Professional Documents

Culture Documents

Weight Belt Feeders

Uploaded by

Raj K Sharma0 ratings0% found this document useful (0 votes)

15 views17 pagesThe document describes the BF 2012 belt feeder system. It can be used to feed bulk materials in industries like cement, glass, and metallurgy. The system provides reliable and durable feeding with long safe operation. It features accurate weighing and flow control, remote operation, communication abilities, and integration with automation systems. The system software runs on Siemens S7 PLCs and supports recipes and monitoring of multiple feeders. The scope of supply includes feeder mechanisms, hoppers, gates, conveyors, motors, sensors, and transmitters from suppliers like SAT, SEW Eurodrive, and Siemens.

Original Description:

Original Title

Untitled

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes the BF 2012 belt feeder system. It can be used to feed bulk materials in industries like cement, glass, and metallurgy. The system provides reliable and durable feeding with long safe operation. It features accurate weighing and flow control, remote operation, communication abilities, and integration with automation systems. The system software runs on Siemens S7 PLCs and supports recipes and monitoring of multiple feeders. The scope of supply includes feeder mechanisms, hoppers, gates, conveyors, motors, sensors, and transmitters from suppliers like SAT, SEW Eurodrive, and Siemens.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views17 pagesWeight Belt Feeders

Uploaded by

Raj K SharmaThe document describes the BF 2012 belt feeder system. It can be used to feed bulk materials in industries like cement, glass, and metallurgy. The system provides reliable and durable feeding with long safe operation. It features accurate weighing and flow control, remote operation, communication abilities, and integration with automation systems. The system software runs on Siemens S7 PLCs and supports recipes and monitoring of multiple feeders. The scope of supply includes feeder mechanisms, hoppers, gates, conveyors, motors, sensors, and transmitters from suppliers like SAT, SEW Eurodrive, and Siemens.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 17

BF 2 0 1 2

Weight Belt Feeders

Introduction

The BF 2012 belt feeder

reveals new horizons for plant

automation

reliable and durable mechanism;

long and safe exploitation;

all types of industries;

improved human-machine

interface;

easy-to-use parameter setup;

based on Siemens, SEW and

Schneider.

Purpose

The BF2012 feeds bulk materials and

can be used in the following

industries:

Cement;

Glass;

Chemistry;

Forage;

Metallurgy;

Other;

Bulk material weighing

Functions Belt speed measurement

Bulk material flow measurement

Belt speed frequency control

Continuos material flow control

Auto centring

Auto belt stretching compensation

Total material measurement

Automated tare and calibration

Local and remote control

Alarm signalling for failures

PROFIBUS-DP communication with

a host computer for data

logging/archiving and reports

Communication abilities for plant-

wide systems incorporation

Advantages

Constantly designed for accuracy

and reliability

Low maintenance, easy belt change

The measuring roller is placed

directly on two load cells. The

concept ensures stable feeding

results over the long term

Safe belt run monitoring and

tracking

Plough scraper (diverting foreign

objects on return belt to the side)

Static belt tension through take-up

screws integrated in frame

Wide feed rate adjustment range

Technical data

Min Max Unit

Capacity 0.5 350 t/h

Belt width 650 2000 mm

Motor speed control range 10 100 %

Measuring section nominal weight 5 500 kg

Weighing error 0.02 0.05 %

Flow control error 0.25 0.5 %

Total ammount measurement error 0.25 0.5 %

Weight overload - 300 %

Material working temperature 0 150 °C

Feeder length (from axis to axis) 1500 8000 mm

Protection

Sensors IP 67

IP 65

Control cabinet IP 55

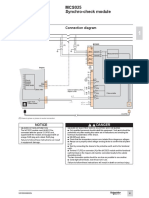

Control system

Layout Block Diagram

Typical constructions

Version 1 – with needle gate, inlet hopper and

discharge hood

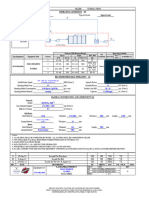

BELT WEIGH-FEEDER - DATASHEET

TYPE MILL CEMENT MILL

1. Material Limestone

2. Bulk density t/m3 1,2...1,5

3. Particle size mm max 50

4. Temperature oC 80

5. Capacity t/h 5…50

6. Type belt 1000ЕР-315/3 4+2-Z

7. Type drive KA67R37DT80K4

MM07

8. Ratio i 279

9. Power nominal kW 0.75

Typical constructions

Version 2 – with slide gate, inlet hopper and discharge

hood

BELT WEIGH-FEEDER - DATASHEET

TYPE MILL CEMENT MILL

1. Material Slag

2. Bulk density t/m3 1,2...1,5

3. Particle size mm max 50

4. Temperature oC 80

5. Capacity t/h 5…50

6. Type belt 1000ЕР-315/3 4+2-Z

7. Type drive KA67R37DT80K4

MM07

8. Ratio i 279

9. Power nominal kW 0.75

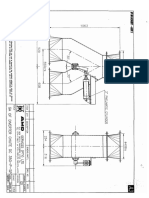

Typical constructions

Version 3 – with needle gate, inlet hopper, discharge

hood and spillage conveyor

BELT WEIGH-FEEDER - DATASHEET

TYPE MILL RAW MILL

1. Material Limestone

2. Bulk density t/m3 1,4

3. Particle size mm max 50

4. Temperature oC 50

5. Capacity t/h 3…30

6. Type belt 1400EP 400/3 5+2 Z

7. Type drive KA107R77 DT90S2

8. Ratio i 1166

9. Power nominal kW 1.5

SPILLAGE CONVEYOR - DATASHEET

TYPE MILL RAW MILL

1. Material Limestone

2. Bulk density t/m3 1,4

3. Particle size mm max 50

4. Temperature oC 50

5. Capacity t/h max 2

6. Round steel chain DIN 764 10x35

7. Type drive KA67 DT80N6

8. Ratio i 108,03

9. Power nominal kW 0.55

Typical constructions

Version 4 – with needle gate, inlet hopper with

vibrator, discharge hood and spillage conveyor

BELT WEIGH-FEEDER - DATASHEET

TYPE MILL CEMENT MILL

1. Material Ash

2. Bulk density t/m3 1,1

3. Particle size mm max 150

4. Temperature oC 40

5. Capacity t/h 5…50

6. Type belt 1200 EP400/3 4+2

7. Type drive KA77R37 DT90S4

MM15

8. Ratio i 328

9. Power nominal kW 1.5

SPILLAGE CONVEYOR - DATASHEET

TYPE MILL CEMENT MILL

1. Material Ash

2. Bulk density t/m3 1,1

3. Particle size mm max 150

4. Temperature oC 40

5. Capacity t/h max 2

6. Round steel chain DIN 764 10x35

KA67 DT80N6/TH

7. Type drive M1

8. Ratio i 104,37

9. Power nominal kW 0.55

PLC

The BF2012 system software

is based on the following PLC

platforms:

PLC S7-226 – controls single

belt feeder

PLC S7-1200 – controls single

belt feeder

PLC S7-314C – controls up to 8

feeders. Supports recipes, group

interlocks, complete monitoring

PLC S7-416 – can control unlimited

number of belt feeders

Software

Along with the BF 2012

comes a complete set

of system software

(WinCC or PCS7) and

standard modules

(Cemat or SAT’s

standard modules) for

embedding the feeders

in the whole plant

project.

Solutions

We offer implementation of the belt

feeders in the plant in several ways:

As a part of a complete engineering project developed

by the SAT company;

Mastering of the feeders in existing projects;

Modification of the system software for different

types of communication to meet the particular needs.

Scope of supply

Type Production

Belt feeder mechanism diff. SAT

Inlet hopper (optional) diff. SAT

Discharge hood (optional) diff. SAT

Needle gate/Slide gate (optional) diff. SAT

Spilage conveyor (optional) diff. SAT

Transport belt EP400/3 4+2 diff.

Leading motor and reductor gear KA47…KA107/KAD47..KAD168 SEW Eurodrive/Siemens

Speed sensor Encoder 2500-RTM SIEMENS

Frequency inverter MOVIMOT-C/Sinamics G120 SEW Eurodrive/Siemens

Weight sensor (2 pcs.) PC60 Flintec

Weight transmitter Siwarex MS/Siwarex U/TENZO3-UF Siemens/Siemens/SAT

Belt position sensor (drift switch) XCR-T115/HES 011 SCHNEIDER/Kiepe

Emergency rope (rope switch) XY2-CH13250/HEN002 SCHNEIDER/Kiepe

Block shute sensor (optional) Rotary Paddle Switch Siemens

Control cabinet diff. SAT

Programmable controller S7-200/S7-1200/S7-300 SIEMENS

Local control panel diff. SAT

Communication module (optional) PROFIBUS-DP SIEMENS

Application software WF_2XX / WF_3XX SAT

System software STEP 7 SIEMENS

Scope of services

We offer full scope of services for

fully integration of SAT’s weight

feeders:

Design of weight feeders according specific

client requirements;

Standard Hardware and Application software

for control systems;

Supervision and Installation of weight belt

feeders and control systems;

Testing and Commissioning of weight belt

feeders;

Training of the Client’s personnel.

Contact us

SYSTEMS AUTOMATION TECHNOLOGIES

SAT GROUP

1 Hristo Stefchov Str.

1614 Sofia

BULGARIA

Phone: +359 (2) 957 69 29

Fax: +359 (2) 957 70 19

E-mail: sat@techno-link.com

Web site: http://www.satbg.com

You might also like

- SAT's Weigh Belt Feeder PDFDocument18 pagesSAT's Weigh Belt Feeder PDFMauricio Rodolfo Cuevas DonaireNo ratings yet

- 1-Tiffany, (B) Quotation 5TPH Animal Feed Line, ZONSTAR RICHI PDFDocument14 pages1-Tiffany, (B) Quotation 5TPH Animal Feed Line, ZONSTAR RICHI PDFAnonymous oRXzylDPNNo ratings yet

- CRM 2 PresentationDocument35 pagesCRM 2 Presentationtehseen banuNo ratings yet

- Powder Metallurgy LabDocument8 pagesPowder Metallurgy Labשירי חדדNo ratings yet

- Quotation-1TPH Chicken Feed Line Bali OkDocument6 pagesQuotation-1TPH Chicken Feed Line Bali OkSacha INchi CentreNo ratings yet

- Quotation For Layer Equipment With Capacity 55000 Hens - Janey PDFDocument16 pagesQuotation For Layer Equipment With Capacity 55000 Hens - Janey PDFNasim KurdistanNo ratings yet

- Used Rolling Mill Machinery List Prices & SpecificationDocument51 pagesUsed Rolling Mill Machinery List Prices & Specificationsanjaya srivastavaNo ratings yet

- 1-Vicky, Quotation of 1-1.2TPH Wood Pellet Line, RICHIDocument17 pages1-Vicky, Quotation of 1-1.2TPH Wood Pellet Line, RICHICarlos Soler100% (1)

- QUOTATIONS - 6 ROLLER 1 DDocument4 pagesQUOTATIONS - 6 ROLLER 1 DDrPawan BhardwajNo ratings yet

- Thermal Analysis-2628 PDFDocument11 pagesThermal Analysis-2628 PDFgirish sbNo ratings yet

- Mesin WP CKDDocument4 pagesMesin WP CKDHerry YsNo ratings yet

- Quotations of 80tph Continous Drum Asphalt Plant With Wet Dust Catcher-CJME2023.12.11Document5 pagesQuotations of 80tph Continous Drum Asphalt Plant With Wet Dust Catcher-CJME2023.12.11fernandomelendezfmiNo ratings yet

- Detail PR Description: No Qty Unit DescriptionDocument2 pagesDetail PR Description: No Qty Unit Descriptionbass_121085477No ratings yet

- BF Data Fibre Bundles MM OM2 PDFDocument2 pagesBF Data Fibre Bundles MM OM2 PDFMo SibNo ratings yet

- Wire Coil Pay-OffDocument2 pagesWire Coil Pay-OffRaul CallejasNo ratings yet

- Four Cavities PVC Wall Edges Extrusion LineDocument7 pagesFour Cavities PVC Wall Edges Extrusion LineguldavistNo ratings yet

- FLD25 3D Printer Filament Extrusion LineDocument7 pagesFLD25 3D Printer Filament Extrusion LineKnezNo ratings yet

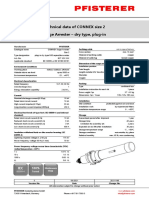

- MV CONNEX Technical Data Surge Arrester Size 2 and DrawingDocument6 pagesMV CONNEX Technical Data Surge Arrester Size 2 and DrawingFelipe Mafioletti SchuartzNo ratings yet

- COMACO LB1000-Asphalt Mixing PlantDocument12 pagesCOMACO LB1000-Asphalt Mixing PlantHermawan Septian Adittya100% (1)

- 3 Piece Tin Can Making Line 2 PDFDocument26 pages3 Piece Tin Can Making Line 2 PDFFELIPE PUENTENo ratings yet

- HTGD - Adss-Xxb1-100m (1.5-9.9) - 2022061310Document3 pagesHTGD - Adss-Xxb1-100m (1.5-9.9) - 2022061310Erick Renzo Hidalgo OrtegaNo ratings yet

- Spek Teknis InceneratorDocument2 pagesSpek Teknis InceneratorSha-Putra Byonic LandakNo ratings yet

- Parameter MachineDocument10 pagesParameter MachinePhuong Thuc Duong LeNo ratings yet

- Huchez Winch 10 TonsDocument6 pagesHuchez Winch 10 TonsPhong DuongNo ratings yet

- Bag Filter Details: Dust Extraction SystemDocument6 pagesBag Filter Details: Dust Extraction SystemAnonymous W9VINoTzaNo ratings yet

- Technical Project For Wire Drawing MachineDocument3 pagesTechnical Project For Wire Drawing MachineZakhamaNo ratings yet

- 120tph Mobile Asphalt Mixing Plant FinalDocument9 pages120tph Mobile Asphalt Mixing Plant FinalCesar AlvaradoNo ratings yet

- Paper Crushing Line Quotation - Chile - 1000kgDocument8 pagesPaper Crushing Line Quotation - Chile - 1000kgsuarezad2014No ratings yet

- Lab Man EditedDocument50 pagesLab Man Editedguravshubham7777No ratings yet

- Lampiran CDocument3 pagesLampiran CFradilla OlsyNo ratings yet

- 220 MZD MZMM 10001 - 0370 Mli 0004Document5 pages220 MZD MZMM 10001 - 0370 Mli 0004pedro jose carrasco oblitasNo ratings yet

- 10-21 JXSC Quote For Gold Wash PlantDocument2 pages10-21 JXSC Quote For Gold Wash PlantErnest First GroupNo ratings yet

- ASCEN SMT Conveyor List 0Document22 pagesASCEN SMT Conveyor List 0Igur EuiNo ratings yet

- Multifunctional Lathe Machine CQ6232GZDocument4 pagesMultifunctional Lathe Machine CQ6232GZAbdelbasset ZaraiNo ratings yet

- 2-Rafael-TDS-625 Sand Dryer doc-CIFDocument20 pages2-Rafael-TDS-625 Sand Dryer doc-CIFRafael ObusanNo ratings yet

- Cutting Mill SM 100: General InformationDocument2 pagesCutting Mill SM 100: General InformationKaca RasaNo ratings yet

- Fujikura 90S: Features/BenefitsDocument4 pagesFujikura 90S: Features/BenefitsYhoni RYNo ratings yet

- Ahs Datasheet-A-Tce-Hzl - BhelDocument10 pagesAhs Datasheet-A-Tce-Hzl - Bhelshameer_sanju1049No ratings yet

- Belt Acc. To DIN 22102: .800 EP 630/4 6/3 M-MEDocument1 pageBelt Acc. To DIN 22102: .800 EP 630/4 6/3 M-MErestu yanuar salamNo ratings yet

- SGII-3L1500 报价统一格式Document5 pagesSGII-3L1500 报价统一格式Mahmoud FathiNo ratings yet

- 2022.11.8 Complete HKJ-250 Poultry Feed Pellet Production Line 1tph PDFDocument25 pages2022.11.8 Complete HKJ-250 Poultry Feed Pellet Production Line 1tph PDFdinero dahustleNo ratings yet

- Teleste Datasheet - Coaxial - Cable - S579590XVQ - 180123Document1 pageTeleste Datasheet - Coaxial - Cable - S579590XVQ - 180123polan78No ratings yet

- WPC Termekleiras JAPANDocument10 pagesWPC Termekleiras JAPANCristian PopaNo ratings yet

- Details of Component:: Material SpecificationDocument1 pageDetails of Component:: Material SpecificationsunilpoulNo ratings yet

- 8270 - T44pdfDocument4 pages8270 - T44pdfriscorenan22No ratings yet

- Powercrusher PC 1000 - For Web - tcm795-2599950Document2 pagesPowercrusher PC 1000 - For Web - tcm795-2599950gugiNo ratings yet

- Basic Specification of Mobile Stone Crusher MachineDocument3 pagesBasic Specification of Mobile Stone Crusher MachineBirhanu DemekeNo ratings yet

- Magnetic Drilling Machine: Technical DataDocument1 pageMagnetic Drilling Machine: Technical DataMimih NunungNo ratings yet

- SM 48F Onshore Data SheetDocument1 pageSM 48F Onshore Data SheetMateen AhmedNo ratings yet

- Technical Data of CONNEX Size 2 Surge Arrester - Dry Type, Plug-InDocument4 pagesTechnical Data of CONNEX Size 2 Surge Arrester - Dry Type, Plug-InAasdasNo ratings yet

- Chain Link and Fence Making MachinesDocument6 pagesChain Link and Fence Making MachinesRavi Kumar HaldiyaNo ratings yet

- JRF-C&Z 70 - 300Document16 pagesJRF-C&Z 70 - 300Ravi ChandranNo ratings yet

- Material Handling Machine (30t)Document3 pagesMaterial Handling Machine (30t)Muhammad IqbalNo ratings yet

- List of Silo System For PT SUBUR - FAMSUNDocument5 pagesList of Silo System For PT SUBUR - FAMSUNAquinas ThomazNo ratings yet

- Charcoal Briquette Production Line 2-3tonDocument32 pagesCharcoal Briquette Production Line 2-3tonБат-Эрдэнэ ЭрдэнэчулуунNo ratings yet

- Description: 1 of 2 mp-01010 CDocument2 pagesDescription: 1 of 2 mp-01010 CkoalaboiNo ratings yet

- NanoFlow Max - DataSheet - 06.08.2020Document2 pagesNanoFlow Max - DataSheet - 06.08.2020Erhan IsufovNo ratings yet

- Load-Bearing Fibre Composites: International Series on the Strength and Fracture of Materials and StructuresFrom EverandLoad-Bearing Fibre Composites: International Series on the Strength and Fracture of Materials and StructuresNo ratings yet

- Manual 121019 Imcdp-1000 Ribbon BlenderDocument12 pagesManual 121019 Imcdp-1000 Ribbon BlenderRaj K Sharma100% (1)

- Thermax Bag FiltersDocument12 pagesThermax Bag FiltersRaj K SharmaNo ratings yet

- Sabs Idlers CatalogueDocument31 pagesSabs Idlers CatalogueRaj K SharmaNo ratings yet

- Cement Manufacturing OverviewDocument20 pagesCement Manufacturing OverviewRaj K SharmaNo ratings yet

- Weigh Feeder 14 4381 TF 90 125 Spec ADocument4 pagesWeigh Feeder 14 4381 TF 90 125 Spec ARaj K SharmaNo ratings yet

- ManualDocument21 pagesManualmohammad.zNo ratings yet

- FPP - BR - All Things KLD - 21-10 (V8)Document8 pagesFPP - BR - All Things KLD - 21-10 (V8)Raj K SharmaNo ratings yet

- Superfort Datasheet EnglishDocument2 pagesSuperfort Datasheet EnglishRaj K SharmaNo ratings yet

- PolyethyleneDocument2 pagesPolyethyleneRaj K SharmaNo ratings yet

- Vibro SifterDocument3 pagesVibro SifterRaj K SharmaNo ratings yet

- Diverter Chute DC 350-P-SPDocument1 pageDiverter Chute DC 350-P-SPRaj K SharmaNo ratings yet

- XL70 W Textured Coating Mar 2019Document2 pagesXL70 W Textured Coating Mar 2019Raj K SharmaNo ratings yet

- Moret Mining BrochureDocument20 pagesMoret Mining BrochureRaj K SharmaNo ratings yet

- DBP Conveyor Belting Product Portfolio ENDocument28 pagesDBP Conveyor Belting Product Portfolio ENRaj K SharmaNo ratings yet

- Compact Power Unit R3Document5 pagesCompact Power Unit R3Raj K SharmaNo ratings yet

- 682 03 Fenner Friction Belts PDFDocument54 pages682 03 Fenner Friction Belts PDFchagar_harshNo ratings yet

- XL70 SolventDocument3 pagesXL70 SolventRaj K SharmaNo ratings yet

- ABB Publication 1MRK509015-BEN C en High Impedance Differential Relay RADHADocument5 pagesABB Publication 1MRK509015-BEN C en High Impedance Differential Relay RADHAjavedsmg1No ratings yet

- 42NH Ductable in Room Fan Coil With Multi Speed Motor: Performance Summary For Sobe SpratDocument2 pages42NH Ductable in Room Fan Coil With Multi Speed Motor: Performance Summary For Sobe Spratvelikimag87No ratings yet

- Traction Accelerator PDFDocument4 pagesTraction Accelerator PDFF Allende GonzalezNo ratings yet

- Bus Card Payment System 23.10.2019 MaracaiboDocument2 pagesBus Card Payment System 23.10.2019 MaracaiboRafael VillarrealNo ratings yet

- INSTRUMENTSDocument3 pagesINSTRUMENTSjesunathan44@yahoo.comNo ratings yet

- SSH Buku IDocument335 pagesSSH Buku IVoteJokowiNo ratings yet

- Mf15 Performance Diagnostics Eged535Document14 pagesMf15 Performance Diagnostics Eged535Trung hiếu Nguyễn lêNo ratings yet

- Trolley Weight EstimationDocument7 pagesTrolley Weight EstimationRaj KumarNo ratings yet

- ZY-ZJ-800&1000 Operation & Maintenance Manual PDFDocument69 pagesZY-ZJ-800&1000 Operation & Maintenance Manual PDFOperaciones Gep100% (1)

- Preventive Maintenance: Basic Management Development Program EngineeringDocument63 pagesPreventive Maintenance: Basic Management Development Program EngineeringBunga Panjaitan100% (1)

- Hydraulic ValvesDocument5 pagesHydraulic ValvesDevendra BangarNo ratings yet

- HP Air CompressorDocument4 pagesHP Air CompressorŞef Utas AwijNo ratings yet

- N4 Physics 1.3 - ElectronicsDocument20 pagesN4 Physics 1.3 - ElectronicsNoniNo ratings yet

- Electronic Instrumentation PracticalDocument3 pagesElectronic Instrumentation PracticalABHISHEK PATELNo ratings yet

- Spek Teknis AFKUPengadaan Peralatan Kantor Bidang 1 Batch 1revDocument10 pagesSpek Teknis AFKUPengadaan Peralatan Kantor Bidang 1 Batch 1revArtha Arjuna MandiriNo ratings yet

- 45e Pas 174Document18 pages45e Pas 174jads301179No ratings yet

- Wheel Rim Diameter ExplainedDocument5 pagesWheel Rim Diameter ExplainedLakan BugtaliNo ratings yet

- Tutorial L298N Driver MotorDocument5 pagesTutorial L298N Driver MotorHairul Anam SNo ratings yet

- Acb Master Pact CatalogueDocument159 pagesAcb Master Pact CatalogueariessukmawanNo ratings yet

- TORO Reelmaster 3100-DDocument306 pagesTORO Reelmaster 3100-Ddalidelia100% (1)

- Agilent AEDS-962x For 300 LPI Ultra Small Optical Encoder ModulesDocument11 pagesAgilent AEDS-962x For 300 LPI Ultra Small Optical Encoder ModulesLucio UbelluNo ratings yet

- MCS025 Synchro-Check Module: InstallationDocument1 pageMCS025 Synchro-Check Module: Installationوسام وسامNo ratings yet

- SolarBright MaxBreeze Solar Roof Fan Brochure Web 1022Document4 pagesSolarBright MaxBreeze Solar Roof Fan Brochure Web 1022kewiso7811No ratings yet

- Manual de Uso Rm6Document82 pagesManual de Uso Rm6Leonel Márquez EspinozaNo ratings yet

- Q5 2015+ A005FY20020-Basic Equipment (L0L) From September 2016Document1,612 pagesQ5 2015+ A005FY20020-Basic Equipment (L0L) From September 2016Dmitriy GevkoNo ratings yet

- Customer Stancil RecorderDocument21 pagesCustomer Stancil RecorderGS MeenaNo ratings yet

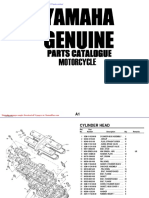

- Yamaha Fzr1000 93 Parts CatalogDocument7 pagesYamaha Fzr1000 93 Parts Catalogmarsha100% (30)

- Manual Programador Profesional Bat v1Document2 pagesManual Programador Profesional Bat v1Julio Sanchez ANo ratings yet

- Service Manual Vox VT40+Document16 pagesService Manual Vox VT40+Marco Antonio Chaparro Acosta100% (2)

- KCCEC List of EquipmentDocument45 pagesKCCEC List of Equipmentahmedsaber2007No ratings yet