping Design Program

Copyright 1998 Skidmore, Owings & Merrill. All rights reserved.

_______________________________________________________________________________

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 15

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Piping Systems and Networks

Piping systems can be open or closed. An open system is affected by atmospheric pressure. The

flow in open condensate return and plumbing drainage systems is gravitational. The flow in an

open cooling tower water system is forced. The pipe sections of an open network system are

either all supply or all return. A closed network system includes both supply and return sections.

A closed network system begins with a first supply section and ends with a last return section.

Open Network Systems

Pumps and static heads are used to force circulation in Open Systems except as noted

Steam supply

Open steam condensate return (gravitational)

Closed condensate return

Cooling tower water (partially gravitational)

Fuel oil supply

Fuel oil return

Gasoline supply

Fuel gas supply

Domestic cold water supply

Domestic hot water supply

Storm sewer return (gravitational)

Sanitary sewer return (gravitational)

Sanitary vents (gravitational)

Closed Network Systems

Closed systems apply mainly to liquids. Examples of closed network systems include

Chilled water

HVAC hot water

High temperature hot water

Glycols

Brines

Supply-Return Systems

The flow arrangements in closed piping networks can be:

Two-pipes, direct-return

Two-pipes, reverse-return

Primary-secondary

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 16

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Primary-Secondary Systems

Network arrangements can be combinations of direct return and reverse return loops.

Piping Design Data

Properties of Fluids

Fluid types used in HVAC include water, brine, glycol, diesel oil, steam and fuel gas. Water

systems can be temperatures (40 F to 210 F) at standard pressure; temperatures (210 F to 250 F)

at medium pressure; and temperatures (up to 400 F) at high pressure. Properties include

kinematic viscosity, density and specific heat at different temperatures. In the case of steam, the

properties are saturation temperature, saturation pressure, specific volume and latent heat at

different pressures.

Pipe Materials

Pipe materials used in HVAC, Plumbing and Fire Protection include:

Steel: schedule 40, schedule 80, standard weight, and extra strength

Cast Iron: 125, 175 and 250 psi

Copper: types K, L and M

Plastic: Schedule 40 PVC and CPVC thermoplastics

Concrete, Clay

Properties for each nominal pipe size include inner and outer diameters, weight per unit length,

and pipe wall thickness. Other pipe properties include thermal conductivity, inside roughness

factors,

roughness correction factors for the age of the pipe.

Pipe Insulation

Pipe insulations include fibrous glass, urethane, elastomerics, phenolic foam, calcium silicate and

magnesia. Properties include density and thermal conductivity at different temperatures.

Pipe Fittings and Valves

Fittings are piping components that create dynamic pressure losses in the network. Loss

calculations are based on the Hydraulic Institute Engineering Data Book, 1979. A list of fitting

types is shown in Fittings and Valves in this engineering basis. Fitting data include K values for

different pipe diameters, velocities, radius bends and contraction/expansion angles. An

alternative to the K value method, is the use of equivalent straight pipe lengths (L/D) values for

fittings and valves.

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 17

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

HVAC Piping Design Criteria

Design standards include maximum velocity, pressure loss per unit length and flow for different

types of fluids, pipe materials, pipe sizes and applications. Cross-reference tables are included to

check that the appropriate pipe material is used for a given application, fluid type and insulation

type

Plumbing Drainage Design Criteria

The plumbing drainage design criteria consist of tables for analyzing and sizing roof drains and

leaders, horizontal rain water pipes, building drains and sewers, horizontal fixture branches and

stacks, and horizontal and vertical vents. Fixture units values for fittings are also included in the

library. Sizing criteria and tables are provided by ASPE.

Piping System

Piping System consists of:

Pipe Sections

Pipe Circuits

Equipment Components

A piping system must be analyzed for:

Pressures

Temperatures

Critical Circuits (for pressures and temperatures)

Equipment in the piping system network must be analyzed and designed for:

Entering and Leaving Pressures,

Pressure loss,

Entering and Leaving Temperatures

Temperature Change.

Network Identification

Pipe Sections: A piping system is made up of linked pipe sections. The physical properties of the

pipe and the properties of the fluid flow inside the pipe section are unique to the section. By

definition a pipe section occurs under one or more of these conditions:

there is a change in the fluid flow rate through the pipe

there is a change in the fluid velocity in the pipe

there is a change in pipe insulation or material

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 18

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

the pipe section contains fluid handling equipment; (a new section must begin

downstream of such equipment)

Supply Sections: Pipe sections from the discharge side of the primary pumping station node to

the section with the terminal equipment are defined as supply sections.

Return Sections : Pipe sections on the downstream side of the terminal equipment to the

suction side of the primary pump are defined as return sections.

Exclude Sections (or independent sections): These are defined as pipes that are not part of the

supply or return tree networks. Examples of such pipe sections are bypass piping at terminal

equipment, parallel piping at pump stations & primary equipment, and piping to compression

tanks.

Pipe Circuit is a series of pipe sections from the pump to the terminal equipment (heat

exchanging equipment, plumbing fixture, etc.) for open systems and back to the pump for closed

systems.

Exception: In the case of cooling tower and condenser water systems, the piping from the

cooling tower to the condenser is Supply, and from the condenser and pumps to the cooling

tower is Return.

Terminal equipment (unit heaters, fan coil units, etc.) is not usually connected in series within a

section of the piping network system. Therefore, the number of pipe circuits in a piping system is

equal to the number of terminal equipment units.

Piping Network

A piping network consists of several circuits. A supply network begins with a single pipe section

that is common to all the circuits. This section is referred to as the first section in the supply side

of the network. Similarly, a return network ends with a last section.

The first section of the network must have enough pressure to drive the fluid through all the

circuits in the network. This starting pressure is the highest circuit pressure loss. In the case of

steam and fuel gas, the starting design pressure is determined by the application’s requirements.

For steam, initial pressure can also be calculated from the initial temperature that you specify.

Plumbing drainage and steam condensate return systems are based on gravitational flow. Sizing

is based on tables provided by ASPE.

The source of network pressure in the first supply section for liquid systems is typically a pump or

group of pumps referred to as the primary pumping station. In addition to this primary source of

pressure, the pressure in any secondary circuit ca be boosted using a booster pump.

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 19

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Use only one booster pump in series with the primary pump in any one circuit. A piping network

may consist of a primary system and one or more secondary systems arranged in a series with

the primary system

Example of Piping Systems & Networks

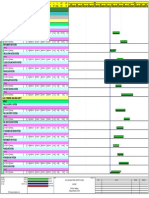

Fig. 1-3 shows a primary-secondary system. The primary pumping station consists of six pumps

arranged in a 3-parallel x 2-series system. All the pumps in the pumping station are identical in

type and size. This is recommended design. The flow in each pump is, therefore, one-third or

the total system flow and the pressure head for each pump is one-half of the required system

head.

The entire pumping station is treated as a single pressure source with a first supply (S) section

(101) leaving the system and a last return (R) section (201) entering the system. All the other

sections in the pumping station are identified as X sections that must be excluded from the

network analysis.

Fig. 1-3 : Primary-Secondary System

The piping network identification information from Fig. 1-3 is shown in tabular form in Fig. 1-4.

This information is rearranged and presented in Fig. 1-5 through Fig. 1-9 as circuits with the

sections in each circuit arranged in flow sequence.

Fig. 1-5 shows complete circuits starting from the primary pumping station, passing through a

terminal equipment and back to the pumping station. This is the typical circuit arrangement

when there are no booster pumps.

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 20

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Section ID Upstream Downstream Section Terminal Booster Primary

No. Section ID. Section ID. Type Equipment Pump Equipment

20 103 - S - BP-1 -

21 20 - S - - -

22 21 - S TE-1 - -

23 21 - S ─ - -

24 23 - S TE-2 - -

25 23 - S TE-3 - -

26 - 28 R - - -

27

30 -

10 28

- RS -- -

BP-2 --

31 30 - S - - -

32 31 - S TE-4 - -

33 31 - S TE-5 - -

34 - 36 R - - -

35 - 36 R - - -

36 - 205 R - - -

40 105 0 S TE-6 - -

41 - 204 R - - -

50 106 - S - - -

51 50 - S - - -

52 51 - S TE-7 - -

53 51 - S TE-8 - -

54 - 56 R - - -

55 - 56 R - - -

56 - 203 R - - -

71 - - X - - -

72 - - X - - -

81 - - X - - -

82 - - X - - -

83 - - X - - -

84 - - X - - -

85 - - X - - -

91 - - X - - -

101 Pump - S - - PE-1

102 101 - S - - -

103 102 - S - - -

104 103 - S - - -

105 104 - S - - -

106 105 - S - - -

201 Pump R - - -

203 201 R - - -

204 - 203 R - - -

205 - 204 R - - -

206 - 205 R - - -

-

Fig. 1-4: Piping Network Identification Information

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 21

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Fig. 1-6 is the primary system and Fig. 1-7, Fig. 1-8 and Fig. 1-9 are the secondary systems. Note

that the circuit that passes through the terminal equipment having the label TE-6 does not have a

booster pump. That entire circuit becomes a part of the primary system.

Ckt # of

Sections in Each Circuit Arranged in Flow Sequence

No. Sect

1 20

4 101 102 103

BP-1

30

2 5 101 102 103 104

BP-2

40 201

3 10 101 102 103 104 105 41 204 203

TE-6 BP-2

50

4 7 101 102 103 104 105 106

BP-3

Fig. 1-6: Primary System Identification

Ckt # of

Sections in Each Circuit Arranged in Flow Sequence

No. Sect

1 8 21 22 29 206 205 204 203 201

TE-1

2 10 21 23 24 27 28 206 205 204 203 201

TE-2

3 10 21 23 25 26 28 206 205 204 203 201

TE-3

Fig. 1-7: Secondary System from Booster Pump BP-1

Ckt # of

Sections in Each Circuit Arranged in Flow Sequence

No. Sect

1 8 31 32 35 36 205 204 203 201

TE-4

2 8 31 33 34 36 205 204 203 201

TE-5

Fig 1-8: Secondary System from Booster Pump BP-2

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 22

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Ckt # of Sections in Each Circuit Arranged in Flow

No. Sect Sequence

1 6 51 52 55 56 293 201

TE-7

2 6 51 53 54 56 203 201

Fig. 1-9: Secondary System from Booster Pump BP-3

Ckt # of

Sections in Each Circuit Arranged in Flow Sequence

No. Sect

20 22

1 12 101 102 103

BP-1

21

TE-1

29 206 205 204 203 201

20 24

2 14 101 102 103

BP-1

21 23

TE-2

27 28 206 205 204 203 201

20 25

3 14 101 102 103

BP-1

21 23

TE-3

26 28 206 205 204 203 201

30 32

4 13 101 102 103 104

BP-2

31

TE-4

35 36 205 204 203 201

30 33

5 13 101 102 103 104

BP-2

31

TE-5

34 36 205 204 203 201

40

6 10 101 102 103 104 105

TE-6

41 204 203 201

50 52

7 13 101 102 103 104 105 106

BP-3

51

TE-7

55 56 203 201

50 53

8 13 101 102 103 104 105 106

BP-3

51

TE-8

54 56 203 201

Fig. 1-5: Complete System Identification

TE-<number> = Terminal Equipment No. BP-<number> = Booster Pump No.

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 23

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Closed and Open Piping Network Systems

Fig 1-10: Closed System

Fig1-11: Open System

Closed systems are made up of two components:

a supply system that ends at a terminal air conditioning equipment unit

a return system that starts at the terminal equipment

Fig. 1-10 shows a closed system network. The system shown is a reverse return system with

both supply and return sections. Closed systems are not affected by atmospheric pressure. The

pump head of open systems include atmospheric pressure. Fig. 1-11 illustrates an open supply

system.

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 24

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Network Analysis

The piping system analysis uses a general tree structure. A pipe network can be either an open

or closed network. To simplify analysis, a closed network can be divided into two open networks,

one supply and one return, with the break between them at the terminal equipment.

An open network can be analyzed as a tree with a single trunk fanning out into branches, sub-

branches, then leaves. Forward network analyses begin with the main pump (tree trunk) and

work down each pipe section (branch, sub-branch) to a terminal equipment (leaf). Reverse

network analysis works from a terminal equipment to the pump.

The tree structure is handled as a number of linear linked lists, one for each junction in the pipe

network. A pipe section is analyzed only once and and the sections are arranged in flow

sequence into complete circuits.

The pipe sections are linked into circuits. A supply section can have only one upstream section

and any number of downstream sections. A return section can have only one downstream

section and any number of upstream sections.

The network analysis to determine the fluid flow in each pipe section starts with each terminal

equipment, a circuit end, and moves backwards, assigning the fluid quantity of the terminal

equipment to all the sections in the circuit.

Thermal analysis begins with the fluid temperature leaving the primary equipment section, and

moves forward through each section in the circuit. The heat gains or losses and the temperature

at the end of each section are calculated.

The temperature at the end of the last section in the circuit is the actual fluid temperature at the

terminal equipment. The pressure analysis also moves forward through the network, starting at

the pump section.

Fig. 1-12 through Fig. 1-16 are examples of basic liquid system. The systems described in the

next few pages use water, although brine and glycol may be substituted in the piping network

system.

Two-Pipe Direct Return Systems

A two-pipe direct return system illustrated in Fig. 1-12 is difficult to balance because the terminal

equipment with the shortest supply line also has the shortest return line. The circuit analysis

report will indicate the balancing requirements of each circuit.

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 25

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Fig. 1-12:Two-Pipe Direct Return

Two-Pipe Reverse Return Systems

A two-pipe reverse return system illustrated in Fig. 1-13 provides uniform pressure drop through

all the heating units. The length of straight piping through all the circuits is approximately the

same. The unbalanced pressure heads are primarily due to equipment and fitting losses in the

circuits.

Fig. 1-13: Two-Pipe Reverse Return

Primary-Secondary Systems and Loops

By definition, a secondary system is created when a booster pump is located in one of the

sections. Fig. 1-3 shows a primary system with three secondary systems downstream of these

booster pumps.

Fig. 1-14 shows a reverse-return primary loop and direct-retur secondary loops. Since there are

no booster pumps, the entire network is treated as one primary system.

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 26

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Fig. 1-14: Primary-Secondary

Systems and Loops

Primary loops may be direct-return or reverse-return. They may be combined with one or more

secondary loops that may all be direct-return, reverse-return, or a combination of the two.

From Fig. 1-13 and Fig. 1-14, you can see that secondary systems are also secondary loops, but

secondary loops are not always secondary systems.

Three-Pipe Systems

The three-pipe system illustrated in Fig. 1-15 uses two piping systems to supply the terminal

equipment, one for cold water and the other for hot water, along with a common return.

Fig. 1-15: Three Pipe Systems

The three-pipe system may be terminal mix or return mix. In both types, hot and cold water is

provided at the terminal equipment. In the terminal mix system, hot and cold water are mixed at

the terminal equipment to obtain the required equipment temperature.

In the return mix system, each terminal equipment in the network uses either hot water or cold

water and discharges into a common return system where mixing takes place.

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 27

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Four-Pipe Systems

The four-pipe system, illustrated in Fig. 1-16, derives its name from the four pipes to and from

each terminal equipment: cold water supply, cold water return, hot water supply and hot water

return. The four-pipe system satisfies the variations in the heating and cooling loads by providing

independent sources of heating and cooling to the room or zone. During the period between

seasons, any unit can be operated at maximum heating or maximum cooling.

Fig. 1-16: Four Pipe Systems

Systems

Systems types are based on the application, fluid type and piping arrangement (open or closed)

System System Fluid Network

System Type System Description

Group Open/Closed Type Type

CW closed water closed chilled water

HW closed water closed hot water heating

C open water closed condenser water

DCW closed water open domestic cold water

DHW closed water open domestic hot water

Liquids GLYCOL closed glycol closed 50% ethylene glycol 25%

BRINE closed brine closed calcium chloride brine

DIESEL closed diesel open diesel fuel oil #2 gasoline

GASOLINE closed gasoline open (petrol) high temperature

HTHW closed water closed hot water

STEAM closed steam open steam supply

Steam CONDENSATE open/closed steam open steam condensate return

FUELGAS closed fuel gas open fuel gas supply

Gas

STORM open water open storm drainage

Other DRAIN open --- open sanitary drainage

VENT open air open sanitary vent

Fig. 1-17: System, Fluid and Network Types

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 28

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

System Engineering Units

Remarks

Group Flow Velocity Pressure

ft of

Liquids gpm ft/sec psia where appropriate

liquid

Steam lb/hr ft/min psi

Gas cfh ft/min psi

Other fixture units or drainage area

Fig. 1-18: System Types and Engineering Units

Density and kinematic viscosity are used in frictional loss calculations. The specific heat is used in

thermal analysis. Default fluids are 50% ethylene glycol, 25% calcium chloride, diesel fuel oil #2,

and gasoline with a specific gravity of 0.72. In Fig. 1-19 and Fig. 1-20, the defaults shown express

kinematic viscosity in 10-6. Glycol may be a different concentration of ethylene glycol or glycerol.

Brine may be a different concentration of sodium chloride or calcium chloride. Diesel fuel oil and

gasoline may represent different blends of these liquids.

Temperature oF

Liquid Properties

-30 0 30 60 100 150 212

Density (lb/cu ft)

62.42 62.37 62.00 61.20 59.81

Kinematic viscosity (sq

WATER 20.0 12.17 7.39 4.76 3.2

ft/sec)

Specific heat (Btu/lb oF) 1.0 1.0 1.0 1.0 1.005

Density (lb/cu ft)

67.98 67.55 67.11 66.55 65.74 64.68 63.12

Kinematic viscosity (sq

GLYCOL 595.0 190.0 85.4 48.6 22.6 12.5 6.4

ft/sec)

Specific heat (Btu/lb oF) 0.70 0.73 0.76 0.78 0.81 0.85 0.88

Density (lb/cu ft)

78.59 78.21 77.71 77.21 76.09

Kinematic viscosity (sq

BRINE 171.7 77.5 34.7 21.8 8.9

ft/sec)

Specific heat (Btu/lb oF) 0.66 0.67 0.68 0.69 0.71

Density (lb/cu ft)

59.2 57.4 56.1 54.9 53.0 51.1

Kinematic viscosity (sq

DIESEL 376.7 161.5 80.7 48.3 29.1 7.5

ft/sec)

Specific heat (Btu/lb oF) 0.47 0.48 0.49 0.50 0.51 0.52

Density (lb/cu ft)

46.1 45.5 44.9 44.7 44.3 42.4

GASOLI Kinematic viscosity (sq

11.0 9.8 8.8 7.0 5.5 3.0

NE ft/sec)

Specific heat (Btu/lb oF) 0.47 0.48 0.49 0.50 0.51 0.52

Fig. 1-19: Properties of Liquids (Water, Glycol, Brine, Diesel and Gasoline)

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 29

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

High Temperature Hot Water

The temperature range for water in Fig. 1-19 is 32F to 212F. Fig. 1-20 shows the properties of

water for the HTHW system type (high temperature hot water). The temperature range for

HTHW is 212F to 450F. It includes the temperature range defined in the 1987 ASHRAE

Handbook for medium temperature hot water (212 to 350). An additional fluid property,

saturation pressure, is included in this table and is included in the output reports for your

information. The saturation pressures are not used in the calculations.

Saturation Kinematic Specific

Temperat Density

Pressure Viscosity Heat

ure lb/cu ft

PSIG sq ft/sec Btu/lb oF

212 0 59.81 3.2 1.0055

220 2.5 59.63 3.0 1.0068

240 10.3 59.10 2.7 1.0104

260 20.7 58.51 2.5 1.0148

280 34.5 57.94 2.3 1.020

300 52.3 57.31 2.1 1.26

350 119.9 55.59 1.9 1.044

400 232.6 53.65 1.7 1.067

450 407.9 51.55 1.5 1.095

Fig. 1-20: Properties of High Temperature Hot Water

Properties of Steam

Fig. 1-21 and Fig. 1-22, compiled from information published in Flow of Fluids, Crane, pp. A-2, A-

9, A-12 to A-14, show the properties of steam. Portions of this information can also be found in

manufacturers' steam tables. The information in this table is used in the thermal analysis to

determine the quality of steam

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 30

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Fig. 1-21 & 1-22: Properties of Steam

Enthalpy

Specific Enthalpy Kinematic Isentropic

Pressure o Saturate Specific

Temp. F Volume Evaporatn Viscosity Exponent

PSIG d Liquid Heat Cp

cuft/lb Btu/lb sq ft/sec K = Cp/Cy

Btu/lb

0 212.0 26.80 180.1 970.3 2.34 x 10-4 0.45 1.32

1 215.5 25.13 183.6 968.1 2.19 x 10-4 0.45 1.32

2 218.7 23.72 186.8 966.0 2.07 x 10-4 0.45 1.32

3 221.7 22.47 189.8 964.1 1.96 x 10-4 0.45 1.32

4 224.5 21.35 192.7 962.3 1.87 x 10-4 0.45 1.32

5 227.3 20.34 195.5 960.5 1.78 x 10-4 0.47 1.31

6 229.9 19.42 198.2 958.8 1.70 x 10-4 0.47 1.31

7 232.4 18.58 200.7 957.2 1.62 x 10-4 0.47 1.31

8 234.9 17.81 203.2 955.6 1.56 x 10-4 0.47 1.31

9 237.2 17.11 205.6 954.1 1.49 x 10-4 0.47 1.31

10 239.5 16.46 207.9 952.5 1.44 x 10-4 0.47 1.31

11 241.7 15.86 210.1 951.1 1.39 x 10-4 0.47 1.31

12 243.8 15.31 212.2 949.7 1.34 x 10-4 0.47 1.31

13 245.9 14.79 214.3 948.3 1.29 x 10-4 0.47 1.31

14 247.9 14.31 216.4 946.9 1.25 x 10-4 0.47 1.31

15 249.8 13.86 218.3 945.6 1.30 x 10-4 0.47 1.31

16 251.7 13.43 220.3 944.3 1.26 x 10-4 0.47 1.31

17 253.6 13.03 222.2 943.0 1.22 x 10-4 0.47 1.31

18 255.4 12.66 224.0 941.8 1.19 x 10-4 0.47 1.31

19 257.1 12.31 225.7 940.6 1.16 x 10-4 0.47 1.31

20 258.8 11.98 227.5 939.5 1.13 x 10-4 0.47 1.31

21 260.5 11.67 229.2 938.3 1.10 x 10-4 0.47 1.31

22 262.2 11.37 230.9 937.2 1.07 x 10-4 0.47 1.31

23 263.8 11.08 232.5 936.1 1.04 x 10-4 0.47 1.31

24 265.4 10.82 234.1 935.0 1.02 x 10-4 0.47 1.31

25 266.9 10.56 235.6 934.0 0.99 x 10-4 0.47 1.31

30 274.1 9.45 243.0 928.9 0.89 x 10-4 0.47 1.31

35 280.7 8.56 249.8 924.2 0.86 x 10-4 0.47 1.31

40 286.8 7.83 256.0 919.8 0.79 x 10-4 0.47 1.31

45 292.4 7.20 261.8 915.7 0.73 x 10-4 0.47 1.31

50 297.7 6.68 267.2 911.8 0.67 x 10-4 0.47 1.31

55 302.7 6.23 272.4 908.1 0.66 x 10-4 0.47 1.31

60 307.3 5.83 277.2 904.6 0.62 x 10-4 0.47 1.31

65 311.8 5.49 281.8 901.3 0.59 x 10-4 0.47 1.31

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 31

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Enthalpy

Specific Enthalpy Kinematic Isentropic

Pressure o Saturate Specific

Temp. F Volume Evaporatn Viscosity Exponent

PSIG d Liquid Heat Cp

cuft/lb Btu/lb sq ft/sec K = Cp/Cy

Btu/lb

70 316.4 5.18 286.2 898.0 0.55 x 10-4 0.47 1.31

75 320.1 4.91 290.4 894.8 0.53 x 10-4 0.47 1.31

80 323.9 4.66 294.4 891.9 0.50 x 10-4 0.47 1.31

85 327.6 4.44 298.2 899.0 0.48 x 10-4 0.47 1.31

90 331.2 4.24 301.9 886.1 0.46 x 10-4 0.48 1.30

95 334.6 4.06 305.5 883.3 0.44 x 10-4 0.48 1.30

100 337.9 3.89 308.9 880.7 0.42 x 10-4 0.48 1.30

105 341.1 3.74 312.3 878.1 4.27 x 10-6 0.48 1.30

110 344.2 3.59 315.5 875.5 4.10 x 10-6 0.48 1.30

115 347.2 3.46 318.7 873.0 3.95 x 10-6 0.48 1.30

120 350.1 3.34 321.7 870.7 3.82 x 10-6 0.48 1.30

125 352.9 3.23 324.7 868.3 3.69 x 10-6 0.48 1.30

130 355.6 3.12 327.6 865.9 3.56 x 10-6 0.48 1.30

135 358.3 3.02 330.4 863.7 3.45 x 10-6 0.48 1.30

140 360.9 2.93 333.1 861.5 3.35 x 10-6 0.48 1.30

145 363.4 2.84 335.8 859.3 3.30 x 10-6 0.48 1.30

150 365.9 2.76 338.4 857.2 3.33 x 10-6 0.48 1.30

155 368.3 2.68 340.9 855.0 3.24 x 10-6 0.48 1.30

160 370.6 2.61 343.4 853.0 3.14 x 10-6 0.48 1.30

165 372.9 2.54 345.9 850.9 3.06 x 10-6 0.48 1.30

170 375.2 2.47 348.3 848.9 2.98 x 10-6 0.48 1.30

175 377.4 2.41 350.7 846.9 2.90 x 10-6 0.48 1.30

180 379.5 2.35 353.0 845.0 2.83 x 10-6 0.48 1.30

185 381.6 2.30 355.2 843.1 2.77 x 10-6 0.48 1.30

190 383.7 2.24 357.4 841.2 2.70 x 10-6 0.48 1.30

195 385.8 2.19 359.6 839.2 2.64 x 10-6 0.48 1.30

200 387.8 2.13 361.9 837.4 2.57 x 10-6 0.48 1.30

210 391.7 2.04 366.0 833.8 2.46 x 10-6 0.48 1.30

220 395.5 1.95 370.1 830.3 2.35 x 10-6 0.48 1.30

230 399.1 1.88 374.1 826.8 2.27 x 10-6 0.48 1.30

240 402.7 1.81 377.8 823.4 2.18 x 10-6 0.48 1.30

250 406.1 1.74 381.6 820.1 2.10 x 10-6 0.48 1.30

Fig. 1-21 & 1-22: Properties of Steam

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 32

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Pipe Materials

Materi Material

Description Description

al Code Code

S40 Schedule 40 steel CI 250 250 psi cast iron

S80 Schedule 80 steel CK Type K copper

ST Standard weight steel CL Type L copper

XS Extra strength steel CM Type M copper

CI 125 125 psi cast iron PVC PVC schedule 40 plastic

CI 175 175 psi cast iron CPVC CPVC schedule 40 plastic

Fig. 1-23: Pipe Materials

The default information in the pipe materials library was compiled from the Hydraulic Institute

Engineering Data Book and the Hydraulic Handbook, Colt Industries. It can vary slightly with

manufacturer. Density (lb/cu ft) is used to calculate the weight of a pipe section. Conductivity

(btu/hr.oF.sp ft. in) is used in the thermal analysis. Inside roughness factors (ft) for open and

closed piping systems are used in the Colebrook equation to calculate the frictional loss in the

pipe .

Pipe Nominal

Roughness Factor Conduc

Materi Description Diameter Density

t-ivity

al Minim Maxim Closed Open

S40 Steel: Schedule 40 .250" 24" .00015 .0018 489.02 2.5

S80 Steel: Schedule 80 .250" 24" .00015 .0018 489.02 2.5

Steel: Standard

ST .250" 36" .00015 .0018 489.02 2.5

Weight

XS Steel: Extra Strength .250" 36" .00015 .0018 489.02 2.5

Cl 125 Cast Iron: 125 psi 3" 48" .00085 .0018 483.84 0.767

Cl 175 Cast Iron: 175 psi 3" 48" .00085 .0018 483.84 0.767

Cl 250 Cast Iron: 250 psi 6" 36" .00085 .0018 483.84 0.767

.00000 .00000

CK Copper: Type K .250" 12" 558.14 16.33

5 5

.00000 .00000

CL Copper: Type L .250" 12" 558.14 16.33

5 5

.00000 .00000

CM Copper: Type M .375" 12" 558.14 16.33

5 5

.00000 .00000

PVC Plastic: PVC .500" 12" 94.7 0.1

5 5

.00000 .00000

CPVC Plastic: CPVC .500" 6" 105.7 0.079

5 5

Fig. 1-24: Pipe Material Properties

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 33

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

The minimum and maximum nominal diameter limits shown in Fig. 1-24 indicate the range of

sizes in Fig. 1-24, Fig. 1-26, Fig. 1-27, and Fig. 1-28. These figures contain inside and outside

diameters for each pipe material and each nominal size. A blank in these tables indicates that

the nominal size for that particular pipe material is not available.

Roughness Factors

Roughness factors shown in Fig. 1-24 for closed pipe systems were obtained from ASHRAE

Handbook: 1985 Fundamentals, Table 2, p. 2-10. Piping for open systems such as cooling tower

water systems is subject to corrosion and scaling over a period of time. Open system roughness

factors are included in the library, even though they are not a property of the pipe material but a

function of the usage and age of the pipes. The value shown in Fig. 1-24 for Schedule 40 steel is

based on Handbook of Air-Conditioning System Design, Chart 4, p. 3-23. The Colebrook-White

equation shown as equation 20 in Pipe Sizing was applied using trial values for the friction factor

f until results approximated those of that chart.

Values for other steel pipes and for cast iron pipes are assumed to be the same as those for the

Schedule 40 steel pipes with the same age and usage. The effect of corrosion on copper pipes is

assumed to be negligible. Plastic pipes are not affected by corrosion. The values shown in Fig. 1-

24 are identical for both closed and open systems.

Physical Dimensions

Schedule 40 Schedule 80 Stand Weight Extra Strong

Nomin

steel Steel Steel Steel

al Pipe

Diameter (in.) Diameter (in.) Diameter (in.) Diameter (in.)

Size

Outsid Outsid Outsid Outsid

In. Inside Inside Inside Inside

e e e e

1/4 .540 .364 .540 .302 .540 .364 .540 .302

3/8 .675 .493 .675 .423 .675 .493 .675 .423

1/2 .840 .622 .840 .546 .840 .622 .840 .546

3/4 1.050 .824 1.050 .742 1.050 .824 1.050 .742

1 1.315 1.049 1.315 .957 1.315 1.049 1.315 .957

1 1/4 1.660 1.380 1.660 1.278 1.660 1.380 1.660 1.278

1 1/2 1.900 1.610 1.900 1.500 1.900 1.610 1.900 1.500

2 2.375 2.067 2.375 1.939 2.375 2.067 2.375 1.939

2 1/2 2.875 2.469 2.875 2.323 2.875 2.469 2.875 2.323

3 3.500 3.068 3.500 2.900 3.500 3.068 3.500 2.900

4 4.500 4.026 4.500 3.826 4.500 4.026 4.500 3.826

5 5.563 5.047 5.563 4.813 5.563 5.047 5.563 4.813

6 6.625 6.065 6.625 5.761 6.625 6.065 6.625 5.761

8 8.625 7.981 8.625 7.625 8.625 7.981 8.625 7.625

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 34

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

10 10.750 10.020 10.750 9.562 10.750 10.020 10.750 9.750

12 12.750 11.938 12.750 11.374 12.750 12.000 12.750 11.750

14 14.000 12.500 14.000 13.250 14.000 13.000

16 16.000 15.000 16.000 14.312 16.000 15.250 16.000 15.000

18 18.000 16.876 18.000 16.124 18.000 17.250 18.000 17.000

20 20.000 18.812 20.000 17.938 20.000 19.250 20.000 19.000

22 22.000 19.750 22.000 21.250 22.000 21.000

24 24.000 22.624 24.000 21.562 24.000 23.250 24.000 23.000

26 26.000 25.250 26.000 25.000

28 28.000 27.250 28.000 27.000

30 30.000 29.250 30.000 29.000

32 32.000 31.250 32.000 31.000

34 34.000 33.250 34.000 33.000

36 36.000 35.250 36.000 35.000

Fig. 1-25: Pipes Material Physical Dimensions - Steel

(adapted from Hydraulic Institute Engineering Data Book, pp. 121-127)

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 35

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Nominal 125 PSI Cast Iron 175 PSI Cast Ironl 250 PSI Cast lron

Pipe Size Diameter (in.) Diameter (in.) Diameter (in.)

In. Outside Inside Outside Inside Outside Inside

2

2 1/2

3 3.96 3.06 3.96 3.00

4 5.00 4.04 5.00 3.96

5

6 7.10 6.08 7.10 6.00 7.22 6.00

8 9.30 8.18 9.30 8.10 9.42 8.00

10 11.40 10.16 11.40 10.04 11.60 10.00

12 13.50 12.14 13.50 12.00 13.78 12.00

14 15.65 14.17 15.65 14.01 15.98 14.00

16 17.80 16.20 17.80 16.02 18.16 16.00

18 19.92 18.18 19.92 18.00 20.34 18.00

20 22.06 20.22 22.06 20.00 22.54 20.00

22

24 26.32 24.22 26.32 24.00 26.90 24.00

26

28

30 32.40 30.00 32.74 30.00 33.46 30.00

32

34

36 38.70 35.98 39.16 36.00 40.04 36.00

42 45.10 42.02 45.58 42.02

48 51.40 47.98 51.98 48.06

Fig. 1-26: Pipes Material Physical Dimensions - Cast Iron

(Hydraulic Handbook, Colt Industries, p. 174)

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 36

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Nominal Type K Copper Type L Copper Type M Copper

Pipe Size Diameter (in.) Diameter (in.) Diameter (in.)

In. Outside Inside Outside Inside Outside Inside

1/4 .375 .305 .375 .315

3/8 .500 .402 .500 .430 .500 .450

1/2 .625 .527 .625 .545 .625 .569

3/4 .875 .745 .875 .785 .875 .811

1 1.125 .995 1.125 1.025 1.125 1.055

1 1/4 1.375 1.245 1.375 1.265 1.375 1.291

1 1/2 1.625 1.481 1.625 1.505 1.625 1.527

2 2.125 1.959 2.125 1.985 2.125 2.009

2 1/2 2.625 2.435 2.625 2.465 2.625 2.495

3 3.125 2.907 3.125 2.945 3.125 2.981

4 4.125 3.857 4.125 3.905 4.125 3.935

5 5.125 4.805 5.125 4.875 5.125 4.907

6 6.125 5.741 6.125 5.845 6.125 5.881

8 8.125 7.583 8.125 7.725 8.125 7.785

10 10.125 9.449 10.125 9.625 10.125 9.701

12 12.125 11.315 12.125 11.565 12.125 11.617

Fig. 1-27: Pipes Material Physical Dimensions - Copper

(reproduced with permission from ASPE Data Book, P. 10-8, 10-10, 10-12)

Nominal Schedule 40 - PVC Schedule 40 - CPVC

Pipe Size Diameter (in.) Diameter (in.)

(in.) Outside Inside Outside Inside

3/8

1/2 .8400 .6220 .8400 .6200

3/4 1.050 .824 1.050 .824

1 1.315 1.049 1.315 1.049

1 1/4 1.660 1.380 1.660 1.380

1 1/2 1.900 1.610 1.990 1.610

2 2.375 2.067 2.375 2.067

2 1/2 2.875 2.469 2.875 2.469

3 3.500 3.068 3.500 3.068

4 4.500 4.026 4.500 4.026

5

6 6.625 6.065 6.625 6.065

8 8.625 7.981

10 10.750 10.020

12 12.750 11.938

Fig. 1-28: Pipes Material Physical Dimensions – Plastic

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 37

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Pipe Age

Fig. 1-29 shows the correction factor that can be applied to the frictional loss in order to account

for the age of the pipe. This factor is a function of the pipe size (surface areas to flow area). Fig.

1-29, is based on Hydraulic Handbook, Colt Industries, Table 6, p. 64, has been modified for pipes

used in buildings. Pipe age factors and pipe material roughness factors are closely related. You

can use the correction factor to design closed systems with any pipe material. The roughness

factors for pipes shown in Fig. 1-24 are for new and clean pipes and does not account for the age

of the pipe.

Age of Pipes Small Pipes Medium Pipes Large Pipes

(Years) (1" to 3") (4" to 12") (14" to 48")

0 1.00 1.00 1.00

5 1.40 1.35 1.30

10 2.20 1.90 1.60

15 3.60 2.70 1.80

20 5.00 3.50 2.00

25 6.30 4.20 2.10

30 7.25 4.73 2.20

35 8.10 5.20 2.30

40 8.75 5.58 2.40

45 9.25 5.93 2.60

50 9.60 6.23 2.86

Fig. 1-29: Increase in Friction Loss Due to Aging of Pipe

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 38

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Insulation Types

Fig. 1-30 shows the insulation types used for piping in buildings It includes the five insulation

classes with typical insulation types within each class. For information on applications for each

insulation type, turn to the ASPE Data Book, Vol. 1, Fundamentals of Plumbing Design, 1983-

1984, p. 12-1. Insulation density is used to determine the weight of the insulation for the pipe

section. Conductivity is used in the thermal analysis.

Code Densit Thermal Conductivity BTU / (hr ft2 oF per inch)

Nam Description y

e Lbs/ft3 0 30 75 100 200 300 400

Elastomeric 0.2

EL 2.0 0.23 0.27 0.28 0.37 0.50

Class A 2

Fibrous Glass 0.2

FG 5.0 0.22 0.25 0.26 0.33 0.40 0.50

Class B 0

Urethane Foam 0.1

UF 2.0 0.16 0.17 0.20 0.25 0.30

Class C 5

Phenolic Foam 0.1

PF 4.0 0.20 0.22 0.28 0.35 0.50

Class D 9

Calcium Silicate

CS 13.0 0.38 0.41 0.44 0.48

Class E

85% Magnesia

MG 12.0 0.35 0.38 0.42 0.46

Class E

Fig. 1-30: Properties of Insulation

Fig. 1-31 shows an alternative way to enter the insulation thickness for each pipe section. It uses

the recommended thickness for insulation code MG and pipe material code S40 as an example

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 39

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Pipe Size Temperature Range (oF)

(in) 110 160 210 250 300 400 500

1/2 1 1 1 1.5 1.5 2 2.5

3/4 1 1 1 1.5 1.5 2 2.5

1 1 1 1 1.5 1.5 2 2.5

1 1/4 1 1 1 1.5 1.5 2 2.5

1 1/2 1 1 1 1.5 1.5 2 2.5

2 1 1 1 1.5 1.5 2 2.5

2 1/2 1 1 1 2 2 2.5 3

3 1 1 1 2 2 2.5 3

4 1 1 1 2 2 2.5 3

5 1 1 1 2 2 2.5 3

6 1 1 1 2 2 3 3.5

8 1.5 1.5 1.5 2 2 3 3.5

10 1.5 1.5 1.5 2.5 2.5 3 3.5

12 1.5 1.5 1.5 2.5 2.5 3 3.5

14 1.5 1.5 1.5 2.5 2.5 3.5 4

16 1.5 1.5 1.5 2.5 2.5 3.5 4

18 1.5 1.5 1.5 2.5 2.5 3.5 4

20 1.5 1.5 1.5 2.5 2.5 3.5 4

22 1.5 1.5 1.5 2.5 2.5 3.5 4

24 1.5 1.5 1.5 2.5 2.5 3.5 4

26 1.5 1.5 1.5 2.5 2.5 3.5 4

28 1.5 1.5 1.5 2.5 2.5 3.5 4

30 1.5 1.5 1.5 2.5 2.5 3.5 4

32 1.5 1.5 1.5 2.5 2.5 3.5 4

34 1.5 1.5 1.5 2.5 2.5 3.5 4

36 1.5 1.5 1.5 2.5 2.5 3.5 4

42 1.5 1.5 1.5 2.5 2.5 3.5 4

48 1.5 1.5 1.5 2.5 2.5 3.5 4

Fig. 1-31: Insulation Thickness vs. Pipe Size and Temperature

Insulation Type: 85% Magnesia / Class E.

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings & Merrill, LLP 40

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Cross-Checking Tables

Fig. 1-32 shows the various types of pipe materials used for different types of piping systems.

Pipe S40 S80 ST XS Cl 125 CK CL CM PVC CPVC

Material

Sched Sched X 125 psi

Std Wt Type K Type L Type M Sched Sched

40 80 Strong Cast

Steel Copper Copper Copper 40 PVC 40 CPVC

System Steel Steel Steel Iron

Chilled

X X

Water

Condenser

X X

Water

Hot Water

X X X

(HVAC)

Domestic

X X X X

Cold Water

Domestic

X X X X

Hot Water

Glycol X

Brine X

Diesel X X X

Gasoline

Storm

X X X X

Drainage

Sanitary

X X X X

Drainage

Sanitary

Vents

Fuel Gas X

High Temp.

X X X

Hot Water

Steam X X X

Condensat

X X X

e

Fig. 1-32: System vs. Pipe Material

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings

23 & Merrill, LLP 23

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

EL FG UF PF CS MG

SYSTEMS

INSULATION Elasto- Fibrous Uretha

ne

85%

Phenoli Calcium Magnes

meric Glass Foam c Foam Silicate ia

CW Chilled Water X X X X

C Condensed Water X

HW Hot Water HVAC X

DCW Domestic Cold Water X X X X

DHW Domestic Hot Water X X X

GLYCOL Glycol X X X

BRINE Brine X X X

DIESEL Diesel

GASOL Gasoline

STORM Storm Drainage

DRAIN Sanitary Drainage

VENT Sanitary Vents

FUELGAS Fuel Gas

HTHW High Temp. Hot X X X

Water

STEAM Steam X X X

COND Condensate X X X

Fig. 1-33: System vs. Insulation

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings

24 & Merrill, LLP 24

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Fixture Unit Data:

Fixture units are used to estimate the flow quantities in domestic water supply and sanitary

drainage systems. Fixture units are quantitative values associated with the fixture to account for

the diversity of usage (not all fixtures are in use at the same time)

The total fixture unit data is used to calculate the flow rate in the main section. If a diversity

factor is also entered for the main section, then first calculate the flow based on the sum of all

total fixture units in the system, and multiply this flow by the diversity factor.

The remaining system analysis and design procedures are described in earlier sections of this

engineering basis and are summarized below.

A flow rate is assigned to all sections in the network based on the required flow rate at

the fixtures. See Network Analysis.

Pipe sizing options can be based on pressure drop per unit length, velocity or maximum

flow. See Sizing Criteria.

The Colebrook-White and Darcy-Weisbach equations are used to calculate the pressure

losses through pipe sections. See Pipe Sizing.

Fitting and valve loss calculations can be based on velocity pressure factors, K, or

equivalent lengths, L/D. See Fittings and Valves.

Heat gains and losses and temperature changes in the system are based on the thermal

data that you can specify in the input forms. See Thermal Analysis.

Static and dynamic heads are calculated for all nodes in the pipe network. See Circuit

Pressure Analysis.

The system can be designed to provide the minimum pressure required at fixtures and

maintain the maximum pressure limit at the water main. See Circuit Balancing.

The primary pump station is analyzed if a primary pump is used to develop the pressure

in the main pipe section. See Pump Performance Based on System Requirements.

Booster pumps can be located in any supply pipe circuit to increase the pressure in the

circuit. See Network Analysis.

Pressurization tanks can be located on the discharge side of the pump, on the suction

side of the pump, or at the high point of the pipe system. See Pressurization Tanks.

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings

25 & Merrill, LLP 25

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Sizing Criteria

The values, shown in Fig. 1-34, were obtained by reading points along lines drawn between two

points in ASHRAE Handbook: 1985 Fundamentals, Figure 1, p. 34.3. The criteria is based on the

following points in that figure.

Criteria Point 1 Point 2

Low 3 ft/100 ft for 1/2-in. pipe 10 ft/sec for 24-in. pipe

Design 5 ft/100 ft for 1/2-in. pipe 12 ft/sec for 24-in. pipe

High 7 ft/100 ft for 1/2-in. pipe 15 ft/sec for 24-in. pipe

Maximum 8 ft/100 ft for 1/2-in. pipe 18 ft/sec for 24-in. pipe

Pipe Criteria Low Criteria: Design Criteria: High Criteria: Maxim

Size P.D. / Veloc. Flow P.D. / Veloc. Flow P.D. / Veloc. Flow P.D. / Veloc. Flow

100 ft (ft/sec) (gpm) 100 ft (ft/sec) (gpm) 100 ft (ft/sec) (gpm) 100 ft (ft/sec) (gpm)

3/8 3.3 1.5 0.70 5.5 1.85 0.95 7.5 2.25 1.25 8.5 2.5 1.25

1/2 3.0 1.6 1.5 5.0 2.2 2.0 7.0 2.7 2.5 8.0 2.8 2.75

3/4 2.6 1.9 3.0 4.5 2.5 4.1 6.5 3.0 5.0 7.3 3.3 5.5

1 2.5 2.2 6.0 4.1 2.75 7.5 6.0 3.5 9.0 6.8 3.8 10

1 1/4 2.25 2.5 12 3.8 3.25 15 5.6 3.9 17 6.4 4.5 20

1 1/2 2.2 2.7 17 3.5 3.5 22 5.2 4.2 27 6.3 5.0 30

2 2.0 3.0 32 3.2 3.9 40 4.9 5.0 50 6.0 5.5 55

2 1/2 1.8 3.4 52 3.0 4.5 65 4.6 5.5 80 5.5 5.9 90

3 1.7 3.8 90 2.8 5.0 120 4.3 5.8 130 5.3 6.5 160

4 1.6 4.1 170 2.6 5.5 210 3.9 6.5 260 5.0 7.5 300

5 1.5 5.0 300 2.4 6.0 390 3.7 7.5 480 4.8 8.5 550

6 1.5 5.5 500 2.2 6.5 600 3.4 8.1 750 4.5 9.5 850

8 1.3 6.0 950 2.1 7.5 1200 3.2 9.1 1500 4.2 10.5 1700

10 1.25 7.0 1650 1.80 8.5 2100 3.0 10.0 2500 4.0 12.0 3000

12 1.2 7.5 2500 1.70 9.0 3200 2.8 11.0 4000 3.8 13.2 4600

14 1.1 7.8 3200 1.65 9.5 4000 2.7 11.5 5000 3.7 13.5 6000

16 1.1 8.2 4500 1.60 10.0 5500 2.60 12.0 7000 3.5 14.8 8000

18 1.05 8.8 6000 1.55 10.5 7500 2.50 13.25 9000 3.4 15.5 11000

20 1.02 9.0 8000 1.60 11.5 9700 2.40 13.5 12000 3.3 16.5 14500

22 1.05 9.7 10000 1.55 11.8 12500 2.35 14.4 16000 3.2 17.4 19000

24 1.00 10.0 12000 1.50 12.0 15000 2.30 15.0 19000 3.1 18.0 22000

26 1.00 10.5 14000 1.45 12.3 17000 2.25 15.5 22000 3.1 18.7 26000

28 0.95 11.0 16500 1.45 12.6 20000 2.25 16.0 25000 3.05 19.4 31000

30 0.95 11.5 20000 1.40 13.0 23000 2.20 16.5 29000 3.05 20.0 36000

32 0.93 11.7 24000 1.36 13.2 26000 2.13 16.7 33000 3.03 20.6 41000

34 0.91 11.9 26000 1.33 13.4 30000 2.06 16.9 37000 3.01 21.3 46000

36 0.90 12.0 28000 1.30 13.5 33000 2.00 17.2 42000 3.0 22.0 52000

42 0.85 12.5 36000 1.25 14.5 44000 1.95 18.0 55000 2.95 22.0 65000

48 0.80 13.0 45000 1.20 15.0 52000 1.85 18.0 65000 2.80 22.0 75000

Fig. 1-34: Pipe Sizing Criteria

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings

26 & Merrill, LLP 26

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Fittings and Valves

Dynamic Pressure Losses

Dynamic pressure losses are a function of the geometry of the fitting or valve, and the flow

velocity. There are two methods for determining the dynamic pressure losses through valves

and fittings. In the first method, the velocity pressure is multiplied by a resistance factor K. The

K factor is a function of the fitting or valve type and its diameter.

2

V

PD (fitting / valve) = K

2g

where: PD = pressure drop through fitting or valve

K = resistance factor for fitting or valve

V = fluid velocity

2g = gravitational constant

Fig. 1-35 and Fig. 1-36 show the coefficient C and exponent E for the equation that determines

the resistance factor K at varying diameters. The equation is:

K = C (diameter )E

Default values for C and E are shown in Fig. 1-35 and Fig. 1-36.

Values for water were estimated by reading off points from graphically presented data in the

Hydraulic Institute Engineering Data Book, pp. 58 and 59. That data is reproduced with permis-

sion in Fig. 1-39 and Fig. 1-40 in this engineering basis.

Values for glycol, brine, diesel and gasoline were based on the water K factors using K x 1/specific

gravity + 10%. Apply a contingency factor of 10% to account for the range of available qualities

and types for these liquids.

Another method to estimate pressure losses in valves and fittings is to use equivalent length to

diameter (L/D) ratios for different fluid types. Fig. 1-37 and Fig. 1-38 show default L/D. All values

are approximations.

The pressure loss through the fitting or valve is the frictional loss through an equivalent length of

pipe calculated using the Colebrook and Darcy-Weisbach equations.

L d (diameter)

L (Equivalent Length) =

D 12

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings

27 & Merrill, LLP 27

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

where L = length (ft)

D = diameter (ft)

d = diameter (in.)

The K factor for 90o bends of uniform diameters is shown in Fig. 1-41 (reproduced with

permission from the Hydraulic Institute Engineering Data Book, 1979). The K factor for

enlargement and contractions is obtained from these equations:

Resistance factor K for sudden and gradual enlargements in pipes

If 45 , If 45 < 180 ,

K 1 = 2.6 sin

2

1- 2

2

K1= 1 -

2

2

Resistance factor K for sudden and gradual contractions in pipes.

If 45 , If 45 < 180 ,

K 1 = 0.8 sin

2

1- 2

K 1 = .5 sin / 2 1 -

2

where = Angle of convergence or divergence in enlargements or contractions in pipes

= Ratio of smaller to larger pipe diameter

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings

28 & Merrill, LLP 28

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Velocity Pressure Factor K

Fitting Identification

No. Name Coefficient Exponent Description

C E

1 90EL1 1.50 -0.6092 Regular - screwed

90 elbow

Regular - flanged

3 90EL3 0.45 -0.2530

90 elbow

Long radius - flanged

4 90EL4 0.40 -0.4630

90 elbow

Regular - screwed

5 45EL1 0.35 -0.1365

45 elbow

Long radius - flanged

6 45EL2 0.22 -0.1414

45 elbow

7 BEND1 1.35 -0.50 Screwed return bend

Regular - flanged return

8 BEND2 0.425 -0.2550

bend

Long radius - flanged

9 BEND3 0.425 -0.5182

return bend

10 TEE1 (line flow) 0.90 0.0 Screwed tee

TEE1 (branch

11 1.85 -0.3747 Screwed tee

flow)

12 TEE3 (line flow) 0.265 -0.4695 Flanged tee

TEE3 (branch

13 1.00 -0.2851 Flanged tee

flow)

14 STRAIN 2.40 -0.5609 Basket strainer

15 UNION 0.083 -0.6644 Couplings & unions

16 INLET1 0.05 0.0 Inlet - bell mouthed

17 INLET2 0.50 0.0 Inlet - square edged

18 OUTLET 1.0 0.0 Outlet - all types

Fig. 1-35: Typical Fitting K Factors: S40 Pipe and Water (pressure loss calculation)

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings

29 & Merrill, LLP 29

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Velocity Pressure Factor

E

Valve Identification K = C (diameter)

No. Name Valve Description

Coefficient Exponent

C E

1 ANGLE1 4.50 -1.169 Angle Screwed

2 ANGLE2 4.25 -0.6861 Angle Flanged

3 BALANCING 12.50 -0.6438 Balancing

4 BALL 0.240 -0.4499 Ball

5 BFLY 12.50 -0.6438 Butterfly

6 CHECK1 3.50 -0.6374 Check Swing - Screwed

7 CHECK2 2.00 0.0 Check Swing - Flanged

8 GATE1 0.240 -0.4499 Gate - Screwed

9 GATE2 1.00 -1.1714 Gate - Flanged

10 GATE_EM 0.240 -0.4499 EM Gate

11 GATE_AM 0.240 -0.4499 AM Gate

12 GLOBE1 12.50 -0.6438 Globe - Screwed

13 GLOBE2 12.50 -0.3602 Glove - Flanged

14 GLOBE_EM 12.50 -0.6438 EM Globe

15 GLOBE_AM 12.50 -0.6438 AM Globe

16 LCK_SHLD 0.240 -0.4499 Lock shield

17 PLUG 12.50 -0.6438 Plug, cock

18 PRV 0.240 -0.449 Pressure Reducing

19 QUK_OPN 12.50 -0.6438 Quick Open

20 PREG 0.240 -0.449 Pressure Regulating

21 RELIEF 0.0 0.0 Relief (safety)

22 SOLEN 12.50 -0.6438 Solenoid

23 FOOT 0.80 0.0 Foot

24 OTHER 0.0 0.0 Other

Fig. 1-36: Typical Valve K Factors: S40 Pipe and Water (pressure loss calculation)

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings

30 & Merrill, LLP 30

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

L/D Ratio = Equivalent Length / Diameter Fitting Description

Fitting Identification

No. Name Stea

Water Glycol Brine diesel Gasol Gas

m

90EL1 regular - screwed

1 45 53 61 45 36 30 35

90 elbow

long radius -

2 90EL2 25 29 34 25 20 15 20

screwed 90 elbow

regular - flanged

3 90EL3 45 53 61 45 36 30 35

90 elbow

long radius - flanged

4 90EL4 25 29 34 25 20 15 20

90 elbow

regular - screwed

5 45EL1 25 29 34 25 20 20 25

45 elbow

long radius - flanged

6 45EL2 15 18 20 15 12 15 20

45 elbow

screwed

7 BEND1 90 105 123 90 72 70 75

return bend

regular - flanged

8 BEND2 90 105 123 90 72 70 75

return bend

long radius - flanged

9 BEND3 50 59 68 50 40 45 45

return bend

10 TEE1 line 20 24 27 20 16 20 25 screwed tee

11 TEE1 branch 65 76 89 65 52 65 70 screwed tee

12 TEE3 line 20 24 27 20 16 20 25 flanged tee

13 TEE3 branch 65 76 89 65 52 65 70 flanged tee

14 STRAINER 90 105 123 90 72 70 75 basket strainer

15 UNION 45 53 61 45 36 30 35 couplings & unions

16 INLET1 20 24 27 20 16 20 25 inlet bell-mouthed

17 INLET2 45 53 61 45 36 30 35 inlet square edged

18 OUTLET 65 76 89 65 52 65 70 outlet all types

Fig. 1-37: Typical Fitting Equivalent Length Data ( L/D Factors)

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings

31 & Merrill, LLP 31

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Valve Identif. L/D Ratio = Equivalent Length / Diameter Valve

No. Name Description

Water Glycol Brine Diesel Gasol. Steam Gas

1 ANGLE1 175 205 238 175 140 150 200 angle-screwed

2 ANGLE2 175 205 238 175 140 150 200 angle-flanged

3 BALANCING 350 410 477 350 280 30 350 balancing

4 BALL 10 12 14 10 8 10 10 ball

5 BFLY 50 59 68 50 40 0 0 butterfly

check swing -

6 CHECK1 150 176 204 150 120 75 100 screwed

check swing -

7 CHECK2 150 176 204 150 120 75 100 flanged

8 GATE1 10 12 14 10 8 10 10 gate - screwed

9 GATE2 10 12 14 10 8 10 10 gate - flanged

10 GATE_EM 10 12 14 10 8 10 10 EM gate

11 GATE_AM 10 12 14 10 8 10 10 AM gate

12 GLOBE1 350 410 477 350 280 300 350 globe - screwed

13 GLOBE2 350 410 477 350 280 300 350 globe - flanged

14 GLOBE_EM 350 410 477 350 280 300 350 EM globe

15 GLOBE_AM 350 410 477 350 280 300 350 AM globe

16 LCK_SHLD 10 12 14 10 8 10 10 lock shield

17 PLUG 150 176 204 150 120 130 150 plug, cock

18 PRV 10 12 14 10 8 10 10 pressure reducing

19 QUK_OPN 350 410 477 350 280 300 350 quick open

20 PREG 10 12 14 10 8 10 10 pressure regulator

21 RELIEF 0 0 0 0 0 0 0 relief (safety)

22 SOLEN 350 410 477 350 280 300 350 solenoid

23 FOOT 50 59 68 50 40 0 0 foot

24 OTHER 0 0 0 0 0 0 0 other

Fig. 1-38: Typical Valve Equivalent Length Data

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings

32 & Merrill, LLP 32

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Fig. 1-39 & Fig 1-40: Resistance Coefficients of Fittings & Valves

Fig. 1-41: Resistance Coefficients

of 90o Bends

Pressure Drop Through Control Valves

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings

33 & Merrill, LLP 33

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Liquids

Control valves are associated with sections with terminal equipment. The valve flow coefficient

Cv is defined as the flow in U.S. gallons per minute of water at 60F with a pressure drop of 1 psi.

Cv is a measure of the valve flow capacity and is determined by flow tests.

Q = Cv PD (62.4 / )

where Q = flow (GPM)

Cv = valve flow coefficient

PD = pressure drop through valve at full flow and standard conditions (psi)

= weight density of fluid (lb/cu ft)

The pressure drop for water and liquids at other temperatures is calculated using the equation:

l 1

0.25

PD1 = PD s

s s

where PD = pressure drop through valve (psi)

= density of liquid (lb/cu ft)

= kinematic viscosity (sq ft/sec)

l,s = subscripts representing given liquid and standard liquid (water at 60F)

The pressure drop in psi is converted to feet of liquid with the equation:

pd l 144

PD =

l

where PD = pressure drop through valve (liquids)

Steam

The equation for pressure drop for steam at full flow using the valve flow coefficient is:

Q / 3 C v 2

PD st =

P

where PDst = pressure drop through valve (psi)

Q = flow rate through section (lb/hr)

Cv = control valve coefficient

P = leaving pressure at control valve or minimum supply pressure to terminal

equipment (psia)

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings

34 & Merrill, LLP 34

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Note: A minimum supply pressure to the terminal equipment is required for Equation 11. If

you do not specify a valve for this input field, the default value will be assumed.

Domestic Water Fixtures

Terminal equipment definitions for domestic hot and cold water use the data categories shown

in Fig. 1-42. The supply code for flush valve is VALVE and for flush tanks, TANK. If you use these

codes, then the quantity of fixture units for the valve or tank is converted into flow GPM

according to Fig. 1-43. For other fixture types, you can estimate the terminal flow GPM. Supply

pressure must account for the minimum pressure and pipe size connection for the fixture.

Mini Trminl Private Use Public Use Minimum

Supply Fixture Units Fixture Units Connection

Descript. Press Flow

Code

PSIG GPM Cold Hot Tot Cold Hot Tot Cold Hot

Bathroom TANK 8 0 4.5 3 6 4.5 3 6 1/2 1/2

Group

Bathroom VALVE 8 0 6 3 8 4.5 3 6 1/2

1

Group

Water Closet TANK 8 0 3 0 3 5 0 5 3/8 0

Water Closet VALVE 15 0 6 0 6 10 0 10 1 0

Urinal TANK 8 0 3 0 3 3 0 3 3/8 0

Urinal VALVE 8 0 4 0 4 5 0 5 1 0

Shower Head TANK 8 3 2 2 3 4 4 5 1/2 1/2

Bathtub TANK 8 4 7.5 7.5 10 7.5 7.5 10 1/2 1/2

Lavatory TANK 8 2 1 1 1.5 2 2 3 3/8 3/8

Service Sink TANK 8 3 2 2 3 4 4 5 1/2 3/4

Kitchen Sink TANK 8 3 2 2 3 4 4 5 1/2 1/2

Restaurant TANK 8 3 3 3 4 3 3 4 1/2 1/2

Sink

Drinking TANK 8 2 1 0 1 2 0 2 3/8 0

Fountain

Dish Washer TANK 8 3 2 2 3 3 3 4 3/8 3/8

Clothes TANK 8 4 2 2 3 3 3 4 1/2 1/2

Washer

Fig. 1-42: Fixture Data: Domestic Hot and Cold Water

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings

35 & Merrill, LLP 35

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Flow Fixture Units Flow Fixture Units Flow Fixture Units

GPM Tank Valve GPM Tank Valve GPM Tank Valve

1 0 45 107 37 145 611 521

2 1 46 111 39 150 638 559

3 3 47 115 42 155 665 596

4 4 48 119 44 160 692 631

5 6 49 123 46 165 719 666

6 7 50 127 48 170 748 700

7 8 51 130 50 175 778 739

8 10 52 135 52 180 809 775

9 12 53 141 54 185 840 811

10 13 54 146 57 190 874 850

11 15 55 151 60 200 945 931

12 16 56 155 63 210 1018 1009

13 18 57 160 66 220 1091 1091

14 20 58 165 69 230 1173 1173

15 21 59 170 73 240 1254 1254

16 23 60 175 76 250 1335 1335

17 24 62 185 82 260 1418 1418

18 26 64 195 88 270 1500 1500

19 28 66 205 95 280 1583 1583

20 30 68 215 102 290 1668 1668

21 32 70 225 108 300 1755 1755

22 34 5 72 236 116 310 1845 1845

23 36 6 74 245 124 320 1926 1926

24 39 7 76 254 132 330 2018 2018

25 42 8 78 264 140 340 2110 2110

26 44 9 80 275 148 350 2204 2204

27 46 10 82 284 158 360 2298 2298

28 49 11 84 294 168 370 2388 2388

29 51 12 86 305 176 380 2480 2480

30 54 13 88 315 186 390 2575 2575

31 56 14 90 326 195 400 2670 2670

32 58 15 92 337 205 410 2765 2765

33 60 16 94 348 214 420 2862 2862

34 63 18 96 359 223 430 2960 2960

35 66 20 98 370 234 440 3060 3060

36 69 21 100 380 245 450 3150 3150

37 74 23 105 406 270 500 3620 3620

38 78 25 110 431 295 550 4070 4070

39 83 26 115 455 329 600 4480 4480

40 86 28 120 479 365 700 5380 5380

41 90 30 125 506 396 800 6280 6280

42 95 31 130 533 430 900 7280 7280

43 99 33 135 559 460 1000 8300 8300

44 103 35 140 585 490

Fig. 1-43: Conversions: Gallons per Minute to Fixture Units

(reproduced with permission from ASPE Data Book, Vol. 1, p. 3-8)

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings

36 & Merrill, LLP 36

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Gas Appliances

Fig. 1-44 shows the approximate gas demand for common appliances. These default values were

obtained from the ASPE Data Book, Vol. 1, Fundamentals of Plumbing Design, 1983-1984, p. 6-8.

The heating value of the gas is used to convert the Btu/hr value into cu ft/hr flow of gas.

Appliance Output

Btu/hr

Commercial kitchen equipment:

Small broiler 30,000

Large broiler 60,000

Combination broiler and roaster 66,000

Coffee maker, 3-burner 18,000

Coffee maker, 4-burner 24,000

Deep fat fryer, 45 lbs of fat 50,000

Deep fat fryer, 75 lbs of fat 75,000

Doughnut fryer, 200 lbs of fat 72,000

2-deck baking and roasting oven 100,000

3-deck baking oven 96,000

Revolving oven, 4 or 5 trays 210,000

Range with hot top and oven 90,000

Range with hot top 45,000

Range with fry top and oven 100,000 Fig. 1-44: Common Appliances:

Range with fry top 50,000 Approximate Gas Demand

Coffee urn, single, 5 gallon 28,000 (reproduced with permission from ASPE

Data Book, Vol. 1, p. 3-8.)

Coffee urn, twin, 10 gallon 56,000

Coffee urn, twin, 15 gallon 84,000

Residential equipment:

Clothes dryer 35,000

Range 65,000

Stove top burners 40,000

Oven 25,000

30-gallon water heater 30,000

40- to 50-gallon water heater 50,000

Log lighter 25,000

Barbecue 50,000

Miscellaneous equipment:

Commercial log lighter 50,000

Bunsen burner 3,000

Gas engine, per horsepower 10,000

Steam boiler, per horsepower 50,000

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings

37 & Merrill, LLP 37

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

Thermal Analysis

The heat gain/loss and temperature calculation options apply to liquids and steam only.

You can choose between two options for determining the fluid temperature in each pipe section.

In the first option, you can assume an average supply and return fluid temperature for all supply

and return sections. This data is used to calculate the fluid properties. An example of the use of

average temperatures is 200 oF supply and 160 oF return for a hot water heating system.

In the case of un-insulated pipes and high temperature steam and hot water, the supply

temperature at each terminal must be calculated. This is done by calculating the entering and

leaving temperature of each supply section, beginning with the initial temperature of the first

section. The first section must be identified. In the case of liquids, the first section is the section

downstream of the pump station.

The entering temperature of any supply section is the leaving temperature of the upstream

section. You can reset the leaving section temperature for sections that have primary

equipment.

The following equations are used to calculate liquid and steam heat gains and losses:

T avg - T amb

Qs =

Ro Rs

R s log e R s log e

Ri + Ro + 1 / h

K1 K2

where Qs = rate of heat transfer per square foot of outer surface (Btu/hr sq ft)

Tavg = average temperature of section (F)

Tamb = temperature of ambient air (F)

Ri = inside radius of pipe, (in.)

Ro = outside radius of pipe, (in.)

Rs = outside radius of insulation (in.) - Ro + insulation thickness

K1 = thermal conductivity of pipe (Btu in./hr sq ft F)

K2 = thermal conductivity of insulation (Btu in./hr sq ft F)

1/h = outside surface resistance (hr sq ft F/Btu in. = 0.6)

Equation 12 is based on heat flow Equations 11 and 12 in ASHRAE Handbook: 1981

Fundamentals, p. 23.8. The average temperature of the section is the mean value of the

temperatures entering and leaving the section. Since the leaving temperature is unknown, the

average temperature is calculated iteratively.

Q s = q s As

where Qs = total rate of heat transfer from pipe section (Btu/hr)

As = outside surface area of pipe (sq ft)

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings

38 & Merrill, LLP 38

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

The temperature of the liquid flowing through the pipe section is obtained from Equation 14.

The procedure for determining steam temperature changes is described in Steam Piping.

Q s (Btu / hr)

dT s =

gal. cu ft min . lb btu

Fs 0.13368 x 60 x Df xCp lb F

min . gal. hr cu ft

where dTs = change in liquid temperature in section (F)

Fs = flow through section (GPM)

Df = density of liquid (lb/cu ft)

Cp = specific heat of liquid (Btu/lb F)

Tl=Te - d Ts

where Tl = temperature of fluid leaving section (F)

Te = temperature of fluid entering section (F)

T l +T e

T avg =

2

The average temperature Tavg in Equation 12 depends on the leaving section temperature in

Equation 16. The procedure consists of initializing the leaving temperature to the entering

section temperature and then iterating through Equations 12 through 16 until a steady state

value of Tavg occurs.

Pipe Sizing

The general principles of pipe sizing are described in the ASHRAE Handbook: 1985 Fundamentals,

Chapter 34, p. 34.1. The Darcy-Weisbach and Colebrook-White equations are used to calculate

the pressure drop in a pipe section due to fluid friction. The Darcy-Weisbach equation is:

L V2

h= f 2 g

D

where h = head loss due to friction (ft)

f = friction factor, dimensionless

D = inside diameter of pipe (ft)

L = length of pipe section (ft)

V = average velocity (ft/sec)

g = acceleration of gravity (ft/sec2)

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings

39 & Merrill, LLP 39

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

The friction factor f is a function of the pipe roughness , inside diameter D and a dimensionless

parameter, the Reynolds number.

Dv

R e=

where = fluid density at given temperature (lb/cu ft)

= dynamic viscosity of fluid (lb/ft sec)

The ratio / is the kinematic viscosity in sq ft/sec

Laminar flow exists where Re < 2100. For this condition, the friction factor f is obtained from:

64

f=

Re

Where Re > 2100, the flow is assumed to be turbulent. The Moody diagram that relates the

friction factor f with Reynolds number and the relative roughness /D is shown in ASHRAE

Handbook: 1985 Fundamentals, p. 2.10, fig. 13. The Colebrook-White equation for turbulent

flow, shown in Equation 20, is used for the friction factor f.

1 9.3

= 1.14 + 2 log 10 (D / ) - 2 log 10 1 +

f R e ( / D ) f

where = absolute roughness of inside pipe wall (ft)

For fully rough flow, the value of Reynolds number is high and the last term in Equation 20 can

be neglected. Equation 21 can be used in its place.

1 D

= 1.14 + 2 log10

f

Equation 20 is used to calculate the friction factor f for turbulent flow. The Newton-Raphson

iterative method is used to solve for f since f appears on both sides of the equation. The initial

value of f for this iteration is obtained from Equation 21. As Reynolds number increases, the

values from Equation 20 approach those that would be obtained by applying Equation 21 directly

for fully rough flow.

Pipe sizing and the size of each pipe section depend on your criteria (See Sizing Criteria in this

engineering basis). The criteria can be based on the limits for pressure loss per 100 ft, maximum

velocity or maximum flow. The sizing iteration consists of comparing the pressure drop/100 ft,

velocity or flow against the limits you specify. This is done for each standard pipe size, beginning

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings

40 & Merrill, LLP 40

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

with the smallest size and continuing until a size is found that meets the criteria. When the

maximum pipe size limit is reached, you must use your engineering judgement to decide whether

to:

maintain the sizing criteria and increase the pipe size above the maximum limit or

maintain the pipe size limit and calculate the new criteria for this size.

Steam Piping

Steam distribution network pipe sizing requires flow rates and sizing criteria for the pipe

sections. The flow rate for dry steam or steam with a small amount of water (condensate) is in

accordance with the laws of fluid flow. The flow is a function of these properties:

Steam

Pipe

temperature

length

pressure

diameter

viscosity

pressure drop

density

The Darcy-Weisbach and Colebrook-White equations (Equations 17 through 21) are used to size

steam pipes,. These equations are described in Pipe Sizing.

The flow of steam is automatically induced by the volume shrinkage that occurs when steam

gives up its latent heat and condenses. Therefore, steam flow involves the analysis of two-phase

flow. Condensate flows in the same direction as steam and must be trapped at intervals along

the pipe length. Typical pressure classifications of steam in HVAC applications include

Vacuum : less than 0 PSIG

Low pressure : 0 to 15 PSIG

Medium pressure 15 to 100 PSIG

High pressure 100 PSIG and above

The basis of pressure classification is the initial pressure. Default values are shown in Fig. 1-45.

Initial Steam Pressure Maximum Maximum Minimum

Pressure Class

Pressure Drop System Velocity Velocity

Initial PSI

(PSIG) (PSI/100 ft) P.D. (PSIG) (ft/min) (ft/min)

low 3.5 3.5 0.25 1 4000 0.0

low 12 12 0.70 3.4 4000 0.0

medium 30 30 2 7.5 6000 0.0

high 50 50 3 12.5 10000 0.0

high 100 100 4 20 10000 0.0

high 150 150 6 27.5 10000 0.0

Fig. 1-45: Steam Pipe Sizing Criteria

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings

41 & Merrill, LLP 41

Piping Design Program - Engineering Basis SOM-IBM Architecture & Engineering Series (AES) - 1988

In addition to selecting a pressure classification, you can specify additional sizing criteria and

constraints for the project including

Initial steam pressure (PSIG)

Maximum circuit pressure drop (psi)

Pressure drop per 100 ft (psi)

Maximum velocity (ft/min)

Minimum velocity (ft/min)

The maximum system pressure drop criterion is met by successively reducing the sizes of pipe

sections for circuits that exceed the limit. This procedure is described in Circuit Balancing in this

engineering basis.

Pipe sizing iteration consists of checking the pressure drop/100 ft and the maximum velocity of

each standard pipe size of a given pipe material against your sizing criteria. This sequence begins

with the smallest pipe size and continues until the required size is found or the maximum pipe

size limit for the given material is reached.

The general laws of gas flow can be used in sizing steam pipes. This assumes that the steam

temperature and pressure maintains the steam quality above its saturation level (gas) and the

small amount of condensate in the system flows in the same direction as the steam.

In the program, you can enter graphic and text input to a steam supply system and its

condensate return system simultaneously since they serve the same terminal equipment. The

two systems are analyzed separately. Flow quantities for the terminal equipment are not

automatically transferred from steam supply to condensate return since the quality of steam

downstream of the terminal equipment depends on the equipment type, heat losses, pressure

losses, steam traps, sub-cooling, and other design factors.

Return systems are described in Steam Condensate Return Piping in this engineering basis.

Changes in Steam Conditions

Fig. 1-46 shows steam flow and heat loss conditions for a pipe section.

Fig. 1-46: Changes in Steam Conditions

The changes in steam conditions for a section are due to heat loss and pressure loss. For a given

section,

Varkie C. Thomas, Ph.D., P.E. Skidmore, Owings

42 & Merrill, LLP 42