Professional Documents

Culture Documents

23 Fall 2006 (Product Value & Plane)

Uploaded by

RahmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

23 Fall 2006 (Product Value & Plane)

Uploaded by

RahmaCopyright:

Available Formats

Volume 29 Number 2 I Fall 2006

contents: inside this iSSLIC::

Increasing

Editor's Comments

Dr Roy M. Woodheacl, CVS 1 Value in

Editor Value World

Product

Integrating Value Methodology 2

into Product Development and

Project Management Processes

Design

at Pratt Ei Whitney Canada

Alain LeBlanc, CD, PEng, MSc, MEng

Methodological and Practical 8

Aspects of Data Mining in the

Product Development Process

Prof Tai Shen Huang

-

Value Driven Design 18

Paul D. Collopy, PhD

Joseph E Otero, Jr, CVS-Life

Managing Value Engineering 26

In New Product Development

Don J. Gerhardt, CVS, PhD, PE

Extending Our Reach

This edition of Value World has four papers that provide We plan to address this situation by republishing

insights into ways value management can be used in the conference papers from around the world—not just SAVE

context of increasing value in product design. This is International conferences—to reliably send out three

appropriate not only to members of SAVE International,

editions per year. Our hope here is that by increasing

but also to our own publication. If we view Value World as a

publication reliability we will become a more trusted place

product, then we can learn from these papers and question

for potential authors. We also plan to make Value World an

whether our proposed strategies are maximising value. My

electronic publication so that we can dramatically increase

analysis is that we are not, and so need to do something

different. our circulation numbers and extend our reach without

This realisation was triggered by a need to find a new creating cost burdens for our society. We hope this will

editor. We owe a lot to the hard work of Derek Thomson also make it more appealing to new authors and that, in

and Kirsty Hunter from Glasgow Caledonian University in time, we can move away from republishing conference

Scotland. Particular thanks go to Derek for the excellent papers and get back to our goal of only publishing original

work he has done in modernising the operational processes material.

used to review, publish, and disseminate Value World.

In order to make this even more beneficial to SAVE

His efforts have made Value World a more professional

International, we will also carry advertisements and hope

publication and one we can be proud of. This has been

that we can build a revenue stream that will later open the

done whilst he has started a new career and the time

way to other options such as a ValueWorld discussion forum

constraints that have brought have caused a heavy burden

for him. Due to his current workloads, meeting deadlines and blogs.

has become difficult for him; but that does not diminish the So, we are reinventing our plan to grow Value World and

excellent contribution he has made to our community. He hope you the readers will enjoy the benefits of a wider reach

has delivered some good editions and will be remembered to other practitioners, managers, clients and academics

for his achievements. We thank him and wish him well in from around the world.

his future career. We also acknowledge the excellent work

Kirsty has done to build links with other societies and the

Best wishes

potential to access their conference papers.

The big problem facing Value World right now is the

low number of papers submitted to our review process.

Given we only circulate about 2,000 copies, the marketing

potential for authors is obviously not high enough and so Roy Woodhead, Ph.D., CVS, TVM, PVM

we need to extend our reach to attract more authors and Vice Presidents - Education

spread awareness of our capabilities as a community of SAVE International

value managers.

VALUE ORLD Volume 29, Number 2, Fall 2006 1

Integrating Value Methodologies into

Product Development and

Project Management Processes

at Pratt & Whitney Canada

Alain LeBlanc, CD, P.Eng., MSc., MEng.

This article is reprinted from the SAVE International 2004 Confer- the design evolution process.

ence Proceedings. For the purpose of this paper, these methodologies are:

• value engineering

Abstract • function performance specification

Value methodologies have been integrated into the • quality function deployment

product development and project management processes • parametric paired comparison

for the past eight years at Pratt & Whitney Canada. Val- • direct value measurement

ue engineering, function performance specification, qual- • risk assessment.

ity function development, parametric paired comparison,

direct value measurement and risk assessment are among

some of these different methodologies that have found their Value Methodologies at P&WC

respective niche in the different phases of the product de- Value Engineering (VE). In 1996 a VE program was initi-

velopment. This has led to a significant increase in prod- ated at P&WC to tackle the pressing need to preserve the

uct value creation and project management effectiveness. cost margin on existing products and new products un-

This paper will describe how these methodologies were der development. This led to a solid cost reduction plan

integrated into the design organisation and its processes, in which VE played a key role in providing the means to

and that they are more effective when applied upon project develop alternative solutions (LeBlanc, 2000). This first

management's buy-in. wave of VE deployment led to the development of internal

expertise and the application of VE at the front end of the

new program introduction process, integrating the func-

Introduction tion analysis within the target costing process. The VE

The engineering organisation at Pratt & Whitney Can- methodology is defined under an internal Work Instruc-

ada is divided into three major groups, each responsible for tion Manual (WIM 448).

playing a key role in the introduction of new value prod- Function P erformance Specification (FPS). Function analysis

ucts. The design group is responsible for the conceptual has been applied to the development of a product perfor-

and definition activities associated with new products. The mance specification tool. Based on the environment method

development group is responsible for the testing and sub- (Brun, 1992), a function specification table was developed

stantiation of new products. The project engineering group in 1998 for the development of the engine control specifi-

manages the entire product development process with re- cation. Although similar to the technical FAST diagram, it

spect to interface with the customer, budget management, provides for a rigorous definition of the customer and stake-

product certification and ensuring an integrated design holders' needs. The FPS model (Report VE-1998-044) was

and development cycle. The value management expertise used on two new programs to challenge the relationships

resides primarily within the project engineering group, al- and the trade-offs between the engine control function and

though some experts are resident outside the Engineering other related product functions.

organisation due to personnel rotation and application of 9uality Function Deployment (ED). QFD uses a series of

the value methodologies in other areas of the business. Dif- matrices which focus on gathering, understanding and de-

ferent value methodologies have been adapted to the busi- ploying the "voice of the customer" throughout an organisa-

ness environment and their applications are a function of tion, ensuring that this "voice" is reflected throughout the

2 Volume 29, Number 2, Fall 2006 VALUE ORLD

development, production, installation, service and disposi- Value Methodologies Integration

tion of a product. The most common arrangement of these

matrices is known as the House of Quality, for its obvious

into the Concept Phase

The concept phase, also called the study phase, is the

shape (ASI, 1997).

first very important step. It defines the market we are aiming

QFD was introduced, in 1998, as a tool to prioritise the

for and is used to develop a good understanding of the cus-

product portfolio and technologies. Subsequently it was

tomer drivers, an analysis of the potential competition, the

used to validate the contractual scope for a new industrial

possible solution architectures, and, of course, the business

engine product in collaboration with the power plant in-

case drivers. The main deliverables of the study phase are:

tegrator and a risk-sharing partner. The next application

was for the recently launched PW610 engine program in • market definition

the general aviation market area. Its application has been • competitive analysis

limited to the first level of deployment, i.e. the House of • product specification

Quality. QFD was also used extensively for the purpose of • technology readiness

strategic sourcing and core competency analysis. • architecture study

Parametric Paired Comparison(PPC). PPC is a systematic • product target cost

tool used to provide weighted priorities by comparing mul- • project risk exposure

tiple attributes against each other (in pairs). It is a com- • business case study.

plementary process to the QFD and VE methodologies. A Direct value measurement (DVM), parametric paired

developed Pratt & Whitney tool (Otero, 1997) was used comparison (PPC), and quality function deployment (QFD)

extensively from 1997 to 1998. Lessons learned and an inno- are very effective at measuring and prioritising the customer

vative approach led to an internal Work Instruction Manu- values and transferring these values into the product char-

al (WIM 451) called "Parametric Paired Comparison". acteristics (Modafferi, 2003). DVM allowed us to quantify

Direct Value Measurement (DVM). DVM was applied in- specific product values through market surveys such as the

ternally to quantify market values through interventions at example described in Figure 1. In this case, the take-off dis-

key aerospace gatherings. It defines an intrinsic value for tance was assessed among others where potential custom-

a product or service independent of its cost (Cook, 1999). ers were asked to quantify the price increase they would

The market survey data allowed marketing and advanced pay for a substantial decrease in the aircraft take-off dis-

design organisations to validate perceived values against tance. This was instrumental for the market definition pro-

the customers' feedback and reinforce the QFD analysis. cess, which lead to the creation of several value curves in-

Risk Assessment. A risk assessment methodology was dicating the threshold points at which the customer would

adapted from a process developed at the United Tecimol- switch to the baseline proposition.

ogy Research Centre called "Risk-Reduced Development Understanding the relative importance of these values

Planning" (Zeidner, 1997) and available as an internal helped us in prioritising these values using the paramet-

Work Instruction Manual (WIM 447) called "Risk Assess- ric paired comparison (PPC). This methodology helped

ment Methodology". Risk assessment identifies the risk as- us determining value proposition for which the customer

sociated with each value proposition. One of the resulting would be differentiating our product from another. It is

impacts is the quantification of a more reliable product cost

risk exposure during the concept phase, its inclusion into

the cost targets and a more accurate product cost expecta-

tion curve as a function of the development cycle (Routhier ecalvallm -

PC4,:t1.7+7, 0'17 •ht° ,Iir1 ,17 , 77., 1 ,-17 1 .

and Delisle, 2001). .14 .e.,t UltrUtt

Finally, although not discussed in this paper, other

methodologies such as value stream mapping and Kaizen

have been used in support of achieving competitive excel-

lence in other business processes.

The paper will now describe how these methodologies 1+7C43 rt

have been integrated at P&WC as part of the new produc- 111111111111.1

tion introduction process. An overview of the product defi-

nition process and examples of value methodology applica-

tions are discussed.

Figure 1: Direct value measurement applied to take-off distance.

VALUE ORLD Volume 29, Number 2, Fall 2006 3

Attribute Minimum Significant Maximum Absolute Relative

Description Acceptable Improvement Differentiation A B C D E F G H Score Score

A Reliability al a2 al el fl gl a3 7 6

B Life b2 d3 e2 fl g2 b2 4 3

Installation

C . d3 e3 f2 g2 cl 1 1

Time

Development

D el dl gl d2 9 8

Time

Direct

E Operating el el e3 12 10

Cost

Acquisition

F fl f3 8 7

Cost

Maintenance

G g3 9 8

Time

Maintenance

H 0 1

Frequency

Figure 2: Parametric paired comparison methodology.

(1 = "Slightly More Important", 2 = "More Important, 3 = "Much More Important')

important to quantify the minimum acceptable, significant into the QFD first House of Quality. The advantage of the

improvement and maximum differentiation value levels for QFD was that it brought into a two dimensional framework

each of the key market attributes (Routhier, 2001). PPC is a vast amount of highly organised material to facilitate the

also playing a key role in getting the consensus within the direction of the concepts and the trade-offs. These results

Study team. The essence of the methodology is to compare were very effective in the preparation of the product defini-

attributes, two by two. This is done using the matrix in the tion requirement specification.

right hand of the spreadsheet, as illustrated in Figure 2. Once the former methodologies have been applied and

For example, considering attributes A (Reliability) and B concepts were derived, risk assessment came into play in as-

(Life or durability), the participants were asked to quantify sessing the risk exposure associated with the value proposi-

between a significant im.provement over the minimum ac- tions. When first introduced, quantifying the risk exposure

ceptable of A and a significant imp' rovement over the mini- was first seen as an obstacle to sell a project. It eventually

mum acceptable of B. A scale between one (slightly more became instrumental in selling the projects as the passport

process forced a more stringent discipline in the business

important) to 3 (most important) is used to score the dif-

case accuracy and confidence level of the cost targets. At

ferential between each attribute.

this stage, project scope and risk management were shown

Once completed, the PPC results can be incorporated

to be very critical for planning the right

Table 1: Risk Assessment Methodology— projects prior to offering to customers

Process Input and Output (Halpin, 2003; Faucher, 2003). The in-

put and output of the risk assessment

Process Input Process Output process are summarised in Table 1.

• Product (weight, performance, ...) • Risk summary known as "Risk The Risk assessment has been

• Key project characteristics (sched- Cube"

ule, budget)

forcing the study team lead by proj-

• Qualification of risks in terms of

• Design cross-section relative risk importance ect engineering to quantify the impact

• Engineering cost estimate • Top risks list with quantified im- of the value proposition (Plan A) and

• Technology level assessment pact on project and product values its probability to revert a lower value

• Risk historical checklist • Overall program risk exposure proposition (Plan B). The relationship

• Agreed severity matrix • Others

• Applicable likelihood dimensions

between the likelihood of failure and

• Trade off risk factors the consequence of not delivering the

• Contractual penalties value proposition is called the risk ex-

• Others posure. Figure 3 shows an extract of

4 Volume 29, Number 2, Fall 2006 VALUE ORLD

an application of the methodology. The interesting element • Entry-into-Service

of the methodology is that for each uncertainty the team The value methodologies are applied to support the

must derive the success vision and the alternative design

product design and project management teams for the

solution or fallback vision. In some instances reverting to

product optimisation and program decision-making. The

the fall back vision may turn out to be a more valuable solu-

function performance specification tool for engine controls

tion when considering all the impacts on the project.

was used at this stage to define and do the trade-offs be-

The main deliverables of this phase are:

tween the operability definition team and the other engine

• Component and System Specifications modules. Important trade-offs have been reported internal-

• Partnership Specifications for risk sharing venture ly for the recent new product definition programs. It was

• Supplier Selection demonstrated that it is critical to provide the design team

• Component Level Cost Targets with a mechanism that focus not only on the product design

• Technology Risk Mitigation Plan but also on the functions and the best way to achieve them

• Business Case Validation from a total system viewpoint. As the renowned French pi-

At this point, budgets are validated; partners and sup- lot said, "A designer knows he has achieved perfection not

pliers are confirmed. Successful completion of this review when there is nothing to add, but when there is nothing left

launches the detail design phase and effectively a 30-month to take away."

countdown to certification. The Full Design machine is en- PPC was shown to be a valuable decision-making tool

gaged with project management and design resources ap- for design alternatives and other project issues. When

plying the company's best practices, knowledge and skills conducting VE events it is imperative to build a team con-

in optimising the study concept and the subsequent pre- sensus at the beginning of the event. PPC has shown to be

detail design. very effective to achieve this as the team members are faced

The ultimate deliverables of this phase are: to challenge each other on their perceived values of the

• Bill of Materials Definition product. VE was very effective at understanding the cost

• Bill of Materials Characterisation structure of the product and generating alternative ideas.

• Product Certification Moreover, the VE methodology was also very effective at

• Production Plan bringing the suppliers onboard in discrete events where

Likelihood Matrix Severity Matri

Sever ity of Fa i lure

>,

Req u iremene ts

Ris k Leve l

Know le dg e of

Req u iremen ts

Li ke li hoo d of

CL) 73

KNow le dg e /

U

Comm itte d

Exp e r ience

Sta bi lity of

Resou rces

CU r ,cfY

Fa i lu re

-(13) 5 2' fn

L

'el) . ,t7)

Uncertainty Issue Success Vision L.) c' Y-i L' 0

togippl implymoup

Ability to meet Aerosmoothness Red e sign

Imp ro ba ble

Imp ro ba b le

Imp ro ba ble

Imp ro ba ble

Marg inal

Marg ina l

aerosmoothness requirements are tion fo man u factur-

requirements met

Accoustics External noise

Imp ro ba b ly

Very Li ke ly

Marg ina l

VerYLi ke ly

levels are met

with current .c7)

- - .-

design

2 0 0

I

Sig n i fican t I

Diameter of air Adequate cross- Modificat i on

S ig n i fican t

starter duct start capability cowl inner loft lines -irs

Me dium

Ala

c

with 2 in. versus to avoidin er e —

2.5 in. duct ()cation o

FT

(El

ge nerator 2

Figure 3: Risk Assessment Methodology—Extract from a Risk Assessment Event

VALUE ORLD Volume 29, Number 2, Fall 2006 5

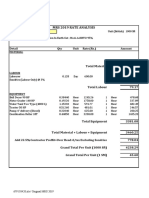

Component Name Before VE After VE moves further, risk as-

sessment is applied to

D is tr ibu t ion

D is tr ibu t ion

production readiness,

Fu nct ion

Actuator

Funct ion

Funct ion

Cost pe r

Cos t per

Hous ing

Therma l

Num ber

customer support and

Bun dle

Cover

S lider

Tu be

other issues that form

Cost

Cost

Function Name part of the total pro-

1 Transfer Heat 313 X X X X 313 30% 256 31% gram deliverables.

2 Contain Fluid 110 100 X X 0 210 20% 188 23%

3 Modulate Fuel Temperature X X 82 83 X 165 16% 165 20% Conclusion

4 Locate/Position 33 69 56 7 0 165 This paper has

16% 110 13%

5 Respect Envelope 17 33 X X X 50 5% 17 2% described the extent

6 Resist Environment 0 33 X 10 X 43 4% 33 4%

of integration of the

7. Permit Maintainability

value methodologies

0 0 15 X 28 43 4% 18 2%

that has occurred at

8 Mix hot and cold fuel X X X 18 X 18 2% 13 2%

P&WC over the past

9 Interface 0 18 X X X 18 2% 11 1% eight years. Originally

10 Prevents Leaks/Seal 10 5 X X 0 15 1% 15 2% launched as part of a

11 Achieve Service Life 0 0 0 0 X 0 0% 0 0% cost reduction pro-

Total Cost per Component —4 483 258 153 118 28 826 gram, value engineer-

Before VE (%) 46% 25% 15% 11% 3% ing and the subsequent

After VE (%) 52% 19% 19% 10% 0.4%

other methodologies

were adapted to the

Figure 4: VE application at component design level. business and their ap-

plication moved from

both the design and manufacturing requirements can be cost reduction to tar-

challenged in a controlled manner. Major cost reductions get costing to cost and value management.

and product enhancement were achieved over the eight The value methodologies have been used extensively

years influenced by a value improvement embedded culture during the concept, pre-detail and detail design phases

within project engineering, design and other groups such were most suited to help the development teams to plan

as manufacturing. Figure 4 shows a typical component cost and define the most competitive value products. Signifi-

breakdown against its functions before and after the VE cant shifts in P&WC product value curves were achieved

event, conducted with a supplier. in part due to the effectiveness of these methodologies and

Risk assessment, as a pro-

cess, takes more importance

as the product development

moves forward being extend-

ed to Risk Management, as

risk response must be dem- 100

Uncertainty #1

RISK EXPOSU RE

onstrated. Risk mitigation 90 Eliminated

plans are defined for the top 60

Uncertainty #2

Eliminated — Baseline

product risk items, which are

monitored through risk wa- 40

• •, +3 Months

terfall charts, as shown in Fig- 20

ure 5 (Bharath, 2003). As the Uncertainty #3, 4, 5, 6, 7

product evolves further risk 0 Eliminated

is re-assessed on a regular ba- 2002 2003 2004 v

. 2005 2006 2007 2008

sis with a new perspective, as Bundled Risk

more knowledge is available Reduction Tasks TIMELINE

to validate the assumptions Figure 5:Risk waterfall chart example.

made at the previous stages. (Risk Exposure andN on Recurring Cost (NRE) with Time)

As the development schedule

6 Volume 29, Number 2, Fall 2006 VALUE ORLD

their integration in the new product development process. Halpin, John, Achieving Project Management Excellence—

The key lessons learned to successfully implement value Key to Value Management, Pratt & Whitney Canada,

methodologies are as follows: CSVA Annual Conference, Longueuil, 2003

• Their full effectiveness requires their integration with LeBlanc, Alain, Four Years of Value Engineering Experience

design and project management processes. at Pratt & Whitney Canada, Using Value Methodolo-

• The methodologies must be adapted to the organisa- gies from Cost Reduction to Cost Targeting to Cost &

tion culture and must continue to evolve as the require- Value Management, CSVA Annual Conference, Mon-

treal, 2000

ments develop.

• Their continued effectiveness over time depends upon Modafferi, Mario, Creating Product Value - Process, Meth-

the accountability of the process owner, the buy-in of odology and Results, Pratt & Whitney Canada, CSVA

Annual Conference, Longueuil, 2003

the process users and the support from management.

Otero, Joseph F., Real-time Integrated Computer tools for Value

Engineering Events (Value Management software tool-

Acknowledgement set). SAVE International conference proceedings, 1997

The author wants to recognise all those who contribut-

Routhier, Pierre, Parametric Paired Comparison: a New

ed to the implementation of the value methodologies over

Methods for Rapid and Accurate Customer Needs As-

the last eight years at Pratt & Whitney Canada. It includes

sessment, QFD Institute 13th Symposium on QFD, 2001

the value methodology champions, the VE team members,

the management, and the Valorex consulting teams, which Routhier, Pierre and Eric Delisle, Risk Management—Over-

was onboard during the first three years of the VE pro- view of Risk Theory and its Applications in VE, CSVA

gram. Annual Conference, Toronto, 2001

Zeidner L.E., Risk-Reduced Development Planning, United

Technology Research Center, 1997

Quoted References and

Communications Other References and Communications

Anonymous, Work Instruction Manual 447, Risk Assessment Cooper, Robin and Regine Slagmulder, Target Costing and

Methodology, Pratt & Whitney Canada, 1999, 13 pp. Value Engineering, Institute of Management Accoun-

Anonymous, Work Instruction Manual 448, Value Engineering tants, Productivity Press, Portland, ON, 1997, 387 pp.

Methodology, Pratt & Whitney Canada, 1999, 11 pp. Kaufman, Jerry J., Managing Value Management, SAVE In-

Anonymous, Work Instruction Manual 451, Parametric Paired ternational Accredited CVS Module 2 Training Mate-

Comparison, Pratt & Whitney Canada, 2003, 6 pp. rial, Montreal, 1999

Anonymous, VE-1998-044, Function Performance Specifica- LeBlanc, Alain, Value Methodologies and Target Costing,

tion, Pratt & Whitney Canada, 1998 CSVA Annual Conference, Toronto, 2001

Anonymous, quality Function Deployment for Products, Ameri- Prichard, Carl L., Risk Management, Concept and Guidance, second

can Supply Institute, Livonia, MI, 1997 edition, ESI International, Arlington, VA, 2001, 342 pp.

Bharath, Keppel, Risk Identification and Mitigation in Proj- Tahmazian, Berge, Quest for Value, American Value Jour-

ect Management Excellence, McGill University 5th Sup- nal, 1997

ply Chain Management Conference, Montreal, 2003 Thiry, Michel, Value Management Practice, Project Manage-

•Brun, Guy. Analyse fonctionnelle et le cahier des charges ment Institute, Sylva, NC, 1997, 112 pp.

fonctionnel. Training Material, Valorex, 1992 Transport Canada, "Railway Safety Management System

Cook, Harry E., Product Value and Target Costing, Depart- Guide" (TP13548, 2001).

ment of General Engineering, University of Illinois at Wideman, R. Max, 1992, Project and ProgramRisk Management,

Urbana-Champaign, CSVA Annual Conference, Mon- The PMBOK Handbook Series, Vol.6, Project manage-

treal, 1999 ment Institute

Faucher, Christian, Process Integrity and its Application Zeidner L.E., The Collaborative Innovative (CI) Process,

to Project Management Excellence, Pratt & Whitney United Technology Research Centre, CSVA Annual

Canada, CSVA Annual Conference, Longueuil, 2003 Conference, Montreal, 1999

VALUE ORLD Volume 29, Number 2, Fall 2006 7

Methodological and Practical Aspects of

Data Mining in the Product Development

Process

Prof Tai-Shen Huang

Abstract Keywords: Data mining, product design process, Industrial

It is well recognized in industry that product design Design

and development significantly impacts a company's busi-

ness success in competitive markets. Increasingly, business

enterprises are realizing how important it is to "know what 1. Introduction

they know" and to be able to make use of the vast amounts This research describes the structure of data mining as

of knowledge accumulated in recent years. Understanding it applies to the management of new product innovation

technologies of knowledge management, such as data ware- (see figure 1). One of the most important question that prod-

housing, data mining, as it applies to product innovation uct innovation is concerned with is in trying to determine

can give companies a competitive advantage. In particular, the sort of innovation that could result in a new product.

it is through data mining that the extraction of hidden pre- In order to answer that question, it is necessary to define

dictive information from large databases can identify valu- "newness" into commonly accepted categories as this will

able customers, predict future markets, enhance product influence the outcome of the product innovation inquiry.

innovation efficiency, and enable firms to

make knowledge-driven decisions.

Research into this area provides a data Defining problems

mining structure for discovering the in-

flow of resources that can be used to opti-

mize product innovation. Such structures Building databases

include various hi.dden knowledge. For

example, when the life-cycle of a product

Analyzing and searching

shortens, manufacturers and designers Inflow of resources

need to realize that a reduction of cost rules

is necessary to maintain a competitive

advantages. The purpose of data mining Strategic planning Building models

is to excavate information that will help

companies arrive at such conclusions. It

is imperative that effective methods are Applying data mining to

developed to further product design in- Concept generation

product innovation

novation.

This research focuses on building a

data mining structure that fits new prod- Strategic evaluation Evaluating models

uct innovation and design development

and adopts the decision-tree model to fa-

cilitate the prediction of trends. The ap- Technical development Data mining process

plication of the proposed structure and

system to a horticulture tools company

for the design of various tools is presented

Commercialization

to elaborate benefits of data mining for

product innovation.

Figure 1: Datamining process vs. product innovation process

8 Volume 29, Number 2, Fall 2006 VALUE ORLD

We can define "newness" into five accepted categories: builds a data mining structure that supports this step.

• New-to-the-world products: products that constitute • Concept generation: This step functions as the prob-

inventions. lem-solving phase that follows strategic planning. This

• New category entries: products that launch firms into is vital to product innovation as the most fruitful ide-

new markets. These products are not new to the world, ation involves identifying problems and suggesting so-

merely products from a market that was not previously lutions to the strategic planning.

available to the firm. • Strategic evaluation: Strategic evaluation is the step

• Additions to product lines: products that operate as where the ideas derived from concept generation are

line extensions, flankers, etc. evaluated. During this step, firms actually propose solu-

• Product improvement: products that have been im- tions to the competitive problem, followed by concept

proved. This is the most prevalent form of "newness" as tests to determine its effects on potential consumers.

virtually every product on the market today has been Strategic evaluation uses a scoring model of some type

improved, often many times. to aid corporations in deciding whether to undertake

• Repositioning: products that are retargeted for a new development.

user or application [3-4]. • Technical development: This step consists of invento-

The product innovation process consists of six steps: rying the firm's operations (manufacturing and other)

• Inflow of resources: This paper focuses on uncovering skills.

data regarding the inflow of new product resources. • Commercialization: Tradition211y, the term commer-

This includes customer, product, and market resources ciali7ation has described either the decision to market

(see figure 2). Data about product resources come from or the point when the firm decides to market a prod-

competitive activities, comparisons with competitors, uct [4] .

and investigations into competitive sources (custom- We propose that the data associated with product

ers' need) to find the core competitive opportunities. process innovations will become relatively more explicit

• Strategic planning: This step focuses on special op- through data mining. Data mining in the practice of a new

portunity analysis. The process of creatively recogniz- design method can enable the implementation of better in-

ing opportunities is called opportunity identification. novation ideas and concepts.

Product innovation opportunities that are ongoing, This application of data mining adopts a decision-tree

standing, and strategic must be checked. This research as its predictive model[17]. Each branch of the tree is a clas-

sified category with the representing the partitions of the

1---

Customer data within their classifications. Because decision-trees

score so highly on so many of the critical features of data

Competitive advantage source mining, they can be used in to explore and predict a wide

variety of business problems.

2. Data mining overview

"Mining" means to find something that already exists.

Product

Therefore, data mining can be defined as a process of identi-

ore competitive activity fying hidden patterns and relationships, and trends within

data. For our purposes, data mining is described function-

ally with the specific goal of uncovering relevant data for

business professionals [1]. The objective of data mining,

whether for business or otherwise, is to extract new infor-

C I : product-oriented database mation from large quantities of data. The benefit of data

C2: customer-oriented database

mining is that it can turn data into actionable results. In

particular, data mining makes possible the extraction of

C3: market-oriented database hidden predictive information from large database orga-

C : core competitive opportunity nizations for identifying valuable customers, predicting

future behaviors, and enabling firms to make knowledge-

Figure 2: The core competitive opportunity resources. driven decisions [16].

VALUE ORLD Volume 29, Number 2, Fall 2006 9

Data mining is a process that attempts to identify and using data mining, deciding the input and output for-

interpret patterns in information that are important for the mat, deciding cost effectiveness, and so on. In product

performance of certain tasks. This research integrates the innovation, there are three defined categories: custom-

inflow of data about new product process with new prod- er, product, and market.

uct innovation by using data mining technology. Under-

2) Building database: building database means the discov-

standing the characteristics of data mining associated with

ery of data dependencies. In the relational data model,

a specific transformation system will provide more strate-

the definition of the relations is about the relationship

gic choices for new product innovation. For example, suc-

among their attributes. These attributes come from four

cess in an increasingly competitive marketplace depends

steps: defining the problem, selecting the data, building

critically on the quality of organized knowledge which de-

the model, and selecting the models (See figure 4).

pends on the successful integration of data mining technol-

ogy with product innovation. 3) Analyzing and searching rules: data expressed in logi-

In industry, there are clear reasons for investing in data cal languages are distinguished by two main features:

mining technology. If data mining can provide actionable (I) They are readable and understandable. (2) They are

results that improve the product design process, then data excellent for representing crisp boxes and data element

mining becomes a competitive tool. Presently, data mining groupings.

is used to both increase revenues and to reduce costs. In- 4) Building models: include the development of models

novative organizations are using data mining to reconfigure (or the extraction of knowledge patterns). These are

product offerings for the purposes of increasing sales and to the major result of data mining. Equally important is

minimizing losses due to error or fraud. their presentation and visualization.

2.1. The data mining process 5) Applying data mining to product innovation: searching

Data mining is a process that uses a variety of data product data from database which consists of inflow

analysis tools to discover patterns and relationships in data of resources (the first step of the product innovation

in order to make valid predictions. The resources derived process).

from the data result from setting up a large data warehouse 6) Evaluating the model: estimating how well a particular

that integrates data from multiple sources, resolves data pattern meets the criteria of the data mining process.

problems, and loads the data into a database. Therefore, evaluating the model reflects whether the

Having examined the overall infrastructure of data strategic planning is in place. The cycle of evaluating

mining, we are now ready to take a closer look at data min- the model supplies feedback that support product in-

ing as a process. This novation.

research delineates Defining problems 4

six major stages in 2.2. Building database

the data mining pro- Data mining begins at the bottom of knowledge with

cess: defining prob- Building databases flow data. Some of the flow data must define the scope of

lems, building data our design problems. We select for data obtained through

bases, analyzing and queries or filters becomes they are applicable to the task.

searching for rules, Analyzing and

The selected data becomes the base for building an inte-

building models, ap- searching rules grated database. After building the database, the selected

plying data mining data must be analyzed to build models. In product design,

to product innova- the database needs many formal models in order to apply

tion, and evaluating Building models

data mining to new product innovation. Selecting models

models (see figure is the final step of the database process. If hidden data can

3):

Applying data mining be made explicit through visualization, it can be used to ef-

1) Define the prob- fectively improve product innovation.

to product innovation

lem: includes The four steps to building a database are as follows:

accurately de- A defining problems, selecting data, building models, and se-

scribing the Evaluating models lecting models (see figure 4).

problem to de-

1) Defining problems: includes accurately describing de-

termine the ap-

sign problems obtained from searching the inflow of

propriateness of Figure 3: Dating mining process.

product innovation data.

10 Volume 29, Number 2, Fall 2006 VALUE ORLD

Inflow of data

41--

Feedback

1. Defining problem

Purpose :

2. Selecting data Pattern

1. Decision making

-

3. Building models mined

2. Prediction

4. Selecting models

Building database

Figure 4: The relation of database to data mining.

2) Selecting data: determines the appropriateness of using ues of other variables of interest. The aim of prediction

data that will be integrated into the database. is to predict certain data values based on similar groups

3) Building models: includes researching rules and devel- of data.

oping models.

4) Selecting models: involves selecting the best model for 3. Decision tree

solving the problems. Selecting models is key to suc- The reality is that data mining should always be con-

cessful product innovation. sidered a process, and data interpretation is the heart of

Why is building a database so important? Because the this process. How should we interpret data? Because of

database is the base of data mining. Data mining is used to the complexity of data mining, many algorithms and tech-

uncover hidden data and to predict, and to support deci- niques have been developed. These algorithms include neu-

sion-making. We describe the relationship of a database to ral networks, fuzzy theory, and decision trees, etc [16].

data mining. This research chose the decision tree to organize prod-

uct data resources, because of its commonality and long-

1) Building a database: data mining may involve data from

standing utility in describing and classifying data sets in

multiple data sources, which may reside in a distribut-

the field of computer science. Decision-tree approaches are

ed database system, or in a tighter form, a multi-data-

good for handling classification problems. Classification is

base. The complexity involved in distributed database

the process of using historical data to build a model for the

systems has stimulated organization to find alternative

purpose of understanding and prediction. Many programs

ways to achieve decision support. In effect, the database

have been developed that perform automatic induction of

is an emerging approach for effective decision support.

a decision tree. The greatest benefit to decision-tree ap-

2) Visualization: data visualization graphically represents proaches is understandability.

the structure that exists among data sets.

3) Pattern mined: extracted patterns are the major result 3.1. The meaning of a decision tree

of data mining Equally important are their presenta- Decision-tree is a common knowledge representation

tion and visualization. used for classification. In classification, one is given data

from a specific instance, and the decision tree predicts,

4) Users: data mining should benefit human users. Al- based on the data, into which of two or more classes the in-

though data mining could be an automated process, stance belongs. Each instance contains data from multiple

human users can play a very important role in guiding attributes. Instances are collections of previously acquired

the mining process. However, data mining focuses on data which are sorted into class labels. It does so by deter-

finding human-interpretable patterns describing the mining which tests best divide the instances into separate

data. classes, forming a tree. This procedure can be conceived as

5) Prediction: it is very important to determine the major a greedy search through the space of all possible decision

factors that influence the prediction and the develop- trees by scanning through the instances in a given node to

ment of trends. Prediction involves using variables or determine the gain from each split and picking the single

fields in the database to predict unknown or future val- split that provides the greatest gain. Then the instances are

VALUE ORLD Volume 29, Number 2, Fall 2006 11

partitioned based on the split, and this procedure is applied prioritization tool (See figure 6).

recursively until all the instances in a node are of the same

The prediction of a decision tree is based on the data

class [16-20] .

derived from classified instances. Each instance contains

3.2. The two types of decision tree data from multiple attributes. The decision tree struc-

The two types of decision tree include: top-down deci- ture consists of a number of branches, one root, a number

sion tree and bottom-up decision tree. Top-down decision of nodes and a number of leaves. One branch is a chain of

tree starts at the abstract and general levels of the ontol- nodes from root to a leaf; and each node involves one attri-

ogy. One benefit of top-down decision tree is that general bute. An attribute in a tree provides the information about

objects can be defined to cover "what if" scenarios, even if the importance of the associated attributes.

they are not totally implemented at first. Bottom-up deci-

sion tree begins with more concrete objects and then moves

up to complete the design.

4. Product innovation decision-tree

In this paper, we propose the structure for combin-

ing a top-down and bottom-up decision-tree. In the first

step of the data-mining process, three resources are em-

ployed to define problems: customer, product, and market

4. Root

direction(see figures 2 and 3).

1) The direction of product indicates core competitive ac-

tivity. It divides into four departments: function, mate-

op Node

rial, technique, and form

0 Leaf 2) The direction of customer indicates sources of compet-

itive advantages. It includes three departments: cus-

XI X2 and X3 Attributes tomer needs, wants, and cycles.

CI C2 C3 and C4 Classes 3) The direction of market indicates competitors. It includes

five departments: market size and marketing, etc.

Figure 5: Top-down structure of decision. The second step of the data-mining process, building

the database, includes three categories: customer-oriented,

1) Top-down : strategic buckets method: this begins with product-oriented, and market-oriented databases.

the business's strategy and then moves to setting aside 1) Customer-oriented database: the combination of cus-

funds-envelopes or buckets of money destined for dif- tomer and product directions. The core problem is

ferent types of projects (See figure 5). whether customers are satisfied with the product.

2) Bottom-up : building strategic criteria into project se- 2) Product-oriented database: the combination of product

lection tools: here strategic fit is achieved simply by in- and market directions. The core problem is whether the

cluding numerous strategic criteria into the go/kill and

product fits the capability of market.

Root

Node

0 Leaf

X I X2 ... X4 Attributes

CI C2 C3 ... C5 Classes

Figure 6: Bottom-up structure of decision tree.

12 Volume 29, Number 2, Fall 2006 VALUE ORLD

Design purpose

eed

Customer Level

Cl

Fit

Product Level

F2

Needed place

Market Level ,Stop Stop/

T1

Functionl Function2 I Function3 Function4 I Function5

/

Extracting data

M1 1 M22

\ /

Figure 8: Detailed fimction decision-tree.

Figure 7: Product target decision-tree.

gestions (see figure 8).

3) Market-oriented database: the combination of market When developing product innovation, the research

and customer directions. The core problem is whether used integrated decision tree systems, which include bot-

the market could discover and achieve customer needs tom-up and top-down decision trees.

(see figure2). Making an integrated decision adopts a top-down de-

cision tree because it can hold the targets that support the

The third step of data mining process, analyzing and

development of new product innovation. Making detailed

searching rules, adopts a decision-tree. The fourth step of the

designs adopt a bottom-up decision tree because it can have

data mining process, building models, take uses top-down

potential activities that explore new product design.

and bottom-up decision tree models. The structure then, has

a top-down product targeting design (see figure 7) and a de-

tailed bottom-up design structures (see figure 8). 5. Case study

The product target decision-tree (see figure 7) needs We have implemented these data-mining techniques

tangible targets and so determining design purpose is the into an innovation design case and will illustrate their test

initiating step of the design project. The term is classified results. The case study comes from design companies using

into four levels: customer, product, market, and extracting WWW techniques. The identities of their clients are with-

data. Arriving at a decision for the design purpose begins at held at the client's request. These companies had conduct-

the customer level. If a customer level concern could fit the ed extensive market studies of customer experiences with

design purpose, then the project will go query product level various functionalities of related hand tools and electronic

concerns. The last level, extracting data, is to find whether a products.

search data is appropriate to supporting the design purpose.

The detailed function decision-tree creates the plat- 5.1 Case study: horticulture tools

form for collecting various data. Choosing different models, This shape design system provides comprehensive, en-

data-mining through visualization, will show different sug- terprise-level, design solutions and professional services.

HTML

HTTP (HTML) Case-Based

Designer ITS Server SQL Server Database

HTTP (ASP)

*.ASP, ASP.DLL

Figure 9: The structure of communication between designer and the system.

VALUE ORLD Volume 29, Number 2, Fall 2006 13

-

,VTO 12 - B 174

EB_I

-..11tia#.9.i ;Z-.1.1.11140:0519:Fit

Ilortictilture cutti, H.ndhold torrnnfrvo xiIiazy design sy,tr•rn

[

A , B C D ' E

1 AA DI @Sketch D1 @Sketch D1 @PRI D1 @I'M

2 al 1 60' 30i 30 120

3 o2 1 50! 251 251 100

5 :43

, 40 I 201 20 80

301 15 ! 15 1 60

6 a5 I 20i 101 10 40

7 i i

Figure 10: The system home page.

Figure 11: Feature data for product shape design.

mm

feEkld.Fig

1;Sig■lhOF

r- r

It)

•:1.7_,1.1.4101111016440;W:

Figure 12: Design options. Figure 13: Fundamental shapes.

Figure 14: Case-based shape database. Figure 15: Design variable parameters.

The decision series suite of knowledge tools solves design to less-than-optimal product demand forecasting. The de-

challenges in a variety of markets, including product trend, signer was perplexed with product innovation design and

shape design, and future development. The decision series development, and could not advance either design or devel-

suite includes pattern discovery tools based on the grey opment because of a lack of design knowledge for finalizing

prediction theory, clustering, and association rules. The a design strategy.

communication structure between designer and shape de-

sign system is shown in Figure 9. 5.3 The solution

A solution, that combined elements of clustering and

5.2 The problem grey prediction theory, which enabled the designer to au-

A designer found that product value was suffering due tomatically review a product's history and equate feature

14 Volume 29, Number 2, Fall 2006

VALUE ORLD

data groupings to design patterns, has been designed and 6.1. Tools

implemented in the shape design system. Management is The tool used in this research is the logical approach,

now able to explore the lowest level of detail and forecast which can be understood as a set of rules, whereas a neu-

development requirements for creating an innovative de- ral network is obscure, with weights that have no intuitive

sign. In addition, the designer receives exacted data which meaning. The model is easy to explain to a design user be-

enables them to continuously fine-tune replenishment sys- cause it applies background domain knowledge.

tems by combining feature design data with fundamental

6.2. Userability

shape basis.

The performance of the logical approach will be faster

5.4 The results than the neural network; the risk of missing code is lower

The shape design system is able to forecast product de- than neural network too. It is a very easy method for creat-

ing a models.

sign trends at the beginning design stage. Meanwhile, the

system can cluster similar items into actionable groups to 6.3. Properties of model

streamline the design process. Design company can now Although neural networks provide more accurate mod-

predict demand for product development trends and more els, it has problems with over-fitting and finding sub-opti-

effectively create a good product shape.. System operation mal solutions. The Logical approach needs more data for a

steps, including user interface, feature data, case-based pre- model to ensure that there is critical mass in the leaf nodes

diction database, shape database, and are shown in Figure. following the many branches. Neural networks require that

10 to Figure. 15. the data be transformed into a binary format.

For the construction of a model, the logical approach

is quicker and easier than neural networks because neural

6. Logical (Decision Trees) vs. networks have many parameters that must be set and re-

Equational (Neural Nets) quire more skilled manipulation to ensure over-fitting does

In earlier approaches to data mining, the data set was not occur. So, the cost of building a neural network model

maintained for future pattern matching. Approaches based is higher than the logical approach, and it requires more

on pattern distillation fall into three categories: logical, time and building skills.

crosstabulation, and equational. These technologies ex-

tract patterns from a data set and then use the patterns for 7. Conclusion

various purposes. The logical approach deals with both nu- Supporting design innovation processes with tecimol-

meric and non-numeric data. Equations require all data to ogy and methods from the field of knowledge management

be numeric, while crosstabulations work only on non-nu- can have a beneficial effect both on product and financial

meric data. Table 1 summarizes the pros and cons of these development. The new knowledge made available by data

categories. mining can lead to more competitive products. To process

Approach Pros Cons

Logical Work well with multidimensional and OLAP Unable to work with smooth surfaces that

data typically occur in nature

Able to deal with numeric and nonnumeric

data in a uniform manner

Cross-tabulation Simple to use with small number of non- Not scalable

numeric values

Equational Works well on large sets of data Ability to handle numeric values

Works well with complex multi-dimen- Ability to handle conjunctions

sional models

Ability to approximate smooth surfaces Require all data to be numeric (nonnu-

meric must be coded)

System can quickly become a "blackbox"

Table 1: Pros and cons to data mining approaches.

VALUE ORLD Volume 29, Number 2, Fall 2006 15

this information we found that the integrated decision tree ference on engineering design, Glasgow, UK, pp.13-20

systems, which include bottom-up and top-down deci-

[10]V Hubka and W E Eder, 2001, functions revisited,

sion tree are most applicable to product innovation. New

13th international conference on engineering design,

product innovative development adopts a top-down deci-

Glasgow, UK, pp.6 9-76

sion tree because it can hold the target. Making detailed

designs adopts a bottom-up decision tree because it can [11] C T Hansen, 2001, verification of a new model of de-

analyze new product design. Finally, tools and experience cision-making in design Decision-making in design,

from knowledge management and best business practices 13th international conference on engineering design,

are vital in the assessment of designs in relation to business Glasgow, UK, pp.101-108

goals. [12]Motokazu Orihata and Chihiro Watanabe, 1999, the

Knowledge management in design will support deci- interaction between product concept and institutional

sion-making with broader, more transparent and acces- inducement: a new driver of product innovation, Tech-

sible knowledge bases, and organize data in generally rec- novation Vol. 20, pp.11-23

ognized and widely used decision-making models such as

the Integrated Decision Tree model. It will also provide an [13]Raghavan Parthasarthy and Jan Hammond, 2001, Prod-

objective and quantifiable foundation for trend-analysis uct innovation input and outcome: moderating effects

and market predictions. Such technology, constructs, and of the innovation process, Journal of Engineering and

models will greatly improve design, product, and design- Technology Management, Vol.19, pp.75-91

related business decisions. [14] John H. Friar, 1995, Competitive advantage through

product performance innovation in a competitive mar-

ket, the Journal of product innovation management,

Acknowledgements Vol. 12, pp.33-42

This research was partially supported by Chaoyang

University of Technology in Taiwan under the project [15]Udo-Ernst Haner, 2002, Innovation quality-a concep-

number CYUT93-D-003 tual framework, International journal of product eco-

nomics, Vol.80, pp.31-37

[16]Chris Rygielski, Jyun-Cheng Wang, David C. Yen, 2002,

References

Data mining techniques for customer relationship man-

[1] Robert Groth, 2000, Data Mining, Hall PTR, New Jer-

sey agemet, Technology in Society, Vol. 24, pp.483-502

[17]Chris Clifton, Bhavani Thuraisingham, 2001, Emerging

Zhengxin Chen, 2001, Data Mining and Uncertain Rea-

standards for data mining, Computer standards and in-

soning, Wiley Inter-science, Canada

terfaces, Vol. 23, pp.187-193

Robert G. Cooper, 2001, Winning at New Product, Per-

seus publishing, New York [18]Jules J. Berman, 2002, Confidentiality issues for medi-

cal data miners, Artficial Intelligence in Medicine, Vol.

C. Merle Crawford, 1996, New Products Management, 26, pp.25-36

Mc Graw Hill, America

[19]Helen M. Moshkovich, Alexander I. Mechitove, and

Paul Belliveau, Abble Griffin, and Stephen Somermeyer, David L. Olson, 2002, Rule induction in data mining:

2002, the PDMA Toolbook for New Product Develop- effect of ordinal scales, Expert Systems with Applica-

ment, Wiley Inter-science, Canada tions, Vo122, pp.303-311

[6] Vijay Atluri and John Hale, 2000, Research Advances

[20]Nianyi Chen, Dongping Daniel Zhu, and Wenhua

in Database and Information Systems Security, Kluwer Wang, 2000, Intelligent materials processing by hyper-

Academic, America

space data mining, Vol. 13, pp.527-532

[7] Ranjit K. Roy, 2001, Design of Experiments Using the

[21]Jeffrey P. Bradford and Jose A. B. Fortes, 2001, Charac-

TAGUCHI Approach,Wiley Inter-science, Canada terization and Parallefization of decision-tree induc-

[8] John M. Usher, Utpal Roy, and Hamid R. Parsaei, 1998, tion, Journal of Parallel and Distributed Computing ,

Integrated Product and Process Development, Methods Vol. 61, pp.322-349

tools and Technologies, Wiley Inter-science, Canada

[22]Zhou Yuanhui, Lu Yuchang, and Shi Chunyi, 1997,

[9] Horvdth, 2001, A contemporary survey of scientific re- Mining classification rules in multistrategy learning

search into engineering design, 13th international con- approach, Intelligent Data Analysis, Vol.2 pp.165-185

16 Volume 29, Number 2, Fall 2006

VALUE ORLD

•

[23]S. Lavington, N. Dewhurst, E. Wilkins, and A. Freitas, W.L. Ip, 2002, An innovative scheme for product and

1999, Interfacing knowledge discovery algorithms to process design, Journal of Materials Processing Tech-

large database management systems, Information and

nology, Vol.123, pp.85-92

Software Technology, Vol. 41, pp. 605-617

[24]M. A. Friedl and C. E. Brodley, 1997, Decision tree clas- [36] Leslie Monplaisir, 1999, An integrated CSCW architec-

sification of land cover from remotely sensed data, Re- ture for integrated product/ process design and devel-

mote Sensing of Environment, Vol. 61, pp. 399-409 opment, Robotics and Computer-Integrated Manufac-

[25]Cristina Olaru and Louis Wehenkel, 2003, A complete turing, Vol.15, pp.145-153

fuzzy decision tree technique, Fuzzy Sets and Systems, [37]Ting-Kuo Peng and Amy J.C. Trappey, 1997, A step to-

Vol. 138, pp.221-254

ward STEP-compatible engineering data management:

[26]Richard Nock and Pascal Jappy, 1999, Decision tree the data models of product structure and engineering

based induction of decision lists, Intelligent Data Anal-

changes, Robotics and Computer-Integrated Manufac-

ysis, Vol. 3, pp. 227-240

turing, Vol.14, pp.89-109

[27]L. M. Bartlett and J. D. Andrews, 2000, An ordering

heuristic to develop the binary decision diagram based [38]X.F. Zha and H. Du, 2002, A PDES/STEP-based model

on structural importance, Reliability Engineering and and system for concurrent integrated design and as-

System Safety, Vol.72, pp. 31-38 sembly planning, Computer-Aided Design, Vol.34,

[28]Han-Pang Huang and Chao-Chiun Liang, 2002, Strat- pp.1087-1110

egy-based decision making of a soccer robot system us-

[39]Philippe Girard and Guy Doumeingts, 2003, Modeling

ing a real-time self-organizing fuzzy decision tree, Vol.

127,pp. 49-64 the engineering design system to improve performance,

Computers and Industrial Engineering, Vol.46, pp.43-

[29]Pi-Sheng Deng, 1996, Using case-based reasoning ap-

67

proach to the support of ill-structured decisions, Euo-

pean Journal of Operational Research, Vol. 93, pp. 511- [40]Roger J. Calantone, Shawnee K. Vickery and Cornelia

521 Droge, 1995, Business performance and strategic new

[30]Kweku-Muata and Osei-Bryson, 2004, Evaluation of product development activities: an empirical investiga-

decision trees: a multi-criteria approach, Computers tion, The Journal of Product Innovation Management,

and Operations Research, Vol. 31, pp.1933-1945

Vol.12, pp.214-223

[31]Rattikorn Hewett and John Leuchner, 2002, Restruc-

turing decision tables for elucidation of knowledge, [41]David D. Ardayfio, 2000, Principles and practices of de-

Data and Knowledge Engineering, Vol. 46, pp. 271-290 sign innovation, Technological Forecasting and Social

Change, Vol.64, pp.155-169

[32]Pedro Domingos, 1997, Knowledge discovery via mul-

tiple models, Intelligent Data Analysis, Vol.2, pp.187- [42] Information Discovery, Inc. A characterization of

202 data mining technologies and processes: an Infor-

[33]Arun Sen, 2002, Metadata management: past, present mation Discovery, Inc. White Paper. http://www.

and future, Decision Support System, Vol.37, pp.151-173 dmreview.com/portal —ros.cfm?NavID-92&White-

[34]Fujun Wang, John J. Mills and Venkat Devarajan, 2001, Paper-6 0 &PortalID-9

A conceptual approach managing design resource,

Computers in Industry, Vol.47, pp.169-183 Professor Tai Shen Huang teaches at the Guaduate Institute of De-

-

[35] Henry C.W. Lau, Bing Jiang, Felix T.S. Chan and Ralph sign, Chaoyang University Technology in Taiwan.

It's not a REAL value study without a CERTIFIED VALUE SPECIALIST.

• For more information on finding a Certified Value Specialist or becoming certified, contact SAVE International. SAVE

• International is the only organization renowned throughout the world as the value industry standard for certification.

• 136 South Keowee Street, Dayton, OH 45402 USA • T 937.224.7283 • info@value-eng.org • www.value-eng.org

VALUE WORLD Volume 29, Number 2, Fall 2006 17

Value Driven Design

Paul D. Collopy, Ph.D. and Joseph F. Otero, Jr., CVS-Life

Abstract sible airplane? Optiinization literally means choosing the

In October of 2005, the Value-Driven Design Program best. When optimization is available, all other design pro-

Committee held a one-day workshop in Hartford, Con- cesses are inferior.

necticut, sponsored by Pratt & Whitney, to explore the Optimization has three essential parts:

application of Value-Driven Design to a commercial aero- 1) A definition of better;

space product. The trial application was a supersonic busi- 2) Generation of alternatives; and,

ness jet.

Value-Driven Design is a tool to enable design optimi- 3) Evaluation of pairs of alternatives to determine which

is better.

zation of large systems, such as aircraft, by the formulation

of system and component value models. In the workshop, a By successive comparison of alternatives, we can find

team of engineers primarily from the American Institute ofwhich is best. At its core, optimization is that simple.

Aeronautics and Astronautics and SAVE International for- Optimization is a very refined techni.que that can in-

mulated a value model for the aircraft and derived a value clude far more than these essentials. For example, in engi-

model for a critical component, the supersonic jet engine.neering design, better is defined in terms of attributes such

This paper describes the workshop and what we learned as energy efficiency, reliability, and manufacturing cost.

from the experience. It introduces the Value-Driven DesignAlternatives are created through imagination, skill and ex-

(VDD) process and explains the benefits of VDD. In re- perience. The design optimization process is shown in Fig-

ure 1 (below left). Creation of alternatives is the upper right

counting the workshop, the authors describe what worked

arc. Initially, alternatives are rough descriptions in terms

well, and what lessons were learned of value to future users

of a few parameters. For example, a wing design might be

of VDD.

described by the span, chord, taper, sweep and thickness.

In the lower left arc, this description is elaborated into, for

Optimization example, a computer-aided design model of the wing, with

Why would we ever design an airplane that simply the entire outer surface and inner structure modeled. The

meets requirements, rather than designing the best pos- lower right arc assesses this detailed configuration to es-

timate the attributes of the wing:

Value lift, drag, weight, cost, and so on.

Formal training in engineering

Search school is almost entirely focused

on how to do the analyses in the

lower left arc.

Finally, the upper left arc

evaluates the attributes so that

Attributes Design Cycle Parametem this particular design can be com-

pared to others. Making such

comparisons is equivalent to plac-

ing the designs in order, or, math-

ematically, mapping them into an

Analysis Definition t`.< ordered set. Real numbers are the

Including Mass complete ordered field, so evalu-

Performance, and ation, in practice, always entails

Cost Estimation mapping a set of attributes onto

Configuration

the real numbers. In Value-Driven

F igure 1: Design optimization process. Design, we call the map from at-

tributes to real numbers a value

18 Volume 29, Number 2, Fall 2006 VALUE ORLD

model. You can think of a value model as a scoring process the shortfall, or the program is canceled.

where better designs receive higher scores. Value-Driven Design (VDD) aims to achieve the best

Optimal design has been seriously studied by a large design by moving away from requirements and working in-

academic community for decades. The discipline has made stead from a value model for every system, subsystem, and

great strides forward, and increases in computer capability component, to enable universal application of optimal de-

have enabled practical application of powerful optimization sign. The key to VDD is the value model, in particular, value

techniques. However, most design tasks do not use optimi- models for subsystems and components. The mathematical

zation. Why do engineering teams neglect the opportunity derivation of component value models is presented in Col-

to design the best possible system or component? lopy (2004' To understand the issues, it is worthwhile to

Mainly, it is because today's systems engineering pro- review the basis for requirements-based design.

cess does not provide a value model. When optimization Complex systems cannot be designed in a single act

is done, it uses a single attribute as the score, yielding the by a single person—they are too complicated. Therefore,

lowest weight or lowest cost design, invariably not what is a strategy of divide and conquer is employed (Dykstra,

desired. Within the standard requirements-based process 1965).2 The system in partitioned into a hierarchy of sub-

there is no effective way to distinguish which of two de- systems and components. Given a set of requirements for

signs is better. Requirements give only a crude measure: if the system, requirements are chosen for the components

Design A meets the requirements, and Design B does not, A such that, if every subsystem and component meets its re-

is better. However, requirements provide no guidance for quirements, the entire system, when integrated, will meet

choosing among designs when all meet the requirements. its requirements.

If an engineer can sacrifice reliability to reduce weight or Analogously, Value-Driven Design works from a sys-

increase durability at a higher weight, requirements pro- tem value model to create component value models, such

vide no guidance. Also, it is not unusual for an engineer to that, if each component is the very best design possible, ac-

determine that there is no way for a component to meet all cording to its value model, then the system will be the very

its requirements. Perhaps it can meet the efficiency require- best design according to its own value model.

ment, but exceed the weight limit; or meet the weight limit The basic steps in VDD are:

and miss the required efficiency. Requirements provide no

indication as to which alternative is better. 1) Development of a system value model.

Cost as an Independent Variable (CAIV) is a newer 2) Derivation of subsystem and component value models

process that gives more guidance. CAIV says the best de- from the system value model.

sign is one that meets all requirements at the lowest pos- 3) Optimal design of all components and all subsystems.

sible cost. As long as at least one design alternative meets

requirements, CAIV can lead to selection of a best design, 4) Integration of the parts into the full system.

where best is all about cost. The Hartford workshop was held to work through

Both traditional requirements-based design and CAIV steps (1) and (2), and to get a feel for their difficulty and

can lead to absurd choices. Imagine an aircraft with a re- practicality. We also learned useful lessons about how to

quirement of 2500 mile range and 5000 hours mean time apply VDD to actual projects.

between failure. Consider two alternatives: Design A has

7000 miles of range and 4999 hours between failures. De-

sign B has 2501 miles of range and 5001 hours between fail- Details Of How A Value Model Is

ures. In all other measures, the designs are identical. Re- Created

quirements-based design and CAIV will both pick B over At the October, 2005, meeting, the team developed a

A, although A is obviously the better design. value model for a supersonic business jet and derived from

The way we execute such designs in practice is to let the value model an objective function to optimize engine

the design proceed for a time until the system is perceived design for the hypothetical aircraft. The point of this exer-

to be too heavy, too unreliable, or whatever. At that point, cise was to show that, using Value-Driven Design, once the

great consternation is expressed over weight or whichever value model for the top level system is established, consis-

attribute exceeded requirements, and the design is redone tent objective functions can be derived for all components

with everyone admonished to do better about weight or of the system. These objective functions largely replace

other unsatisfactory measure. The whole process can be re- requirement specifications as guidance for component de-

peated again for another attribute. Eventually, the system signers. The trial application was chosen to avoid inference

meets requirements, or the customer becomes resigned to with any potential products then under consideration by

ORLD Volume 29, Number 2, Fall 2006 19

Pratt & Whitney, a designer and manufac- U.S. CMI and Jcint Use Airperts

.uoliMJrpera

with Highest Frequencyof GA Aircraft

turer of turbine engines, rocket engines, and Maximum WeigFrt Re5trictiora

10 OIL .44rpor Is

turbine engine services. 350000

The following steps were taken. Each AIRPOIrrs

AVAILABLE

will be discussed shortly in some detail. ap0000

to ihe OSILI

1) The workshop began with a review of

background material on supersonic

business jets (SSBJ5). 4

* •

—41-4 1.4*

2) Then, the basic structure of the value ,4 4 4, 4-

model was decided on. 1 4.ren,

144

3) Next, stakeholders were identified.

4) That made it possible to select the key

attributes of the SSBJ design.

5) Then the team completed the SSBJ value

model.

6) Then key attributes of the engine design 2E00 4000 soto ono 1 00G0 120E0 14000 16030

Langti crt Longa it Runwa y (113 et)

were next identified.

7) Relationships between engine at- Figure 2: Gross weight and takeoff field length limitations.

tributes and aircraft attributes were

worked out.

Total Mission Range with Subsonic Portion

8) A spreadsheet was put together High Boom, 6 pax, Full Fuel, ISA, No Wind

5500

with all this information, and the

objective function for engine de- 5250

sign was derived.

55 % Survey Respondents Require 5000 nm

5000

Tota l Miss ion Rang e ( nm)

Step 1. Review Back- 4750

ground On The Super-

4500

sonic Business Jet 38 % Survey Respondents:

We reviewed a Raytheon Study, Require 4500 rim,

4250

sponsored by NASA, on the feasibil- 1

ity of a supersonic business jet (SSBJ). 4000 - - - - - - - - - -

16 % Survey Respondents "."-*-4

Two of the most important elements of I

Require 4000 nm

-4...

3750 1

the study are shown below. The first 1

shows how gross weight and take-

3500

off field length can limit the number 0 500 1000 1500 2000 2500 3000 3500 4000

of airports available to a business jet. Subsonic Range of Mission (nm)

(See Figure 2, above.) The second chart

Figure 3: Results of surveys concerning importance of aircraft range.

shows results of surveys of potential

SSBJ customers concerning

the importance of aircraft

Goodness = NPV (Production Profit) + Societal Good - Developmental Cost

range. (See Figure 3, midle.)

Production Profit = Market Share X Market Size X (Price - Manufacturing Cost)

Price + NPVC (Customer Profit) + Charm - Competition

Customer Profit + Utilization X (Value per Flight - Cost per Flight)

Figure 4: Value model based on profit to the manufacturer.

20 Volume 29, Number 2, Fall 2006 VALUE ORLD

Step 2; Determine Val- the design: O Passengers

O Customer company

ue Model Structure • Flight crew

• Customer corporations • Utilization

A straightforward value model

• Passengers O Customer company

might be the following, where value

• Leasing company O Passengers

is based on profit to the manufactur-

• Key acquisition decision makers O Leasing company