Professional Documents

Culture Documents

QAV2 FORMAT (New) One

Uploaded by

QSSD ENTERPRISESOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QAV2 FORMAT (New) One

Uploaded by

QSSD ENTERPRISESCopyright:

Available Formats

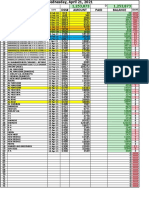

QUALITY ASSURANCE VISIT - 2 REPORT Hero MotoCorp Ltd.

REV_ 01 SHEET ---- / ----

NAME MODEL PARTS NAME DATE GUIDELINES

-- Spring Valve Outer (14751-AAB-1000) 06.04.22 1 SELF TRIALS BY SUPPLIERS - MINIMUM 3 TRIALS TO BE VERIFIED

COMPANY NAME

FACTORY NAME OBJECTIVE : Self QAV for location change

2

DATE

POSITION NAME

COMPILATION : 3

VENDOR : Self QAV

4

PRESENT PERSON

HMCL :

6

10

SL. Operation Description CONTROL ITEM JUDGEMENT ( wherver applicable ) C.M.EXECUSION CHECK (HMCL)

Manpower Adequacy ( Training / Skill

Daily Maint / PM (M/c / Jig / Fixture /

NO. Process Name : RESP. TARGET INCHARGE DATE RESULT

Set up approval system ( First off /

Process Capability ( CP / CPK ) of

Parameters & Insp Freq ( PQCS /

Insp Method (Gauges / Masters)

Adequacy of Product / Process

OBSERVED DETAILS REASON COUNTERMEASURE

Poka Yoke & its valiation

Product quality

qualification&Manufacturing

Adherence to PQCS

Make of Machine conditions control parameters.

Material Handling

(Product & Process Parameters)

Straight Pass %

Data Recording

Year Of Mfg

Work Stds )

Cycle Time

last Off )

level )

CTQs

Die )

Product Parameter

Wire Dia.(3.30 ± 0.03) O O O NA NA O O NA NA NA O 3.307 mm

Grade( SWOSC-VHV) O O O NA NA O O NA NA NA O SWOSC-VHV

UTS(2060 - 2160) N/mm2 O O O NA NA O O NA NA NA O 2107 N/mm2

10 RM/Incoming % Ra(43 % min) O O O NA NA O O NA NA NA O 51.5

Wrapp test(Standard QAD R 01) O O O NA NA O O NA NA NA O OK

Deep etch(Standard QAD R 01) O O O NA NA O O NA NA NA O OK

Chemical compo.(RESPECTIVE

O O O NA NA O O NA NA NA O OK as per MTC and third party report

STD.)

Product Parameter

Free Length(As per TPSR) O O O O O O O O O NA O Test piece setting report verified and free length is found OK as per spec.

Inside Dia. (As per TPSR) O O O NA O O O O NA NA O Test piece setting report verified and ID is found OK as per spec.

No scraches & Marks

O O O NA O O O O NA NA O Test piece setting report verified and found OK as per spec.

(As per TPSR)

No of turns(As per TPSR) O O O NA O O O O NA NA O Test piece setting report verified and Nt is found OK as per spec.

20 Process 1(Coiling)

Process Parameters

Roller Grove Size

O O O NA O O O O NA NA O OK as per TPSR

(As per MFG R37)

Finger Groove Size

O O O NA O O O O NA NA O OK as per TPSR

(As per MFG R37)

Wire Guide Groove

O O O NA O O O O NA NA O OK as per TPSR

(As per MFG R37)

Finger Size

O O O NA O O O O NA NA O OK as per TPSR

(As per MFG R37)

Process Parameters

Temperature(AS PER ENG

30 Process 2(Stress Relieving) O O O NA NA O O O NA NA O Verified as per the standard ENG R 11 Section I and Found OK.

R11 SECTION I)

Time(AS PER ENG

O O O NA NA O O O NA NA O Verified as per the standard ENG R 11 Section I and Found OK.

R11 SECTION I)

Product Parameter

Free Length (As per TPSR) O O O NA O O O O NA NA O Test piece setting report verified and free length is found OK as per spec.

Grinding Roughness

O O O NA O O O O NA NA O Test piece setting report verified and roughness is found OK as per spec.

(As per TPSR)

Squareness e1 (As per TPSR) O O O NA O O O O NA NA O Test piece setting report verified and squareness is found OK as per spec.

Grinding angle (As per TPSR) O O O NA O O O O NA NA O Test piece setting report verified and grinding angle is found OK as per spec.

40 Process 3(Grinding) Tip thickness (As per TPSR) O O O NA O O O O NA NA O Test piece setting report verified and tip thickness is found OK as per spec.

Solid Length (As per TPSR) O O O NA O O O O NA NA O Test piece setting report verified and solid length is found OK as per spec.

Process Parameters

Down Feed ( As per MFG R 54) O O O NA O O O O NA NA O OK as per TPSR

Loading Plate Speed

O O O NA O O O O NA NA O OK as per TPSR

( As per MFG R 54)

Loading Plate Hole O O O NA O O O O NA NA O OK as per TPSR

Size (As per MFG R 54)

Product Parameter

60 Process 4(IDC)

ID Chamfer (0.50 x 45) O O O NA O O O O NA NA O OK (0.50 X 45)

Product Parameter

Coverage(90 % Min) O O O NA NA O O O NA NA O Coverage OK ,found more than 90% .

Process Parameters

80 Process 5 (Shot Peening) Shot size (AS PER ENG R11 O O O NA NA O O O NA NA O Verified as per the standard ENG R 11 Section II and Found OK.

SECTION II)

Amperage (AS PER ENG R11 O O O NA NA O O O NA NA O Verified as per the standard ENG R 11 Section II and Found OK.

SECTION II)

SP Time (AS PER ENG R11 O O O NA NA O O O NA NA O Verified as per the standard ENG R 11 Section II and Found OK.

SECTION II)

Almen Arc Height O O O NA NA O O O NA NA O Verified as per the standard ENG R 11 Section II and Found OK.

(AS PER ENG R11 SECTION II)

Process Parameters

Temperature(AS PER ENG

85 Process 6(Stress Relieving) O O O NA NA O O O NA NA O Verified as per the standard ENG R 11 Section I and Found OK.

R11 SECTION I)

Time(AS PER ENG

O O O NA NA O O O NA NA O Verified as per the standard ENG R 11 Section I and Found OK.

R11 SECTION I)

Product Parameter

AS PER QA MASTER CARD ENG

O O O NA NA O O O NA NA O Verified as per QAMC and found OK,.

R 20

Inside Dia (16.60 +0.40)mm O O O NA NA O O O O NA O 16.67, 16.71, 16.69, 16.65, 16.76.

-- Process 7(Pre Inspection) Installed Load (8.45 ± 0.90 Kgf ) O O O NA NA O O O O NA O 8.58, 8.79, 8.77, 8.49, 8.41.

Load At Working ( 40.90 ± 2.50 Kgf

O O O NA NA O O O O NA O 41.43, 41.67, 41.56, 41.39, 40.81.

)

Ground Roughness( Rz 25 Max) O O O NA NA O O O NA NA O Ok

Surface Treatment

O O O NA NA O O O NA NA O OK

(Shotpeen Coverage)

Product Parameter

Process 8

150

(Surface Treatment)

Yellow Indelible Ink dot on open O O O O NA O O O NA NA O OK

pitch side unground portion.

O - O.K. - SATISFACTORY X - N.G.

QUALITY ASSURANCE VISIT - 2 REPORT Hero MotoCorp Ltd.

SHEET ---- / ----

SL. Operation Description CONTROL ITEM JUDGEMENT C.M.EXECUSION CHECK (HMCL)

NO. Process Name : RESP. TARGET INCHARGE DATE RESULT

Adequacy of Product / Process

Insp Method (Gauges / Masters)

Parameters & Insp Freq

Daily Maint / PM (M/c / Jig /

Poka Yoke & its valiation

OBSERVED DETAILS REASON COUNTERMEASURE

Handling /Ergonomics

Manpower Adequacy

Make of Machine Product quality

qualification&Manufacturing

CP / CPK ( CTQs)

conditions control parameters.

Set up approval

Data Recording

Year Of Mfg

Fixture / Die )

Rejection %

Adherence

Cycle Time

Product Parameter

Material (SWOSC-VHV) O O O NA NA O O O NA NA O SWOSC-VHV

Wire Diameter (3.30 mm) O O O NA NA O O O NA NA O 3.30, 3.30, 3.30, 3.30, 3.30.

Helix(RH) O O O NA NA O O O NA NA O RH,RH,RH,RH,RH,RH.

Ends(CL & GR) O O O NA NA O O O NA NA O Ends are closed and ground.

Free Length(36.20 REF.) mm O O O NA NA O O O NA NA O 36.52, 36.54, 36.36,36.55,36.54

Solid Length (23.60 MAX.)mm O O O NA NA O O O NA NA O 23.20, 22.50, 22.30,22.70, 22.80.

Process 9

-- Inside Dia (16.60 +0.40)mm O O O NA NA O O O O NA O 16.63, 16.68, 16.65, 16.78, 16.73

(Final Inspection)

No of Total Turns( 7.15) Ref. O O O NA NA O O O NA NA O 6.90, 6.90, 6.95, 6.90, 6.90 .

Squareness (1.26 MAX.) mm O O O NA NA O O O NA NA O 1.02, 1.11, 1.06, 1.15, 0.96

Installed Load P1 at 33.30 mm

O O O NA NA O O O O NA O 8.62, 8.54, 8.36, 8.52, 8.47.

(7.55 - 9.35) Kg

Working Load P2 at 24.76 mm

O O O NA NA O O O O NA O 42.60, 41.90, 42.05, 41.69, 42.05.

(38.40 - 43.40) Kg

ID Chamfer (0.50 X 45°) O O O NA NA O O O NA NA O OK

Surface Treatment (Shot peening) O O O NA NA O O O NA NA O Done

Visual (No Burr, Scratches, Rust,

O O O NA NA O O O NA NA O OK

Dust, etc.)

Process Parameters

Process 10

160

Oiling & Packing

AS PER PACKING STANDARD

O O O NA NA O O O NA NA O OK, packing is as per the packing standard.

ENG R 11

O - O.K. - SATISFACTORY X - N.G.

You might also like

- BattleTech BattleMaster Blueprint RevDocument1 pageBattleTech BattleMaster Blueprint RevSantiago de la Esperanza100% (1)

- Fact Sheet - ITIL® 4 Specialist - Create, Deliver and Support - ClassroomDocument6 pagesFact Sheet - ITIL® 4 Specialist - Create, Deliver and Support - ClassroomEduardo MucajiNo ratings yet

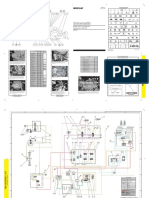

- Caterpillar Multiterreno 277CDocument4 pagesCaterpillar Multiterreno 277CAnonymous KOtSfT6qNo ratings yet

- As 5169Document5 pagesAs 5169Wuod JipangaNo ratings yet

- 966M and 972M Wheel Loader 966mDocument2 pages966M and 972M Wheel Loader 966mF Labio AlexNo ratings yet

- BattleTech BattleMaster Blueprint RevDocument1 pageBattleTech BattleMaster Blueprint RevMenthro100% (1)

- Aerospace Standard AS4330: Custodian: Sae G-3/G-3BDocument2 pagesAerospace Standard AS4330: Custodian: Sae G-3/G-3BHenry100% (2)

- Instant Assessments for Data Tracking, Grade 3: MathFrom EverandInstant Assessments for Data Tracking, Grade 3: MathRating: 5 out of 5 stars5/5 (2)

- Key Notes: Bdlg. 2527/P423Document1 pageKey Notes: Bdlg. 2527/P423Cristo BglezNo ratings yet

- 1 Key Notes: MECH (F-Viii)Document1 page1 Key Notes: MECH (F-Viii)Cristo BglezNo ratings yet

- Batching Plant LBPD22142035 A00Document1 pageBatching Plant LBPD22142035 A00mechajay2002No ratings yet

- Extracted Pages From PID BinderDocument15 pagesExtracted Pages From PID Bindermangesh patilNo ratings yet

- Woolworths Supermarket Main Switchboard Single Line Diagram: ConsultingDocument1 pageWoolworths Supermarket Main Switchboard Single Line Diagram: ConsultingMitch WennNo ratings yet

- Sectional View of 220Kv Xmer Bay & Metering Bay: Cost Basis ReportDocument1 pageSectional View of 220Kv Xmer Bay & Metering Bay: Cost Basis Reportask.kulkarni KulkarniNo ratings yet

- Conveyor Data & Equipment Summary Sheet, Mill Feed: M M M MDocument1 pageConveyor Data & Equipment Summary Sheet, Mill Feed: M M M MUğur YılmazNo ratings yet

- Uen R 02310001Document4 pagesUen R 02310001gianmarcoNo ratings yet

- STR BnderDocument6 pagesSTR Bnderhemanthkumar67008No ratings yet

- Notice The Complete Requirements For Procuring The Product Described Herein Shall Consist of This Document and The Latest Issue of As85049Document3 pagesNotice The Complete Requirements For Procuring The Product Described Herein Shall Consist of This Document and The Latest Issue of As85049daNo ratings yet

- Casa Modelo Tipo A-ModelDocument39 pagesCasa Modelo Tipo A-ModelJuan Pino EcheverríaNo ratings yet

- Schematic Flow ChartDocument1 pageSchematic Flow ChartShawn KamauNo ratings yet

- As85052 - 2b-Clamp, Loop Tube 17-7PH, Cres, 275 °f, Phosphate Ester Fluid ResistantDocument3 pagesAs85052 - 2b-Clamp, Loop Tube 17-7PH, Cres, 275 °f, Phosphate Ester Fluid ResistantJicheng PiaoNo ratings yet

- X Ref - JF-P0015 - Oasis Cafe - 11052019 - A-2 TablesDocument1 pageX Ref - JF-P0015 - Oasis Cafe - 11052019 - A-2 TablesCOTA ESTUDIO DE ARQUITECTURANo ratings yet

- Material List: Saudi Arabian Oil CompanyDocument1 pageMaterial List: Saudi Arabian Oil CompanybalajiNo ratings yet

- Estructura de Nomina 15-06-2022 - Ajustada Corregida - Multi Serviciosub-CeroDocument25 pagesEstructura de Nomina 15-06-2022 - Ajustada Corregida - Multi Serviciosub-CeroBRYAN NOGUERANo ratings yet

- P&ID Drawing of Underground Solvent TanksDocument1 pageP&ID Drawing of Underground Solvent Tankshps sgNo ratings yet

- Bods - Dehradun 15-12-2017Document5 pagesBods - Dehradun 15-12-2017designselvaNo ratings yet

- 825H Soil Compactor Hydraulic SystemDocument2 pages825H Soil Compactor Hydraulic SystemTom SouzaNo ratings yet

- Plan 4Document9 pagesPlan 4rnz mrnNo ratings yet

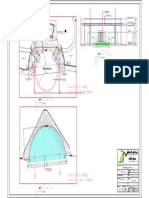

- Building Face Line: Proposed Work For Mr. Sanjay Shinde, Anita Super Shopee at Khanapur, Dis. - SangliDocument1 pageBuilding Face Line: Proposed Work For Mr. Sanjay Shinde, Anita Super Shopee at Khanapur, Dis. - SangliRoyal JadhavNo ratings yet

- Smoke DetectorDocument1 pageSmoke DetectorRiteshNo ratings yet

- Notes: Equipment List Item No DescriptionDocument6 pagesNotes: Equipment List Item No DescriptionKonge ThethtunaungNo ratings yet

- Group 2 Electrical Circuit (1/3)Document21 pagesGroup 2 Electrical Circuit (1/3)Taha RdmanNo ratings yet

- Key Notes:: Hvac Floor PlanDocument1 pageKey Notes:: Hvac Floor PlanNon Etabas GadnatamNo ratings yet

- B700 C AD1-01 .: Lo29 (Cape Datum)Document1 pageB700 C AD1-01 .: Lo29 (Cape Datum)Kaka KuxNo ratings yet

- Med LT U6 Hmda 08112019Document1 pageMed LT U6 Hmda 08112019anil kumarNo ratings yet

- Decal, Schematic SD / 60 HZ Intellisys 22182356 LDocument2 pagesDecal, Schematic SD / 60 HZ Intellisys 22182356 LJose Marie AsuncionNo ratings yet

- Top-Title Bottom-Title: Entrance/Exit PlazaDocument1 pageTop-Title Bottom-Title: Entrance/Exit Plazaمعاذ كروبينNo ratings yet

- MC Nichols Grip Strut DrawingsDocument4 pagesMC Nichols Grip Strut Drawingsananda ganeshNo ratings yet

- Dashboard ReportDocument140 pagesDashboard Reportm13naserrajaNo ratings yet

- Materiales #2Document6 pagesMateriales #2andresromerounirNo ratings yet

- MA2273Document3 pagesMA2273gagalunar789No ratings yet

- Foundation Plan and Anchor Locations: Section CDocument1 pageFoundation Plan and Anchor Locations: Section CJavier Guerra TriviñoNo ratings yet

- Eco Drawing of Indication MarkDocument1 pageEco Drawing of Indication MarkM.Usama MustafaNo ratings yet

- RAHEEM CHANNA (0333-3112542) : C-Karachi (Qayoom Solangi 1000/ )Document1 pageRAHEEM CHANNA (0333-3112542) : C-Karachi (Qayoom Solangi 1000/ )Vishal RawlaniNo ratings yet

- Model 72400 Servo Controlled Piston Pump: Parts InformationDocument20 pagesModel 72400 Servo Controlled Piston Pump: Parts InformationhidraulicavarginhadivulgacaoNo ratings yet

- Panel Wiring 380VDocument1 pagePanel Wiring 380VEvandro AvoriNo ratings yet

- FINAL RAILWAY CROSSING PROPOSAL OF UER 2-ModelDocument1 pageFINAL RAILWAY CROSSING PROPOSAL OF UER 2-ModelSaurav KumarNo ratings yet

- Puddle Flange Details (1) (4) - ModelDocument1 pagePuddle Flange Details (1) (4) - ModelYusuf HungundNo ratings yet

- Denah Kusen Pintu Dan Jendela Lantai P2: Tower A Tower BDocument1 pageDenah Kusen Pintu Dan Jendela Lantai P2: Tower A Tower Bharianto al faisNo ratings yet

- QP10 Q 2426 - TypicalSteelTank10,000m TopInlet Rev0Document1 pageQP10 Q 2426 - TypicalSteelTank10,000m TopInlet Rev0Nassif Abi AbdallahNo ratings yet

- E 1688 84.2Document1 pageE 1688 84.2ZABIHULLAH SAFINo ratings yet

- 01 - Amort. Pulsação - 1# Sucção - LP-1Document1 page01 - Amort. Pulsação - 1# Sucção - LP-1joaofbragasNo ratings yet

- Páginas desde70180-00-CW - YDA-TRE-001Document1 pagePáginas desde70180-00-CW - YDA-TRE-001Leonel Perez RubioNo ratings yet

- Incremental A1 - Erf 873-743 231 - 65-CombinedDocument50 pagesIncremental A1 - Erf 873-743 231 - 65-Combinedbuildingplans2008No ratings yet

- Floor Pattern Layout 1: Masterpiece Asia Properties IncDocument7 pagesFloor Pattern Layout 1: Masterpiece Asia Properties Incerwin leeNo ratings yet

- Diagrama Hidraulico 420E CATERPILLAR PDFDocument4 pagesDiagrama Hidraulico 420E CATERPILLAR PDFWilmer0% (1)

- H019-MND-MHS4-CVS-S-DFM-005 - 491 of 721 - 00Document1 pageH019-MND-MHS4-CVS-S-DFM-005 - 491 of 721 - 00Rahul MahajanNo ratings yet

- Irrigation Control Cable LayoutDocument4 pagesIrrigation Control Cable Layoutalivesince1091No ratings yet

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: MathFrom EverandInstant Assessments for Data Tracking, Grade 1: MathRating: 4 out of 5 stars4/5 (1)

- Extrusion Plant Report: Total MandaysDocument2 pagesExtrusion Plant Report: Total MandaysQSSD ENTERPRISESNo ratings yet

- Supplier Rating System: Quality (35 Points)Document2 pagesSupplier Rating System: Quality (35 Points)QSSD ENTERPRISESNo ratings yet

- Risk Assessment RegisterDocument26 pagesRisk Assessment RegisterQSSD ENTERPRISESNo ratings yet

- Quality CricleDocument22 pagesQuality CricleQSSD ENTERPRISESNo ratings yet

- frdA190220A1421665 PDFDocument2 pagesfrdA190220A1421665 PDFVeritaserumNo ratings yet

- A16z Comment Letter Final 1.4.21Document21 pagesA16z Comment Letter Final 1.4.21ForkLogNo ratings yet

- Accenture Cover LetterDocument8 pagesAccenture Cover Letterafjwrcqmzuxzxg100% (2)

- 5.tender Process N DocumentationDocument35 pages5.tender Process N DocumentationDilanka MJ Dassanayake100% (1)

- Tenant Verification Form PDFDocument2 pagesTenant Verification Form PDFmohit kumarNo ratings yet

- Freight CalculatorDocument2 pagesFreight CalculatorOverhauled ArtsNo ratings yet

- Employee Performance Management Literature ReviewDocument6 pagesEmployee Performance Management Literature Reviewea8d1b6nNo ratings yet

- Introduction and Instructions: ForewordDocument20 pagesIntroduction and Instructions: ForewordDanang WidoyokoNo ratings yet

- Fighting Food Waste Using The Circular Economy ReportDocument40 pagesFighting Food Waste Using The Circular Economy ReportCaroline Velenthio AmansyahNo ratings yet

- ACT 141-Module 1-Assurance ServicesDocument98 pagesACT 141-Module 1-Assurance ServicesJade Angelie FloresNo ratings yet

- AshZjxFuEemP8Qpm209XvA Rewiring-Trade-FinanceDocument5 pagesAshZjxFuEemP8Qpm209XvA Rewiring-Trade-Financezvishavane zvishNo ratings yet

- Review of Related Literature OutlineDocument4 pagesReview of Related Literature OutlineSiote ChuaNo ratings yet

- Evike Order 3939175Document3 pagesEvike Order 3939175Carlos CrisostomoNo ratings yet

- Basic Pre-Contractual Information: Name and Address of N26 Bank GMBH, Sucursal en EspañaDocument6 pagesBasic Pre-Contractual Information: Name and Address of N26 Bank GMBH, Sucursal en EspañaJosué BoteroNo ratings yet

- CPAR 92 AUD-1st PB SolDocument3 pagesCPAR 92 AUD-1st PB SolEmmanuel TeoNo ratings yet

- Elimination Questions Elimination QuestionsDocument4 pagesElimination Questions Elimination QuestionsasffghjkNo ratings yet

- Target Shots I-UnlockedDocument257 pagesTarget Shots I-Unlockedsaumya ranjan nayakNo ratings yet

- MARINGO Category 1 (HOUSE 1310) Occupier For January 2023Document1 pageMARINGO Category 1 (HOUSE 1310) Occupier For January 2023sophia sambaNo ratings yet

- QC Senior Compliance Attorney in Washington DC Resume Tina GreeneDocument2 pagesQC Senior Compliance Attorney in Washington DC Resume Tina GreeneTinaGreeneNo ratings yet

- Assignment of Contract (Correct Version)Document2 pagesAssignment of Contract (Correct Version)Heru Atiba El - BeyNo ratings yet

- Wiley CFA Test Bank 180527 (20 Preguntas)Document12 pagesWiley CFA Test Bank 180527 (20 Preguntas)rafav10No ratings yet

- Data Dictionary+Document4 pagesData Dictionary+Abirami SivakumarNo ratings yet

- La Campañia Maritima vs. Francisco Muñoz, 12 December 1907, GR No. L-3704Document8 pagesLa Campañia Maritima vs. Francisco Muñoz, 12 December 1907, GR No. L-3704Marianne Hope VillasNo ratings yet

- Ebook Business Law and The Regulation of Business 11Th Edition Mann Test Bank Full Chapter PDFDocument37 pagesEbook Business Law and The Regulation of Business 11Th Edition Mann Test Bank Full Chapter PDFelizabethclarkrigzatobmc100% (10)

- StatementDocument2 pagesStatementAndile mthethwaNo ratings yet

- e-StatementBRImo 585401009753509 Jul2023 20230731 081457Document2 pagese-StatementBRImo 585401009753509 Jul2023 20230731 08145709. BUNGA NUR YUNITA SARINo ratings yet

- Cloud - Security - Checklist - 221216 - 134458Document8 pagesCloud - Security - Checklist - 221216 - 134458Sumit ThatteNo ratings yet

- Andhra Pradesh ShepDocument91 pagesAndhra Pradesh ShepKanagarajan UmapathiNo ratings yet

- Chapter 6 PRACTICING AS AN ETHICAL ADMINISTRATIONDocument8 pagesChapter 6 PRACTICING AS AN ETHICAL ADMINISTRATIONJR Rolf NeuqeletNo ratings yet