Professional Documents

Culture Documents

Equipment Inspection Checklist

Uploaded by

Febrian Tamara0 ratings0% found this document useful (0 votes)

61 views13 pagesCopyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

61 views13 pagesEquipment Inspection Checklist

Uploaded by

Febrian TamaraCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 13

Doc No.

:

Rev No. : 00

CHEKLIST CHAIN PULLEY BLOCK

Date :

Page :1

Equipment Number

Note: Please tick (√) in the given box Yes or No.

No. Description Yes No Remarks

Chain pulley block should be in good and working

1

condition and certified by TPI.

Chain should be free from defects. (e.g. crack,

2

corrosion, etc.)

3 Hook should be in good condition, not stretched

more than 15% of its original shape.

4 Safety latch should be in hook.

5 Safe working load should be marked and visible.

6 Rotating part should be covered.

RESULT PASS FAIL

Inspected By Reviewed By Acknowladge By

Name: Name: Name:

Signature with date: Signature with date: Signature with date:

Doc No. :

Rev No. : 00

CHEKLIST TOOLS & TACKELS

Date :

Page :1

Equipment Number

Note: Please tick (√) in the given box Yes or No.

No. Description Yes No Remarks

Wire sling should be free from defects, (e.g.

1

corrosion, crack, cuts & oily, etc.)

2 Use thimble for making l-shape.

3 Wire rope should be knotted with proper clamp.

Web sling should be free from defects, (e.g. cuts,

4

abrasion, knot, hole & oily, etc.)

5 l-shape should be free from damages.

D-shackle should be in good condition and its face

6 should not expand more than 15% of its original

shape.

7 Suitable l-bolt should be used.

Lifting tools & tackles should be used having suitable

8 strength & capacity.

Lifting tools & tackles should be handle and store in

9

safe manner.

RESULT PASS FAIL

Inspected By Reviewed By Acknowladge By

Name: Name: Name:

Signature with date: Signature with date: Signature with date:

Doc No. :

Rev No. : 00

CHEKLIST DRILL MACHINE

Date :

Page :1

Equipment Number

Note: Please tick (√) in the given box Yes or No.

No. Description Yes No Remarks

Drill machine should be in good and working

1

condition.

Power cable should be free from damages and

2

connection taken through industrial plug.

3 A flexible cord should be provided to keep cable free

from damage.

4 Dead man switch should be in working condition.

5 Handle should be provided for better control.

Drill bit should be in good condition and free from

6

defect.

7 Always use designated key for removing and

changing drill bit.

Drill machine should be double insulated otherwise

8

grounded.

9 Machine operated by competent person.

RESULT PASS FAIL

Inspected By Reviewed By Acknowladge By

Name: Name: Name:

Signature with date: Signature with date: Signature with date:

Doc No. :

Rev No. : 00

CHEKLIST PORTABLE GRINDER

Date :

Page :1

Equipment Number

Note: Please tick (√) in the given box Yes or No.

No. Description Yes No Remarks

Grinding machine should be in good and working

1

condition.

2 Power cable should be free from damages and

connection taken through industrial plug.

A flexible cord should be provided to keep cable free

3

from damage.

4 Motor capacity should be marked in RPM.

5 Dead man switch should be in working condition.

6 Handle should be provided for better control.

Wheel guard should be properly installed with

7 machine, so that gap between guard and wheel

should not be more than 3mm.

Grinding/cutting wheel should free from defect and

8

rotating capacity should be marked.

Grinding machine should be double insulated

9

otherwise grounded.

Always use designated key for removing and

10

changing wheel.

11 Machine operated by competent person.

12 RPM of wheel Should be more than RPM of motor.

RESULT PASS FAIL

Inspected By Reviewed By Acknowladge By

Name: Name: Name:

Signature with date: Signature with date: Signature with date:

Doc No. :

Rev No. : 00

CHEKLIST WELDING MACHINE

Date :

Page :1

Equipment Number

Note: Please tick (√) in the given box Yes or No.

No. Description Yes No Remarks

Welding machine should be in good and working

1

condition.

2 Power cable should be free from damages and

connection taken through industrial plug.

3 Switches should be free from defects, (e.g.

unInsulated & damagees, etc.)

Welding led & return led connection should be

4

tightly by means of lugs/socket.

Welding led & return led should be free from

5

damage, (e.g. cuts, naked, too many joint, etc.)

Welding holder should be in good condition and free

6

from metal contact.

Earthing holder should be in good condition and free

7 from rust.

Welding machine should be grounded as per ISO

8

3043:1987.

9 Keep fire extinguisher at working place.

10 Provide booth, made by fire retardent metarial (if

required).

11 Work carried out by competent person.

RESULT PASS FAIL

Inspected By Reviewed By Acknowladge By

Name: Name: Name:

Signature with date: Signature with date: Signature with date:

Doc No. :

Rev No. : 00

CHEKLIST ELECTRICAL PUMP MOTOR

Date :

Page :1

Equipment Number

Note: Please tick (√) in the given box Yes or No.

No. Description Yes No Remarks

1 Physical condition of pump should be good.

2 Power cable should be free from damages and

connection taken through industrial plug.

3 Cable entry point should be fully packed, so that

water cannot enter.

4 Junction box of motor should be free from defects.

5 On/off switch should be properly insulated.

Rotating part of machine should be covered by fixed

6

guard.

7 Machine grounded as per ISO 3043:1987.

RESULT PASS FAIL

Inspected By Reviewed By Acknowladge By

Name: Name: Name:

Signature with date: Signature with date: Signature with date:

Doc No. :

Rev No. : 00

CHEKLIST AIR COMPRESSOR

Date :

Page :1

Equipment Number

Note: Please tick (√) in the given box Yes or No.

No. Description Yes No Remarks

1 Physical condition of compressor tank should be in

good and certified by TPI.

2 Piston should be in good condition.

3 Motor should be in good and working condition.

4 Inspection date and due date should be clearly

marked.

5 Pressure gauge should be in working state and free

from defects.

6 Safety valve should be calibrated at regular interval.

7 Any other valve should be free from defects and in

working condition.

8 Rotating part should be covered with fixed guard.

9 All joints should be properly tighten.

10 Compressor should be grounded as per IS

3043:1087.

11 Power cable should be free from defects and

connection taken through industrial plug.

12 Whip arrestor is in good condition.

RESULT PASS FAIL

Inspected By Reviewed By Acknowladge By

Name: Name: Name:

Signature with date: Signature with date: Signature with date:

Doc No. :

Rev No. : 00

CHEKLIST BENCH CUTTING MACHINE

Date :

Page :1

Equipment Number

Note: Please tick (√) in the given box Yes or No.

No. Description Yes No Remarks

1 Physical condition of body should be good and

sound.

2 On/Off switch should be in proper condition.

3 Fixed guard should be in good condition.

Auto adjustable guard should be functional

4 condition.

Cutting wheel should free from defect and rotating

5 capacity should be marked, standard quality of

cutting wheel used.

6 Positioning screw should be in working condition.

7 Power cable should be free from damage and

connection should taken through industrial plug.

8 Machine should be double insulated or grounded.

9 Always use designated key for changing wheel.

10 Machine operated by competent person.

RESULT PASS FAIL

Inspected By Reviewed By Acknowladge By

Name: Name: Name:

Signature with date: Signature with date: Signature with date:

Doc No. :

Rev No. : 00

CHEKLIST PEDESTAL GRINDER

Date :

Page :1

Equipment Number

Note: Please tick (√) in the given box Yes or No.

No. Description Yes No Remarks

Physical condition of body should be good and

1

sound.

2 On/Off switch should be in proper condition.

3 Wheel guard should be in good condition.

4 Tool rest should be available at distance of 3 mm

from rotating wheel.

5 Eye guard and spark deflector should be available.

6 Machine should be double insulated or grounded.

Wheel should free from defect and rotating capacity

7 should be marked.

Power cable should be free from damage and

8

connection taken through industrial plug.

9 Always use designated key for changing wheel.

10 Machine operated by competent person.

RESULT PASS FAIL

Inspected By Reviewed By Acknowladge By

Name: Name: Name:

Signature with date: Signature with date: Signature with date:

Doc No. :

Rev No. : 00

CHEKLIST CIRCULAR SAW

Date :

Page :1

Equipment Number

Note: Please tick (√) in the given box Yes or No.

No. Description Yes No Remarks

Physical condition of body should be good and

1

sound.

2 On/Off switch should be in proper condition.

3 Fixed guard should be in good condition.

4 Auto adjustable guard should be functional

condition.

Wheel should free from defect and rotating capacity

5

should be marked.

Power cable should be free from damage and

6 connection taken through industrial plug.

7 Machine should be double insulated or grounded.

8 Always use designated key for changing wheel.

9 Machine operated by competent person.

RESULT PASS FAIL

Inspected By Reviewed By Acknowladge By

Name: Name: Name:

Signature with date: Signature with date: Signature with date:

Doc No. :

Rev No. : 00

CHEKLIST JACK HAMMER

Date :

Page :1

Equipment Number

Note: Please tick (√) in the given box Yes or No.

No. Description Yes No Remarks

1 Panel Electrical

2 Machine should be double insulated or grounded.

3 On/Off switch should be in proper condition.

4 BIT

5 Always use designated key for Bit.

6 Wiper in good working condition

7 Condition of Nut

8 Machine operated by competent person.

RESULT PASS FAIL

Inspected By Reviewed By Acknowladge By

Name: Name: Name:

Signature with date: Signature with date: Signature with date:

Doc No. :

Rev No. : 00

CHEKLIST FORKLIFT

Date :

Page :1

Equipment Number

Note: Please tick (√) in the given box Yes or No.

No. Description Yes No Remarks

1 No Damage- Bent, dented or broken parts

2 No Leaks – Fuel, oil, radiator, hydraulics

3 No damage in tire (Bolts, crack, cuts, air pressure, etc)

4 CHAINS, CABLES & HOSES – In place

BATTERY – Battery cable and connector condition.

5 Cable routing (not outside of truck). Battery retainer

securely in place.

GUARDS – All guards in place and condition.

6 Overhead, load backrest, etc. Gates and side rails

7 Seat belt available

OPERATOR COMPARTMENT/CONTROLS – All

8 controls, steer tiller, pedals, etc. in good

condition. Seat locks in position.

POWER UP – Turn on key. All indicator lights and

9

alarms are working.

POWER DISCONNECT – Cuts off all electrical

10

power.

ELECTRICAL SAFETY DEVICES – Horn, audible

11 signals, entry bar, flashing lights, indicator lights,

etc. work properly

12 STEERING – No binding, no excessive play

BRAKES & TRAVEL CONTROLS – Check braking

13 & plugging distances while traveling slowly at first. If ok,

then check at higher speeds. Acceleration

14 smooth,

PARKINGnot jerky.

BRAKE – Seat, hand or foot

HYDRAULIC CONTROLS – Test all hydraulic

15 functions for smooth and proper operation and no

unusual noise.

16 LIMIT SWITCHES – Travel limit, lift limit, tilt limit,

safety reverse (walkies), etc.)

BATTERY CHARGE – Discharge meter in full green

17

or 75% charge after raising forks.

18 Fire extinguisher in operator cabin

19 Driver have valid license

Normal & emergency break in good

20

working condition

RESULT PASS FAIL

Inspected By Reviewed By Acknowladge By

Name: Name: Name:

Signature with date: Signature with date: Signature with date:

You might also like

- Bar Cutting Machine Safety Inspection ChecklistDocument1 pageBar Cutting Machine Safety Inspection ChecklistsanjeetNo ratings yet

- LBMDocument4 pagesLBMmekotechNo ratings yet

- Contoh CSMS: 1. GeneralDocument11 pagesContoh CSMS: 1. GeneralariesyihaNo ratings yet

- I & M P S H: Nspection Aintenance Rocedure For Afety ArnessesDocument4 pagesI & M P S H: Nspection Aintenance Rocedure For Afety ArnessesUlviyye ElesgerovaNo ratings yet

- Operation Control - Powered and Hand Tools Procedure: Pt. Eskimo WieraperdanaDocument7 pagesOperation Control - Powered and Hand Tools Procedure: Pt. Eskimo WieraperdanadennisjuntakNo ratings yet

- JSA Steel Structure FabricationDocument8 pagesJSA Steel Structure FabricationArib RahmanNo ratings yet

- Lifting Plan Mobilisasi TMCDocument9 pagesLifting Plan Mobilisasi TMCbobbyNo ratings yet

- Compro Russindo Group Tahun 2018 UpdateDocument44 pagesCompro Russindo Group Tahun 2018 UpdateElyza Farah FadhillahNo ratings yet

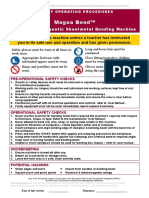

- Magna Bend SopDocument1 pageMagna Bend SopClarkKent Fabro Batucan0% (1)

- General or Cold PTWDocument2 pagesGeneral or Cold PTWVijayakumar KarunanidhiNo ratings yet

- Lifting Permit FormDocument4 pagesLifting Permit FormMohammed SameenNo ratings yet

- Scissor Lift ChecklistDocument1 pageScissor Lift ChecklistDIBNESH PANDITA100% (1)

- Gas Cutting (Welding Inspection)Document1 pageGas Cutting (Welding Inspection)Adhy DarmawanNo ratings yet

- CsmsDocument42 pagesCsmsrizkiNo ratings yet

- Chain Block Inspection Checklist FormDocument1 pageChain Block Inspection Checklist FormIhsan yaqoobNo ratings yet

- Daily Progress Report: SI Number: RIG PDSI#403/DS1500.EDocument71 pagesDaily Progress Report: SI Number: RIG PDSI#403/DS1500.EAgung Tri SugihartoNo ratings yet

- Form ChecklistDocument6 pagesForm ChecklistWiwin LatifahNo ratings yet

- Inspection Check ListDocument2 pagesInspection Check ListMustain Hafid100% (1)

- 006 PLI - Form - Inspection Lifting GearDocument3 pages006 PLI - Form - Inspection Lifting GearRicky Stormbringer ChristianNo ratings yet

- Job Safety Analysis/Hiradc: Cut & Fill, Install RCPDocument10 pagesJob Safety Analysis/Hiradc: Cut & Fill, Install RCPMuhammad Azhar100% (1)

- Bench GrinderDocument6 pagesBench GrinderGaurav KhamkarNo ratings yet

- CP PT TTI (Jan 2018) New PDFDocument38 pagesCP PT TTI (Jan 2018) New PDFHaryadiNo ratings yet

- 2 JHA On Shot Grit Blasting1Document3 pages2 JHA On Shot Grit Blasting1Akhilesh KumarNo ratings yet

- Katalog TSP PTDocument24 pagesKatalog TSP PTendroNo ratings yet

- 3.hiradc Install Steel Structure .FDocument65 pages3.hiradc Install Steel Structure .FHerman SyahNo ratings yet

- Risk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelDocument3 pagesRisk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelMohamed ElnagdyNo ratings yet

- JTB Unitization Gas Project: Electrical Equipment/ Tools Inspection ChecklistDocument1 pageJTB Unitization Gas Project: Electrical Equipment/ Tools Inspection ChecklistAK MizanNo ratings yet

- LIFTING PLAN Crane 7tonDocument1 pageLIFTING PLAN Crane 7tonSeftian Muhardy100% (1)

- M/S Kapoor Enterprises Vendor Code: K635: Mechanized Rock Breaker ChecklistDocument2 pagesM/S Kapoor Enterprises Vendor Code: K635: Mechanized Rock Breaker Checklistprojit basu100% (1)

- 2 0 2 0 Rigging Study & Lifting Study: SeptemberDocument57 pages2 0 2 0 Rigging Study & Lifting Study: SeptemberTaufan Arif ZulkarnainNo ratings yet

- SWP Manual Bending Rolls AS524Document2 pagesSWP Manual Bending Rolls AS524jason cepadaNo ratings yet

- SOP Overhead Crane-Rev.1Document5 pagesSOP Overhead Crane-Rev.1RonniNo ratings yet

- Hiab Crane Preuse Inspection ChecklistDocument2 pagesHiab Crane Preuse Inspection ChecklistBeyar. Sh100% (2)

- EEBD Inspection Checklist: SR - No. Yes No Points To CheckDocument1 pageEEBD Inspection Checklist: SR - No. Yes No Points To CheckAbdul HadiNo ratings yet

- Transferring Fuel: Task Detailed Steps Hazards or Potential Incidents Recommended Hazard ReductionDocument2 pagesTransferring Fuel: Task Detailed Steps Hazards or Potential Incidents Recommended Hazard ReductionCarlos SantosNo ratings yet

- FC 4.1.31 - Crawler Crane Checklist FormDocument2 pagesFC 4.1.31 - Crawler Crane Checklist Formkhrayzie bhoneNo ratings yet

- Form Check List Maintenance: Activity 250 500 1000 2000 RemarksDocument1 pageForm Check List Maintenance: Activity 250 500 1000 2000 Remarksferry saputra100% (2)

- EHS-F16-R00 - Gas Cutting Set-DailyDocument7 pagesEHS-F16-R00 - Gas Cutting Set-DailyVaibhav RaiNo ratings yet

- Jadwal Training 2019 JakartaDocument4 pagesJadwal Training 2019 JakartaTsudjatmikoNo ratings yet

- Webbing Sling Safety Inspection Checklist Report PilotDocument1 pageWebbing Sling Safety Inspection Checklist Report PilotThirumaran MuthusamyNo ratings yet

- DEL - 064 Jsa For Load Test of Davit ArmsDocument4 pagesDEL - 064 Jsa For Load Test of Davit ArmsMohammed Minhaj100% (1)

- Contractor EHS Statistics: Contractor Company Name: Month: July - 2022Document4 pagesContractor EHS Statistics: Contractor Company Name: Month: July - 2022fasilNo ratings yet

- Crawler Crane Checklist Rev 0Document2 pagesCrawler Crane Checklist Rev 0Maizatul Akmar Manshor100% (2)

- Inspection Checklist of Drill Machine: Project Name: Date: Time: Checked byDocument1 pageInspection Checklist of Drill Machine: Project Name: Date: Time: Checked byRaza Muhammad Soomro0% (1)

- Hazards Identification Risk AssessmentRRRRDocument7 pagesHazards Identification Risk AssessmentRRRRArshad KhanNo ratings yet

- Daftar Peralatan KerjaDocument10 pagesDaftar Peralatan KerjaDicky SupriadiNo ratings yet

- High Pressur Hydro Testing JSA 03Document5 pagesHigh Pressur Hydro Testing JSA 03Saiyad RiyazaliNo ratings yet

- Consolidated Construction Consortium LTD.: DOC No.:CCCL/HSE/003 OCP No.31 DateDocument1 pageConsolidated Construction Consortium LTD.: DOC No.:CCCL/HSE/003 OCP No.31 DateradhouaneNo ratings yet

- FC 4.1.6 - Synthetic Sling Inspection Checklist FormDocument2 pagesFC 4.1.6 - Synthetic Sling Inspection Checklist FormJosef Demner Tiu PaspeNo ratings yet

- Jsa-Wif-9 Pulling CableDocument12 pagesJsa-Wif-9 Pulling CableY a n i. A h m e dNo ratings yet

- 03 - Form - PPE StockDocument5 pages03 - Form - PPE StockAli Rizki BudimanNo ratings yet

- SMF&W 851-01-07 Manual Arc Welding 220319Document9 pagesSMF&W 851-01-07 Manual Arc Welding 220319Shahid RazaNo ratings yet

- Fire Extinguisher InspectionDocument1 pageFire Extinguisher InspectionAdhy DarmawanNo ratings yet

- Lifting Operation BahasaDocument2 pagesLifting Operation BahasaDoo PLTGUNo ratings yet

- Form Inspeksi CompressorDocument1 pageForm Inspeksi CompressorekoimampNo ratings yet

- HSE Monthly ReportDocument1 pageHSE Monthly ReportHussein Abumais100% (1)

- HIRA-22 Logistic & Commissioning Activity OKDocument8 pagesHIRA-22 Logistic & Commissioning Activity OKadityajailani19No ratings yet

- Color Code Lifting EquipmentDocument8 pagesColor Code Lifting Equipmentarslanahmedkhawaja100% (1)

- Contoh LIfting Plan #2Document2 pagesContoh LIfting Plan #2jonser gultom100% (1)

- Guidelines For InspectionDocument12 pagesGuidelines For Inspectionjunel manuodNo ratings yet

- Cash-Handling Policy: IntentDocument3 pagesCash-Handling Policy: IntentghaziaNo ratings yet

- Interpretive Dance RubricDocument1 pageInterpretive Dance RubricWarren Sumile67% (3)

- Burger 2005Document7 pagesBurger 2005Stefania PDNo ratings yet

- Power Electronics For RenewablesDocument22 pagesPower Electronics For RenewablesShiv Prakash M.Tech., Electrical Engineering, IIT(BHU)No ratings yet

- Robotics Kinematics and DynamicsDocument5 pagesRobotics Kinematics and Dynamicsfadyah yulitaNo ratings yet

- CHAPTER 15 Rizal's Second Journey To ParisDocument11 pagesCHAPTER 15 Rizal's Second Journey To ParisVal Vincent M. LosariaNo ratings yet

- RetrofitDocument4 pagesRetrofitNiket ShahNo ratings yet

- Test Bank For Biology 7th Edition Neil A CampbellDocument36 pagesTest Bank For Biology 7th Edition Neil A Campbellpoupetonlerneanoiv0ob100% (31)

- Research EssayDocument8 pagesResearch Essayapi-509696875No ratings yet

- Beginner Guide To Drawing AnimeDocument14 pagesBeginner Guide To Drawing AnimeCharles Lacuna75% (4)

- Eris User ManualDocument8 pagesEris User ManualcasaleiroNo ratings yet

- The Impact of Social Media: AbstractDocument7 pagesThe Impact of Social Media: AbstractIJSREDNo ratings yet

- Prosthetic Aspects of Dental Implants - IIDocument73 pagesProsthetic Aspects of Dental Implants - IIKomal TalrejaNo ratings yet

- Letters of Travell by George SandDocument332 pagesLetters of Travell by George SandRocío Medina100% (2)

- Assessment Guidelines For Processing Operations Hydrocarbons VQDocument47 pagesAssessment Guidelines For Processing Operations Hydrocarbons VQMatthewNo ratings yet

- The Theory of Paulo FreireDocument8 pagesThe Theory of Paulo FreireLola Amelia100% (3)

- RONIN Hold The BridgeDocument3 pagesRONIN Hold The BridgekamaeqNo ratings yet

- Running Head: Mental Illness As A Cause of Homelessness 1Document12 pagesRunning Head: Mental Illness As A Cause of Homelessness 1api-286680238No ratings yet

- Forge Innovation Handbook Submission TemplateDocument17 pagesForge Innovation Handbook Submission Templateakil murugesanNo ratings yet

- Soal Passive VoiceDocument1 pageSoal Passive VoiceRonny RalinNo ratings yet

- Solution pdf-51Document68 pagesSolution pdf-51Tanmay GoyalNo ratings yet

- PRTC Tax Final Preboard May 2018Document13 pagesPRTC Tax Final Preboard May 2018BonDocEldRicNo ratings yet

- Modern America Study Guide With Answers 2020 21Document2 pagesModern America Study Guide With Answers 2020 21maria smithNo ratings yet

- Business Communication EnglishDocument191 pagesBusiness Communication EnglishkamaleshvaranNo ratings yet

- Group5 (Legit) - Brain Base-Curriculum-InnovationsDocument6 pagesGroup5 (Legit) - Brain Base-Curriculum-InnovationsTiffany InocenteNo ratings yet

- Libro de Social Studies PDFDocument76 pagesLibro de Social Studies PDFNoheNo ratings yet

- Sand Cone Method: Measurement in The FieldDocument2 pagesSand Cone Method: Measurement in The FieldAbbas tahmasebi poorNo ratings yet

- NLP - Neuro-Linguistic Programming Free Theory Training Guide, NLP Definitions and PrinciplesDocument11 pagesNLP - Neuro-Linguistic Programming Free Theory Training Guide, NLP Definitions and PrinciplesyacapinburgosNo ratings yet

- SSoA Resilience Proceedings 27mbDocument704 pagesSSoA Resilience Proceedings 27mbdon_h_manzano100% (1)

- ARTIKEL MUAMMAR CCDocument10 pagesARTIKEL MUAMMAR CCJaini SuryanaNo ratings yet