Professional Documents

Culture Documents

Certificados Placa Brasil Junio

Uploaded by

JAIRO ARGAEZ MENDESOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Certificados Placa Brasil Junio

Uploaded by

JAIRO ARGAEZ MENDESCopyright:

Available Formats

PAGE

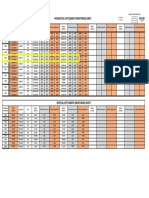

MILL TEST / QUALITY CERTIFICATE 1/2

CUSTOMER CUSTOMER ORDER SALES ORDER DIMENSIONS DATE

ACEROS CORSA SA DE CV AC 19022021 - LA FER 10366820-000001 1/2" x 6 foot x 20Foot 05.13.2021

Gerdau Açominas S.A. PRODUCT EDGE TYPE DELIVERY CONDITION DOCUMENT NUMBER

ROD MG 443 KM 7 SN FAZENDA DO CADETE Plate Cut edge As rolled

0001296E21

OURO BRANCO MG SPECIFICATION

36420-000 BRAZIL ASTM A36 2019

Gerdau S.A. certifies that the material herein described is in accordance with the applicable technical specifications. As mutual protection for costumer and supplier, this certificate is considered as confidential and can not be transcribed or reproduced without the writtenauthorization of Gerdau S.A.

PACKAGES

PLATE # WEIGHT (MT) HEAT SAMPLE PLATE # WEIGHT (MT) HEAT SAMPLE PLATE # WEIGHT (MT) HEAT SAMPLE

3128999801 1.111 27119595 27119595001 3129000704 1.111 28120255 28120255001 3129050006 1.111 28120260 28120260001

3128999802 1.111 27119595 27119595001 3129000705 1.111 28120255 28120255001 3129050007 1.111 28120260 28120260001

3128999803 1.111 27119595 27119595001 3129000706 1.111 28120255 28120255001 3129090801 1.111 28120251 28120251001

3128999804 1.111 27119595 27119595001 3129000707 1.111 28120255 28120255001 3129090802 1.111 28120251 28120251001

3128999805 1.111 27119595 27119595001 3129000801 1.111 28120255 28120255001 3129090803 1.111 28120251 28120251001

3128999806 1.111 27119595 27119595001 3129000802 1.111 28120255 28120255001 3129090804 1.111 28120251 28120251001

3128999901 (*) 1.111 27119595 27119595001 3129000803 1.111 28120255 28120255001 3129090805 1.111 28120251 28120251001

3128999902 1.111 27119595 27119595001 3129000804 1.111 28120255 28120255001 3129090806 1.111 28120251 28120251001

3128999903 1.111 27119595 27119595001 3129000805 1.111 28120255 28120255001 3129090901 1.111 28120251 28120251001

3128999904 1.111 27119595 27119595001 3129000806 1.111 28120255 28120255001 3129090902 1.111 28120251 28120251001

3128999905 1.111 27119595 27119595001 3129000807 1.111 28120255 28120255001 3129090903 1.111 28120251 28120251001

3128999906 1.111 27119595 27119595001 3129000901 1.111 28120255 28120255001 3129090904 1.111 28120251 28120251001

3129000001 1.111 27119595 27119595001 3129000902 1.111 28120255 28120255001 3129090905 1.111 28120251 28120251001

3129000002 1.111 27119595 27119595001 3129000903 1.111 28120255 28120255001 3129090906 1.111 28120251 28120251001

3129000003 1.111 27119595 27119595001 3129000904 1.111 28120255 28120255001 3129095701 1.111 28120255 28120255001

3129000004 1.111 27119595 27119595001 3129000905 1.111 28120255 28120255001 3129095702 1.111 28120255 28120255001

3129000005 1.111 27119595 27119595001 3129000906 1.111 28120255 28120255001 3129095703 1.111 28120255 28120255001

3129000006 1.111 27119595 27119595001 3129000907 1.111 28120255 28120255001 3129095704 1.111 28120255 28120255001

3129000101 1.111 27119595 27119595001 3129001001 (*) 1.111 28120260 28120260001 3129095705 1.111 28120255 28120255001

3129000102 1.111 27119595 27119595001 3129001002 1.111 28120260 28120260001 3129095706 1.111 28120255 28120255001

3129000103 1.111 27119595 27119595001 3129001003 1.111 28120260 28120260001 3129095707 1.111 28120255 28120255001

3129000104 1.111 27119595 27119595001 3129001004 1.111 28120260 28120260001 3129095801 1.111 28120260 28120260001

3129000105 1.111 27119595 27119595001 3129001005 1.111 28120260 28120260001 3129095802 1.111 28120260 28120260001

3129000106 1.111 27119595 27119595001 3129001006 1.111 28120260 28120260001 3129095803 1.111 28120260 28120260001

3129000201 1.111 27119595 27119595001 3129001007 1.111 28120260 28120260001 3129095804 1.111 28120260 28120260001

3129000202 1.111 27119595 27119595001 3129049501 1.111 28120251 28120251001 3129095805 1.111 28120260 28120260001

3129000203 1.111 27119595 27119595001 3129049502 1.111 28120251 28120251001 3129095806 1.111 28120260 28120260001

3129000204 1.111 27119595 27119595001 3129049503 1.111 28120251 28120251001 3129138601 1.111 27119595 27119595001

3129000205 1.111 27119595 27119595001 3129049504 1.111 28120251 28120251001 3129138602 1.111 27119595 27119595001

3129000206 1.111 27119595 27119595001 3129049505 1.111 28120251 28120251001 3129138603 1.111 27119595 27119595001

3129000301 1.111 27119595 27119595001 3129049506 1.111 28120251 28120251001 3129138604 1.111 27119595 27119595001

3129000302 1.111 27119595 27119595001 3129049601 1.111 28120251 28120251001 3129138605 1.111 27119595 27119595001

3129000303 1.111 27119595 27119595001 3129049602 1.111 28120251 28120251001 3129138606 1.111 27119595 27119595001

3129000304 1.111 27119595 27119595001 3129049603 1.111 28120251 28120251001 3129138701 1.111 27119595 27119595001

3129000305 1.111 27119595 27119595001 3129049604 1.111 28120251 28120251001 3129138702 1.111 27119595 27119595001

3129000306 1.111 27119595 27119595001 3129049605 1.111 28120251 28120251001 3129138703 1.111 27119595 27119595001

3129000401 1.111 28120255 28120255001 3129049606 1.111 28120251 28120251001 3129138704 1.111 27119595 27119595001

3129000402 1.111 28120255 28120255001 3129049701 (*) 1.111 28120251 28120251001 3129138705 1.111 27119595 27119595001

3129000403 1.111 28120255 28120255001 3129049702 1.111 28120251 28120251001 3129138706 1.111 27119595 27119595001

3129000404 1.111 28120255 28120255001 3129049703 1.111 28120251 28120251001 3129138801 1.111 28120255 28120255001

3129000405 1.111 28120255 28120255001 3129049704 1.111 28120251 28120251001 3129138802 1.111 28120255 28120255001

3129000406 1.111 28120255 28120255001 3129049705 1.111 28120251 28120251001 3129138803 1.111 28120255 28120255001

3129000407 1.111 28120255 28120255001 3129049706 1.111 28120251 28120251001 3129138804 1.111 28120255 28120255001

3129000501 1.111 28120255 28120255001 3129049801 1.111 28120251 28120251001 3129138805 1.111 28120255 28120255001

3129000502 1.111 28120255 28120255001 3129049802 1.111 28120251 28120251001 3129138806 1.111 28120255 28120255001

3129000503 1.111 28120255 28120255001 3129049803 1.111 28120251 28120251001 3129138807 1.111 28120255 28120255001

3129000504 1.111 28120255 28120255001 3129049804 1.111 28120251 28120251001 3129138901 1.111 28120255 28120255001

3129000505 1.111 28120255 28120255001 3129049805 1.111 28120251 28120251001 3129138902 1.111 28120255 28120255001

REMARKS QUALITY ASSURANCE SURVEYOR

Todas as fontes de radiação são monitoradas e controladas. Toda sucata utilizada

no processo de fabricação doaço na usina de Ouro Branco é gerada internamente.

Certificamos que este material é isento de contaminação por radiação.

All radiation sources are verified and controlled.

All scrap used at Gerdau Ouro Branco is internally generated.

We certify that this material is free of contamination by radiation.

THAYANE OLIVEIRA SILOTTI – GERENTE ENGENHARIA PROCESSOS E PRODUTOS THAYENE OLIVEIRA SILOTTI

thayene.silotti@gerdau.com.br – TEL.: +55 – 31-3749-5630 CREA 249773

PAGE

MILL TEST / QUALITY CERTIFICATE 2/2

CUSTOMER CUSTOMER ORDER SALES ORDER DIMENSIONS DATE

ACEROS CORSA SA DE CV AC 19022021 - LA FER 10366820-000001 1/2" x 6 foot x 20Foot 05.13.2021

Gerdau Açominas S.A. PRODUCT EDGE TYPE DELIVERY CONDITION DOCUMENT NUMBER

ROD MG 443 KM 7 SN FAZENDA DO CADETE Plate Cut edge As rolled

0001296E21

OURO BRANCO MG SPECIFICATION

36420-000 BRAZIL ASTM A36 2019

Gerdau S.A. certifies that the material herein described is in accordance with the applicable technical specifications. As mutual protection for costumer and supplier, this certificate is considered as confidential and can not be transcribed or reproduced without the writtenauthorization of Gerdau S.A.

PACKAGES

PLATE # WEIGHT (MT) HEAT SAMPLE PLATE # WEIGHT (MT) HEAT SAMPLE PLATE # WEIGHT (MT) HEAT SAMPLE

3129000506 1.111 28120255 28120255001 3129049806 1.111 28120251 28120251001 3129138903 1.111 28120255 28120255001

3129000507 1.111 28120255 28120255001 3129049901 1.111 28120251 28120251001 3129138904 1.111 28120255 28120255001

3129000601 (*) 1.111 28120255 28120255001 3129049902 1.111 28120251 28120251001 3129138905 1.111 28120255 28120255001

3129000602 1.111 28120255 28120255001 3129049903 1.111 28120251 28120251001 3129138906 1.111 28120255 28120255001

3129000603 1.111 28120255 28120255001 3129049904 1.111 28120251 28120251001 3129138907 1.111 28120255 28120255001

3129000604 1.111 28120255 28120255001 3129049905 1.111 28120251 28120251001 3129139001 (*) 1.111 28120255 28120255002

3129000605 1.111 28120255 28120255001 3129049906 1.111 28120251 28120251001 3129139002 1.111 28120255 28120255002

3129000606 1.111 28120255 28120255001 3129050001 1.111 28120260 28120260001 3129139003 1.111 28120255 28120255002

3129000607 1.111 28120255 28120255001 3129050002 1.111 28120260 28120260001 3129139004 1.111 28120255 28120255002

3129000701 1.111 28120255 28120255001 3129050003 1.111 28120260 28120260001 3129139005 1.111 28120255 28120255002

3129000702 1.111 28120255 28120255001 3129050004 1.111 28120260 28120260001 3129139006 1.111 28120255 28120255002

3129000703 1.111 28120255 28120255001 3129050005 1.111 28120260 28120260001 3129139007 1.111 28120255 28120255002

CHEMICAL COMPOSITION

HEAT C(%) Mn(%) Si(%) P(%) S(%) Al T(%) Cr(%) Cu(%) Ti(%) Mo(%) Nb(%) Ni(%) V(%) B(%) Ca(%) N(%)

27119595 0.15 0.84 0.19 0.013 0.008 0.033 0.01 0.00 0.001 0.00 0.000 0.01 0.003 0.0001 0.0000 0.0044

28120251 0.15 0.81 0.20 0.021 0.008 0.033 0.01 0.00 0.001 0.00 0.000 0.01 0.003 0.0001 0.0016 0.0048

28120255 0.13 0.81 0.19 0.014 0.009 0.027 0.01 0.00 0.001 0.00 0.001 0.01 0.003 0.0001 0.0000 0.0066

28120260 0.15 0.84 0.20 0.017 0.010 0.038 0.01 0.00 0.001 0.00 0.000 0.01 0.003 0.0001 0.0018 0.0057

HEAT CEQ1(%) CEQ2(%)

27119595 0.29 0.29

28120251 0.29 0.29

28120255 0.27 0.27

28120260 0.29 0.29

TENSILE TEST

SAMPLE DIRECTION POSITION YS/RE(MPa) TS/RT(MPa) YS/TS ELONG/ALARG(%)

27119595001 Transversal Corner / Borde 299 457 0.65 40.0

28120251001 Transversal Corner / Borde 300 454 0.66 44.0

28120255001 Transversal Corner / Borde 302 449 0.67 43.0

28120255002 Transversal Corner / Borde 304 451 0.67 38.0

28120260001 Transversal Corner / Borde 313 465 0.67 43.0

TENSILE TEST

GAUGE LENGTH/LONGITUD DE REFERENCIA:

L0: 50 mm

ABBREVIATIONS

(*) Mother Plate YS/RE Yield Point TS/RT Tensile Strength YS/TS Elastic Ratio ELONG/ALARG Elongation

REMARKS QUALITY ASSURANCE SURVEYOR

Todas as fontes de radiação são monitoradas e controladas. Toda sucata utilizada

no processo de fabricação doaço na usina de Ouro Branco é gerada internamente.

Certificamos que este material é isento de contaminação por radiação.

All radiation sources are verified and controlled.

All scrap used at Gerdau Ouro Branco is internally generated.

We certify that this material is free of contamination by radiation.

THAYANE OLIVEIRA SILOTTI – GERENTE ENGENHARIA PROCESSOS E PRODUTOS THAYENE OLIVEIRA SILOTTI

thayene.silotti@gerdau.com.br – TEL.: +55 – 31-3749-5630 CREA 249773

TOTAL NUMBER OF PIECES: 180

TOTAL NET/GROSS WEIGHT: 199.980 M/T

PAGE

MILL TEST / QUALITY CERTIFICATE 1/1

CUSTOMER CUSTOMER ORDER SALES ORDER DIMENSIONS DATE

ACEROS CORSA SA DE CV AC 19022021 - LA FER 10366820-000002 1/2" x 8 foot x 20Foot 05.13.2021

Gerdau Açominas S.A. PRODUCT EDGE TYPE DELIVERY CONDITION DOCUMENT NUMBER

ROD MG 443 KM 7 SN FAZENDA DO CADETE Plate Cut edge As rolled

0001296E21

OURO BRANCO MG SPECIFICATION

36420-000 BRAZIL ASTM A36 2019

Gerdau S.A. certifies that the material herein described is in accordance with the applicable technical specifications. As mutual protection for costumer and supplier, this certificate is considered as confidential and can not be transcribed or reproduced without the writtenauthorization of Gerdau S.A.

PACKAGES

PLATE # WEIGHT (MT) HEAT SAMPLE PLATE # WEIGHT (MT) HEAT SAMPLE PLATE # WEIGHT (MT) HEAT SAMPLE

3129057401 1.481 27119592 27119592002 3129057407 1.481 27119592 27119592002 3129057504 1.481 27119592 27119592002

3129057402 1.481 27119592 27119592002 3129057408 1.481 27119592 27119592002 3129057505 1.481 27119592 27119592002

3129057403 1.481 27119592 27119592002 3129057501 (*) 1.481 27119592 27119592002 3129057506 1.481 27119592 27119592002

3129057404 1.481 27119592 27119592002 3129057502 1.481 27119592 27119592002 3129057507 1.481 27119592 27119592002

3129057405 1.481 27119592 27119592002 3129057503 1.481 27119592 27119592002 3129057508 1.481 27119592 27119592002

3129057406 1.481 27119592 27119592002

CHEMICAL COMPOSITION

HEAT C(%) Mn(%) Si(%) P(%) S(%) Al T(%) Cr(%) Cu(%) Ti(%) Mo(%) Nb(%) Ni(%) V(%) B(%) Ca(%) N(%)

27119592 0.14 0.78 0.19 0.014 0.009 0.038 0.01 0.00 0.001 0.00 0.000 0.01 0.003 0.0001 0.0000 0.0041

HEAT CEQ2(%)

27119592 0.27

TENSILE TEST

SAMPLE DIRECTION POSITION YS/RE(MPa) TS/RT(MPa) YS/TS ELONG/ALARG(%)

27119592002 Transversal Corner / Borde 315 448 0.70 42.0

TENSILE TEST

GAUGE LENGTH/LONGITUD DE REFERENCIA:

L0: 50 mm

ABBREVIATIONS

(*) Mother Plate YS/RE Yield Point TS/RT Tensile Strength YS/TS Elastic Ratio ELONG/ALARG Elongation

REMARKS QUALITY ASSURANCE SURVEYOR

Todas as fontes de radiação são monitoradas e controladas. Toda sucata utilizada

no processo de fabricação doaço na usina de Ouro Branco é gerada internamente.

Certificamos que este material é isento de contaminação por radiação.

All radiation sources are verified and controlled.

All scrap used at Gerdau Ouro Branco is internally generated.

We certify that this material is free of contamination by radiation.

THAYANE OLIVEIRA SILOTTI – GERENTE ENGENHARIA PROCESSOS E PRODUTOS THAYENE OLIVEIRA SILOTTI

thayene.silotti@gerdau.com.br – TEL.: +55 – 31-3749-5630 CREA 249773

TOTAL NUMBER OF PIECES: 16

TOTAL NET/GROSS WEIGHT: 23.696 M/T

PAGE

MILL TEST / QUALITY CERTIFICATE 1/1

CUSTOMER CUSTOMER ORDER SALES ORDER DIMENSIONS DATE

ACEROS CORSA SA DE CV AC 19022021 - LA FER 10366820-000003 3/4' x 6 foot x 20Foot 05.13.2021

Gerdau Açominas S.A. PRODUCT EDGE TYPE DELIVERY CONDITION DOCUMENT NUMBER

ROD MG 443 KM 7 SN FAZENDA DO CADETE Plate Cut edge As rolled

0001296E21

OURO BRANCO MG SPECIFICATION

36420-000 BRAZIL ASTM A36 2019

Gerdau S.A. certifies that the material herein described is in accordance with the applicable technical specifications. As mutual protection for costumer and supplier, this certificate is considered as confidential and can not be transcribed or reproduced without the writtenauthorization of Gerdau S.A.

PACKAGES

PLATE # WEIGHT (MT) HEAT SAMPLE PLATE # WEIGHT (MT) HEAT SAMPLE PLATE # WEIGHT (MT) HEAT SAMPLE

3129048801 (*) 1.667 28120222 28120222003 3129049101 1.667 28120222 28120222003 3129049401 1.667 28120222 28120222003

3129048802 1.667 28120222 28120222003 3129049102 1.667 28120222 28120222003 3129049402 1.667 28120222 28120222003

3129048803 1.667 28120222 28120222003 3129049103 1.667 28120222 28120222003 3129049403 1.667 28120222 28120222003

3129048804 1.667 28120222 28120222003 3129049104 1.667 28120222 28120222003 3129049404 1.667 28120222 28120222003

3129048901 1.667 28120222 28120222003 3129049201 1.667 28120222 28120222003 3129091001 1.667 28120222 28120222003

3129048902 1.667 28120222 28120222003 3129049202 1.667 28120222 28120222003 3129091002 1.667 28120222 28120222003

3129048903 1.667 28120222 28120222003 3129049203 1.667 28120222 28120222003 3129091003 1.667 28120222 28120222003

3129048904 1.667 28120222 28120222003 3129049204 1.667 28120222 28120222003 3129091004 1.667 28120222 28120222003

3129049001 1.667 28120222 28120222003 3129049301 1.667 28120222 28120222003 3129091101 1.667 28120222 28120222003

3129049002 1.667 28120222 28120222003 3129049302 1.667 28120222 28120222003 3129091102 1.667 28120222 28120222003

3129049003 1.667 28120222 28120222003 3129049303 1.667 28120222 28120222003 3129091103 1.667 28120222 28120222003

3129049004 1.667 28120222 28120222003 3129049304 1.667 28120222 28120222003 3129091104 1.667 28120222 28120222003

CHEMICAL COMPOSITION

HEAT C(%) Mn(%) Si(%) P(%) S(%) Al T(%) Cr(%) Cu(%) Ti(%) Mo(%) Nb(%) Ni(%) V(%) B(%) Ca(%) N(%)

28120222 0.15 0.84 0.21 0.014 0.006 0.036 0.01 0.00 0.002 0.00 0.000 0.01 0.003 0.0001 0.0000 0.0041

HEAT CEQ1(%) CEQ2(%)

28120222 0.29 0.29

TENSILE TEST

SAMPLE DIRECTION POSITION YS/RE(MPa) TS/RT(MPa) YS/TS ELONG/ALARG(%)

28120222003 Transversal Corner / Borde 296 462 0.64 45.0

TENSILE TEST

GAUGE LENGTH/LONGITUD DE REFERENCIA:

L0: 50 mm

ABBREVIATIONS

(*) Mother Plate YS/RE Yield Point TS/RT Tensile Strength YS/TS Elastic Ratio ELONG/ALARG Elongation

REMARKS QUALITY ASSURANCE SURVEYOR

Todas as fontes de radiação são monitoradas e controladas. Toda sucata utilizada

no processo de fabricação doaço na usina de Ouro Branco é gerada internamente.

Certificamos que este material é isento de contaminação por radiação.

All radiation sources are verified and controlled.

All scrap used at Gerdau Ouro Branco is internally generated.

We certify that this material is free of contamination by radiation.

THAYANE OLIVEIRA SILOTTI – GERENTE ENGENHARIA PROCESSOS E PRODUTOS THAYENE OLIVEIRA SILOTTI

thayene.silotti@gerdau.com.br – TEL.: +55 – 31-3749-5630 CREA 249773

TOTAL NUMBER OF PIECES: 36

TOTAL NET/GROSS WEIGHT: 60.012 M/T

PAGE

MILL TEST / QUALITY CERTIFICATE 1/1

CUSTOMER CUSTOMER ORDER SALES ORDER DIMENSIONS DATE

ACEROS CORSA SA DE CV AC 19022021 - LA FER 10366820-000004 3/4' x 8 foot x 20Foot 05.13.2021

Gerdau Açominas S.A. PRODUCT EDGE TYPE DELIVERY CONDITION DOCUMENT NUMBER

ROD MG 443 KM 7 SN FAZENDA DO CADETE Plate Cut edge As rolled

0001296E21

OURO BRANCO MG SPECIFICATION

36420-000 BRAZIL ASTM A36 2019

Gerdau S.A. certifies that the material herein described is in accordance with the applicable technical specifications. As mutual protection for costumer and supplier, this certificate is considered as confidential and can not be transcribed or reproduced without the writtenauthorization of Gerdau S.A.

PACKAGES

PLATE # WEIGHT (MT) HEAT SAMPLE PLATE # WEIGHT (MT) HEAT SAMPLE PLATE # WEIGHT (MT) HEAT SAMPLE

3129054201 2.222 28120175 28120175002 3129054405 2.222 28120175 28120175002 3129054703 2.222 28120175 28120175002

3129054202 2.222 28120175 28120175002 3129054406 2.222 28120175 28120175002 3129054704 2.222 28120175 28120175002

3129054203 2.222 28120175 28120175002 3129054501 2.222 28120175 28120175002 3129054705 2.222 28120175 28120175002

3129054204 2.222 28120175 28120175002 3129054502 2.222 28120175 28120175002 3129054706 2.222 28120175 28120175002

3129054205 2.222 28120175 28120175002 3129054503 2.222 28120175 28120175002 3129054801 2.222 28120175 28120175004

3129054206 2.222 28120175 28120175002 3129054504 2.222 28120175 28120175002 3129054802 2.222 28120175 28120175004

3129054301 2.222 28120175 28120175002 3129054505 2.222 28120175 28120175002 3129054803 2.222 28120175 28120175004

3129054302 2.222 28120175 28120175002 3129054506 2.222 28120175 28120175002 3129054804 2.222 28120175 28120175004

3129054303 2.222 28120175 28120175002 3129054601 (*) 2.222 28120175 28120175002 3129054805 2.222 28120175 28120175004

3129054304 2.222 28120175 28120175002 3129054602 2.222 28120175 28120175002 3129054806 2.222 28120175 28120175004

3129054305 2.222 28120175 28120175002 3129054603 2.222 28120175 28120175002 3129054901 (*) 2.222 28120175 28120175004

3129054306 2.222 28120175 28120175002 3129054604 2.222 28120175 28120175002 3129054902 2.222 28120175 28120175004

3129054401 2.222 28120175 28120175002 3129054605 2.222 28120175 28120175002 3129054903 2.222 28120175 28120175004

3129054402 2.222 28120175 28120175002 3129054606 2.222 28120175 28120175002 3129054904 2.222 28120175 28120175004

3129054403 2.222 28120175 28120175002 3129054701 2.222 28120175 28120175002 3129054905 2.222 28120175 28120175004

3129054404 2.222 28120175 28120175002 3129054702 2.222 28120175 28120175002 3129054906 2.222 28120175 28120175004

CHEMICAL COMPOSITION

HEAT C(%) Mn(%) Si(%) P(%) S(%) Al T(%) Cr(%) Cu(%) Ti(%) Mo(%) Nb(%) Ni(%) V(%) B(%) Ca(%) N(%)

28120175 0.16 0.85 0.19 0.016 0.005 0.036 0.02 0.00 0.002 0.00 0.000 0.01 0.003 0.0001 0.0001 0.0034

HEAT CEQ1(%) CEQ2(%)

28120175 0.30 0.31

TENSILE TEST

SAMPLE DIRECTION POSITION YS/RE(MPa) TS/RT(MPa) YS/TS ELONG/ALARG(%)

28120175002 Transversal Corner / Borde 300 458 0.66 44.0

28120175004 Transversal Corner / Borde 284 454 0.63 46.0

TENSILE TEST

GAUGE LENGTH/LONGITUD DE REFERENCIA:

L0: 50 mm

ABBREVIATIONS

(*) Mother Plate YS/RE Yield Point TS/RT Tensile Strength YS/TS Elastic Ratio ELONG/ALARG Elongation

REMARKS QUALITY ASSURANCE SURVEYOR

Todas as fontes de radiação são monitoradas e controladas. Toda sucata utilizada

no processo de fabricação doaço na usina de Ouro Branco é gerada internamente.

Certificamos que este material é isento de contaminação por radiação.

All radiation sources are verified and controlled.

All scrap used at Gerdau Ouro Branco is internally generated.

We certify that this material is free of contamination by radiation.

THAYANE OLIVEIRA SILOTTI – GERENTE ENGENHARIA PROCESSOS E PRODUTOS THAYENE OLIVEIRA SILOTTI

thayene.silotti@gerdau.com.br – TEL.: +55 – 31-3749-5630 CREA 249773

TOTAL NUMBER OF PIECES: 48

TOTAL NET/GROSS WEIGHT: 106.656 M/T

PAGE

MILL TEST / QUALITY CERTIFICATE 1/1

CUSTOMER CUSTOMER ORDER SALES ORDER DIMENSIONS DATE

ACEROS CORSA SA DE CV AC 19022021 - LA FER 10366820-000005 2" x 6 foot x 20Foot 05.13.2021

Gerdau Açominas S.A. PRODUCT EDGE TYPE DELIVERY CONDITION DOCUMENT NUMBER

ROD MG 443 KM 7 SN FAZENDA DO CADETE Plate Cut edge As rolled

0001296E21

OURO BRANCO MG SPECIFICATION

36420-000 BRAZIL ASTM A36 2019

Gerdau S.A. certifies that the material herein described is in accordance with the applicable technical specifications. As mutual protection for costumer and supplier, this certificate is considered as confidential and can not be transcribed or reproduced without the writtenauthorization of Gerdau S.A.

PACKAGES

PLATE # WEIGHT (MT) HEAT SAMPLE PLATE # WEIGHT (MT) HEAT SAMPLE PLATE # WEIGHT (MT) HEAT SAMPLE

3129373601 (*) 4.446 28120222 28120222001 3129541101 4.446 27119323 27119323010 3129739001 4.446 27119323 27119323010

3129373602 4.446 28120222 28120222001 3129541102 4.446 27119323 27119323010 3129739002 4.446 27119323 27119323010

3129541001 4.446 27119323 27119323010 3129541201 (*) 4.446 27119323 27119323010 3129739901 (*) 4.446 28120189 28120189005

3129541002 4.446 27119323 27119323010 3129541202 4.446 27119323 27119323010 3129739902 4.446 28120189 28120189005

CHEMICAL COMPOSITION

HEAT C(%) Mn(%) Si(%) P(%) S(%) Al T(%) Cr(%) Cu(%) Ti(%) Mo(%) Nb(%) Ni(%) V(%) B(%) Ca(%) N(%)

27119323 0.17 1.07 0.20 0.019 0.009 0.033 0.02 0.00 0.001 0.00 0.000 0.01 0.003 0.0002 0.0002 0.0061

28120189 0.16 0.87 0.16 0.016 0.008 0.027 0.01 0.00 0.001 0.00 0.000 0.01 0.003 0.0001 0.0000 0.0044

28120222 0.15 0.84 0.21 0.014 0.006 0.036 0.01 0.00 0.002 0.00 0.000 0.01 0.003 0.0001 0.0000 0.0041

HEAT CEQ2(%) CEQ1(%)

27119323 0.35

28120189 0.31 0.31

28120222 0.29 0.29

TENSILE TEST

SAMPLE DIRECTION POSITION YS/RE(MPa) TS/RT(MPa) YS/TS ELONG/ALARG(%)

27119323010 Transversal Corner / Borde 303 482 0.63 57.0

28120189005 Transversal Corner / Borde 313 450 0.70 42.0

28120222001 Transversal Corner / Borde 267 443 0.60 60.0

TENSILE TEST

GAUGE LENGTH/LONGITUD DE REFERENCIA:

L0: 50 mm

ABBREVIATIONS

(*) Mother Plate YS/RE Yield Point TS/RT Tensile Strength YS/TS Elastic Ratio ELONG/ALARG Elongation

REMARKS QUALITY ASSURANCE SURVEYOR

Todas as fontes de radiação são monitoradas e controladas. Toda sucata utilizada

no processo de fabricação doaço na usina de Ouro Branco é gerada internamente.

Certificamos que este material é isento de contaminação por radiação.

All radiation sources are verified and controlled.

All scrap used at Gerdau Ouro Branco is internally generated.

We certify that this material is free of contamination by radiation.

THAYANE OLIVEIRA SILOTTI – GERENTE ENGENHARIA PROCESSOS E PRODUTOS THAYENE OLIVEIRA SILOTTI

thayene.silotti@gerdau.com.br – TEL.: +55 – 31-3749-5630 CREA 249773

TOTAL NUMBER OF PIECES: 12

TOTAL NET/GROSS WEIGHT: 53.352 M/T

PAGE

MILL TEST / QUALITY CERTIFICATE 1/1

CUSTOMER CUSTOMER ORDER SALES ORDER DIMENSIONS DATE

ACEROS CORSA SA DE CV AC 19022021 - LA FER 10366820-000006 3/4' x 6 foot x 20Foot 05.13.2021

Gerdau Açominas S.A. PRODUCT EDGE TYPE DELIVERY CONDITION DOCUMENT NUMBER

ROD MG 443 KM 7 SN FAZENDA DO CADETE Plate Cut edge Thermal Mech Control Process

0001296E21

OURO BRANCO MG SPECIFICATION

36420-000 BRAZIL ASTM A709 TYPE1 50T1 2018 ASTM A572 GR50T1 2018

Gerdau S.A. certifies that the material herein described is in accordance with the applicable technical specifications. As mutual protection for costumer and supplier, this certificate is considered as confidential and can not be transcribed or reproduced without the writtenauthorization of Gerdau S.A.

PACKAGES

PLATE # WEIGHT (MT) HEAT SAMPLE PLATE # WEIGHT (MT) HEAT SAMPLE PLATE # WEIGHT (MT) HEAT SAMPLE

3129087301 1.667 27119432 27119432003 3129087601 1.667 27119432 27119432003 3129087901 1.667 27119432 27119432003

3129087302 1.667 27119432 27119432003 3129087602 1.667 27119432 27119432003 3129087902 1.667 27119432 27119432003

3129087303 1.667 27119432 27119432003 3129087603 1.667 27119432 27119432003 3129087903 1.667 27119432 27119432003

3129087304 1.667 27119432 27119432003 3129087604 1.667 27119432 27119432003 3129087904 1.667 27119432 27119432003

3129087401 1.667 27119432 27119432003 3129087701 1.667 27119432 27119432003 3129088001 1.667 27119432 27119432003

3129087402 1.667 27119432 27119432003 3129087702 (*) 1.667 27119432 27119432003 27119432004

3129087403 1.667 27119432 27119432003 3129087703 1.667 27119432 27119432003 3129088002 (*) 1.667 27119432 27119432003

3129087404 1.667 27119432 27119432003 3129087704 1.667 27119432 27119432003 27119432004

3129087501 1.667 27119432 27119432003 3129087801 1.667 27119432 27119432003 3129088003 1.667 27119432 27119432003

3129087502 1.667 27119432 27119432003 3129087802 1.667 27119432 27119432003 27119432004

3129087503 1.667 27119432 27119432003 3129087803 1.667 27119432 27119432003 3129088004 1.667 27119432 27119432003

3129087504 1.667 27119432 27119432003 3129087804 1.667 27119432 27119432003 27119432004

CHEMICAL COMPOSITION

HEAT C(%) Mn(%) Si(%) P(%) S(%) Al T(%) Cr(%) Cu(%) Ti(%) Mo(%) Nb(%) Ni(%) V(%) B(%) Ca(%) N(%)

27119432 0.15 1.36 0.26 0.023 0.007 0.025 0.02 0.01 0.013 0.00 0.026 0.02 0.005 0.0002 0.0005 0.0052

TENSILE TEST

SAMPLE DIRECTION POSITION YS/RE(MPa) TS/RT(MPa) YS/TS ELONG/ALARG(%)

27119432003 Transversal Corner / Borde 407 532 0.77 44.0

CHARPY IMPACT TEST

SAMPLE DIRECTION POSITION TEMP/TEMP(°C) IND EN/EN IND(J) IND EN/EN IND(J) IND EN/EN IND(J) AVG EN/EN MD(J)

27119432003 Longitudinal Corner / Borde 13 350 272 321 314

27119432004 Longitudinal Corner / Borde 13 351 301 337 330

TENSILE TEST CHARPY IMPACT TEST

GAUGE LENGTH/LONGITUD DE REFERENCIA: SPEC SIZE/DIM MUESTRA: 10X10mm - V 2mm

L0: 50 mm

ABBREVIATIONS

(*) Mother Plate YS/RE Yield Point TS/RT Tensile Strength YS/TS Elastic Ratio ELONG/ALARG Elongation TEMP/TEMP Temperature

IND EN/EN IND Individual Energy AVG EN/EN MD Average Energy

REMARKS QUALITY ASSURANCE SURVEYOR

Tolerâncias dimensionaisconforme ASTM-A6.

Todas as fontes de radiação são monitoradas e controladas. Toda sucata utilizada

no processo de fabricação doaço na usina de Ouro Branco é gerada internamente.

Certificamos que este material é isento de contaminação por radiação.

Tolerances on dimensionsaccording to ASTM-A6.

All radiation sources are verified and controlled.

We certify that this material is free of contamination by radiation. THAYENE OLIVEIRA SILOTTI

All scrap used at Gerdau Ouro Branco is internally generated. CREA 249773

THAYANE OLIVEIRA SILOTTI – GERENTE ENGENHARIA PROCESSOS E PRODUTOS

thayene.silotti@gerdau.com.br – TEL.: +55 – 31-3749-5630

TOTAL NUMBER OF PIECES: 32

TOTAL NET/GROSS WEIGHT: 53.344 M/T

PAGE

MILL TEST / QUALITY CERTIFICATE 1/2

CUSTOMER CUSTOMER ORDER SALES ORDER DIMENSIONS DATE

ACEROS CORSA SA DE CV AC 19022021 - LA FER 10366820-000007 3/4' x 8 foot x 20Foot 05.13.2021

Gerdau Açominas S.A. PRODUCT EDGE TYPE DELIVERY CONDITION DOCUMENT NUMBER

ROD MG 443 KM 7 SN FAZENDA DO CADETE Plate Cut edge Thermal Mech Control Process

0001296E21

OURO BRANCO MG SPECIFICATION

36420-000 BRAZIL ASTM A709 TYPE1 50T1 2018 ASTM A572 GR50T1 2018

Gerdau S.A. certifies that the material herein described is in accordance with the applicable technical specifications. As mutual protection for costumer and supplier, this certificate is considered as confidential and can not be transcribed or reproduced without the writtenauthorization of Gerdau S.A.

PACKAGES

PLATE # WEIGHT (MT) HEAT SAMPLE PLATE # WEIGHT (MT) HEAT SAMPLE PLATE # WEIGHT (MT) HEAT SAMPLE

3129066801 2.222 28120149 28120149001 3129066905 2.222 28120149 28120149001 3129067103 2.222 28120149 28120149001

28120149003 28120149004 28120149004

28120149006 28120149006 28120149006

3129066802 2.222 28120149 28120149001 3129066906 2.222 28120149 28120149001 3129067104 2.222 28120149 28120149001

28120149003 28120149004 28120149004

28120149006 28120149006 28120149006

3129066803 2.222 28120149 28120149001 3129067001 2.222 28120149 28120149001 3129067105 2.222 28120149 28120149001

28120149003 28120149003 28120149004

28120149006 28120149006 28120149006

3129066804 2.222 28120149 28120149001 3129067002 2.222 28120149 28120149001 3129067106 2.222 28120149 28120149001

28120149003 28120149003 28120149004

28120149006 28120149006 28120149006

3129066805 2.222 28120149 28120149001 3129067003 2.222 28120149 28120149001 3129067201 2.222 28120149 28120149001

28120149003 28120149003 28120149004

28120149006 28120149006 28120149006

3129066806 2.222 28120149 28120149001 3129067004 2.222 28120149 28120149001 3129067202 2.222 28120149 28120149001

28120149003 28120149003 28120149004

28120149006 28120149006 28120149006

3129066901 2.222 28120149 28120149001 3129067005 2.222 28120149 28120149001 3129067203 2.222 28120149 28120149001

28120149004 28120149003 28120149004

28120149006 28120149006 28120149006

3129066902 (*) 2.222 28120149 28120149001 3129067006 2.222 28120149 28120149001 3129067204 2.222 28120149 28120149001

28120149004 28120149003 28120149004

28120149006 28120149006 28120149006

3129066903 2.222 28120149 28120149001 3129067101 2.222 28120149 28120149001 3129067205 2.222 28120149 28120149001

28120149004 28120149004 28120149004

28120149006 28120149006 28120149006

3129066904 2.222 28120149 28120149001 3129067102 2.222 28120149 28120149001 3129067206 2.222 28120149 28120149001

28120149004 28120149004 28120149004

28120149006 28120149006 28120149006

CHEMICAL COMPOSITION

HEAT C(%) Mn(%) Si(%) P(%) S(%) Al T(%) Cr(%) Cu(%) Ti(%) Mo(%) Nb(%) Ni(%) V(%) B(%) Ca(%) N(%)

28120149 0.14 1.37 0.28 0.016 0.007 0.027 0.01 0.01 0.014 0.00 0.028 0.02 0.004 0.0001 0.0000 0.0051

TENSILE TEST

SAMPLE DIRECTION POSITION YS/RE(MPa) TS/RT(MPa) YS/TS ELONG/ALARG(%)

28120149001 Transversal Corner / Borde 372 504 0.74 57.0

28120149006 Transversal Corner / Borde 390 512 0.76 39.0

CHARPY IMPACT TEST

SAMPLE DIRECTION POSITION TEMP/TEMP(°C) IND EN/EN IND(J) IND EN/EN IND(J) IND EN/EN IND(J) AVG EN/EN MD(J)

28120149003 Longitudinal Corner / Borde 13 264 341 352 319

28120149004 Longitudinal Corner / Borde 13 212 225 209 215

REMARKS QUALITY ASSURANCE SURVEYOR

Tolerâncias dimensionaisconforme ASTM-A6.

Todas as fontes de radiação são monitoradas e controladas. Toda sucata utilizada

no processo de fabricação doaço na usina de Ouro Branco é gerada internamente.

Certificamos que este material é isento de contaminação por radiação.

Tolerances on dimensionsaccording to ASTM-A6.

All radiation sources are verified and controlled.

We certify that this material is free of contamination by radiation. THAYENE OLIVEIRA SILOTTI

All scrap used at Gerdau Ouro Branco is internally generated. CREA 249773

THAYANE OLIVEIRA SILOTTI – GERENTE ENGENHARIA PROCESSOS E PRODUTOS

thayene.silotti@gerdau.com.br – TEL.: +55 – 31-3749-5630

PAGE

MILL TEST / QUALITY CERTIFICATE 2/2

CUSTOMER CUSTOMER ORDER SALES ORDER DIMENSIONS DATE

ACEROS CORSA SA DE CV AC 19022021 - LA FER 10366820-000007 3/4' x 8 foot x 20Foot 05.13.2021

Gerdau Açominas S.A. PRODUCT EDGE TYPE DELIVERY CONDITION DOCUMENT NUMBER

ROD MG 443 KM 7 SN FAZENDA DO CADETE Plate Cut edge Thermal Mech Control Process

0001296E21

OURO BRANCO MG SPECIFICATION

36420-000 BRAZIL ASTM A709 TYPE1 50T1 2018 ASTM A572 GR50T1 2018

Gerdau S.A. certifies that the material herein described is in accordance with the applicable technical specifications. As mutual protection for costumer and supplier, this certificate is considered as confidential and can not be transcribed or reproduced without the writtenauthorization of Gerdau S.A.

TENSILE TEST CHARPY IMPACT TEST

GAUGE LENGTH/LONGITUD DE REFERENCIA: SPEC SIZE/DIM MUESTRA: 10X10mm - V 2mm

L0: 50 mm

ABBREVIATIONS

(*) Mother Plate YS/RE Yield Point TS/RT Tensile Strength YS/TS Elastic Ratio ELONG/ALARG Elongation TEMP/TEMP Temperature

IND EN/EN IND Individual Energy AVG EN/EN MD Average Energy

REMARKS QUALITY ASSURANCE SURVEYOR

Tolerâncias dimensionaisconforme ASTM-A6.

Todas as fontes de radiação são monitoradas e controladas. Toda sucata utilizada

no processo de fabricação doaço na usina de Ouro Branco é gerada internamente.

Certificamos que este material é isento de contaminação por radiação.

Tolerances on dimensionsaccording to ASTM-A6.

All radiation sources are verified and controlled.

We certify that this material is free of contamination by radiation. THAYENE OLIVEIRA SILOTTI

All scrap used at Gerdau Ouro Branco is internally generated. CREA 249773

THAYANE OLIVEIRA SILOTTI – GERENTE ENGENHARIA PROCESSOS E PRODUTOS

thayene.silotti@gerdau.com.br – TEL.: +55 – 31-3749-5630

TOTAL NUMBER OF PIECES: 30

TOTAL NET/GROSS WEIGHT: 66.660 M/T

PAGE

MILL TEST / QUALITY CERTIFICATE 1/2

CUSTOMER CUSTOMER ORDER SALES ORDER DIMENSIONS DATE

ACEROS CORSA SA DE CV AC 19022021 - LA FER 10366820-000008 1/2" x 8 foot x 20Foot 05.13.2021

Gerdau Açominas S.A. PRODUCT EDGE TYPE DELIVERY CONDITION DOCUMENT NUMBER

ROD MG 443 KM 7 SN FAZENDA DO CADETE Plate Cut edge As rolled

0001296E21

OURO BRANCO MG SPECIFICATION

36420-000 BRAZIL ASTM A709 TYPE1 50T1 2018 ASTM A572 GR50T1 2018

Gerdau S.A. certifies that the material herein described is in accordance with the applicable technical specifications. As mutual protection for costumer and supplier, this certificate is considered as confidential and can not be transcribed or reproduced without the writtenauthorization of Gerdau S.A.

PACKAGES

PLATE # WEIGHT (MT) HEAT SAMPLE PLATE # WEIGHT (MT) HEAT SAMPLE PLATE # WEIGHT (MT) HEAT SAMPLE

3129062601 1.481 28120149 28120149001 3129062702 (*) 1.481 28120149 28120149001 3129062804 1.481 28120150 28120150003

28120149005 28120149005 28120150004

28120149006 28120149006 3129062805 1.481 28120150 28120150003

3129062602 (*) 1.481 28120149 28120149001 3129062703 1.481 28120149 28120149001 28120150004

28120149005 28120149005 3129062806 1.481 28120150 28120150003

28120149006 28120149006 28120150004

3129062603 1.481 28120149 28120149001 3129062704 1.481 28120149 28120149001 3129062807 1.481 28120150 28120150003

28120149005 28120149005 28120150004

28120149006 28120149006 3129062808 1.481 28120150 28120150003

3129062604 1.481 28120149 28120149001 3129062705 1.481 28120149 28120149001 28120150004

28120149005 28120149005 3129062901 1.481 28120150 28120150003

28120149006 28120149006 28120150004

3129062605 1.481 28120149 28120149001 3129062706 1.481 28120149 28120149001 3129062902 (*) 1.481 28120150 28120150003

28120149005 28120149005 28120150004

28120149006 28120149006 3129062903 1.481 28120150 28120150003

3129062606 1.481 28120149 28120149001 3129062707 1.481 28120149 28120149001 28120150004

28120149005 28120149005 3129062904 1.481 28120150 28120150003

28120149006 28120149006 28120150004

3129062607 1.481 28120149 28120149001 3129062708 1.481 28120149 28120149001 3129062905 1.481 28120150 28120150003

28120149005 28120149005 28120150004

28120149006 28120149006 3129062906 1.481 28120150 28120150003

3129062608 1.481 28120149 28120149001 3129062801 1.481 28120150 28120150003 28120150004

28120149005 28120150004 3129062907 1.481 28120150 28120150003

28120149006 3129062802 (*) 1.481 28120150 28120150003 28120150004

3129062701 1.481 28120149 28120149001 28120150004 3129062908 1.481 28120150 28120150003

28120149005 3129062803 1.481 28120150 28120150003 28120150004

28120149006 28120150004

CHEMICAL COMPOSITION

HEAT C(%) Mn(%) Si(%) P(%) S(%) Al T(%) Cr(%) Cu(%) Ti(%) Mo(%) Nb(%) Ni(%) V(%) B(%) Ca(%) N(%)

28120149 0.14 1.37 0.28 0.016 0.007 0.027 0.01 0.01 0.014 0.00 0.028 0.02 0.004 0.0001 0.0000 0.0051

28120150 0.14 1.35 0.27 0.019 0.008 0.033 0.01 0.00 0.014 0.00 0.028 0.01 0.004 0.0001 0.0000 0.0044

TENSILE TEST

SAMPLE DIRECTION POSITION YS/RE(MPa) TS/RT(MPa) YS/TS ELONG/ALARG(%)

28120149001 Transversal Corner / Borde 372 504 0.74 57.0

28120149006 Transversal Corner / Borde 390 512 0.76 39.0

28120150003 Transversal Corner / Borde 404 526 0.77 40.0

28120150004 Transversal Corner / Borde 392 511 0.77 38.0

CHARPY IMPACT TEST

SAMPLE DIRECTION POSITION TEMP/TEMP(°C) IND EN/EN IND(J) IND EN/EN IND(J) IND EN/EN IND(J) AVG EN/EN MD(J)

28120149005 Longitudinal Corner / Borde 13 192 188 212 197

28120150003 Longitudinal Corner / Borde 13 241 303 233 259

REMARKS QUALITY ASSURANCE SURVEYOR

Tolerâncias dimensionaisconforme ASTM-A6.

Todas as fontes de radiação são monitoradas e controladas. Toda sucata utilizada

no processo de fabricação doaço na usina de Ouro Branco é gerada internamente.

Certificamos que este material é isento de contaminação por radiação.

Tolerances on dimensionsaccording to ASTM-A6.

All radiation sources are verified and controlled.

We certify that this material is free of contamination by radiation. THAYENE OLIVEIRA SILOTTI

All scrap used at Gerdau Ouro Branco is internally generated. CREA 249773

THAYANE OLIVEIRA SILOTTI – GERENTE ENGENHARIA PROCESSOS E PRODUTOS

thayene.silotti@gerdau.com.br – TEL.: +55 – 31-3749-5630

PAGE

MILL TEST / QUALITY CERTIFICATE 2/2

CUSTOMER CUSTOMER ORDER SALES ORDER DIMENSIONS DATE

ACEROS CORSA SA DE CV AC 19022021 - LA FER 10366820-000008 1/2" x 8 foot x 20Foot 05.13.2021

Gerdau Açominas S.A. PRODUCT EDGE TYPE DELIVERY CONDITION DOCUMENT NUMBER

ROD MG 443 KM 7 SN FAZENDA DO CADETE Plate Cut edge As rolled

0001296E21

OURO BRANCO MG SPECIFICATION

36420-000 BRAZIL ASTM A709 TYPE1 50T1 2018 ASTM A572 GR50T1 2018

Gerdau S.A. certifies that the material herein described is in accordance with the applicable technical specifications. As mutual protection for costumer and supplier, this certificate is considered as confidential and can not be transcribed or reproduced without the writtenauthorization of Gerdau S.A.

TENSILE TEST CHARPY IMPACT TEST

GAUGE LENGTH/LONGITUD DE REFERENCIA: SPEC SIZE/DIM MUESTRA: 10X10mm - V 2mm

L0: 50 mm

ABBREVIATIONS

(*) Mother Plate YS/RE Yield Point TS/RT Tensile Strength YS/TS Elastic Ratio ELONG/ALARG Elongation TEMP/TEMP Temperature

IND EN/EN IND Individual Energy AVG EN/EN MD Average Energy

REMARKS QUALITY ASSURANCE SURVEYOR

Tolerâncias dimensionaisconforme ASTM-A6.

Todas as fontes de radiação são monitoradas e controladas. Toda sucata utilizada

no processo de fabricação doaço na usina de Ouro Branco é gerada internamente.

Certificamos que este material é isento de contaminação por radiação.

Tolerances on dimensionsaccording to ASTM-A6.

All radiation sources are verified and controlled.

We certify that this material is free of contamination by radiation. THAYENE OLIVEIRA SILOTTI

All scrap used at Gerdau Ouro Branco is internally generated. CREA 249773

THAYANE OLIVEIRA SILOTTI – GERENTE ENGENHARIA PROCESSOS E PRODUTOS

thayene.silotti@gerdau.com.br – TEL.: +55 – 31-3749-5630

TOTAL NUMBER OF PIECES: 32

TOTAL NET/GROSS WEIGHT: 47.392 M/T

PAGE

MILL TEST / QUALITY CERTIFICATE 1/1

CUSTOMER CUSTOMER ORDER SALES ORDER DIMENSIONS DATE

ACEROS CORSA SA DE CV AC 19022021 - LA FER 10366820-000009 1 1/2" x 6 foot x 20Foot 05.13.2021

Gerdau Açominas S.A. PRODUCT EDGE TYPE DELIVERY CONDITION DOCUMENT NUMBER

ROD MG 443 KM 7 SN FAZENDA DO CADETE Plate Cut edge Thermal Mech Control Process

0001296E21

OURO BRANCO MG SPECIFICATION

36420-000 BRAZIL ASTM A709 TYPE1 50T1 2018 ASTM A572 GR50T1 2018

Gerdau S.A. certifies that the material herein described is in accordance with the applicable technical specifications. As mutual protection for costumer and supplier, this certificate is considered as confidential and can not be transcribed or reproduced without the writtenauthorization of Gerdau S.A.

PACKAGES

PLATE # WEIGHT (MT) HEAT SAMPLE PLATE # WEIGHT (MT) HEAT SAMPLE PLATE # WEIGHT (MT) HEAT SAMPLE

3129085201 3.334 27119432 27119432003 3129085401 3.334 28120151 28120151006 3129085502 3.334 28120151 28120151006

27119432005 28120151009 28120151009

3129085202 (*) 3.334 27119432 27119432003 3129085402 3.334 28120151 28120151003 3129085601 3.334 28120151 28120151003

27119432005 28120151006 28120151006

3129085301 3.334 27119432 27119432003 28120151009 28120151009

27119432005 3129085501 3.334 28120151 28120151003 3129085602 (*) 3.334 28120151 28120151003

3129085302 3.334 27119432 27119432003 28120151006 28120151006

27119432005 28120151009 28120151009

3129085401 3.334 28120151 28120151003 3129085502 3.334 28120151 28120151003

CHEMICAL COMPOSITION

HEAT C(%) Mn(%) Si(%) P(%) S(%) Al T(%) Cr(%) Cu(%) Ti(%) Mo(%) Nb(%) Ni(%) V(%) B(%) Ca(%) N(%)

27119432 0.15 1.36 0.26 0.023 0.007 0.025 0.02 0.01 0.013 0.00 0.026 0.02 0.005 0.0002 0.0005 0.0052

28120151 0.14 1.37 0.27 0.017 0.008 0.037 0.01 0.00 0.013 0.00 0.026 0.01 0.004 0.0001 0.0000 0.0043

TENSILE TEST

SAMPLE DIRECTION POSITION YS/RE(MPa) TS/RT(MPa) YS/TS ELONG/ALARG(%)

27119432003 Transversal Corner / Borde 407 532 0.77 44.0

28120151006 Transversal Corner / Borde 374 510 0.73 51.0

28120151009 Transversal Corner / Borde 430 554 0.78 35.0

CHARPY IMPACT TEST

SAMPLE DIRECTION POSITION TEMP/TEMP(°C) IND EN/EN IND(J) IND EN/EN IND(J) IND EN/EN IND(J) AVG EN/EN MD(J)

27119432005 Longitudinal Corner / Borde 13 272 272 251 265

28120151003 Longitudinal Corner / Borde 13 200 198 201 200

TENSILE TEST CHARPY IMPACT TEST

GAUGE LENGTH/LONGITUD DE REFERENCIA: SPEC SIZE/DIM MUESTRA: 10X10mm - V 2mm

L0: 50 mm

ABBREVIATIONS

(*) Mother Plate YS/RE Yield Point TS/RT Tensile Strength YS/TS Elastic Ratio ELONG/ALARG Elongation TEMP/TEMP Temperature

IND EN/EN IND Individual Energy AVG EN/EN MD Average Energy

REMARKS QUALITY ASSURANCE SURVEYOR

Tolerâncias dimensionaisconforme ASTM-A6.

Todas as fontes de radiação são monitoradas e controladas. Toda sucata utilizada

no processo de fabricação doaço na usina de Ouro Branco é gerada internamente.

Certificamos que este material é isento de contaminação por radiação.

Tolerances on dimensionsaccording to ASTM-A6.

All radiation sources are verified and controlled.

We certify that this material is free of contamination by radiation. THAYENE OLIVEIRA SILOTTI

All scrap used at Gerdau Ouro Branco is internally generated. THAYANE OLIVEIRA CREA 249773

SILOTTI – GERENTE ENGENHARIA PROCESSOS E PRODUTOS

thayene.silotti@gerdau.com.br – TEL.: +55 – 31-3749-5630

TOTAL NUMBER OF PIECES: 10

TOTAL NET/GROSS WEIGHT: 33.340 M/T

You might also like

- C00100Document24 pagesC00100Jimmy Deswidawansyah NasutionNo ratings yet

- Sl. No NPS OD Sockloet Rating Pipe Thickness Piping Spec Piping Class Flange Type Sockolet Opening/ Bore Diameter Flange Size Flange FaceDocument3 pagesSl. No NPS OD Sockloet Rating Pipe Thickness Piping Spec Piping Class Flange Type Sockolet Opening/ Bore Diameter Flange Size Flange FaceDeeran VNo ratings yet

- Certificado de CalidadDocument1 pageCertificado de CalidadCoordinador DicNo ratings yet

- Ecas TaltalDocument24 pagesEcas TaltalAlberto Enrique Espinoza FloresNo ratings yet

- Catalog Clutch DiscDocument30 pagesCatalog Clutch DiscPetrus KurniawanNo ratings yet

- Truck & Bus BrochureDocument8 pagesTruck & Bus BrochureAkhilesh RaiNo ratings yet

- Hydraulic Cylinders: Quality With Value GuaranteedDocument3 pagesHydraulic Cylinders: Quality With Value GuaranteedzephyrinNo ratings yet

- SparepartDocument30 pagesSparepartHfksosnaaoNo ratings yet

- BROCHURE Metel Firepump 2017Document8 pagesBROCHURE Metel Firepump 2017Jakir AhmedNo ratings yet

- Dimension - A Series 31-100 To 33-125Document1 pageDimension - A Series 31-100 To 33-125Energy Technology100% (1)

- Last PageDocument1 pageLast PageVente ChowNo ratings yet

- Machine 6 Spare Part Upper FactoryDocument15 pagesMachine 6 Spare Part Upper Factoryahmed hamdyNo ratings yet

- SITESTAR Partes PDFDocument140 pagesSITESTAR Partes PDFNicolas Leon LunaNo ratings yet

- Duct Calculation Fan BlowerDocument2 pagesDuct Calculation Fan Blowerabdul0rohiminNo ratings yet

- SFDEJDocument1 pageSFDEJkevin.larocquepbNo ratings yet

- S.No Date Bilty. No Damper - No Size Qty. RemarksDocument14 pagesS.No Date Bilty. No Damper - No Size Qty. RemarksEngr Ghulam MustafaNo ratings yet

- M-Code Width Series Size Description Wheel Dia. (In) Wheel DiaDocument3 pagesM-Code Width Series Size Description Wheel Dia. (In) Wheel DiaemboscaoNo ratings yet

- Inspection Report RandomlayDocument19 pagesInspection Report Randomlaynate anantathatNo ratings yet

- I NYECTORDocument2 pagesI NYECTORDiesel MotorsNo ratings yet

- Tech Bulletin: SUBJECT: 25 Frame Piston Pump Piston Rod and Seal ChangeDocument2 pagesTech Bulletin: SUBJECT: 25 Frame Piston Pump Piston Rod and Seal Changefrank rodriguezNo ratings yet

- Metals - August 3 2017Document1 pageMetals - August 3 2017Tiso Blackstar GroupNo ratings yet

- Item Quant. Codigo Descrição P. Unit. P. Total 219000498 219000495 219000785 219000499 219001024 219001025 219001026 219001022Document1 pageItem Quant. Codigo Descrição P. Unit. P. Total 219000498 219000495 219000785 219000499 219001024 219001025 219001026 219001022Comercial MartinsNo ratings yet

- SAE 100 (R1-R19) : Hebei Qianli Rubber Products Co., Ltd. Hebei Qianli Rubber Products Co., LTDDocument6 pagesSAE 100 (R1-R19) : Hebei Qianli Rubber Products Co., Ltd. Hebei Qianli Rubber Products Co., LTDdilli123No ratings yet

- National OilwellDocument399 pagesNational OilwellCampo Anibal GrandasNo ratings yet

- Practicas 4Document10 pagesPracticas 4GIOVANNI MARKO LANDA CHAGUANo ratings yet

- Insulation Joint PDFDocument7 pagesInsulation Joint PDFBabatunde OlalekanNo ratings yet

- 924 E 7th Monitoring Monitoring Report Weeks 1-2Document1 page924 E 7th Monitoring Monitoring Report Weeks 1-2Stephen BerryNo ratings yet

- On & Off-Road: TubelessDocument1 pageOn & Off-Road: TubelessCristhianVizarretaNo ratings yet

- Markets and Commodity Figures: MetalsDocument1 pageMarkets and Commodity Figures: MetalsTiso Blackstar GroupNo ratings yet

- PVC 80-619Document9 pagesPVC 80-619ezequiel.barrioszamoraNo ratings yet

- YOKOHAMA Motorsport Catalogue 2019Document6 pagesYOKOHAMA Motorsport Catalogue 2019jlee_296737No ratings yet

- Butterfly Valves Gd-381Fp: SpecificationDocument2 pagesButterfly Valves Gd-381Fp: SpecificationJOSE GABRIELNo ratings yet

- Yanmar - 4TNV98 PDFDocument19 pagesYanmar - 4TNV98 PDFAhmad Shahrul Mohamed100% (5)

- Cube Test ReportDocument12 pagesCube Test ReportRn KisNo ratings yet

- 4TNV98 GGE Spec PDFDocument19 pages4TNV98 GGE Spec PDFAhmad Shahrul Mohamed100% (1)

- 2 - Casing Slip Type UC-3Document1 page2 - Casing Slip Type UC-3leoNo ratings yet

- 4TNV98-GGE For Generator: Specifications and DrawingsDocument19 pages4TNV98-GGE For Generator: Specifications and DrawingsRita RitaNo ratings yet

- Kit de Joint de Verin CaterpillarDocument2 pagesKit de Joint de Verin CaterpillarzephyrinNo ratings yet

- 45DV-MQ Full Freelift 4-Stage Opti-Vis Quad Mast: Arts ManualDocument27 pages45DV-MQ Full Freelift 4-Stage Opti-Vis Quad Mast: Arts ManualRAYMULROONEYNo ratings yet

- Wavistrong Installation Manual Rubber Seal Lock JointDocument17 pagesWavistrong Installation Manual Rubber Seal Lock JointVioleta TaniNo ratings yet

- Liner Man 32Document1 pageLiner Man 32darpan nakhwaNo ratings yet

- Butterfly Valve 2014wp93Document1 pageButterfly Valve 2014wp93Mohamed RaafatNo ratings yet

- 060320Document3 pages060320ORPNo ratings yet

- StadyneDocument2 pagesStadynePatrick MalmbergNo ratings yet

- Instructions For Parts Books: Note About Country CodesDocument34 pagesInstructions For Parts Books: Note About Country CodesalexNo ratings yet

- Astral Aquasafe Price List Dt. 05th May 2018.Document8 pagesAstral Aquasafe Price List Dt. 05th May 2018.PGHOSH11No ratings yet

- Engine Data Sheet As4006 m5 3tnm72 GHFCLDocument15 pagesEngine Data Sheet As4006 m5 3tnm72 GHFCLBW MechanicalNo ratings yet

- InertiaDynamics CBCouplings310 SpecsheetDocument2 pagesInertiaDynamics CBCouplings310 SpecsheetElectromateNo ratings yet

- Easy Switch With Sulzer Adapter Brackets E10640Document2 pagesEasy Switch With Sulzer Adapter Brackets E10640Marcos Chaves MagalhãesNo ratings yet

- Kosfa Liner Kit (Diesel) For NissanDocument6 pagesKosfa Liner Kit (Diesel) For NissanСуханов КонстантинNo ratings yet

- SLG274 US Cut SheetDocument4 pagesSLG274 US Cut SheetMehdi MolavianNo ratings yet

- Server Bomba 83330Document1 pageServer Bomba 83330Matias PerezNo ratings yet

- John Deere - Parts Catalog - Frame 5Document2 pagesJohn Deere - Parts Catalog - Frame 5Jorge MendozaNo ratings yet

- John Deere - Parts Catalog - Frame 5 PDFDocument2 pagesJohn Deere - Parts Catalog - Frame 5 PDFJorge Mendoza100% (1)

- Product Card: Data Rasgos Del ProductoDocument5 pagesProduct Card: Data Rasgos Del Productoalfa24161305No ratings yet

- Metals - August 31 2017Document1 pageMetals - August 31 2017Tiso Blackstar GroupNo ratings yet

- Pressure Seal Check ValveDocument2 pagesPressure Seal Check ValveRajeev MaheshwariNo ratings yet

- Avox Systems: Realized byDocument28 pagesAvox Systems: Realized byAndrew100% (1)

- Blades and End Bits For KOMATSU®Document2 pagesBlades and End Bits For KOMATSU®Tan JaiNo ratings yet

- IJREAMV06I0969019Document5 pagesIJREAMV06I0969019UNITED CADDNo ratings yet

- Dokumen - Tips - Dominick Salvatore Microeconomics Wwwpdfsdocuments2comd38dominick SalvatorepdfDocument2 pagesDokumen - Tips - Dominick Salvatore Microeconomics Wwwpdfsdocuments2comd38dominick SalvatorepdfIshan SharmaNo ratings yet

- Hydrotest Test FormatDocument27 pagesHydrotest Test FormatRähûl Prätäp SïnghNo ratings yet

- Richard IIIDocument36 pagesRichard IIIXuan Mai Nguyen ThiNo ratings yet

- P&CDocument18 pagesP&Cmailrgn2176No ratings yet

- Rizal Noli Me TangereDocument35 pagesRizal Noli Me TangereKristine Cantilero100% (2)

- Thesis Statement On Lionel MessiDocument4 pagesThesis Statement On Lionel Messidwham6h1100% (2)

- Revised Exam PEDocument3 pagesRevised Exam PEJohn Denver De la Cruz0% (1)

- The Role of IT in TQM L'Oreal Case StudyDocument9 pagesThe Role of IT in TQM L'Oreal Case StudyUdrea RoxanaNo ratings yet

- Competent Testing Requirements As Per Factory ActDocument3 pagesCompetent Testing Requirements As Per Factory Actamit_lunia100% (1)

- Homelite 18V Hedge Trimmer - UT31840 - Users ManualDocument18 pagesHomelite 18V Hedge Trimmer - UT31840 - Users ManualgunterivNo ratings yet

- Enter Absence APIDocument45 pagesEnter Absence APIEngOsamaHelalNo ratings yet

- JurnalDocument12 pagesJurnalSandy Ronny PurbaNo ratings yet

- KPR College of Arts Science and Research: Marketing ManagementDocument127 pagesKPR College of Arts Science and Research: Marketing ManagementSekar M KPRCAS-CommerceNo ratings yet

- MATLAB For Data VisualizationDocument63 pagesMATLAB For Data Visualizationfahmi fawjiNo ratings yet

- Activity 4 - Energy Flow and Food WebDocument4 pagesActivity 4 - Energy Flow and Food WebMohamidin MamalapatNo ratings yet

- Good Manufacturing Practices in Postharvest and Minimal Processing of Fruits and VegetablesDocument40 pagesGood Manufacturing Practices in Postharvest and Minimal Processing of Fruits and Vegetablesmaya janiNo ratings yet

- Second Language Learning in The Classroom PDFDocument2 pagesSecond Language Learning in The Classroom PDFThanh Phương VõNo ratings yet

- EN 213 Vertintojui WWWDocument2 pagesEN 213 Vertintojui WWWMonika PetronytėNo ratings yet

- Grade 8 Least Mastered Competencies Sy 2020-2021: Handicraft Making Dressmaking CarpentryDocument9 pagesGrade 8 Least Mastered Competencies Sy 2020-2021: Handicraft Making Dressmaking CarpentryHJ HJNo ratings yet

- TextdocumentDocument254 pagesTextdocumentSaurabh SihagNo ratings yet

- Zanussi Parts & Accessories - Search Results3 - 91189203300Document4 pagesZanussi Parts & Accessories - Search Results3 - 91189203300Melissa WilliamsNo ratings yet

- Saunders & Cornnet Solution Chapter 1 Part 1Document5 pagesSaunders & Cornnet Solution Chapter 1 Part 1Mo AlamNo ratings yet

- Quiz EditedDocument6 pagesQuiz EditedAbigail LeronNo ratings yet

- Kongsberg Oil and Gas Technology LimitedDocument1 pageKongsberg Oil and Gas Technology LimitedGhoozyNo ratings yet

- Ahu 1997 22 1 95Document15 pagesAhu 1997 22 1 95Pasajera En TranceNo ratings yet

- An Enhanced RFID-Based Authentication Protocol Using PUF For Vehicular Cloud ComputingDocument18 pagesAn Enhanced RFID-Based Authentication Protocol Using PUF For Vehicular Cloud Computing0dayNo ratings yet

- Poster PresentationDocument3 pagesPoster PresentationNipun RavalNo ratings yet

- Topic - Temperature SensorDocument9 pagesTopic - Temperature SensorSaloni ChaudharyNo ratings yet

- Water Works RTADocument15 pagesWater Works RTAalfaza3No ratings yet