Professional Documents

Culture Documents

3.9 Water Treatment, Storage & Blowdown For Steam Boilers

Uploaded by

Jhonathan AlejandroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3.9 Water Treatment, Storage & Blowdown For Steam Boilers

Uploaded by

Jhonathan AlejandroCopyright:

Available Formats

Block 3 The Boiler House Water Treatment, Storage and Blowdown for Steam Boilers Module 3.

Module 3.9

Water Treatment, Storage and

Blowdown for Steam Boilers

The Steam and Condensate Loop 3.9.1

Block 3 The Boiler House Water Treatment, Storage and Blowdown for Steam Boilers Module 3.9

Water Treatment, Storage and

Blowdown for Steam Boilers

Before boiler blowdown can be discussed and understood it is necessary to establish a definition

of water along with its impurities and associated terms such as hardness, pH etc.

Water is the most important raw material on earth. It is essential to life, it is used for transportation,

and it stores energy. It is also called the universal solvent.

Pure water (H20) is tasteless, odourless, and colourless in its pure state; however, pure water is

very uncommon. All natural waters contain various types and amounts of impurities.

Good drinking water does not necessarily make good boiler feedwater. The minerals in drinking

water are readily absorbed by the human body, and essential to our well being. Boilers, however,

are less able to cope, and these same minerals will cause damage in a steam boiler if allowed to

remain.

Of the worlds water stock, 97% is found in the oceans, and a significant part of that is trapped

in the polar glaciers - only 0.65% is available for domestic and industrial use.

This small proportion would soon be consumed if it were not for the water cycle (see Figure 3.9.1).

After evaporation, the water turns into clouds, which are partly condensed during their journey

and then fall to earth as rain. However, it is wrong to assume that rainwater is pure; during its fall

to earth it will pick up impurities such as carbonic acid, nitrogen and, in industrial areas, sulphur

dioxide.

Charged with these ingredients, the water percolates through the upper layers of the earth to the

water table, or flows over the surface of the earth dissolving and collecting additional impurities.

These impurities may form deposits on heat transfer surfaces that may:

o Cause metal corrosion.

o Reduce heat transfer rates, leading to overheating and loss of mechanical strength.

Table 3.9.1 shows the technical and commonly used names of the impurities, their chemical

symbols, and their effects.

Atmospheric moisture

Precipitation Evaporation

Evaporation and transportation from oceans

from surface water bodies, land Consumptive

surface and vegetation use

Well

Water

table Percolation Streams flow to oceans

Total surface and

ground water flow

to oceans

Ocean

Fresh Saline

ground water Interface ground water

Fig. 3.9.1 Typical water cycle

The Steam and Condensate Loop 3.9.2

Block 3 The Boiler House Water Treatment, Storage and Blowdown for Steam Boilers Module 3.9

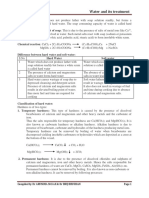

Table 3.9.1 Impurities in water

Name Symbol Common name Effect

Calcium carbonate CaCO3 Chalk, limestone Soft scale

Calcium bicarbonate Ca(HCO3)2 Soft scale + CO2

Calcium sulphate CaSO4 Gypsum, plaster of paris Hard scale

Calcium chloride CaCI2 Corrosion

Magnesium carbonate MgCO3 Soft scale

Magnesium sulphate MgSO4 Magnesite Corrosion

Magnesium bicarbonate Mg(HCO3)2 Epsom salts Scale, corrosion

Sodium chloride NaCI Common salt Electrolysis

Sodium carbonate Na2CO3 Washing soda or soda Alkalinity

Sodium bicarbonate NaHCO3 Baking soda Priming, foaming

Sodium hydroxide NaOH Caustic soda Alkalinity, embrittlement

Sodium sulphate Na2SO2 Glauber salts Alkalinity

Silicon dioxide SiO2 Silica Hard scale

Raw water quality and regional variations

Water quality can vary tremendously from one region to another depending on the sources of

water, local minerals (see Figure 3.9.2). Table 3.9.2 gives some typical figures for different areas

in a relatively small country like the UK.

Soft to moderately soft

Newcastle upon Tyne

Slightly hard to moderately hard

Hard to very hard

York

Leeds

Manchester

Lincoln

Norwich

Birmingham

Cardiff

Bristol London

Brighton

Southampton

Fig. 3.9.2 Regional variations in water quality

Table 3.9.2 Water variation within the UK - All impurities expressed in mg /l calcium carbonate equivalents

Alkaline Non-alkaline Total

Area hardness hardness Total Non-hardness dissolved

(temporary) (permanent) hardness salts solids (TDS)

Leeds 12 10 22 24 46

York 156 92 248 62 310

Birmingham 28 72 100 130 230

London 180 192 372 50 422

The Steam and Condensate Loop 3.9.3

Block 3 The Boiler House Water Treatment, Storage and Blowdown for Steam Boilers Module 3.9

The common impurities in raw water can be classified as follows:

o Dissolved solids - These are substances that will dissolve in water.

The principal ones are the carbonates and sulphates of calcium and magnesium, which are

scale-forming when heated.

There are other dissolved solids, which are non-scale forming.

In practice, any salts forming scale within the boiler should be chemically altered so that they

produce suspended solids, or sludge rather than scale.

o Suspended solids - These are substances that exist in water as suspended particles.

They are usually mineral, or organic in origin.

These substances are not generally a problem as they can be filtered out.

o Dissolved gases - Oxygen and carbon dioxide can be readily dissolved by water.

These gases are aggressive instigators of corrosion.

o Scum forming substances - These are mineral impurities that foam or scum.

One example is soda in the form of a carbonate, chloride, or sulphate.

The amount of impurities present is extremely small and they are usually expressed in any

water analysis in the form of parts per million (ppm), by weight or alternatively in milligrams per

litre (mg /l).

The following sections within this Module describe the characteristics of water.

Hardness

Water is referred to as being either hard or soft. Hard water contains scale-forming impurities

while soft water contains little or none. The difference can easily be recognised by the effect of

water on soap. Much more soap is required to make a lather with hard water than with soft

water.

Hardness is caused by the presence of the mineral salts of calcium and magnesium and it is these

same minerals that encourage the formation of scale.

There are two common classifications of hardness:

o Alkaline hardness (also known as temporary hardness) - Calcium and magnesium

bicarbonates are responsible for alkaline hardness. The salts dissolve in water to form an alkaline

solution. When heat is applied, they decompose to release carbon dioxide and soft scale or

sludge.

The term temporary hardness is sometimes used, because the hardness is removed by boiling.

This effect can often be seen as scale on the inside of an electric kettle.

See Figures 3.9.3 and 3.9.4 - the latter representing the situation within the boiler.

Carbon dioxide combines with water to form carbonic acid:

CO2 H2 0 H2C03

Carbon dioxide Water Carbonic acid

Limestone (calcium carbonate) is dissolved by carbonic acid to form calcium bicarbonate:

H2C03 CaCO3 Ca(HCO3)2

Carbonic acid Calcium carbonate Calcium bicarbonate

Fig. 3.9.3 Alkaline or temporary hardness

The Steam and Condensate Loop 3.9.4

Block 3 The Boiler House Water Treatment, Storage and Blowdown for Steam Boilers Module 3.9

Carbon dioxide combines with steam to form carbonic acid:

Ca(HCO3)2 CaCO3 CO2

H2 0

Calcium Heat Calcium Carbon

water

bicarbonate carbonate dioxide

Similarly, magnesite (magnesium carbonate) is dissolved by carbonic acid to form magnesium bicarbonate:

Mg(HCO3)2 MgCO3 CO2

H 20

Magnesium Heat Magnesium Carbon

water

bicarbonate carbonate dioxide

Fig. 3.9.4 Non-alkaline or permanent hardness (scale + carbonic acid)

o Non-alkaline hardness and carbonates (also known as permanent hardness) - This is also

due to the presence of the salts of calcium and magnesium but in the form of sulphates and

chlorides. These precipitate out of solution, due to their reduced solubility as the temperature

rises, and form hard scale, which is difficult to remove.

In addition, the presence of silica in boiler water can also lead to hard scale, which can react

with calcium and magnesium salts to form silicates which can severely inhibit heat transfer

across the fire tubes and cause them to overheat.

Total hardness

Total hardness is not to be classified as a type of hardness, but as the sum of concentrations of

calcium and magnesium ions present when these are both expressed as CaCo3. If the water is

alkaline, a proportion of this hardness, equal in magnitude to the total alkalinity and also expressed

as CaCo3, is considered as alkaline hardness, and the remainder as non-alkaline hardness.

(See Figure 3.9.5)

Non-alkaline hardness Alkaline hardness Total

(permanent) (temporary) hardness

Fig. 3.9.5 Total hardness

Non-scale forming salts

Non-hardness salts, such as sodium salts are also present, and are far more soluble than the salts

of calcium or magnesium and will not generally form scale on the surfaces of a boiler, as shown

in Figure 3.9.6.

2NaHCO3 Na2CO3 CO2

H2 0

Sodium Heat Sodium Carbon

water

bicarbonate carbonate dioxide

Na2CO3 2NaOH

H2 0 C02

Sodium Heat Sodium

water Carbon dioxie

carbonate hydroxide

Adding the total hardness + non-hardness salts gives:

Total Non hardness Total dissolved solids

hardness salts (TDS)

Fig. 3.9.6 The effects of heat

The Steam and Condensate Loop 3.9.5

Block 3 The Boiler House Water Treatment, Storage and Blowdown for Steam Boilers Module 3.9

Comparative units

When salts dissolve in water they form electrically charged particles called ions.

The metallic parts (calcium, sodium, magnesium) can be identified as cations because they are

attracted to the cathode and carry positive electrical charges.

Anions are non-metallic and carry negative charges - bicarbonates, carbonate, chloride, sulphate,

are attracted to the anode.

Each impurity is generally expressed as a chemically equivalent amount of calcium carbonate,

which has a molecular weight of 100.

pH value

Another term to be considered is the pH value; this is not an impurity or constituent but merely

a numerical value representing the potential hydrogen content of water - which is a measure of

the acidic or alkaline nature of the water. Water, H2O, has two types of ions - hydrogen ions (H+)

and hydroxyl ions (OH-).

If the hydrogen ions are predominant, the solution will be acidic with a pH value between 0 and

6. If the hydroxyl ions are predominant, the solution will be alkaline, with a pH value between 8

and 14. If there are an equal number of both hydroxyl and hydrogen ions, then the solution will

be neutral, with a pH value of 7.

Acids and alkalis have the effect of increasing the conductivity of water above that of a neutral

sample. For example, a sample of water with a pH value of 12 will have a higher conductivity

than a sample that has a pH value of 7.

Table 3.9.3 shows the pH chart and Figure 3.9.7 illustrates the pH values already mentioned

both numerically and in relation to everyday substances.

Table 3.9.3 The pH scale

pH Hydrogen ion concentration Hydroxyl ion concentration

Nature

value H+ H-

0 100 10-14 Acid

7 10-7 10-7 Neutral

14 10-14 100 Alkaline

The Steam and Condensate Loop 3.9.6

Block 3 The Boiler House Water Treatment, Storage and Blowdown for Steam Boilers Module 3.9

pH value

0 0.1 Hydrochloric acid (3.6% HCI)

0.3 Sulphuric acid (4.9% H2SO4)

1 1.1 Hydrochloric acid (0.36% HCI)

1.2 Sulphuric acid (0.49% H2SO4)

2.0 Hydrochloric acid (0.036% HCI)

2 2.1 Sulphuric acid (0.049% H2SO4)

Lemon juice 2.3 2.4 Acetic acid (6% CH3COOH)

Wine 2.8 to 3.8 2.9 Acetic acid (0.6% CH3COOH)

Vinegar 3.1 3

Fruit juice 3.5 to 4.0 3.4 Acetic acid (0.06% CH3COOH)

Marshy water 4.0 4

Beer 4.0 to 5.0 5

5.2 Boric acid (0.2% H3BO3)

6

Milk 6.3 to 6.6

Water, chemically pure 7.0 7

8

Sea water 8.3 8.4 Sodium bi. carb. solution (0.42% NaHCO3)

9

9.2 Borax solution (1.9% Na2B407)

10

10.6 Ammonia solution (0.017% NH3)

11 11.1 Ammonia solution (0.17% NH3)

11.6 Ammonia solution (1.7% NH3)

12 12.0 Potassium hydroxide solution (0.056% KOH)

Lime-water, saturated 12.3

13 13.0 Potassium hydroxide solution (0.56% KOH)

13.0 Sodium hydroxide solution (0.4% NaOH)

14 14.0 Potassium hydroxide solution (5.6% KOH)

Fig. 3.9.7 pH chart 14.0 Sodium hydroxide solution (4% NaOH)

The Steam and Condensate Loop 3.9.7

Block 3 The Boiler House Water Treatment, Storage and Blowdown for Steam Boilers Module 3.9

Questions

1. Temporary hardness salts are reduced by:

a| Raising the water temperature ¨

b| Lowering the water temperature ¨

c| Raising the pH value ¨

d| Letting the water settle ¨

2. What is the effect of CO2 in a steam system ?

a| The formation of scale ¨

b| The formation of sludge ¨

c| Corrosion ¨

d| Acidity ¨

3. Which of the following forms soft scale or sludge ?

a| Magnesium sulphate ¨

b| Sodium carbonate ¨

c| Sodium bicarbonate ¨

d| Calcium bicarbonate ¨

4. Which of the following are principal dissolved solids that are scale forming ?

a| Carbonates and sulphates of sodium ¨

b| Calcium bicarbonate ¨

c| Carbonates and sulphates of magnesium ¨

d| Bicarbonate of sodium and magnesium ¨

5. What is the effect of temperature on calcium and magnesium sulphates ?

a| They separate out as soft scale and sludge ¨

b| They precipitate out of solution and form hard scale ¨

c| Foaming and carryover occurs ¨

d| The TDS is increased ¨

6. What is the treatment for scale forming salts in boiler feedwater ?

a| They are chemically treated to modify the pH ¨

b| The feedwater tank is raised to at least 85°C ¨

c| They are chemically treated to produce suspended solids ¨

d| They are removed by filtration means ¨

Answers

1: a, 2: c, 3: d, 4: c, 5: b, 6: c

The Steam and Condensate Loop 3.9.8

You might also like

- Chemistry The Central Science Practice Exercises Answer KeyDocument85 pagesChemistry The Central Science Practice Exercises Answer KeyImran Khaliq14% (7)

- 128-010 Falk Series C, E, F, G, J, P, Q, S, Y Gear Drives Service Manual RexrothDocument6 pages128-010 Falk Series C, E, F, G, J, P, Q, S, Y Gear Drives Service Manual RexrothnghiaNo ratings yet

- Machine Manual HP Pump - Type P3: Issue No. 2 September 2005Document70 pagesMachine Manual HP Pump - Type P3: Issue No. 2 September 2005Jhonathan AlejandroNo ratings yet

- Chemical Reaction Is When: Chemistry 151 Week 7 - Chemical Reactions College of The Canyons Fall 2020Document10 pagesChemical Reaction Is When: Chemistry 151 Week 7 - Chemical Reactions College of The Canyons Fall 2020Muhammad SaaDiNo ratings yet

- Water Treatment, Storage and Blowdown For Steam Boilers: Academic Manual AC/18/01 - AC/10/04Document78 pagesWater Treatment, Storage and Blowdown For Steam Boilers: Academic Manual AC/18/01 - AC/10/04kISHORENo ratings yet

- Chandan Matty Theory CompleteDocument199 pagesChandan Matty Theory Completemir zainNo ratings yet

- Water TreatDocument15 pagesWater TreatbjosufNo ratings yet

- Water - OfficialDocument62 pagesWater - OfficialPushp BahukhandiNo ratings yet

- Water: Engineering Chemistry-I Unit-6Document70 pagesWater: Engineering Chemistry-I Unit-6Abhyudaya Rajput an idiotNo ratings yet

- Water 2018Document50 pagesWater 2018Shiv PatelNo ratings yet

- B 1667. Irrigation Water Quality Standards and Salinity Management Strategies PDFDocument17 pagesB 1667. Irrigation Water Quality Standards and Salinity Management Strategies PDFmuhammad ishaqNo ratings yet

- Water AnalysisDocument25 pagesWater AnalysisshubhamNo ratings yet

- Water Treatment White Paper PDFDocument20 pagesWater Treatment White Paper PDFWaleed EmaraNo ratings yet

- Cy8151 Engineering Chemistry Unit-I Watertechnology 1. 2 - Hardness of Water - Types - Expression of Hardness - Units 1.2. Hard WaterDocument3 pagesCy8151 Engineering Chemistry Unit-I Watertechnology 1. 2 - Hardness of Water - Types - Expression of Hardness - Units 1.2. Hard WaterNikhil GobhilNo ratings yet

- Ch4 4 Watertreat SofteningDocument23 pagesCh4 4 Watertreat SofteningSUBHAM KumarNo ratings yet

- Unit-Iii Water and Its TreatmentDocument110 pagesUnit-Iii Water and Its TreatmentMeenatchiNo ratings yet

- Engineering Chemistry Material (DR.C)Document98 pagesEngineering Chemistry Material (DR.C)Rohith TellaNo ratings yet

- The Water: by Dr. Rahul ShrivastavaDocument58 pagesThe Water: by Dr. Rahul ShrivastavaAngelou RequironNo ratings yet

- Unit 1 - Chemistry - WWW - Rgpvnotes.inDocument9 pagesUnit 1 - Chemistry - WWW - Rgpvnotes.inRajesh KumarNo ratings yet

- Unit 4water Tech. PPT Aktu ChemistryDocument77 pagesUnit 4water Tech. PPT Aktu ChemistryVAISHNAVI SINGHNo ratings yet

- A Brief Review of Natural Water's Influence On Scale Formation in Heat ExchangersDocument4 pagesA Brief Review of Natural Water's Influence On Scale Formation in Heat ExchangersBramJanssen76No ratings yet

- Irrigation Water Quality Standards and Salinity ManagementDocument16 pagesIrrigation Water Quality Standards and Salinity ManagementShihan NittoNo ratings yet

- Unit-Iii Water and Its TreatmentDocument110 pagesUnit-Iii Water and Its TreatmentDinesh VermaNo ratings yet

- Wet Processing I Water PDFDocument7 pagesWet Processing I Water PDFkabir_ce06038No ratings yet

- Ch4 Watertreat II SofteningDocument20 pagesCh4 Watertreat II SofteningRahul Kr MeenaNo ratings yet

- Chemistry Unit-3Document17 pagesChemistry Unit-3santanu janaNo ratings yet

- Irjet V5i3879 PDFDocument4 pagesIrjet V5i3879 PDFishaq kazeemNo ratings yet

- Hardness Removal of Groundwater by Using Optimum Lime-Soda ProcessDocument4 pagesHardness Removal of Groundwater by Using Optimum Lime-Soda Processishaq kazeemNo ratings yet

- Boiler WaterDocument70 pagesBoiler WaterDarius Dsouza100% (1)

- 192 Sample-Chapter PDFDocument39 pages192 Sample-Chapter PDFsenthil4youNo ratings yet

- Soil Remediation - Brine 6-11Document251 pagesSoil Remediation - Brine 6-11bovairdsupplyNo ratings yet

- Water Quality Characteristics: Nik Azlin Nik AriffinDocument92 pagesWater Quality Characteristics: Nik Azlin Nik AriffinRomaldo ManuelNo ratings yet

- Water Chemistry & Applications in Water TreatmentDocument32 pagesWater Chemistry & Applications in Water TreatmentmasoodismNo ratings yet

- Chemistry Mid EC Material-UpdatedDocument41 pagesChemistry Mid EC Material-Updatedmanepalli.premNo ratings yet

- Boiler WaterDocument70 pagesBoiler WaterDarius DsouzaNo ratings yet

- 2 - Water N TreatmentDocument47 pages2 - Water N TreatmentdarshanNo ratings yet

- PPU NotesDocument38 pagesPPU Noteswadhwachirag524No ratings yet

- Water HardnessDocument82 pagesWater HardnessabirNo ratings yet

- WATER POLLUTION NewDocument9 pagesWATER POLLUTION NewShankar.KNo ratings yet

- WaterDocument40 pagesWaterhimanshuchawla654No ratings yet

- Water and Its Treatment MaterialDocument14 pagesWater and Its Treatment MaterialSameer SamNo ratings yet

- Water Chemistry, Methods of Chemical Analysis and Instrumental Methods of AnalysisDocument21 pagesWater Chemistry, Methods of Chemical Analysis and Instrumental Methods of AnalysisEli ShaneNo ratings yet

- Carbonate Equilibria in Natural WatersDocument26 pagesCarbonate Equilibria in Natural Watersnermeen ahmedNo ratings yet

- Basic Ion Exchange ResinDocument11 pagesBasic Ion Exchange ResinJOHAN SINGGIH PRAYOGONo ratings yet

- Water Treatment, Storage and Blowdown For Steam BoilersDocument12 pagesWater Treatment, Storage and Blowdown For Steam BoilersvikramacbNo ratings yet

- Cha 13Document16 pagesCha 13Tun Lin AungNo ratings yet

- CIVL 529 W2021 Part 02 - Combined Hydration + SCMs + NanoTech - N. BanthiaDocument118 pagesCIVL 529 W2021 Part 02 - Combined Hydration + SCMs + NanoTech - N. BanthiaLuay K. Al-mniniNo ratings yet

- CY8151 QB IQ 2M - by WWW - EasyEngineering.net 2Document22 pagesCY8151 QB IQ 2M - by WWW - EasyEngineering.net 2widav34409No ratings yet

- Water ChemistryDocument19 pagesWater ChemistryNupur ChoudharyNo ratings yet

- Apllied Chemistry - 1 PDFDocument169 pagesApllied Chemistry - 1 PDFwrwetgrfsdfNo ratings yet

- Water: Sources of Water Hard and Soft WaterDocument23 pagesWater: Sources of Water Hard and Soft WatersurenNo ratings yet

- Unit - I: Water TechnologyDocument69 pagesUnit - I: Water TechnologyAkshaya MotamarriNo ratings yet

- Water Treatment and Technology: Dr. M. NAGOOR MEERAN M.SC., M.Phil., PH.DDocument19 pagesWater Treatment and Technology: Dr. M. NAGOOR MEERAN M.SC., M.Phil., PH.DAnudeep ThanikondaNo ratings yet

- Water and Its TreatmentDocument25 pagesWater and Its TreatmentsumitNo ratings yet

- Chem Mod1Document10 pagesChem Mod1baritone.exhaustNo ratings yet

- Microbial Carbon Mineralization (MCM) Carbon Dioxide Removal PathwayDocument16 pagesMicrobial Carbon Mineralization (MCM) Carbon Dioxide Removal PathwayD ArasuNo ratings yet

- Hardness RemovalDocument18 pagesHardness RemovalRuang RenungNo ratings yet

- Water and Its Trea TmentDocument110 pagesWater and Its Trea TmentParth Bhaskar100% (1)

- Boiled Feed WaterDocument31 pagesBoiled Feed WaterNowshad ArefinNo ratings yet

- Kinetico: Confidential 2/7/2008 Version 3.0 DraftDocument29 pagesKinetico: Confidential 2/7/2008 Version 3.0 Draftcb4pdfsNo ratings yet

- Handout BOILER FEED WATERDocument9 pagesHandout BOILER FEED WATERMuhammad Omar AzadNo ratings yet

- Water Chemistry 1Document2 pagesWater Chemistry 1Tushar SharmaNo ratings yet

- Softening FinalDocument23 pagesSoftening FinalSonali Jahagirdar100% (1)

- 3.15 Water Levels in Steam BoilersDocument6 pages3.15 Water Levels in Steam BoilersJhonathan AlejandroNo ratings yet

- 3.6 Boiler Efficiency and CombustionDocument12 pages3.6 Boiler Efficiency and CombustionJhonathan AlejandroNo ratings yet

- 3.10 Water For The BoilerDocument12 pages3.10 Water For The BoilerJhonathan AlejandroNo ratings yet

- 3.8 Steam Headers and Off-TakesDocument8 pages3.8 Steam Headers and Off-TakesJhonathan AlejandroNo ratings yet

- 3.2 Shell BoilersDocument12 pages3.2 Shell BoilersJhonathan AlejandroNo ratings yet

- Product Specifications & Technical Data: Tel: (1) 624-1500 Cel: 315-336-2446Document1 pageProduct Specifications & Technical Data: Tel: (1) 624-1500 Cel: 315-336-2446Jhonathan AlejandroNo ratings yet

- Industrial MetrologyDocument339 pagesIndustrial MetrologyJhonathan Alejandro100% (1)

- Tounsi 2015Document14 pagesTounsi 2015Jhonathan AlejandroNo ratings yet

- Modos de Falla Rodamientosiso - 15243 - 2004 - en - FR PDFDocument11 pagesModos de Falla Rodamientosiso - 15243 - 2004 - en - FR PDFJhonathan AlejandroNo ratings yet

- Modeling and Experimental Validation of The Surface Residual Stresses Induced by Hard Machining of Aisi H13 Tool SteelDocument4 pagesModeling and Experimental Validation of The Surface Residual Stresses Induced by Hard Machining of Aisi H13 Tool SteelJhonathan AlejandroNo ratings yet

- Metal Rolling (URI)Document21 pagesMetal Rolling (URI)Edwin SetiawanNo ratings yet

- Sigra S.A 11 4315 P3029 DK PRM 2X80l 2006Document22 pagesSigra S.A 11 4315 P3029 DK PRM 2X80l 2006Jhonathan AlejandroNo ratings yet

- Spare Parts List: 200 154 KombinatorDocument23 pagesSpare Parts List: 200 154 KombinatorJhonathan AlejandroNo ratings yet

- Klubersynth UH1 14-222 NSFDocument1 pageKlubersynth UH1 14-222 NSFJhonathan AlejandroNo ratings yet

- New C Gearb Cte Plu Boxes US Series S - Twin S Screw Ex Xtruders Equipped D With Ne EwDocument3 pagesNew C Gearb Cte Plu Boxes US Series S - Twin S Screw Ex Xtruders Equipped D With Ne EwJhonathan AlejandroNo ratings yet

- LE8NDocument4 pagesLE8NCarlos Enrique De Gumucio VargasNo ratings yet

- Prolube® High Temp H1 Food Grade Machinery Grease #1 & #2Document1 pageProlube® High Temp H1 Food Grade Machinery Grease #1 & #2Jhonathan AlejandroNo ratings yet

- Rodamientos de Rodillos Esféricos: DimensionesDocument4 pagesRodamientos de Rodillos Esféricos: DimensionesJhonathan AlejandroNo ratings yet

- Dodge MTA 4207 H PDFDocument28 pagesDodge MTA 4207 H PDFJhonathan AlejandroNo ratings yet

- Buffers For and Metal Ion ControlDocument7 pagesBuffers For and Metal Ion ControlSaid Nafik HkiNo ratings yet

- Safety Assessment of Triethanolamine and Triethanolamine-Containing Ingredients As Used in CosmeticsDocument26 pagesSafety Assessment of Triethanolamine and Triethanolamine-Containing Ingredients As Used in CosmeticsAdrian Copa JNo ratings yet

- Chemistry Ssc1Document3 pagesChemistry Ssc1hapy372000100% (1)

- Review of Related Literature - 2Document3 pagesReview of Related Literature - 2Miguel VillarroelNo ratings yet

- 0620 s02 QP 6Document12 pages0620 s02 QP 6Varun PanickerNo ratings yet

- Full Download Biochemistry A Short Course 3rd Edition Tymoczko Test Bank PDF Full ChapterDocument36 pagesFull Download Biochemistry A Short Course 3rd Edition Tymoczko Test Bank PDF Full Chapterdrosera.inclave.pjoui100% (13)

- Be ChemDocument30 pagesBe ChemSka dooshNo ratings yet

- Kumpulan Contoh Soal SBMPTN Bahasa Inggris Dan Pembahasannya 2016Document16 pagesKumpulan Contoh Soal SBMPTN Bahasa Inggris Dan Pembahasannya 2016Fahmi Daud Abdillah100% (1)

- Large Scale and MultiStructured DatabasesDocument223 pagesLarge Scale and MultiStructured DatabasesFranco TerranovaNo ratings yet

- Determination of Organic Acids and Sugars in Cheese, Milk and Whey by High Performance Liquid Chromatography W. J. Mullin & D. B. EmmonsDocument5 pagesDetermination of Organic Acids and Sugars in Cheese, Milk and Whey by High Performance Liquid Chromatography W. J. Mullin & D. B. EmmonsJohana Marcela AcostaNo ratings yet

- SCH3U June 2018 Exam REVIEWDocument5 pagesSCH3U June 2018 Exam REVIEWSab ShahNo ratings yet

- Yr 7 RevisionDocument33 pagesYr 7 Revisionamr ahmedNo ratings yet

- Chemistry Project - Analysis of The Different Samples of Milk For Presence of CaseinDocument27 pagesChemistry Project - Analysis of The Different Samples of Milk For Presence of Caseinmm887167% (3)

- 06 Inquirybio ch06Document42 pages06 Inquirybio ch06HabzboiiNo ratings yet

- Class 8 Chap 4 Metals and Non MetalsDocument34 pagesClass 8 Chap 4 Metals and Non MetalsAncy davidNo ratings yet

- Experiment 32Document14 pagesExperiment 32Morgan Elizabeth Lepley100% (6)

- Pharmaceutical Inorganic Chemistry 3Document4 pagesPharmaceutical Inorganic Chemistry 3DeepikaNo ratings yet

- ACID BAse AssignmentDocument11 pagesACID BAse AssignmentMosfiqur Rahman100% (2)

- 4.2 Laboratory Report Acids and BasesDocument5 pages4.2 Laboratory Report Acids and Basesalejandro pederioNo ratings yet

- Principles of Neutralization TitrationDocument29 pagesPrinciples of Neutralization Titrationanita sukarini100% (2)

- The Periodic Table: Group Number Number of Electrons in Outer ShellDocument17 pagesThe Periodic Table: Group Number Number of Electrons in Outer ShellFakhar LateefNo ratings yet

- Data Sheet Revision PDFDocument2 pagesData Sheet Revision PDFShifa RizwanNo ratings yet

- 0620 Chemistry: MARK SCHEME For The March 2015 SeriesDocument44 pages0620 Chemistry: MARK SCHEME For The March 2015 Seriesaung aungNo ratings yet

- Materials For Aggresive EnvironmentsDocument26 pagesMaterials For Aggresive EnvironmentsfabianoNo ratings yet

- NCHE 211 UNIT 2 VOLUMETRY and Complexometry TitrationDocument49 pagesNCHE 211 UNIT 2 VOLUMETRY and Complexometry Titrationkamohelo tsoeuNo ratings yet

- Unit - 4-Part-1Document65 pagesUnit - 4-Part-1sc21fs301017No ratings yet

- PhenolDocument16 pagesPhenolAmanNo ratings yet

- Chroma Notes 2Document8 pagesChroma Notes 2Marielle GuevaraNo ratings yet