Professional Documents

Culture Documents

Supply Chain Case

Uploaded by

Amreen AkhtarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Supply Chain Case

Uploaded by

Amreen AkhtarCopyright:

Available Formats

Supply Chain Deep Dive

BAT Property – Confidential – For internal use only.

Contents

What is Aromato SmartBrew?

SmartBrew manufacturing and distribution process

Competitor manufacturing information

Our supplier options

Our distribution options

BAT Property – Confidential – For internal use only.

What is Aromato SmartBrew?

Specifications

Size Top diameter 8cm

SmartBrew allows consumers to have all of their Bottom diameter 8cm

favourite Aromato coffees anytime, anywhere. Height 26cm

Capacity 500ml

Weight 0.68kg

Colour options Black, Red, Purple, Green

Once the coffee is brewed, the SmartBrew keeps

Maximum capsules 3

coffee warm for up to 12 hours, in its self-contained Price £49.99

100% leak proof and BPA free travel mug. Battery life 10 cups of coffee

Charge time 1 hour

Purchase Options Price

1 SmartBrew on-the-go £49.99

It is an on-the-go travel cup in which three Aromato coffee travel cup

capsules can be stored inside. At any time of the day, the

2 SmartBrew with 20 £65.99

consumer can select which of the three coffees they would standard Aromato coffee 20x

like at that given moment and enjoy a delicious, high-quality capsules

coffee at a simple press of a button. 3 SmartBrew with 50 £79.99

Aromato coffee capsules

of your choice

50x

BAT Property – Confidential – For internal use only.

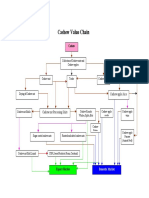

SmartBrew Manufacturing and Distribution Process

For the initial launch, SmartBrew will be manufactured by an

external supplier and distributed globally.

Providing the initial launch is a success, we will then look to bring

SmartBrew is the operations in-house over the next two years, so that

SmartBrew is sold

External supplier then distributed SmartBrew will be produced on-site at one of our Aromato

online and in-store

manufactures to our regional depots across our global

production plants.

SmartBrew across the global market

market

The end-to-end process will need to be as

sustainable and streamlined as possible.

BAT Property – Confidential – For internal use only.

Competitor Manufacturing Information

Competitor Product Manufacturing Issues Figures

Cuppino launched the ‘Warm Cup’ The ‘Warm Cup’ is manufactured in China The Warm Cup is manufactured Time to production: 23

six months ago. The Warm Cup and is made through a simple semi- using non-sustainable materials. days

Cuppino allows consumers to set the automated manufacturing process. The Cuppino customers have

temperature of the cup and keep final product is then shipped worldwide. expressed concern following the Price (500+ units): £16

their coffee warm whilst on the go. lack of social responsibility shown Retail Price: £72

by the organisation.

Royal Café is a medium-sized ‘Royal Café-on-the-go’ is manufactured in The Royal Café cup has seen issues Time to production: 16

European-based business who sell Amsterdam, Netherlands, and then with supply and demand. As the days

‘Royal Café-on-the-go’, a thermal distributed across Europe. Royal Café have product picked up, the demand

cup that complements their Royal partnered with a technology specialist to outgrew the manufacturer’s Price (500+ units): £8

Café machines. The cup attaches to ensure compatibility of the cup with the capacity. This has impacted Royal Retail Price: £32

your home machine and makes your machine. Café’s reputation amongst

Royal Café

coffee whilst you are busy. The cup consumers.

can then be transported around, on

the go with the consumer.

BAT Property – Confidential – For internal use only.

Competitor Manufacturing Information

Competitor Product Manufacturing Issues Figures

Neucafe is an American-based company Neucafe Cup is produced by a Neucafe have experienced some Time to production:

specialising in unique coffee flavours for the small-scale manufacturer who issues with production time, 38 days

vegan market. Their ‘Neucafe Cup’ is a plastic specialise in sustainable which is significantly slower than

Neucafe cup with thermal properties, sourced from 100% products. The manufacturer the estimated production time, Price (500+ units):

recycled materials. The Neucafe cup has an also plants one tree for every leading to increased waiting time £4.80

inbuilt filter system, where consumers insert £5,000 it makes. for consumers. Retail Price: £20

coffee bags into the top.

Caffeinated have experienced Time to production:

some issues with the technology 26 days

Caffeinated’s ‘Filter Flask’ is a technologically- ‘The Filter Flask’ is malfunctioning in both the

enabled thermos flask. It has an inbuilt filter, so manufactured by technology manufacturing process and the Price (500+ units):

Caffeinated all consumers need to do is insert their filter specialists, ensuring quality products themselves, despite the £11

coffee into the top and press go, with the added assurance to their customers. top of the range quality

advantage of being able to set the temperature. Retail Price: £46

assurance and artificial

intelligence used.

BAT Property – Confidential – For internal use only.

Supplier Options

Urban England

Overview How they would propose to manufacture this Timeline

product

Founded in 2001, Urban England is located in London, Process Time (per 200 units)

UK. It is a small and local supplier for many consumer 1. Import all materials to their warehouse from Receive Materials 4 weeks

goods businesses in the UK. Although based in the UK, competitive overseas providers. Assembly Process 3 days

the size of the business means that the majority of 2. Ensure the best prices on imported materials. Packaging 2 days

materials are imported from overseas and partnerships 3. Fast turn around from receiving materials to final Total 33 days

with other suppliers are often needed to ensure a product.

sufficient supply chain. Price

Units Assembly cost (per unit)

Manufacturing Process Customer Reviews 0-200 £20

Urban England pride themselves on manufacturing “Urban England are fantastic, we have been trusting 200-500 £18

products in the UK. SmartBrew would be manufactured them to manufacture our products since they 500 + £15.70

using a combination of manual and automated opened and have never had any issues.”

assembly lines. Urban England haven’t updated their Customers

manufacturing equipment in the last four years. “We have frequently experienced supplier issues

Other

However, they are considering the consolidation of with Urban England, ensuring that all materials

warehouses to improve the efficiency of their reach the UK at the same time is difficult, and

Global FMCG

operations. They also don’t have the packaging sometimes can take up to 10 weeks.”

equipment we require and so this would have to be UK FMCG

outsourced to one of their partners.

Start Up FMCG

Supplier Cost Speed Sustainability Reliability

0% 20% 40% 60%

Urban England

BAT Property – Confidential – For internal use only.

Eco-Assemble

Overview How they would propose to manufacture this Timeline

product

Founded in 1990, Eco-Assemble is based in Brazil. They Process Time (per 200 units)

pride themselves on being a sustainable assembly 1. Self contain the assembly of the final product. Receive Materials 2 weeks

point for world changing FMCG products. They allow Assembly Process 2 days

materials to be imported, however, always endeavour 2. Product made from at least 50% recycled material. Packaging 0.5 days

to ensure at least 50% of a product/packaging is from Total 16.5 days

recycled or locally sourced materials. This is in an 3. Packaging is 100% recycled material.

attempt to minimise the carbon footprint of the Price

product. They also use a clear Forecast Accuracy target,

Units Assembly cost (per unit)

constant production wheel reviews, and stock policy

Customer Reviews 0-200 £21

updates to continually work towards a more efficient

process. “Eco-Assemble are the best supplier we’ve found, 200-500 £20

they make sure that our product is made from 500 + £18.90

Manufacturing Process 100% recycled material.”

Eco-Assemble use an efficient semi-automated Customers

process. They have recently upgraded their machinery “Eco-Assemble not only work to manufacture our

to include some of the latest technologies in product on time, but they work in partnership with Other

manufacturing such as artificial intelligence and us to ensure our carbon footprint is as low as

machine learning, which has reduced overall possible, they’re a supplier that really care.” Global FMCG

production time by 12%. UK FMCG

Start Up FMCG

Supplier Cost Speed Sustainability Reliability

0% 20% 40% 60%

Eco-Assemble

BAT Property – Confidential – For internal use only.

Robotiics

Overview How they would propose to manufacture this Timeline

product

Founded in 1989, Robotiics are based in Tokyo, Japan, Process Time (per 200 units)

and pride themselves on being at the forefront of 1. Use leading technology to produce the product. Receive Materials 3 weeks

technology in the manufacturing world; and specialise Assembly Process 0.5 days

in global FMCG. Their aim is to supply smart, which 2. Use imported materials desired by the client. Packaging 0.5 days

means they use leading technologies to make Total 22 days

efficiencies that will reduce the production time of 3. Can produce at late notice by using advanced

products. technology. Price

4. Use crowdshipping approach for last-mile delivery. Units Assembly cost (per unit)

Manufacturing Process

0-200 £30

Robotiics use a stripped back manufacturing process 200-500 £29

that utilises technology to its full potential. They have Customer Reviews 500 + £26.50

brand new equipment that is highly reliable and will

“Robotiics are brilliant, the technology they use is the

endeavour to use AI and machine learning, along with

best on the market, meaning that the time-to-product Customers

the newest 3D printing technology to ensure a speedy

completion is extremely quick.”

manufacturing process.

Other

“Robotiics are significantly more expensive because of

the technology involved, and sometimes we have faced Global FMCG

delays due to some malfunctions in the technology UK FMCG

used.”

Start Up FMCG

Supplier Cost Speed Sustainability Reliability

0% 20% 40% 60% 80%

Robotiics

BAT Property – Confidential – For internal use only.

Refinement

Overview How they would propose to manufacture this Timeline

product

Founded in 2006, Refinement are located in Shanghai, Process Time (per 200 units)

China. They pride themselves on their quality 1. Use leading technology in quality assurance. Receive Materials 3 weeks

assurance standards, and ensure quality at every stage Assembly Process 1 day

of the manufacturing process. They believe this is key 2. Deliver an efficient and single manufacturing Packaging 0.5 days

to both client and FMCG customer satisfaction. process from product to packaging. Total 22.5 days

3. Use imported materials desired by the client. Price

4. Use 3PL provider to hold/deliver finished goods. Units Assembly cost (per unit)

Manufacturing Process

0-200 £25.50

Refinement use a semi-automated production system, 200-500 £22.40

with built-in quality assurance measures at each Customer Reviews 500 + £20.00

individual stage. The process ensures that the number

“We switched to Refinement one year ago, and since

of damaged goods are minimal. Since implementing

we’ve seen our damaged goods decrease significantly, Customers

their new QA technology two years ago, they’ve seen

and with the use of technology, the end-to-end process

the incidents of damaged goods decrease by almost

is still quite speedy.” Other

50%.

“You pay for quality, and although Refinement is slightly Global FMCG

more expensive than some other manufacturers, we’ve

UK FMCG

found it’s worth it to maintain our reputation.”

Start Up FMCG

Supplier Cost Speed Sustainability Reliability

0% 20% 40% 60% 80%

Refinement

BAT Property – Confidential – For internal use only.

Distribution Options

Average supplier Average supplier Supplier distance from

Supplier Air Cargo per 5000 Shipping per 5000 units

Aromato Regional Depot lead time through Air lead time through Aromato regional depot

Name units (cost per mile) (cost per mile)

Considerations:

Cargo Shipping (miles)

North and Central America 23 days 37 days 4,255

Europe 21 days 35 days 1,432

Different suppliers have

Middle East 26 days 40 days 6,972 partnerships with different

Urban

Africa 24 days 38 days 5,292 £0.13 £0.06 distributors, which vary on several

England

South America 28 days 42 days 8,156 parameters. We will need to take

Asia-Pacific 29 days 43 days 4,842 this into consideration when

Oceania 31 days 45 days 2,723 considering how the product will be

transported from the manufacturer

North and Central America 15 days 19 days 4,554 to the regional depots.

Europe 16 days 20 days 4,875

Eco- Middle East 17 days 21 days 6,293 For the launch, there will need to be

Assemble Africa 17 days 21 days 200 £0.16 £0.08 50,000 units sent to each of our

South America 14 days 18 days 4,829 seven regional depots.

Asia-Pacific 16 days 20 days 10,237

Oceania 18 days 22 days 6,956

North and Central America 22 days 26 days 5,146

Europe 23 days 27 days 6,613 Maximum load per journey:

Middle East 26 days 30 days 5,979

Robotiics Africa 25 days 29 days 6,281 £0.09 £0.07 Shipping: 87,500 units

South America 24 days 28 days 8,748

Asia-Pacific 18 days 22 days 1,892 Air Cargo: 175,000 units

Oceania 19 days 23 days 5,340

CO2 Emissions (average per 3,000

North and Central America 22 days 26 days 7,230 miles):

Europe 23 days 27 days 5,457 Shipping: 300kg CO2e

Middle East 25 days 29 days 4,220

Refinement Africa 24 days 28 days 10,164 £0.10 £0.09 Air Cargo: 750kg CO2e

South America 24 days 28 days 6,978

Asia-Pacific 18 days 22 days 700

Oceania 18 days 22 days 3,557

BAT Property – Confidential – For internal use only.

BAT Property – Confidential – For internal use only.

You might also like

- Leadership CaseDocument12 pagesLeadership CaseAmreen Akhtar100% (3)

- New Product Business Case + Financials CaseDocument9 pagesNew Product Business Case + Financials CaseAmreen Akhtar100% (1)

- 15.6" Octave Backpack, Black: TBB593GLDocument1 page15.6" Octave Backpack, Black: TBB593GLMiguel Angel Falcon ReyNo ratings yet

- Thefashionbook PDFDocument257 pagesThefashionbook PDFSeno PratamaNo ratings yet

- Pres. ENG GISE CAFFE'Document26 pagesPres. ENG GISE CAFFE'Marco MirandaNo ratings yet

- The Cmplete Windows 11 User Manual - Issue 2 2022 - The Complete Windows 11 User ManualDocument248 pagesThe Cmplete Windows 11 User Manual - Issue 2 2022 - The Complete Windows 11 User Manualoctavianulici0% (1)

- 100 Laptop: 17 Monitors From 159Document133 pages100 Laptop: 17 Monitors From 159fuyukawiNo ratings yet

- Processing Lines and Equipment For The Instant Coffee IndustryDocument8 pagesProcessing Lines and Equipment For The Instant Coffee Industryouerdien0% (1)

- JumpStart Indonesia Company Profile UpdateDocument23 pagesJumpStart Indonesia Company Profile UpdateeciticonNo ratings yet

- Topic Overview Slide - BlockaccinoDocument2 pagesTopic Overview Slide - Blockaccinonelson_lucianoNo ratings yet

- Start-Up Introduction: Mission of SmartpourDocument6 pagesStart-Up Introduction: Mission of SmartpourReemNo ratings yet

- Grove Magazine by GallopDocument73 pagesGrove Magazine by GallopLove ChildeNo ratings yet

- RVM X3: (Pet, Can & Glass)Document2 pagesRVM X3: (Pet, Can & Glass)NabilBouabanaNo ratings yet

- Super Automatic Coffee MachinesDocument8 pagesSuper Automatic Coffee MachinesVictor VazNo ratings yet

- Cashew Value ChainDocument9 pagesCashew Value ChainAtish100% (1)

- Bühler Smartdry Food. Dryers For Snacks and Rte CerealDocument2 pagesBühler Smartdry Food. Dryers For Snacks and Rte CerealPa MurugesanNo ratings yet

- Espresso Products PDFDocument52 pagesEspresso Products PDFMichael MillerNo ratings yet

- FeasibDocument39 pagesFeasibHannah YnciertoNo ratings yet

- Choose Your New Macbook Pro and Select A FinishDocument4 pagesChoose Your New Macbook Pro and Select A FinishxuyihangNo ratings yet

- Automatic Water Tank Level Controller With Dry Pump Run Protection Using ArduinoDocument17 pagesAutomatic Water Tank Level Controller With Dry Pump Run Protection Using Arduinodewasuryanto100% (1)

- Smartbox Brochure PDFDocument32 pagesSmartbox Brochure PDFKidz to Adultz Exhibitions100% (1)

- Computeractive - January 31, 2024 UKDocument76 pagesComputeractive - January 31, 2024 UKestebanurdemalesNo ratings yet

- Mac - AppleDocument15 pagesMac - AppleRubenNo ratings yet

- Ayush Chap 6Document6 pagesAyush Chap 6Dhruvi PatelNo ratings yet

- Packaging Range 201 8: Burgopak Brochure - 201 8Document20 pagesPackaging Range 201 8: Burgopak Brochure - 201 8Talaitola TolilliNo ratings yet

- Mars 3 - Nebula UShDocument1 pageMars 3 - Nebula UShAnunay GuptaNo ratings yet

- Engineered For The Best True Wireless: Calls and Music ExperienceDocument2 pagesEngineered For The Best True Wireless: Calls and Music Experiencenani yeshuNo ratings yet

- SDM PresentationDocument12 pagesSDM PresentationHarshitaNo ratings yet

- BNA 828 - GB GEA Niro Coffee Brochure 1008-6-1551Document18 pagesBNA 828 - GB GEA Niro Coffee Brochure 1008-6-1551leong2007No ratings yet

- Art Range Jun22 v2.3 STRONG-1Document16 pagesArt Range Jun22 v2.3 STRONG-1Khanh An NguyenNo ratings yet

- The Future Unfolds: Gain On High-Growth Business With The Step-Function Press For Short-Run Folding CartonsDocument2 pagesThe Future Unfolds: Gain On High-Growth Business With The Step-Function Press For Short-Run Folding CartonsIrad CastroNo ratings yet

- Portable Kashaya Making MachineDocument6 pagesPortable Kashaya Making MachineInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Armina Cataloque 2023-3Document23 pagesArmina Cataloque 2023-3Krdnz KrdnzNo ratings yet

- Customer Experience in 2020: of Buying Decisions Are Based On Customer Experience.Document17 pagesCustomer Experience in 2020: of Buying Decisions Are Based On Customer Experience.Bea GujuliNo ratings yet

- Pureit Marvella Ro Slim ManualDocument17 pagesPureit Marvella Ro Slim ManualSiddhant JainNo ratings yet

- Wulian New Catalog 2021Document96 pagesWulian New Catalog 2021benyNo ratings yet

- Burgopak-Tailored Catalogue v1Document18 pagesBurgopak-Tailored Catalogue v1jiu8oy7t6No ratings yet

- Project Chap 6Document6 pagesProject Chap 6Dhruvi PatelNo ratings yet

- KLJKLLJNJJKNJKNKJDocument30 pagesKLJKLLJNJJKNJKNKJanastasius manurung100% (1)

- A Brand Is A Business Person's Best FriendDocument24 pagesA Brand Is A Business Person's Best FriendkandysuchakNo ratings yet

- Sprso: Eye-Catching Bean-To-Cup MachineDocument4 pagesSprso: Eye-Catching Bean-To-Cup MachineJennivieve Venice EismaNo ratings yet

- Pocketbook Inkpad 3 (User Manual, EN)Document99 pagesPocketbook Inkpad 3 (User Manual, EN)Alex TiperNo ratings yet

- How To Choose The Right Machine For YouDocument5 pagesHow To Choose The Right Machine For Youpradeep danielNo ratings yet

- Virtuoso Plus Overall DatasheetDocument11 pagesVirtuoso Plus Overall Datasheetapi-529798489No ratings yet

- 2MBA Biz PlanDocument22 pages2MBA Biz PlanCarinna Saldaña - PierardNo ratings yet

- X Series - en 1Document16 pagesX Series - en 1Hocine AminiNo ratings yet

- LaRhea Variplus Brochure 05.2017 Ilovepdf CompressedDocument14 pagesLaRhea Variplus Brochure 05.2017 Ilovepdf CompressedAndrés Morales CanalesNo ratings yet

- WIT-Color Ultra 9000 High Definition Printer Operations ManualDocument95 pagesWIT-Color Ultra 9000 High Definition Printer Operations ManualHerbert M. ZaycoNo ratings yet

- Enhancement of An Interactive Smart Refrigerator Based On Embedded SystemDocument1 pageEnhancement of An Interactive Smart Refrigerator Based On Embedded SystemAbhishek ChakrabortyNo ratings yet

- Aur Changes Nhi KarengeDocument7 pagesAur Changes Nhi Karengepinky.sarkar3No ratings yet

- MM Brochure - IQ7000 - MERCK - InaDocument12 pagesMM Brochure - IQ7000 - MERCK - InaArdian Rizki SetiawanNo ratings yet

- Buy Iphone 15 Pro and Iphone 15 Pro Max - AppleDocument1 pageBuy Iphone 15 Pro and Iphone 15 Pro Max - AppleAnnier JimenezNo ratings yet

- How To Choose The Best Gifts For Your Parents?Document8 pagesHow To Choose The Best Gifts For Your Parents?MehakNo ratings yet

- 2023 HAOMUK Catalogue of Headphone and Earphone - AmyDocument21 pages2023 HAOMUK Catalogue of Headphone and Earphone - Amyarhamx01No ratings yet

- Features: Superior Reading Performance. Convenient CommunicationDocument2 pagesFeatures: Superior Reading Performance. Convenient CommunicationPrivado DiezynueveNo ratings yet

- AML Monarch Data SheetDocument2 pagesAML Monarch Data SheetMandukotNo ratings yet

- BX300 - Product BrochureDocument8 pagesBX300 - Product BrochureShaik MohammedNo ratings yet

- TPS Factsheet MailDocument4 pagesTPS Factsheet MailDivyeshNo ratings yet

- Datasheet PodDocument2 pagesDatasheet PodoptisearchNo ratings yet

- HDFC Reward CatalogueDocument196 pagesHDFC Reward CatalogueAnmohieyNo ratings yet

- PESTLE Analysis of AmazonDocument13 pagesPESTLE Analysis of AmazonCineops0% (1)

- Blaze Dream Corporate ProfileDocument12 pagesBlaze Dream Corporate ProfileAbhinav MishraNo ratings yet

- Comsats University Islamabad Abbottabad Campus Engineering Economics Assigment 04Document13 pagesComsats University Islamabad Abbottabad Campus Engineering Economics Assigment 04yaseen ayazNo ratings yet

- Walastic: "Paper Packaging Using Banana Peel and Egg Shells"Document5 pagesWalastic: "Paper Packaging Using Banana Peel and Egg Shells"Charles ManggaNo ratings yet

- Evolve Brands: The Factory at WorkDocument28 pagesEvolve Brands: The Factory at WorkrajimedNo ratings yet

- Abstract of ASTM F835 2000Document7 pagesAbstract of ASTM F835 2000Jesse ChenNo ratings yet

- Kotler Mm16e Inppt 10Document29 pagesKotler Mm16e Inppt 10marius.straussNo ratings yet

- Week 6-11 Pre-Tut Quiz Ans.Document83 pagesWeek 6-11 Pre-Tut Quiz Ans.Samiha RashidNo ratings yet

- Final Project On Innovation of Textiles (NCBA&E)Document29 pagesFinal Project On Innovation of Textiles (NCBA&E)Amna KhanNo ratings yet

- Have You Seen ?: Tim WoodsDocument7 pagesHave You Seen ?: Tim WoodsGalkandaNo ratings yet

- System Oriented Sustainable Supply Chain Management Innovations in Automotive Industry - SKODA Auto Case StudyDocument7 pagesSystem Oriented Sustainable Supply Chain Management Innovations in Automotive Industry - SKODA Auto Case StudyMohamed FouadNo ratings yet

- For Posting - ABM - Q4 - M5 - Relationship Between Market Analysis, Planning, Implementation, & ControlDocument15 pagesFor Posting - ABM - Q4 - M5 - Relationship Between Market Analysis, Planning, Implementation, & ControlGerlie Bornea86% (7)

- Certificate: Ebm-Papst Mulfingen GMBH & Co. KGDocument5 pagesCertificate: Ebm-Papst Mulfingen GMBH & Co. KGDANNYNo ratings yet

- Chapter 1-Introduction To Supply Chain ManagementDocument34 pagesChapter 1-Introduction To Supply Chain Managementآفاق بن یوسفNo ratings yet

- Ex Squeeze MeDocument16 pagesEx Squeeze MeFreeNet CodesNo ratings yet

- Quality AssuaranceDocument150 pagesQuality Assuarancelamia97100% (1)

- Ijams July Issue 52 75Document24 pagesIjams July Issue 52 75albaricoangelie29No ratings yet

- Case Presentation - Group1: Srinivas Bhattiprolu Falk Scherzer Georg WieningerDocument19 pagesCase Presentation - Group1: Srinivas Bhattiprolu Falk Scherzer Georg WieningerAshutosh VikramNo ratings yet

- Dawlance Case StudyDocument21 pagesDawlance Case StudySidra ShoukatNo ratings yet

- Assignments-Mba Sem-Ii: Subject Code: MB0028Document9 pagesAssignments-Mba Sem-Ii: Subject Code: MB0028Anu AhamadNo ratings yet

- Bigbazaar Case AnalysisDocument30 pagesBigbazaar Case AnalysisPushpa Prakash100% (1)

- Researchh ReviseeeDocument112 pagesResearchh ReviseeeShaina VelasquezNo ratings yet

- VocabularyDocument5 pagesVocabularyDunia SossaNo ratings yet

- BPC SAP ERP CH 05 Fulfillment 1e FInalDocument70 pagesBPC SAP ERP CH 05 Fulfillment 1e FInalToàn Vũ ĐạiNo ratings yet

- PVT LTD: DelhiveryDocument3 pagesPVT LTD: DelhiveryHemantJanku KomteNo ratings yet

- 2013 Paper F1 QandA Sample Download v1Document34 pages2013 Paper F1 QandA Sample Download v1Georges NdumbeNo ratings yet

- Cost MGT& Acc IIDocument8 pagesCost MGT& Acc IIkiduse100% (1)

- JWT Pak Affairs MR ShawDocument233 pagesJWT Pak Affairs MR ShawSaharghafoor SaharNo ratings yet

- NEW - Public Training LENTERA SAFETY 2020Document3 pagesNEW - Public Training LENTERA SAFETY 2020HandokoNo ratings yet

- Final ERP Report - MBA II Yr. Trim IV, V & VI-2022-23Document56 pagesFinal ERP Report - MBA II Yr. Trim IV, V & VI-2022-23PIYUSHNo ratings yet