Professional Documents

Culture Documents

Testing of CNC Machine Tools: Acceptance Tests

Uploaded by

he maOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Testing of CNC Machine Tools: Acceptance Tests

Uploaded by

he maCopyright:

Available Formats

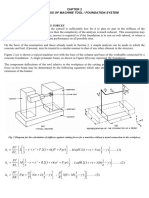

9.

3 TESTING

OF CNC MACHINE TOOLS

Every machine tool created by the manufacturer undergoes testing of machine is necessary to keep the workpiece quality

properties – comparison of the designed and expected parameters and for a long time.

properties with the reached parameters and properties. This testing is made The standards which are most often met

at a newly developed machine, at a machine which is generally produced as in the measuring and inspection branch are

well as at a machine after the major overhaul. The tests are performed in from the group ČSN ISO 230, ČSN ISO

dependence on the prescribed standards and procedures. 10791 and for example VDI/DGI 3441. The

other foreign equivalents are ANSI B5:54

Testing of machine tools represents the The prototype tests (Fig. 9.3.1) are and JIS B 6330-1980. The standards can be

specific branch of metrological measurings specified to verify the properties of the newly replaced only with big difficulties, therefore it

and by extension it means especially designed and manufactured machines. The is very important to determine in the machine

procedures, management with measuring prototype tests extend the acceptance tests contract which standards and rules will serve

instruments and checking their precision by many measurings which shall give the to assess the machine tool properties.

and others. Testing is subordinate to the important information, especially for the

legislation valid in the particular country. machine creator. The designed and expected Acceptance tests

Considering the metrology as well as properties of the new product are examined Check of technical data – the essential

legislation, the superordinate institutes in the and at the same time the unknown properties building dimensions of the machines and

Czech Republic are the Ministry of Industry are discovered which cannot be anticipated the courses are checked in the particular

and Trade of the Czech Republic, the Czech at the product origination. The target of the coordinates, this check deals also with the

Office for Standards, Metrology and Testing, prototype tests it to find (discover) the limit feed and speed sizes, with the installed

the Czech Metrological Institute, authorized states of the machinery behaviour or such capacities of the motors of the machine itself

metrological centres, centres for calibration operation conditions when the machine and of peripheries (e. g. coolant pressure),

services and the Czech Accreditation Institute. behaves in the unexpected way. The statistic the built up area, etc. (Fig. 9.3.2).

Testing of machine tools is the important acceptance (test of the process capability) The geometric machine accuracy and its

life cycle part of the product – of the machine is used for demanding customers when it measuring are regulated by the standards

tool [Borský 1991]. The machine creator

has the standards available which serve in Standards Procedures Knowledge

Technical aids

many cases for the purpose that the machine and regulations and methodologies and experience

manufacturer and the machine customer can

speak “the same language”. The standards

usually say what shall be measured and Testing of CNC machine tools

checked and therefore they are completed

by the procedures and methodologies which

include directly or indirectly the operating

acceptance prototype operation tests statistic

instructions for measuring technology and tests tests and inspection acceptance

technicians’ knowledge and experience.

• at the manufacturer • they depend on the • operation diagnostics • investigation

The tests of machine tools can be divided • at the customer prototype character • backlash in the of indexes

into three groups (Fig. 9.3.1). The first group of • for internal needs • they link to the drives and guiding of process capability

• part of the acceptance tests • run out and machining

examinations and tests is connected with the machine sale or extend them • heating

• according to • measuring of static, (temperatures)

contractual obligation between the machine international dynamic and thermal • frequencies

seller and the machine buyer. Therefore, standards deformations (speed, teeth)

• according to • measuring of noisiness • dirt and metallic

these tests are contained in the contract. The internal standards and vibrations parts in lubricants

acceptance tests are usually performed in

Fig. 9.3.1: Testing of CNC machine tools

two steps – at first directly at the machine

manufacturer and subsequently at the

customer, after the machine is assembled. Tests of CNC machine tools

The tests have the target to verify the machine

properties declared by the manufacturer.

From the buyer’s point of view, they verify technical data geometric at loading other

whether the machine has the properties and properties accuracy

(output, precision) which the buyer purchased. • dimensions • straightness • ouput • noise

The contents and the extent of the acceptance • courses • perpendicularity • position setting • reliability

• speeds and feeds • parallelity • working precision • idle run

tests are usually arranged in the contract. The • power input • flatness • manufacturing • dynamic properties

• weight • alignment precision • heating

agreed tests are based on the standards which • radial run out • noise etc. • rigidity

are recognized on the international level and • illumination

• clamping force

which determine the particular measuring

types for the particular machine type. Fig. 9.3.2: Acceptance tests of machine tools

696 | MM Industrial Spectrum | Special Issue | 2015

Testing of CNC machine tools

ČSN ISO 230 (previously ČSN 20 0300-1

Standards ČSN ISO 230 – Acceptance tests of machine tools

to ČSN 20 0300-30). The first set of

standards (230-1 to 230-7) is related to

the accuracy tests and it does not deal ČSN ISO 230-1 – measuring of the geometric accuracy

with the functional machine tests (typically

vibrations at machining, jerking motions of

ČSN ISO 230-2 – determination of the position setting accuracy in numerically controlled axes

the parts. etc.). The standards do not deal

with the determination of the characteristic

parameters (speeds, feeds) either, because ČSN ISO 230-3 – measuring of thermal behaviour and temperatures

these test shall be usually performed before

the accuracy tests [ČSN ISO 230]. In

ČSN ISO 230-4 – determination of the circular interpolation accuracy

practice for example it is possible to meet the

requirement on the spindle speed uniformity

(the speed can vary in the specified / agreed ČSN ISO 230-5 – measuring of the acoustic pressure and output

range). These measurings are performed

and checked in addition to the above

ČSN ISO 230-6 – determination of the setting accuracy on the diagonals in the working area

mentioned standards and they are usually

agreed contractually. ČSN ISO 230 – this is

a large set of documents (Fig. 9.3.3) dealing ČSN ISO 230-7 – determination of the spindle run accuracy during rotation

with the purely internal mechanical machine

properties as well as with the temperature

ISO 230-8 – vibrations (between the tool, machine, workpiece influence on the surface quality)

influences on the machine operation and

with the machine influences on the ambient

(noise). The standards ISO 230-8 and the ISO 230-9 – it deals with measuring inaccuracies

other ones are still in the preparation stage

and therefore they have not been able to be

ISO 230-10 – (workpiece) measuring on the machine tools

harmonized up to now.

The geometric accuracy tests are regulated

Fig. 9.3.3: Standards of the ČSN ISO 230 group

specifically by the standard ČSN ISO 230-1

(Geometric accuracy of machines operating

under no-load or finishing conditions). In tools – Test conditions for horizontal spindle in the whole world determine the standards

addition to the introduction and notes turret and single spindle automatic lathes – by themselves and in many cases these

this standard includes the sections about Testing of the accuracy), ČSN ISO 10791-7 standards are stricter that the standardized

preparation of measuring (preparation (Test conditions for machining centres – Part 7: standards.

work), machining tests and geometric tests. Accuracy of a finished test piece).

The standard final part deals with special ČSN ISO 230 also admits the utilization of The purpose of the geometric accuracy

measurings. The other standards dealing other methods which are not included in it, if test is to determine the geometric structure

with accuracy are ČSN ISO 10791-6 they bring comparable or better information of machine tools, i. e. the accuracy of

(Test conditions for machine centres – about the machine. Therefore, the standard shapes, mutual positions and motions

Part 6: Accuracy of feeds, speeds and is not limiting for the manufacturers. The of those functional parts (Fig. 9.3.5, Fig.

interpolations), ČSN ISO 6155 (Machine important (great) machine manufacturers 9.3.6 and Fig. 9.3.7) which can influence

Measuring of the machine geometric accurasy

– technical aids

mechanical optical electronic

• dial gauge • laser interferometers • dial gauges

• water levels • laser tracers and trackers • water levels

• measuring rules • laser tomographs • self centring heads

• angles

• measuring plugs (cylindircal)

• measuring prisms

• aids and jigs

Fig. 9.3.5: Measuring of the accuracy

Fig. 9.3.4: Overview of technical aids specified to measure the machine geometric accuracy (straightness) of the Y axis [Dixi Machines]

2015 | Special Issue | MM Industrial Spectrum | 697

9.3 TESTING

OF CNC MACHINE TOOLS

reach this, it can be a part of an agreement has the significant influence on the measuring

between the manufacturer and the customer. (this is also valid for position setting).

Temperature variation must range from 2 % The test of the rectilinear motion (e. g.

to 10 %, in dependence on the accuracy the motion of the lathe rail head or of the

degree of the machine tool. The same is planing machine table along the bed) is

valid for the used testing instruments and still and still more often performed using

measuring aids. The machine measuring the laser measuring instruments. The

is performed in its condition without assessment is implemented by means of

operation loading or during its idle run sensitive sensors or electronics (the laser

[Prokop 1985]. The main measuring types measuring instruments cannot be designed

are measuring of straightness (Fig. 9.3.5 like the optical autocollimators because

and Fig. 9.3.23), measuring of flatness, of the risk of eyesight damage). The laser

measuring of parallelity, measuring of measuring is very efficient at shorter beds or

alignment, measuring of perpendicularity at middle sized beds, because the laser beam

Fig. 9.3.6: Example of measuring of the rectilinear and measuring of run out. is not influenced very much by the ambient

motion of the slide with the technological pallet The straightness test is performed especially which it passes through. If the measuring is

in the Y axis in the horizontal plane [Toshulin] at the guideways and it is performed by means performed in bigger distances, the ambient

of the water level, of the autocollimator or by has the significant influence on the measuring

means of the measuring telescope and the (this is also valid for position setting).

laser interferometer (Fig. 9.3.4). The water The flatness is tested e. g. at the clamping

level shall have the sensitivity of 0,04/1000 surfaces of the tables of planing machines

mm at least (Note: the water levels having and milling machines, at the tables of

higher sensitivity require longer time to vertical lathes, at the base plates of radial

stabilize the bubble). The water level is moved drilling machines, etc. The surface plates or

along the bed during measuring so that the measuring rules and water levels are used

measured positions can be overlapped. The for this purpose (they are put in the directions

measuring is also influenced by the water which are perpendicular or diagonal to each

level length (the size of the reflector base, other). The bridges and plates with sensitive

see hereinafter), as it can be seen in the dial gauges or optical instruments are used

following figure. The measuring instrument for the flatness measuring having a more

base having bigger dimensions covers demanding character.

inaccuracies artificially (Fig. 9.3.8). The parallelity of guideways (i. e. of two

The test of the rectilinear motion (e. g. planes) is tested e. g. by the water levels

the motion of the lathe rail head or of the put in the transversal direction or by the

planing machine table along the bed) is inside micrometers (the planes are parallel

Fig. 9.3.7: Example of measuring of the radial run still and still more often performed using ones) with dial gauges. The parallelity of the

out of the inside cone in the straight head [Toshulin] the laser measuring instruments. The as- surfaces with the axes or of the axes to each

sessment is implemented by means of other (e. g. at working spindles) is checked

the working precision. This measuring type sensitive sensors or electronics (the laser by the measuring plugs in the spindle axis

was introduced by Dr. Schlesinger in the measuring instruments cannot be designed extension by means of the dial gauges, etc.

first third of the twentieth century. His name like the optical autocollimators because The perpendicularity of two surfaces (e. g.

often appears in the informal name of these of the risk of eyesight damage). The laser of the table clamping surface towards the

tests. Before the geometric accuracy tests measuring is very efficient at shorter beds or guiding on the column) or of the working

start, it is possible to remove the machine at middle sized beds, because the laser beam spindle axis towards the table clamping

protective guards and the other accessories is not influenced very much by the ambient surface is usually checked by means of the

which would obstruct measuring. The which it passes through. If the measuring is measuring cylinders with dial gauges or by

machine tool must be set and levelled in performed in bigger distances, the ambient means of the measuring prisms. If the optical

the horizontal position on the unyielding way is used, the perpendicularity can be

foundation (levelling by a water level), i. e. as measured e. g. by the laser interferometer,

if it were in the operation condition (the tests if the five sided prism guarantees the

can be performed on another place than perpendicularity of the refracted reference

the final machine location is, typically at the straight line.

manufacturer). This position must not be The alignment is checked by two measuring

changed or modified during the tests. The plugs with the dial gauge or if one measuring

machine shall be also put to the stabilized Fig. 9.3.8: Influence of the measuring instrument base plug is wound by the dial gauge attached to

thermal condition. Which method is used to size on the measuring accuracy [Dixi Machines] the co axial plug or in the optical way.

698 | MM Industrial Spectrum | Special Issue | 2015

You might also like

- HC - Come Home To Yourself PDFDocument133 pagesHC - Come Home To Yourself PDFOtilia100% (1)

- Weld SurveillanceDocument33 pagesWeld SurveillancecanakyuzNo ratings yet

- Testing of TurbogeneratorDocument77 pagesTesting of Turbogeneratorsaitejajosyula100% (3)

- Ship Constructor Structure TutorialDocument237 pagesShip Constructor Structure TutorialRodrigo Horta100% (1)

- A Detailed Lesson Plan in English 10: Prepared By: Aira C. Mirandilla L. ObjectivesDocument11 pagesA Detailed Lesson Plan in English 10: Prepared By: Aira C. Mirandilla L. ObjectivesMae Mallapre100% (10)

- Stranger Things Episode Script 2 05 Chapter Five Dig DugDocument67 pagesStranger Things Episode Script 2 05 Chapter Five Dig Dugyonas123No ratings yet

- WPS, PQR and WPQDocument31 pagesWPS, PQR and WPQDhrumil Chauhan100% (1)

- Siemens SW Industrial Quality Testing EBDocument12 pagesSiemens SW Industrial Quality Testing EBAnkurNo ratings yet

- 2023 SD QC Outsource Support RequisitionDocument6 pages2023 SD QC Outsource Support RequisitionKit AnnoncerNo ratings yet

- Lec 2 - Quality AssuranceDocument26 pagesLec 2 - Quality AssuranceJenny Rieta CatenzaNo ratings yet

- Spin Testing Capabilities: Test Devices RigsDocument4 pagesSpin Testing Capabilities: Test Devices RigsxmlbioxNo ratings yet

- TAPPI Dryer Inspeccion Part IIDocument10 pagesTAPPI Dryer Inspeccion Part IICarlos Anibal OrtizNo ratings yet

- Cqi27 Process Table CDocument6 pagesCqi27 Process Table ClalitNo ratings yet

- UntitledDocument22 pagesUntitledTrecita BacoNo ratings yet

- Fab 01 QA of Welds, ISO 3834, RWC Etc.Document17 pagesFab 01 QA of Welds, ISO 3834, RWC Etc.Raghu vamshiNo ratings yet

- Project Monitoring and Control TechniquesDocument17 pagesProject Monitoring and Control TechniquesDangi DilleeRamNo ratings yet

- Quality Control ManualDocument50 pagesQuality Control ManualKhairul Azri100% (1)

- Pressure Equipment Design Verification: Either To Satisfy The National Generic CompetencyDocument6 pagesPressure Equipment Design Verification: Either To Satisfy The National Generic CompetencykrishimaNo ratings yet

- Criticial Utility Qualification Part-1Document22 pagesCriticial Utility Qualification Part-1Terrence Terry BhengoeNo ratings yet

- FMRC 1046 Fire Pump Flowmeter Systems PDFDocument18 pagesFMRC 1046 Fire Pump Flowmeter Systems PDFdyıldırım_4No ratings yet

- Bolt Vibration Machine Tests Fastener LooseningDocument2 pagesBolt Vibration Machine Tests Fastener LooseningSubhasis MallikNo ratings yet

- b9 IwDocument11 pagesb9 IwlakshmipathictiNo ratings yet

- OX - Solutions Profile 2023Document25 pagesOX - Solutions Profile 2023dove4suppliesNo ratings yet

- Factsheet Push Food Coldchain ENDocument2 pagesFactsheet Push Food Coldchain ENHelenette Joy SumagayNo ratings yet

- Renishaw Ballbar System QC-10Document8 pagesRenishaw Ballbar System QC-10ClaudintoshNo ratings yet

- Confidence in MeasurementDocument8 pagesConfidence in MeasurementloleNo ratings yet

- Calibrating UTM, Creep and Torsion Testing MachinesDocument31 pagesCalibrating UTM, Creep and Torsion Testing Machineszilangamba_s4535No ratings yet

- EquipmentqualificationDocument40 pagesEquipmentqualificationSSR PRASAD KOVELAMUDI100% (1)

- Pipeline Integrity Solutions LTR Rev.06 18 WebDocument6 pagesPipeline Integrity Solutions LTR Rev.06 18 WebSabbirHasanNo ratings yet

- Rajendran Updated C.VDocument8 pagesRajendran Updated C.VKannan RajendranNo ratings yet

- Dissoution Apparaus CalibrationDocument3 pagesDissoution Apparaus CalibrationsouravNo ratings yet

- Checking Machine Tools: Their Uses Keywords: Machines Tols, Measurements, Mini-Lathe, Accuracy, CNCDocument5 pagesChecking Machine Tools: Their Uses Keywords: Machines Tols, Measurements, Mini-Lathe, Accuracy, CNCMihai GhitulescuNo ratings yet

- CNC Milling: Technical DescriptionDocument15 pagesCNC Milling: Technical Descriptiongia1985No ratings yet

- Validation Commissioning DocumentsDocument4 pagesValidation Commissioning DocumentsPrashansa ShresthaNo ratings yet

- Technology Transfer Plan & Exhibit TJDocument19 pagesTechnology Transfer Plan & Exhibit TJTejashreeNo ratings yet

- KKKR3723 Part I IntroductionDocument11 pagesKKKR3723 Part I IntroductionPutriNo ratings yet

- NYSSCM QAI GuidelinesDocument12 pagesNYSSCM QAI GuidelinesbarrettshawnNo ratings yet

- Potash Storage Instrument CalibrationDocument13 pagesPotash Storage Instrument CalibrationAhmad DagamsehNo ratings yet

- STP-ELECT-DB Distribution Board TestDocument18 pagesSTP-ELECT-DB Distribution Board TestYouwan LeeNo ratings yet

- National Skill Competitions: Category: Manufacturing & Engineering TechnologyDocument11 pagesNational Skill Competitions: Category: Manufacturing & Engineering Technologyivan bernardNo ratings yet

- 3 Exercises Product Quatity Control Measurement ProceduresDocument29 pages3 Exercises Product Quatity Control Measurement ProceduresHasan Can MuratNo ratings yet

- Draft Guidelines For Model Quality Assurance Plan Mqap For Major Electrical Mechanical Equipment in Thermal Power Sector-2Document185 pagesDraft Guidelines For Model Quality Assurance Plan Mqap For Major Electrical Mechanical Equipment in Thermal Power Sector-2Chiranjeev SahooNo ratings yet

- Nabl 122 09 PDFDocument19 pagesNabl 122 09 PDFmaheshNo ratings yet

- CEA Guidelines Type Tests-1Document23 pagesCEA Guidelines Type Tests-1Somak Mitra100% (1)

- ServiciosCOMIMSA2019 EnglishDocument24 pagesServiciosCOMIMSA2019 EnglishPaola CernaNo ratings yet

- Equipment QualificationDocument64 pagesEquipment QualificationbuuNo ratings yet

- FM 1632Document19 pagesFM 1632osama alabsi100% (1)

- Control Procedures For The Calibration and Measurement of The Welding Power Supplies For PDFDocument11 pagesControl Procedures For The Calibration and Measurement of The Welding Power Supplies For PDFNenad NedeljkovicNo ratings yet

- Prof. Ir. Jamasri, PH.D., IPU., AER. Department of Mechanical & Industrial Engineering Engineering Faculty UGMDocument43 pagesProf. Ir. Jamasri, PH.D., IPU., AER. Department of Mechanical & Industrial Engineering Engineering Faculty UGMKeristiyantoNo ratings yet

- Quality Assurance and Quality ControlDocument4 pagesQuality Assurance and Quality ControlRuli DarmawanNo ratings yet

- Kistler Pliki Produktow Process Automation Nn188Document170 pagesKistler Pliki Produktow Process Automation Nn188martinxueloNo ratings yet

- Impact CalibrationDocument4 pagesImpact CalibrationPrashant PuriNo ratings yet

- Transformer Consulting US1Document2 pagesTransformer Consulting US1Torikul FauziNo ratings yet

- Analysis Level I Course: Introduction to CVCM and Typical Machinery Problems Detected by Vibration AnalysisDocument265 pagesAnalysis Level I Course: Introduction to CVCM and Typical Machinery Problems Detected by Vibration AnalysisSaadKianiNo ratings yet

- Tarang Labs: Product Qualification & Compliance TestingDocument12 pagesTarang Labs: Product Qualification & Compliance TestingAbishek AbhNo ratings yet

- Wireline Operations Techniques: Approach Into Slick, Braided & Electrical Line Equipment, Tools & ApplicationsDocument4 pagesWireline Operations Techniques: Approach Into Slick, Braided & Electrical Line Equipment, Tools & ApplicationsJerome LIKIBINo ratings yet

- Pocket Guide On CallibrationDocument38 pagesPocket Guide On CallibrationMohammed ZuberNo ratings yet

- Sample PDFDocument20 pagesSample PDFvivekdhavanNo ratings yet

- Material Specification: Safety And/Or Government Regulated PartDocument21 pagesMaterial Specification: Safety And/Or Government Regulated PartAbhishek ChauhanNo ratings yet

- Specifications For Field Gravel Roads Test KitDocument2 pagesSpecifications For Field Gravel Roads Test Kitbruce bogwaterNo ratings yet

- Visual Weld InspectionDocument7 pagesVisual Weld InspectioninsiderrNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Af 65Document10 pagesAf 65he maNo ratings yet

- 013107CWH05Document4 pages013107CWH05he maNo ratings yet

- mtd02 3Document4 pagesmtd02 3he maNo ratings yet

- Article 22 Vol III Issue IV 2012 PDFDocument4 pagesArticle 22 Vol III Issue IV 2012 PDFFahmi NurjananiNo ratings yet

- Angular clamping and workholding principlesDocument4 pagesAngular clamping and workholding principleshe maNo ratings yet

- mtd02 2Document2 pagesmtd02 2he maNo ratings yet

- mtd02 4Document2 pagesmtd02 4he maNo ratings yet

- mtd01 92Document1 pagemtd01 92he maNo ratings yet

- mtd01 95Document4 pagesmtd01 95he maNo ratings yet

- mtd03 42Document2 pagesmtd03 42he maNo ratings yet

- mtd01 94Document3 pagesmtd01 94he maNo ratings yet

- mtd01 93Document2 pagesmtd01 93he maNo ratings yet

- Joint loaded normally structure analysisDocument2 pagesJoint loaded normally structure analysishe maNo ratings yet

- mtd02 5mDocument2 pagesmtd02 5mhe maNo ratings yet

- MACHINING VIBRATIONSDocument2 pagesMACHINING VIBRATIONShe maNo ratings yet

- mtd03 2Document4 pagesmtd03 2he maNo ratings yet

- mtd03 41Document6 pagesmtd03 41he maNo ratings yet

- mtd01 7Document5 pagesmtd01 7he maNo ratings yet

- DAT02 LatheDocument3 pagesDAT02 Lathehe maNo ratings yet

- mtd01 8Document2 pagesmtd01 8he maNo ratings yet

- mtd02 66Document1 pagemtd02 66he maNo ratings yet

- mtd02 62Document1 pagemtd02 62he maNo ratings yet

- mtd03 3Document1 pagemtd03 3he maNo ratings yet

- 013107CWH09Document2 pages013107CWH09he maNo ratings yet

- mtd02 63Document2 pagesmtd02 63he maNo ratings yet

- mtd01 91Document1 pagemtd01 91he maNo ratings yet

- 020107EQCS01Document2 pages020107EQCS01he maNo ratings yet

- mtd02 5Document8 pagesmtd02 5he maNo ratings yet

- Machine Tool Joint Classification and TypesDocument2 pagesMachine Tool Joint Classification and Typeshe maNo ratings yet

- Tugas B.INGGRIS ALANDocument4 pagesTugas B.INGGRIS ALANAlan GunawanNo ratings yet

- Salah or Prayer Is One of The Pillars of Islam and It Is AnDocument7 pagesSalah or Prayer Is One of The Pillars of Islam and It Is AnSitti Nauhar AukasaNo ratings yet

- Bacterial Recombination MCQsDocument3 pagesBacterial Recombination MCQsJon HosmerNo ratings yet

- L Earning Activity Sheet - PERDEV 12: Learning Competency With Code: Discuss That Understanding The IntensityDocument13 pagesL Earning Activity Sheet - PERDEV 12: Learning Competency With Code: Discuss That Understanding The IntensityJohn Patrick PanchoNo ratings yet

- Technical Lead with 9 years' experience in .NET, Angular and AzureDocument2 pagesTechnical Lead with 9 years' experience in .NET, Angular and AzureModi SandeepNo ratings yet

- Liban AnalyseDocument12 pagesLiban AnalyseSatish ReddyNo ratings yet

- Black Industries Lost Files - Terror in The DarknessDocument14 pagesBlack Industries Lost Files - Terror in The Darknessjadrax100% (8)

- Ch01 Standard Methods and PractisesDocument44 pagesCh01 Standard Methods and PractisesUsman FarooqNo ratings yet

- Trollbloods Warmachine/Hordes Cross StitchDocument8 pagesTrollbloods Warmachine/Hordes Cross StitchGraeme DawsonNo ratings yet

- Covid19-Drug StudyDocument7 pagesCovid19-Drug StudynicoleNo ratings yet

- Science: Quarter 1 Module 1: Volcanoes, Earthquakes, and Mountain RangesDocument38 pagesScience: Quarter 1 Module 1: Volcanoes, Earthquakes, and Mountain RangesMaria LayupanNo ratings yet

- Far Eastern Shipping Vs CADocument2 pagesFar Eastern Shipping Vs CAAnonymous 5MiN6I78I0No ratings yet

- Exercise For FitnessDocument44 pagesExercise For FitnessSheena Mae Sube PoNo ratings yet

- BS 07579-1992 (1999) Iso 2194-1991Document10 pagesBS 07579-1992 (1999) Iso 2194-1991matteo_1234No ratings yet

- Value-Added ProductsDocument7 pagesValue-Added ProductsTendai MutisiNo ratings yet

- Isoenzyme ClassifiedDocument33 pagesIsoenzyme Classifiedsayush754No ratings yet

- Summative Test 1 English 9 Q1Document2 pagesSummative Test 1 English 9 Q1Katherine Anne Munar0% (1)

- LCP4805-mc Mehta Vs Union of IndiaDocument60 pagesLCP4805-mc Mehta Vs Union of Indiatech hutNo ratings yet

- 2.2 - T - Basic Negotiation Skill Vol. 1Document5 pages2.2 - T - Basic Negotiation Skill Vol. 1Siva 93No ratings yet

- Metrology Instruments Calibration Guide: Mitutoyo Asia PacificDocument6 pagesMetrology Instruments Calibration Guide: Mitutoyo Asia PacificLuis Eduardo García MaltosNo ratings yet

- June 10Document16 pagesJune 10rogeliodmngNo ratings yet

- Civil Rights Web-QuestDocument5 pagesCivil Rights Web-Questapi-367833271No ratings yet

- Cagayan Electric vs. CIRDocument4 pagesCagayan Electric vs. CIRGladys BantilanNo ratings yet

- Improving Oil Recovery with EOR/IOR MethodsDocument1 pageImproving Oil Recovery with EOR/IOR MethodsMuhammad Fawwad ObaidaNo ratings yet

- Alat Studio Dan KomunikasiDocument14 pagesAlat Studio Dan Komunikasiraymon akbarNo ratings yet